Elements of a Lockout/Tagout Program BWC Division of Safety & Hygiene

19 Slides218.00 KB

Elements of a Lockout/Tagout Program BWC Division of Safety & Hygiene Elements of a Lockout / Tagout Program

I. Purpose and Scope / t u o k c o L Tagout Program Elements of a Lockout / Tagout Program

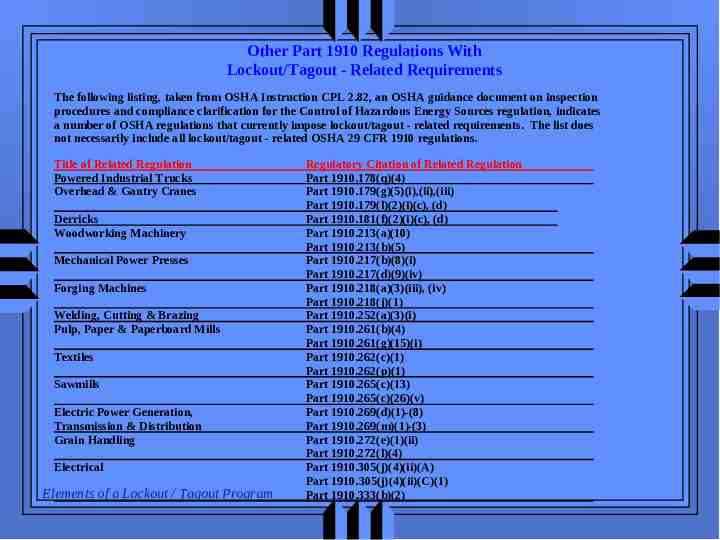

Other Part 1910 Regulations With Lockout/Tagout - Related Requirements The following listing, taken from OSHA Instruction CPL 2.82, an OSHA guidance document on inspection procedures and compliance clarification for the Control of Hazardous Energy Sources regulation, indicates a number of OSHA regulations that currently impose lockout/tagout - related requirements. The list does not necessarily include all lockout/tagout - related OSHA 29 CFR 1910 regulations. Title of Related Regulation Powered Industrial Trucks Overhead & Gantry Cranes Derricks Woodworking Machinery Mechanical Power Presses Forging Machines Welding, Cutting & Brazing Pulp, Paper & Paperboard Mills Textiles Sawmills Electric Power Generation, Transmission & Distribution Grain Handling Electrical Elements of a Lockout / Tagout Program Regulatory Citation of Related Regulation Part 1910.178(q)(4) Part 1910.179(g)(5)(i),(ii),(iii) Part 1910.179(l)(2)(i)(c), (d) Part 1910.181(f)(2)(i)(c), (d) Part 1910.213(a)(10) Part 1910.213(b)(5) Part 1910.217(b)(8)(i) Part 1910.217(d)(9)(iv) Part 1910.218(a)(3)(iii), (iv) Part 1910.218(j)(1) Part 1910.252(a)(3)(i) Part 1910.261(b)(4) Part 1910.261(g)(15)(i) Part 1910.262(c)(1) Part 1910.262(p)(1) Part 1910.265(c)(13) Part 1910.265(c)(26)(v) Part 1910.269(d)(1)-(8) Part 1910.269(m)(1)-(3) Part 1910.272(e)(1)(ii) Part 1910.272(l)(4) Part 1910.305(j)(4)(ii)(A) Part 1910.305(j)(4)(ii)(C)(1) Part 1910.333(b)(2)

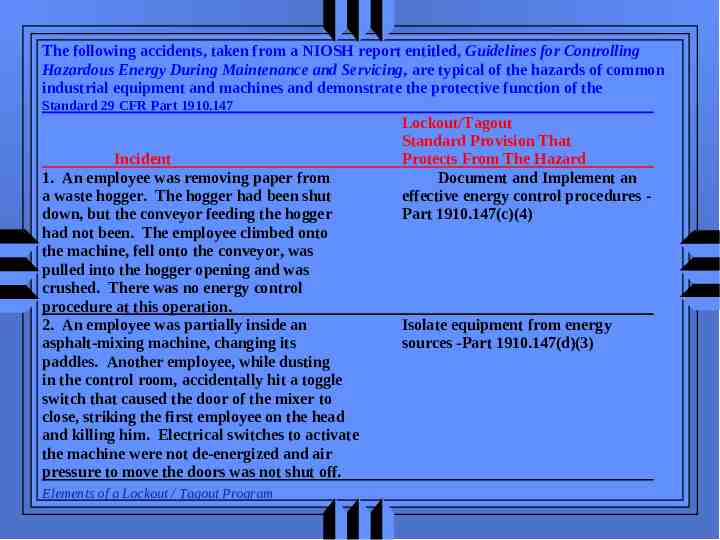

The following accidents, taken from a NIOSH report entitled, Guidelines for Controlling Hazardous Energy During Maintenance and Servicing, are typical of the hazards of common industrial equipment and machines and demonstrate the protective function of the Standard 29 CFR Part 1910.147 Incident 1. An employee was removing paper from a waste hogger. The hogger had been shut down, but the conveyor feeding the hogger had not been. The employee climbed onto the machine, fell onto the conveyor, was pulled into the hogger opening and was crushed. There was no energy control procedure at this operation. 2. An employee was partially inside an asphalt-mixing machine, changing its paddles. Another employee, while dusting in the control room, accidentally hit a toggle switch that caused the door of the mixer to close, striking the first employee on the head and killing him. Electrical switches to activate the machine were not de-energized and air pressure to move the doors was not shut off. Elements of a Lockout / Tagout Program Lockout/Tagout Standard Provision That Protects From The Hazard Document and Implement an effective energy control procedures Part 1910.147(c)(4) Isolate equipment from energy sources -Part 1910.147(d)(3)

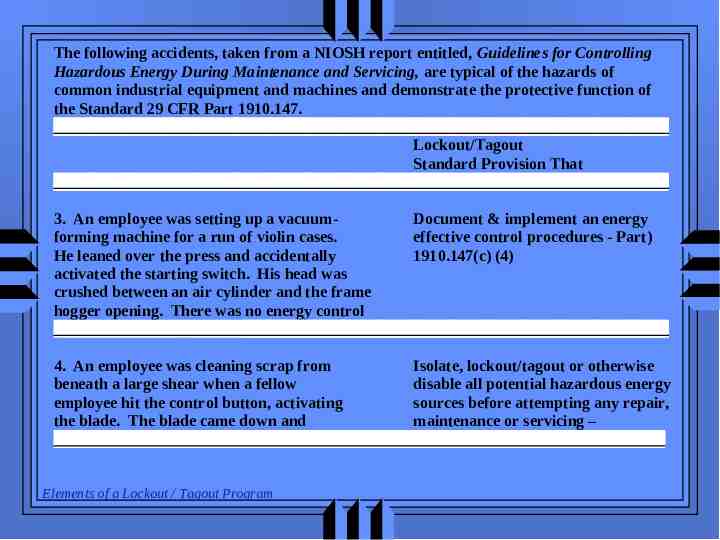

The following accidents, taken from a NIOSH report entitled, Guidelines for Controlling Hazardous Energy During Maintenance and Servicing, are typical of the hazards of common industrial equipment and machines and demonstrate the protective function of the Standard 29 CFR Part 1910.147. Incident Lockout/Tagout Standard Provision That Protects From The Hazard 3. An employee was setting up a vacuumforming machine for a run of violin cases. He leaned over the press and accidentally activated the starting switch. His head was crushed between an air cylinder and the frame hogger opening. There was no energy control procedure at this operation. Document & implement an energy effective control procedures - Part) 1910.147(c) (4) 4. An employee was cleaning scrap from beneath a large shear when a fellow employee hit the control button, activating the blade. The blade came down and decapitated the employee Isolate, lockout/tagout or otherwise disable all potential hazardous energy sources before attempting any repair, maintenance or servicing – Part 1910.147(c)(2) Elements of a Lockout / Tagout Program

II. List & Identify all Sources Of Energy Electrical Chemical Hydraulic Mechanical Pneumatic Cord Thermal Elements of a Lockout / Tagout Program & Plug Equip. Other Types

III. Procedures For Each Piece Of Equipment Written procedures must be documented for each piece of equipment. If machinery or pieces of equipment are similar, just one procedure will cover all like pieces. Elements of a Lockout / Tagout Program

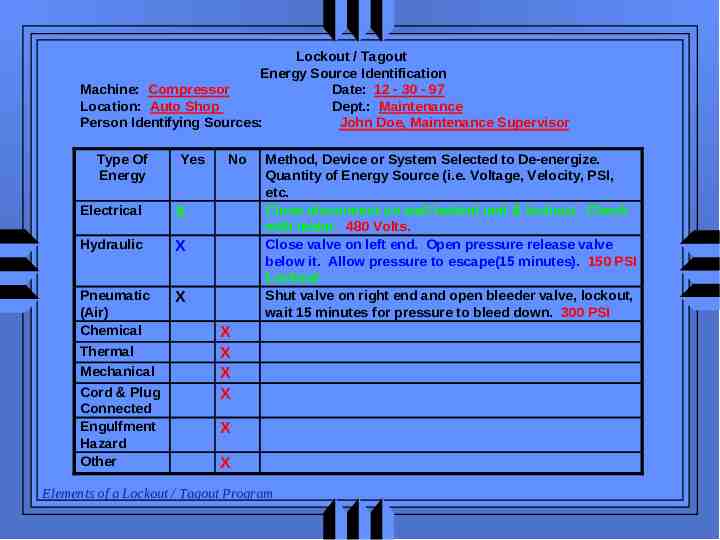

Lockout / Tagout Energy Source Identification Machine: Compressor Date: 12 - 30 - 97 Location: Auto Shop Dept.: Maintenance Person Identifying Sources: John Doe, Maintenance Supervisor Type Of Energy Yes Electrical X Hydraulic X Pneumatic (Air) Chemical Thermal Mechanical Cord & Plug Connected Engulfment Hazard Other X No Method, Device or System Selected to De-energize. Quantity of Energy Source (i.e. Voltage, Velocity, PSI, etc. Close disconnect on wall behind unit & lockout. Check with tester. 480 Volts. Close valve on left end. Open pressure release valve below it. Allow pressure to escape(15 minutes). 150 PSI Lockout Shut valve on right end and open bleeder valve, lockout, wait 15 minutes for pressure to bleed down. 300 PSI X X X X X X Elements of a Lockout / Tagout Program

IV. Safe Procedures for Energy Control Program Steps for Shutting down all energy sources. Steps for Placement, Removal & Transfer Of LO/TO Devices. Steps for testing to verify LO/TO. Enforcement Policy. Elements of a Lockout / Tagout Program

V. Identify Different Personnel Authorized Affected Other Elements of a Lockout / Tagout Program

VI. Lockout Devices. Standardize All Locks and Tags. Identify The User. Must Be Durable. Used Only For Lockout/Tagout. Elements of a Lockout / Tagout Program

VII. Training Of Authorized Employees. Types of Energy. Magnitude Of Energy Sources Locations & How to Lockout Energy Sources. Types of Devices to Be Used. Elements of a Lockout / Tagout Program

VIII. Training Affected & Other Employees Purpose Of The Energy Control Program. Types & How to Identify Lockout Devices. To Understand That They Should Not Tamper With Any Devices Used In Lockout/Tagout Procedures. Elements of a Lockout / Tagout Program

IX. Shift & Personnel Changes. How to transfer locks at the end of shifts. How to transfer locks when personnel leave. Elements of a Lockout / Tagout Program

X. Develop Procedures on how you will Communicate with Contractors on LO/TO. Who What When Where How Elements of a Lockout / Tagout Program

XI. Miscellaneous Items in Your Program. Procedures for removal of a lock when that person is not present. Notifying affected employees when locks are to be applied or removed. Elements of a Lockout / Tagout Program

XII. Group Lockout Procedures. Procedures on how you will handle more than one individual working on the same piece of equipment. Elements of a Lockout / Tagout Program

XIII. Annual Inspection of Your Procedures. Date of Inspection. Machine or Process to review Identified. Names of persons involved in LO/TO. Name of person doing Inspection. Copy of Inspection kept on record. Elements of a Lockout / Tagout Program

XIV. Other Things To Consider. When do You Retrain Personnel. What must you do when you identify problems. When do you have to make changes to your written procedures. Elements of a Lockout / Tagout Program