Planned Maintenance Technique DOWNTIME

43 Slides270.50 KB

Planned Maintenance Technique DOWNTIME

TRAINING OVERVIEW

TPM PROCESS PREPARATION ANNOUNCEMENT LAUNCH CREATE ORGANIZATIONAL STRUCTURE ESTABLISH POLICIES AND GOALS FORM A MASTER PLAN PRELIMINARY IMPLEMENTATION: KICK OFF

TPM PROCESS IMPLEMENTATION IMPROVE CRITICAL EQUIPMENT EFFECTIVENESS SETUP AND IMPLEMENT AUTONOMOUS MAINTENANCE ESTABLISH PLANNED MAINTENANCE SYSTEM PROVIDE TRAINING DEVELOP EARLY EQUIPMENT MANAGEMENT STABILIZE RE-MEASURE START OVER - WORK TOWARD IDEAL STATE

PLANNED MAINTENANCE THIS PROCESS: A PLANT TECHNIQUE IMPROVEMENT METHODOLOGY - IMPROVE MANAGEMENT OF PLANT ASSETS ENABLES CONTINUOUS & RAPID IMPROVEMENT - SPEED OF THE RABBIT, PERSEVERANCE OFTHE TORTOISE

Employee Involvement and Measurements REQUIRES EMPLOYEE INVOLVEMENT & EMPOWERMENT - MY PLANT THEME - INCREASE IN WORKERS’ ROLES - FAILURE DOES NOT DEPEND ON A UNION OR NON-UNION PLANT USES A CLOSED LOOP MEASUREMENT OF RESULTS - ELIMINATE INEFFECTIVE PERFORMANCE MEASURES - QUALITY, COST, PRODUCTIVITY DELIVERY, SAFETY

BENEFITS MAINTAIN THE QUALITY OF THE PRODUCT INCREASE PRODUCTION UP-TIME REDUCE COSTS OF OPERATIONS REDUCE AMOUNT AND COMPLEXITY OF MACHINERY REQUIRED INSURE EQUIPMENT CAPABILITY

TRAINING

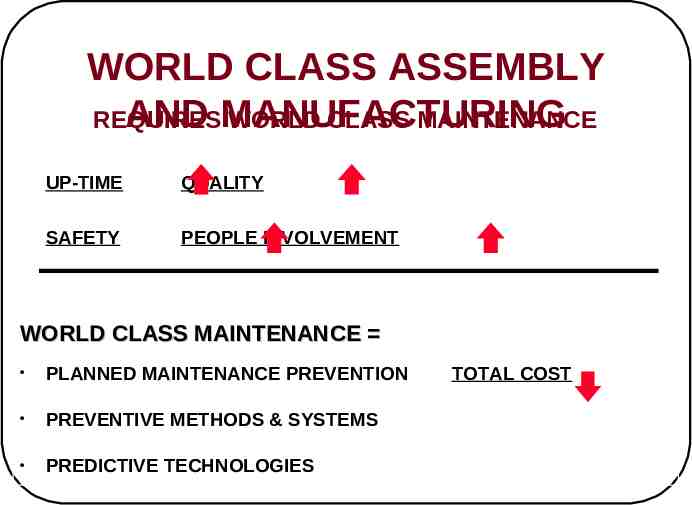

WORLD CLASS ASSEMBLY AND MANUFACTURING REQUIRES WORLD CLASS MAINTENANCE UP-TIME QUALITY SAFETY PEOPLE INVOLVEMENT WORLD CLASS MAINTENANCE PLANNED MAINTENANCE PREVENTION PREVENTIVE METHODS & SYSTEMS PREDICTIVE TECHNOLOGIES TOTAL COST

PLANNED PLANNED MAINTENANCE MAINTENANCE TECHNIQUE TECHNIQUE TRAINING INTRODUCTIONS NAME CURRENT POSITION ADMINISTRATIVE DETAILS RESTROOMS MESSAGES SAFETY ISSUES LUNCH & BREAK

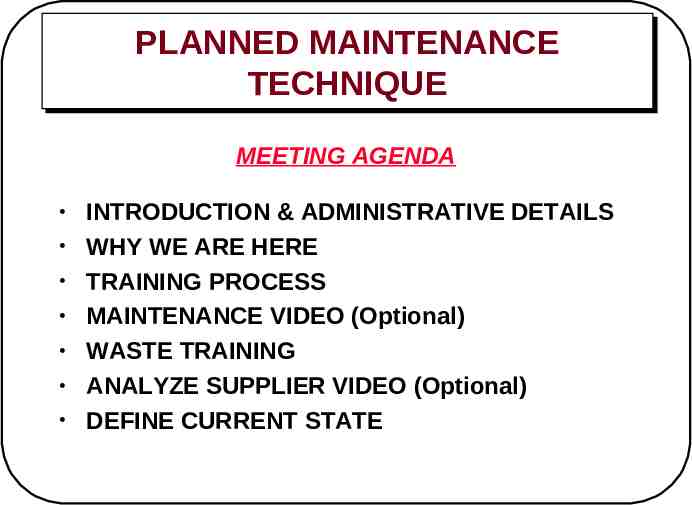

PLANNED PLANNED MAINTENANCE MAINTENANCE TECHNIQUE TECHNIQUE MEETING AGENDA INTRODUCTION & ADMINISTRATIVE DETAILS WHY WE ARE HERE TRAINING PROCESS MAINTENANCE VIDEO (Optional) WASTE TRAINING ANALYZE SUPPLIER VIDEO (Optional) DEFINE CURRENT STATE

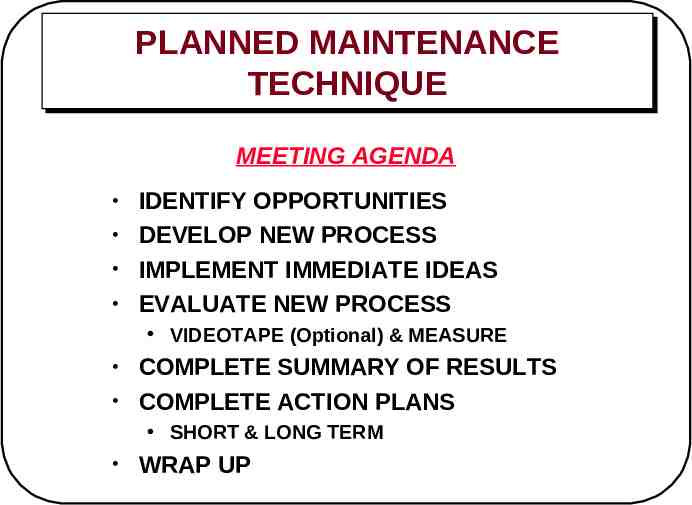

PLANNED PLANNED MAINTENANCE MAINTENANCE TECHNIQUE TECHNIQUE MEETING AGENDA IDENTIFY OPPORTUNITIES DEVELOP NEW PROCESS IMPLEMENT IMMEDIATE IDEAS EVALUATE NEW PROCESS VIDEOTAPE (Optional) & MEASURE COMPLETE SUMMARY OF RESULTS COMPLETE ACTION PLANS SHORT & LONG TERM WRAP UP

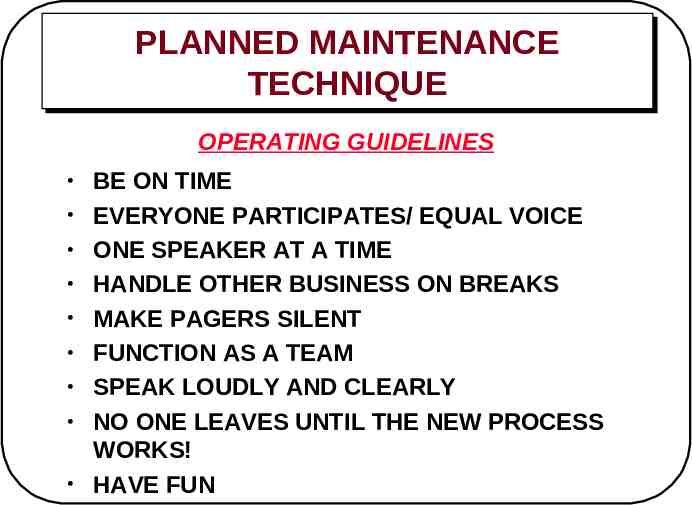

PLANNED PLANNED MAINTENANCE MAINTENANCE TECHNIQUE TECHNIQUE OPERATING GUIDELINES BE ON TIME EVERYONE PARTICIPATES/ EQUAL VOICE ONE SPEAKER AT A TIME HANDLE OTHER BUSINESS ON BREAKS MAKE PAGERS SILENT FUNCTION AS A TEAM SPEAK LOUDLY AND CLEARLY NO ONE LEAVES UNTIL THE NEW PROCESS WORKS! HAVE FUN

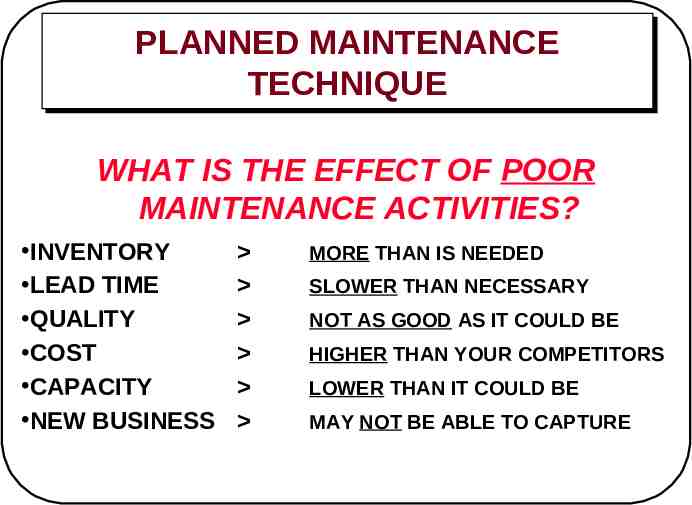

PLANNED PLANNED MAINTENANCE MAINTENANCE TECHNIQUE TECHNIQUE WHAT IS THE EFFECT OF POOR MAINTENANCE ACTIVITIES? INVENTORY LEAD TIME QUALITY COST CAPACITY NEW BUSINESS MORE THAN IS NEEDED SLOWER THAN NECESSARY NOT AS GOOD AS IT COULD BE HIGHER THAN YOUR COMPETITORS LOWER THAN IT COULD BE MAY NOT BE ABLE TO CAPTURE

PLANNED PLANNED MAINTENANCE MAINTENANCE TECHNIQUE TECHNIQUE -- Safety Safety SAFETY WILL NOT BE COMPROMISED !!!

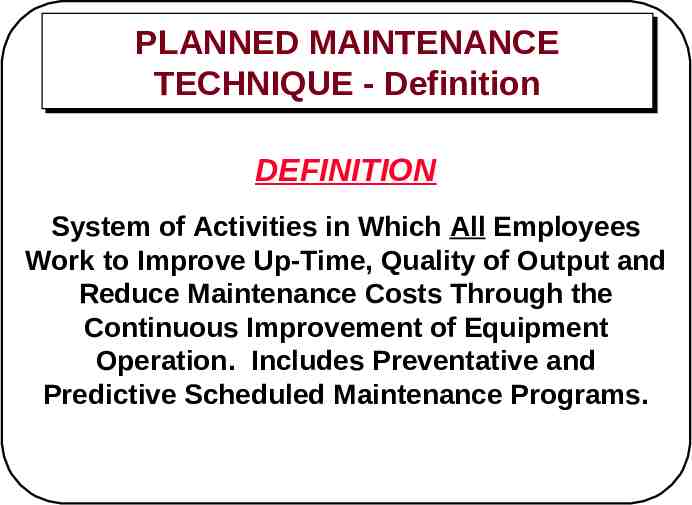

PLANNED PLANNED MAINTENANCE MAINTENANCE TECHNIQUE TECHNIQUE -- Definition Definition DEFINITION System of Activities in Which All Employees Work to Improve Up-Time, Quality of Output and Reduce Maintenance Costs Through the Continuous Improvement of Equipment Operation. Includes Preventative and Predictive Scheduled Maintenance Programs.

PLANNED PLANNED MAINTENANCE MAINTENANCE TECHNIQUE TECHNIQUE -- Goal Goal THE GOAL IS TO ACHIEVE THE ABSOLUTE MINIMUM AMOUNT OF TIME NEEDED FOR EFFECTIVE MAINTENANCE.

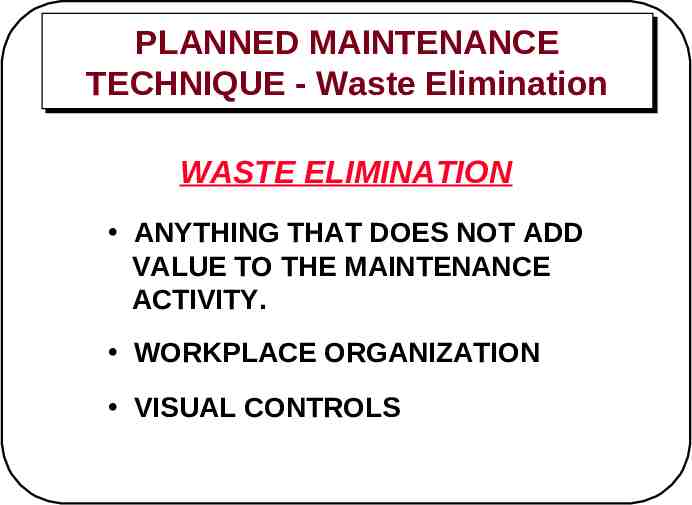

PLANNED PLANNED MAINTENANCE MAINTENANCE TECHNIQUE TECHNIQUE -- Waste Waste Elimination Elimination WASTE ELIMINATION ANYTHING THAT DOES NOT ADD VALUE TO THE MAINTENANCE ACTIVITY. WORKPLACE ORGANIZATION VISUAL CONTROLS

PLANNED PLANNED MAINTENANCE MAINTENANCE TECHNIQUE TECHNIQUE -- More More Waste Waste WASTE OF: INVENTORY OVERPRODUCTION CORRECTION MATERIAL & INFORMATION MOVEMENT PROCESSING WAITING MOTION

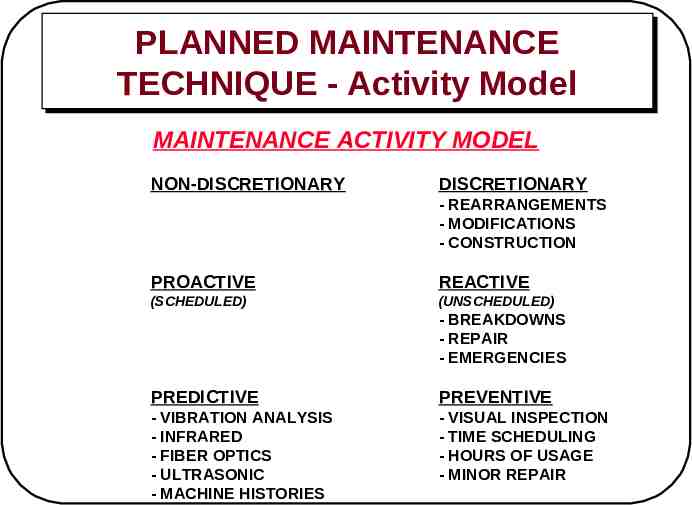

PLANNED PLANNED MAINTENANCE MAINTENANCE TECHNIQUE TECHNIQUE -- Activity Activity Model Model MAINTENANCE ACTIVITY MODEL NON-DISCRETIONARY DISCRETIONARY - REARRANGEMENTS - MODIFICATIONS - CONSTRUCTION PROACTIVE REACTIVE (SCHEDULED) (UNSCHEDULED) - BREAKDOWNS - REPAIR - EMERGENCIES PREDICTIVE PREVENTIVE - VIBRATION ANALYSIS - INFRARED - FIBER OPTICS - ULTRASONIC - MACHINE HISTORIES - VISUAL INSPECTION - TIME SCHEDULING - HOURS OF USAGE - MINOR REPAIR

Types Types of of Maintenance Maintenance FOUR TYPES OF MAINTENANCE REACTIVE PREDICTIVE PREVENTIVE PREVENTION

Reactive Reactive Maintenance Maintenance SYSTEM: RESPONSE TO EQUIPMENT MALFUNCTIONS CHARACTERISTICS: - INEFFICIENT MAINTENANCE DEPARTMENT - UNPREDICTABLE EQUIPMENT OPERATION - ALL MAINTENANCE WORK UNPLANNED EXAMPLE: LIGHT BULB REPLACEMENT RESULTS: STEADY DEGRADATION OF EQUIPMENT PERFORMANCE MAINTENANCE DEPARTMENT RESPONSIBILITY: - RESPOND TO EMERGENCIES - GET PRODUCTION BACK ON LINE

Preventive Preventive Maintenance Maintenance SYSTEM: - PERIODIC ADJUSTMENTS & CHECKS - PERIODIC REPLACEMENT OF WORN PARTS - PERIODIC OVERHAUL CHARACTERISTICS: - MORE PREDICTABLE - MORE EFFICIENT EXAMPLE: CHANGING OIL & FILTERS RESULTS: MAINTAIN LEVEL OF EQUIPMENT MAINTENANCE DEPARTMENT RESPONSIBILITY: - CHECKING, REPLACING & OVERHAULING - PERFORM CHECKS DURING MAINTENANCE

Predictive Predictive Maintenance Maintenance SYSTEM: PERIODIC MEASUREMENT & TRENDING OF EQUIPMENT PROCESS CHARACTERISTICS: - PREDICTABLE MAINTENANCE REQUIREMENTS - PLANNED & SCHEDULED EQUIPMENT REPAIRS EXAMPLE: VIBRATION ANALYSIS RESULTS: MAINTAIN EQUIPMENT PERFORMANCE WITH MINIMAL DISRUPTION TO PRODUCTION MAINTENANCE DEPARTMENT RESPONSIBILITY: - LOG EQUIPMENT REPAIRS - TREND DATA - PREDICT EQUIPMENT REPAIR CYCLES

Prevention Prevention Maintenance Maintenance SYSTEM: EQUIPMENT DESIGN IS BASED ON MINIMAL MAINTENANCE REQUIREMENTS CHARACTERISTICS: - CLOSE RELATIONSHIP WITH EQUIPMENT SUPPLIERS EXAMPLE: SEALED BEARINGS IN SMALL ELECTRONIC MOTORS RESULTS: CONTINUALLY IMPROVING EQUIPMENT MAINTENANCE DEPARTMENT RESPONSIBILITY: - INPUT TO EQUIPMENT DESIGN - MINIMIZE & ELIMINATE MAINTENANCE REQUIREMENTS

The The Six Six Big Big Losses Losses DOWNTIME: 1. 2. BREAKDOWNS DUE TO EQUIPMENT FAILURE SET-UP AND ADJUSTMENT SPEED LOSSES: 3. 4. IDLING AND MINOR STOPPAGES REDUCED SPEED 5. 6. SCRAP AND QUALITY DEFECTS REDUCED YIELD DEFECTS:

Breakdown Breakdown Causes Causes BASIC CONDITIONS NEGLECTED INADEQUATE SKILLS OPERATING STANDARDS NOT FOLLOWED DETERIORATION UNCHECKED INHERENT DESIGN WEAKNESS

Idling Idling and and Minor Minor Stoppages Stoppages CHARACTERISTICS: - EASY TO RESTORE - THEREFORE - EASILY IGNORED CONDITIONS OF OCCURRENCE VARY LOCATION CHANGES CONSTANTLY SCOPE OF LOSS (COST) UNCLEAR STRATEGIES TO REDUCE: - CORRECT SLIGHT DEFECTS IN PARTS AND JIGS ENSURE BASIC EQUIPMENT CONDITIONS ARE MAINTAINED REVIEW BASIC OPERATIONS CONDUCT PHYSICAL ANALYSIS ADOPT AN ANALYTICAL APPROACH

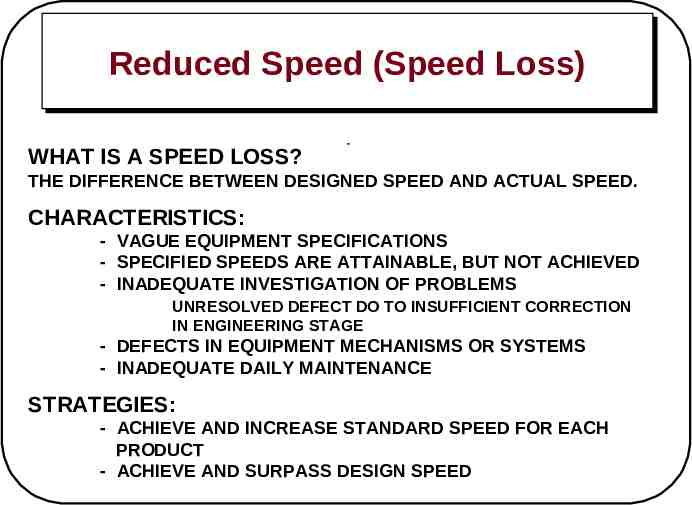

Reduced Reduced Speed Speed (Speed (Speed Loss) Loss) WHAT IS A SPEED LOSS? THE DIFFERENCE BETWEEN DESIGNED SPEED AND ACTUAL SPEED. CHARACTERISTICS: - VAGUE EQUIPMENT SPECIFICATIONS - SPECIFIED SPEEDS ARE ATTAINABLE, BUT NOT ACHIEVED - INADEQUATE INVESTIGATION OF PROBLEMS UNRESOLVED DEFECT DO TO INSUFFICIENT CORRECTION IN ENGINEERING STAGE - DEFECTS IN EQUIPMENT MECHANISMS OR SYSTEMS - INADEQUATE DAILY MAINTENANCE STRATEGIES: - ACHIEVE AND INCREASE STANDARD SPEED FOR EACH PRODUCT - ACHIEVE AND SURPASS DESIGN SPEED

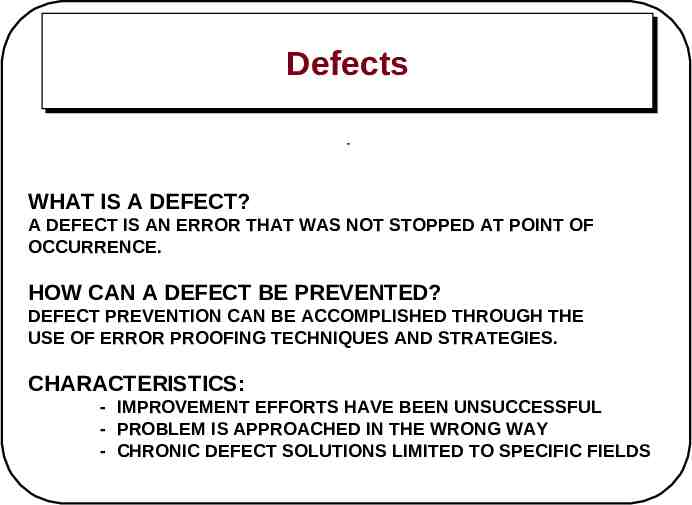

Defects Defects WHAT IS A DEFECT? A DEFECT IS AN ERROR THAT WAS NOT STOPPED AT POINT OF OCCURRENCE. HOW CAN A DEFECT BE PREVENTED? DEFECT PREVENTION CAN BE ACCOMPLISHED THROUGH THE USE OF ERROR PROOFING TECHNIQUES AND STRATEGIES. CHARACTERISTICS: - IMPROVEMENT EFFORTS HAVE BEEN UNSUCCESSFUL - PROBLEM IS APPROACHED IN THE WRONG WAY - CHRONIC DEFECT SOLUTIONS LIMITED TO SPECIFIC FIELDS

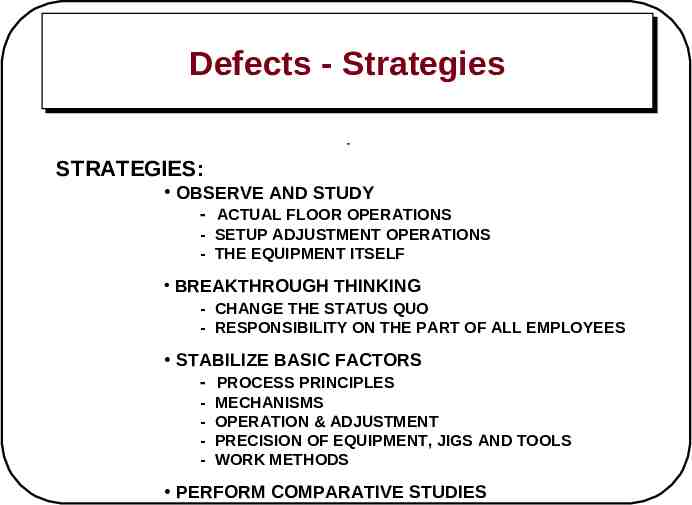

Defects Defects -- Strategies Strategies STRATEGIES: OBSERVE AND STUDY - ACTUAL FLOOR OPERATIONS - SETUP ADJUSTMENT OPERATIONS - THE EQUIPMENT ITSELF BREAKTHROUGH THINKING - CHANGE THE STATUS QUO - RESPONSIBILITY ON THE PART OF ALL EMPLOYEES STABILIZE BASIC FACTORS - PROCESS PRINCIPLES - MECHANISMS OPERATION & ADJUSTMENT PRECISION OF EQUIPMENT, JIGS AND TOOLS WORK METHODS PERFORM COMPARATIVE STUDIES

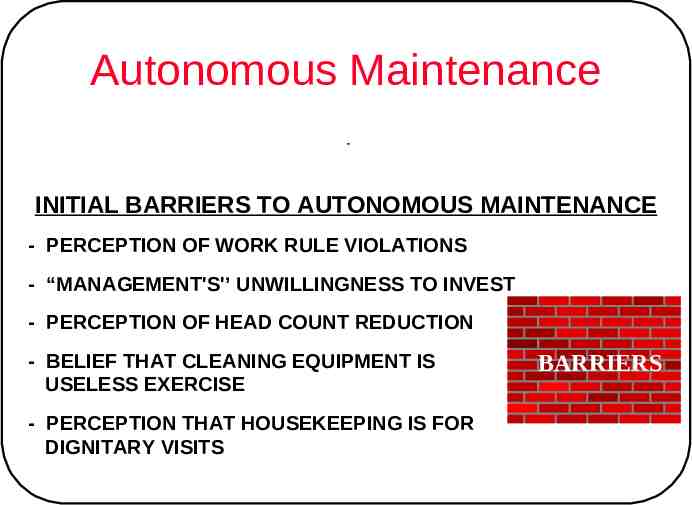

Autonomous Maintenance INITIAL BARRIERS TO AUTONOMOUS MAINTENANCE - PERCEPTION OF WORK RULE VIOLATIONS - “MANAGEMENT'S'’ UNWILLINGNESS TO INVEST - PERCEPTION OF HEAD COUNT REDUCTION - BELIEF THAT CLEANING EQUIPMENT IS USELESS EXERCISE - PERCEPTION THAT HOUSEKEEPING IS FOR DIGNITARY VISITS BARRIERS

77 Levels Levels of of Autonomous Autonomous Maintenance Maintenance SEVEN LEVELS OF AUTONOMOUS MAINTENANCE 1. INITIAL CLEANING 2. PREVENTIVE CLEANING MEASURE 3. DEVELOPMENT OF LUBRICATION & CLEANING STANDARDS 4. GENERAL INSPECTION 5. AUTONOMOUS INSPECTION 6. PROCESS DISCIPLINE 7. INDEPENDENT AUTONOMOUS MAINTENANCE BARRIERS

Autonomous Autonomous Maintenance Maintenance INITIAL CLEANING ACTIVITY: THOROUGHLY REMOVE DUST AND CONTAMINANTS FROM EQUIPMENT - INCLUDE DISCARD OF OLD EQUIPMENT AND PARTS GOALS: PREVENT DETERIORATION ELIMINATE DUST AND DIRT IMPROVE QUALITY OF INSPECTION AND REPAIRS REDUCE FUTURE TIME REQUIREMENTS DISCOVER AND TREAT HIDDEN DEFECTS

Autonomous Autonomous Maintenance Maintenance -- Cleaning Cleaning PREVENTIVE CLEANING MEASURES ACTIVITY: ELIMINATE SOURCES OF DUST AND DIRT IMPROVE ACCESSIBILITY REDUCE LUBE AND CLEANING TIME GOALS: INCREASE RELIABILITY OF EQUIPMENT IMPROVE MAINTAINABILITY OF CLEANING & LUBE 01/03/96

Lubrication Lubrication and and Cleaning Cleaning Standards Standards AUTONOMOUS MAINTENANCE-CONT’D DEVELOPMENT OF LUBRICATION AND CLEANING STANDARDS ACTIVITY: SET CLEAR STANDARDS - CLEANING LUBRICATION BOLTING GOALS: MAINTAIN EQUIPMENT CONDITIONS

General General Inspection Inspection AUTONOMOUS MAINTENANCE-CONT’D GENERAL INSPECTION ACTIVITY: CONDUCT TRAINING ON REQUIRED SKILLS FIND AND CORRECT MINOR DEFECTS MODIFY EQUIPMENT TO AID INSPECTION GOALS: VISUALLY INSPECT MAJOR PARTS RESTORE DETERIORATION ENHANCE RELIABILITY FACILITATE INSPECTION TROUGH INNOVATIVE METHODS

Autonomous Autonomous Inspection Inspection AUTONOMOUS MAINTENANCE-CONT’D ACTIVITY: DEVELOP AND USE AUTONOMOUS CHECKLIST STANDARDIZE - CLEANING, LUBRICATION AND INSPECTION STANDARDS GOALS: MAINTAIN OPTIMAL EQUIPMENT CONDITIONS USE VISUAL CONTROL SYSTEMS REVIEW EQUIPMENT AND HUMAN FACTORS - FIX PROBLEMS AND SAFETY FACTORS - IMPLEMENT IMPROVEMENTS FOR EASIER OPERATIONS

PLANNED PLANNED MAINTENANCE MAINTENANCE TECHNIQUE TECHNIQUE AUTONOMOUS MAINTENANCE-CONT’D PROCESS DISCIPLINE ACTIVITY: IMPROVE WORK EFFECTIVENESS, PRODUCT QUALITY AND SAFETY THROUGH WORKPLACE ORGANIZATION AND HOUSEKEEPING REDUCE SET-UP AND ADJUSTMENT TIME ELIMINATE WORK IN PROCESS INSTITUTE MATERIAL HANDLING STANDARDS COLLECT AND RECORD AND USE DATA CONTROL STANDARDS FOR: RAW MATERIAL, WIP, PRODUCTS, SPARE PARTS, DIES, JIGS AND TOOLS

Process Process Discipline Discipline AUTONOMOUS MAINTENANCE-CONT’D GOALS: REVIEW AND IMPROVE PLANT LAYOUT STANDARDIZE CONTROLS IMPLEMENT VISUAL CONTROL SYSTEMS

PLANNED PLANNED MAINTENANCE MAINTENANCE TECHNIQUE TECHNIQUE AUTONOMOUS MAINTENANCE-CONT’D INDEPENDENT AUTONOMOUS MAINTENANCE ACTIVITY: DEVELOP COMPANY GOALS ENGAGE IN CONTINUOUS IMPROVEMENT ACTIVITIES IMPROVE EQUIPMENT GOALS: COLLECT AND ANALYZE DATA IMPROVE EQUIPMENT TO: - INCREASE RELIABILITY - SIMPLIFY OPERATION PINPOINT WEAKNESSES IN EQUIPMENT IMPLEMENT IMPROVEMENT PLANS TO: - LENGTHEN EQUIPMENT LIFESPAN & INSPECTION CYCLES

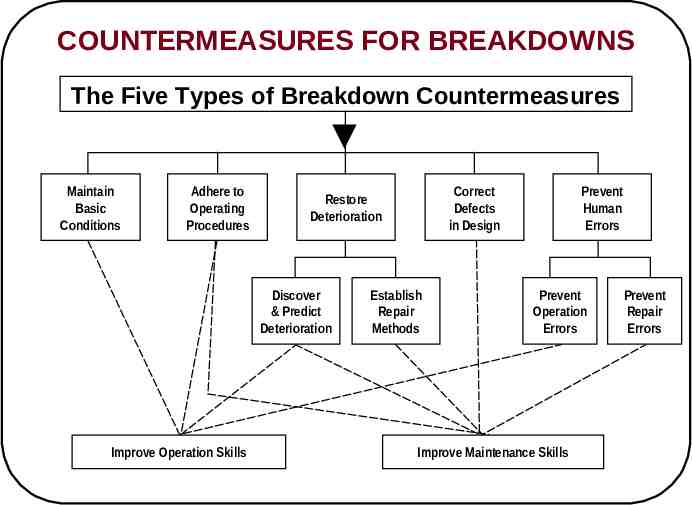

COUNTERMEASURES FOR BREAKDOWNS The Five Types of Breakdown Countermeasures Maintain Basic Conditions Adhere to Operating Procedures Discover & Predict Deterioration Improve Operation Skills Correct Defects in Design Restore Deterioration Establish Repair Methods Prevent Human Errors Prevent Operation Errors Improve Maintenance Skills Prevent Repair Errors

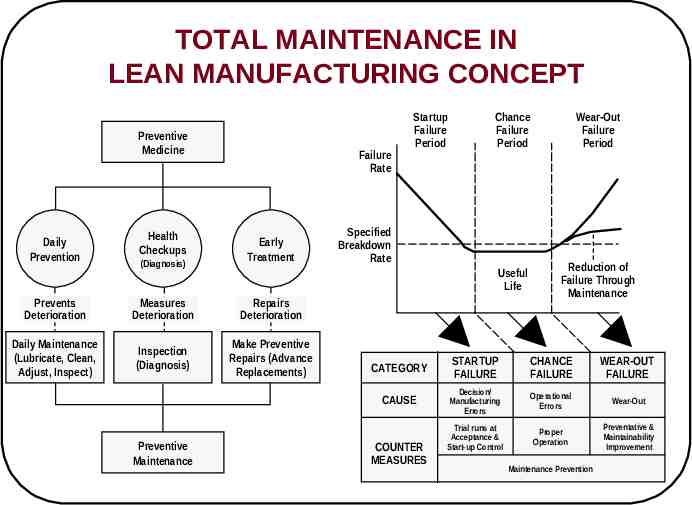

TOTAL MAINTENANCE IN LEAN MANUFACTURING CONCEPT Preventive Medicine Daily Prevention Health Checkups (Diagnosis) Failure Rate Early Treatment Prevents Deterioration Measures Deterioration Repairs Deterioration Daily Maintenance (Lubricate, Clean, Adjust, Inspect) Inspection (Diagnosis) Make Preventive Repairs (Advance Replacements) Preventive Maintenance Startup Failure Period Chance Failure Period Wear-Out Failure Period Useful Life Reduction of Failure Through Maintenance Specified Breakdown Rate CATEGORY STARTUP FAILURE CHANCE FAILURE WEAR-OUT FAILURE CAUSE Decision/ Manufacturing Errors Operational Errors Wear-Out Trial runs at Acceptance & Start-up Control Proper Operation Preventative & Maintainability Improvement COUNTER MEASURES Maintenance Prevention