MEMBRANE PROCESSES Reverse Osmosis Ultrafiltration Microfiltration

18 Slides54.50 KB

MEMBRANE PROCESSES Reverse Osmosis Ultrafiltration Microfiltration

What Are Membranes? Membranes are thin films of synthetic organic or inorganic (ceramic) materials, which can bring about a very selective separation between a fluid and its components. The fluid may be a gas or a liquid but in Environmental Engineering we are more concerned with water and wastewater.

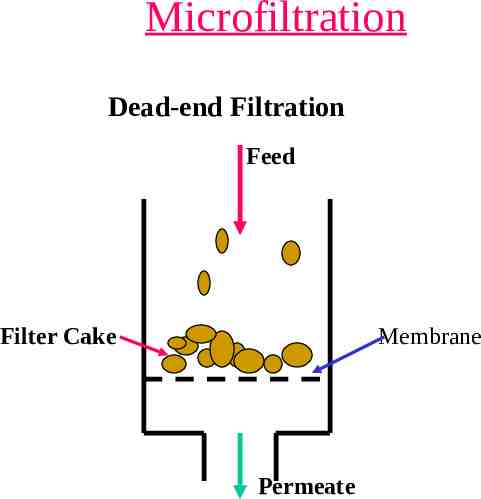

Microfiltration Dead-end Filtration Feed Filter Cake Membrane Permeate

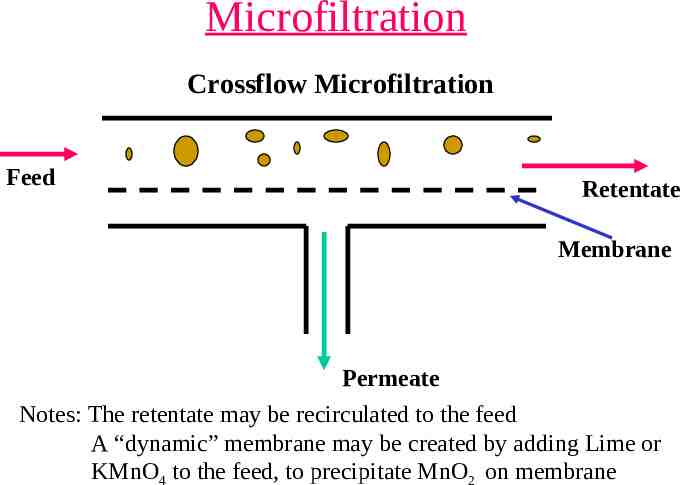

Microfiltration Crossflow Microfiltration Feed Retentate Membrane Permeate Notes: The retentate may be recirculated to the feed A “dynamic” membrane may be created by adding Lime or KMnO4 to the feed, to precipitate MnO2 on membrane

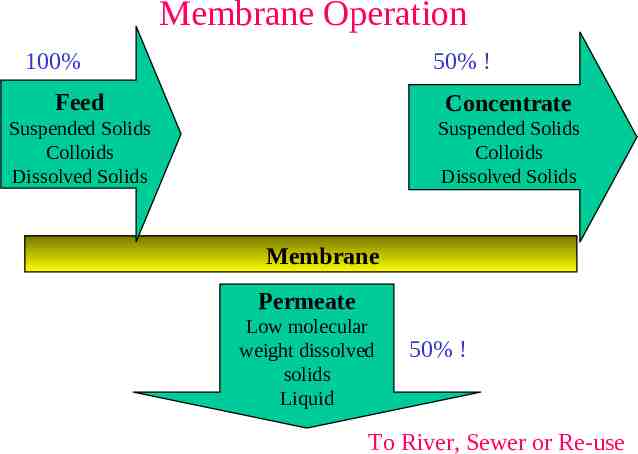

Membrane Operation 100% 50% ! Feed Concentrate Suspended Solids Colloids Dissolved Solids Suspended Solids Colloids Dissolved Solids Membrane Permeate Low molecular weight dissolved solids Liquid 50% ! To River, Sewer or Re-use

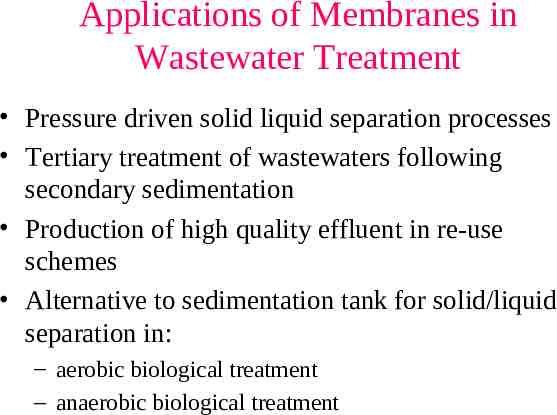

Applications of Membranes in Wastewater Treatment Pressure driven solid liquid separation processes Tertiary treatment of wastewaters following secondary sedimentation Production of high quality effluent in re-use schemes Alternative to sedimentation tank for solid/liquid separation in: – aerobic biological treatment – anaerobic biological treatment

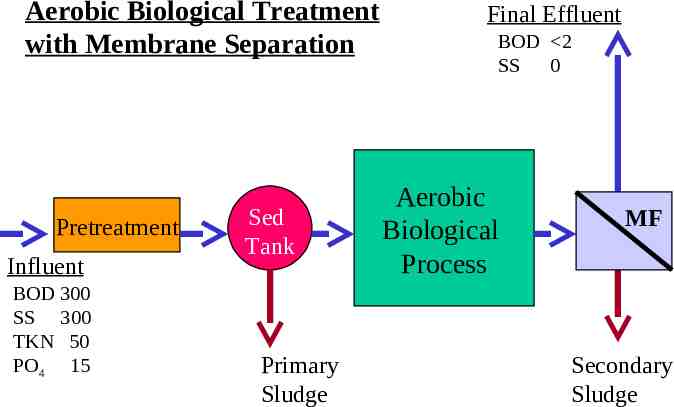

Aerobic Biological Treatment with Membrane Separation Pretreatment Influent BOD 300 SS 300 TKN 50 PO4 15 Sed Tank Primary Sludge Final Effluent BOD 2 SS 0 Aerobic Biological Process MF Secondary Sludge

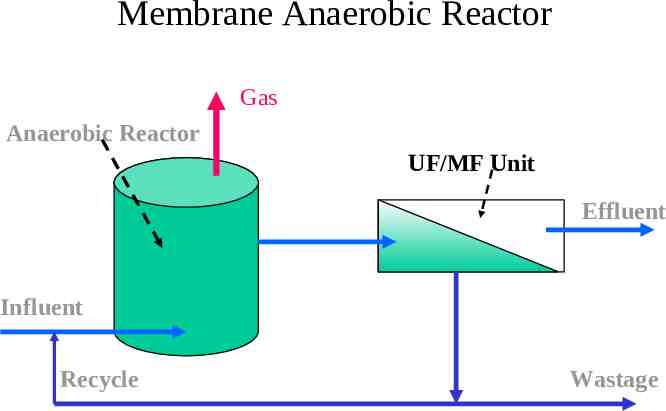

Membrane Anaerobic Reactor Gas Anaerobic Reactor UF/MF Unit Effluent Influent Recycle Wastage

Advantages of Membrane Processes They are usually continuous Comparatively low energy utilisation No phase change of contaminants Small temperature change Modular design Minimum of moving parts Physical separation of contaminants

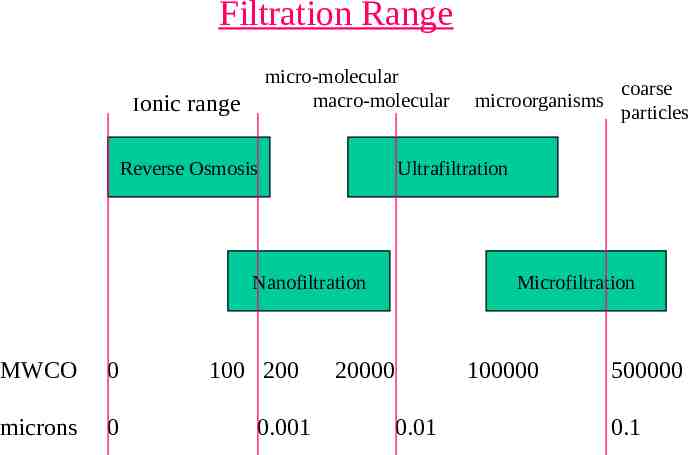

Filtration Range micro-molecular macro-molecular Ionic range Reverse Osmosis 0 microns 0 100 200 0.001 coarse particles Ultrafiltration Nanofiltration MWCO microorganisms Microfiltration 20000 100000 0.01 500000 0.1

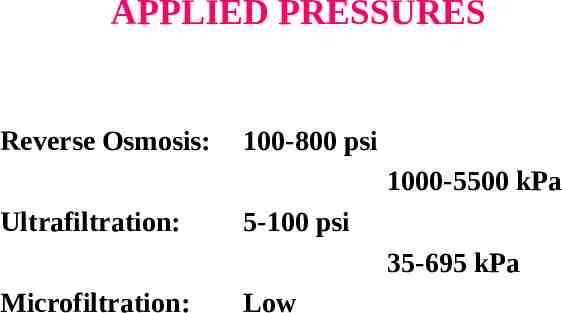

APPLIED PRESSURES Reverse Osmosis: 100-800 psi 1000-5500 kPa Ultrafiltration: 5-100 psi 35-695 kPa Microfiltration: Low

Microfiltration Design Considerations High flux Back-flushable High membrane area/volume ratio allowing low pressure drop whilst maintaining high tangential velocities Simple installation and continuous operation with minimum supervision Low operating pressure Easy maintenance and simple membrane replacement Low energy consumption Relatively low capital costs

Microfiltration Applications Current Future Wine Drinking Water Dextrose clarification Hydrocarbon Separation Haze removal from gelatin Milk-fat Separation Beer clarification Food and Beverage Pharmaceutical/biological Industrial Wastewater Municipal Wastewater Treatment Paint Biotechnology

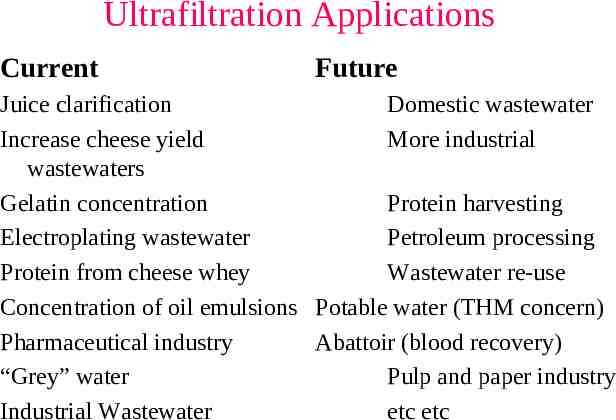

Ultrafiltration Applications Current Future Juice clarification Domestic wastewater Increase cheese yield More industrial wastewaters Gelatin concentration Protein harvesting Electroplating wastewater Petroleum processing Protein from cheese whey Wastewater re-use Concentration of oil emulsions Potable water (THM concern) Pharmaceutical industry Abattoir (blood recovery) “Grey” water Pulp and paper industry Industrial Wastewater etc etc

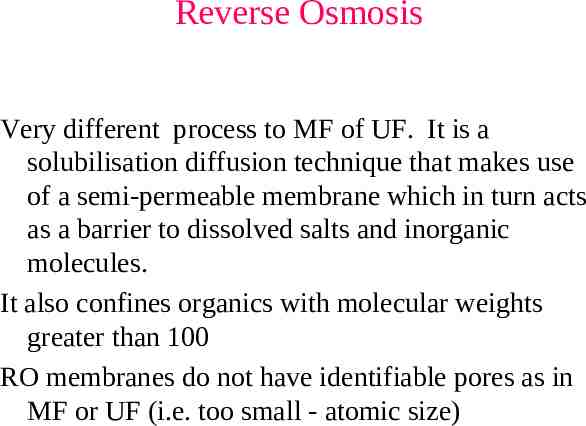

Reverse Osmosis Very different process to MF of UF. It is a solubilisation diffusion technique that makes use of a semi-permeable membrane which in turn acts as a barrier to dissolved salts and inorganic molecules. It also confines organics with molecular weights greater than 100 RO membranes do not have identifiable pores as in MF or UF (i.e. too small - atomic size)

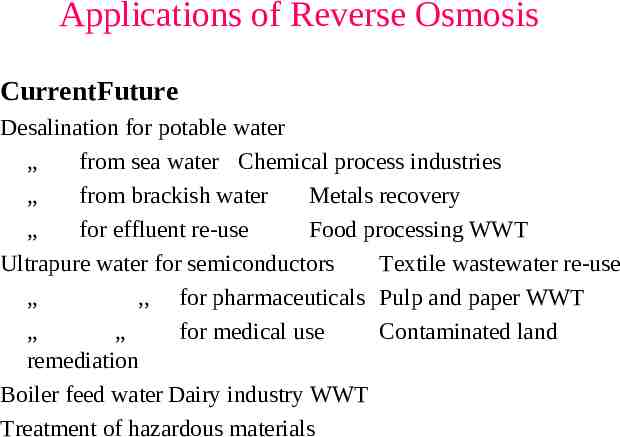

Applications of Reverse Osmosis CurrentFuture Desalination for potable water ,, from sea water Chemical process industries ,, from brackish water Metals recovery ,, for effluent re-use Food processing WWT Ultrapure water for semiconductors Textile wastewater re-use ,, ,, for pharmaceuticals Pulp and paper WWT ,, ,, for medical use Contaminated land remediation Boiler feed water Dairy industry WWT Treatment of hazardous materials

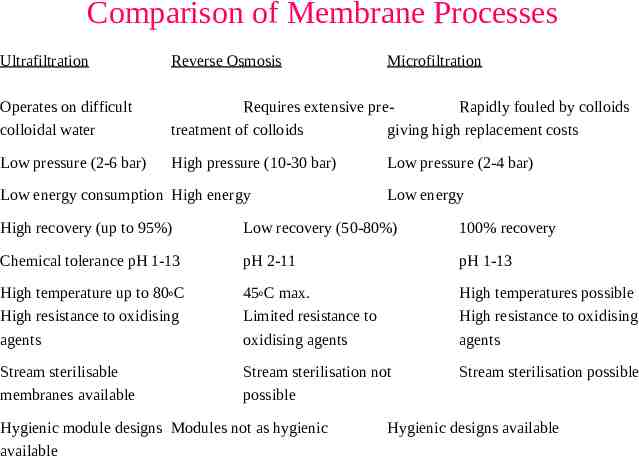

Comparison of Membrane Processes Ultrafiltration Reverse Osmosis Operates on difficult colloidal water Requires extensive preRapidly fouled by colloids treatment of colloids giving high replacement costs Low pressure (2-6 bar) High pressure (10-30 bar) Low energy consumption High energy Microfiltration Low pressure (2-4 bar) Low energy High recovery (up to 95%) Low recovery (50-80%) 100% recovery Chemical tolerance pH 1-13 pH 2-11 pH 1-13 High temperature up to 80oC High resistance to oxidising agents 45oC max. Limited resistance to oxidising agents High temperatures possible High resistance to oxidising agents Stream sterilisable membranes available Stream sterilisation not possible Stream sterilisation possible Hygienic module designs Modules not as hygienic available Hygienic designs available

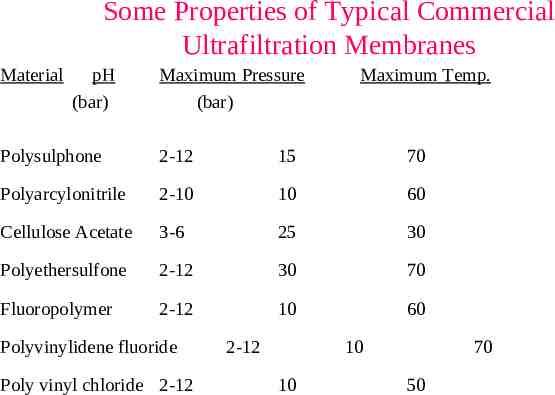

Some Properties of Typical Commercial Ultrafiltration Membranes Material pH (bar) Maximum Pressure (bar) Maximum Temp. Polysulphone 2-12 15 70 Polyarcylonitrile 2-10 10 60 Cellulose Acetate 3-6 25 30 Polyethersulfone 2-12 30 70 Fluoropolymer 2-12 10 60 Polyvinylidene fluoride Poly vinyl chloride 2-12 2-12 10 10 70 50