Delivering Change in the Digital Economy: The Value of Supply Chain

19 Slides1.61 MB

Delivering Change in the Digital Economy: The Value of Supply Chain Collaboration in SA FMCG CGCSA Summit - September 2015 Paul Dickson

Agenda 1. Introduction and Objectives 2. Supply Chain Collaboration: Definitions 3. What supply chain problem are we trying to solve? 4. Collaboration and Integrated Demand Planning: “As-Is” versus “Best-in-Class” 5. So where should local FMCG players start?

Agenda 1. Introduction and Objectives 2. Supply Chain Collaboration: Definitions 3. What supply chain problem are we trying to solve? 4. Collaboration and Integrated Demand Planning: “As-Is” versus “Best-in-Class” 5. So where should local FMCG players start?

Introduction & Objectives Questions we would like to address in this session What is supply chain collaboration? What do we commonly see when FMCG partners are not effectively collaborating? What value is targeted through better supply chain collaboration and integrated planning? How can technology enable better collaboration between trade partners?

Agenda 1. Introduction and Objectives 2. Supply Chain Collaboration: Definitions 3. What supply chain problem are we trying to solve? 4. Collaboration and Integrated Demand Planning: “As-Is” versus “Best-in-Class” 5. So where should local FMCG players start?

How can we define supply chain collaboration? What is “Supply Chain Collaboration”, and what does it really mean? “Collaboration is . a recursive process where two or more people or organizations work together to realize shared goals” - (Wikipedia.org) “Supply Chain Collaboration is the process of integrating supply chain planning and execution activities across multiple trade partners, with the objective of creating optimal and cost-effective logistics and inventory operations across all parties.” - Resolve “Collaborative Planning, Forecasting and Replenishment (CPFR) is a business model that takes a holistic approach to supply chain management and combines the intelligence of multiple trading partners in planning and fulfilling customer demand CFPR links sales and marketing best practices – category management, supply chain planning and execution processes to increase availability while reducing inventory, merchandizing, transportation and logistics costs.” - Voluntary Inter-industry Commerce Standards) (VICS) Association

Agenda 1. 2. 3. 4. Introduction and Objectives Supply Chain Collaboration: Definitions What supply chain problem are we trying to solve? Collaboration and Integrated Demand Planning: “As-Is” versus “Best-in-Class” 5. So where should local FMCG players start?

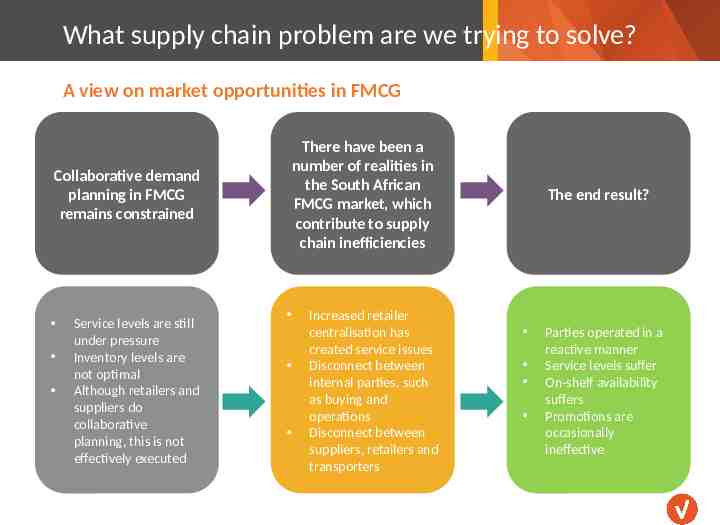

What supply chain problem are we trying to solve? A view on market opportunities in FMCG Collaborative demand planning in FMCG remains constrained Service levels are still under pressure Inventory levels are not optimal Although retailers and suppliers do collaborative planning, this is not effectively executed There have been a number of realities in the South African FMCG market, which contribute to supply chain inefficiencies Increased retailer centralisation has created service issues Disconnect between internal parties, such as buying and operations Disconnect between suppliers, retailers and transporters The end result? Parties operated in a reactive manner Service levels suffer On-shelf availability suffers Promotions are occasionally ineffective

Agenda 1. 2. 3. 4. Introduction and Objectives Supply Chain Collaboration: Definitions What supply chain problem are we trying to solve? Collaboration and Integrated Demand Planning: “As-Is” versus “Best-in-Class” 5. So where should local FMCG players start?

The Supply Chain Collaboration Landscape Tactical Strategic The different functional areas for collaborative focus New product development Range and store clustering Price and promotion Annual Marketing Strategy Pre- and Mid- promotional planning and execution Marketing & Advertising requirements Retailer Stores Retailer Warehouse Supplier Factory Operational Retailer Stores Source (or farm) Supplier Warehouse eCommerce Customers

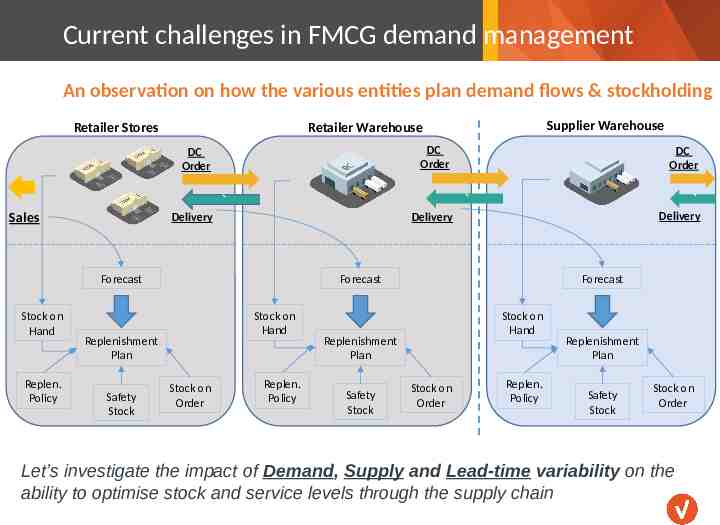

Current challenges in FMCG demand management An observation on how the various entities plan demand flows & stockholding DC Order DC Order Delivery Replen. Policy Delivery Forecast Stock on Hand Replenishment Plan Safety Stock Delivery Forecast Stock on Hand DC Order Sales Supplier Warehouse Retailer Warehouse Retailer Stores Stock on Order Replen. Policy Forecast Stock on Hand Replenishment Plan Safety Stock Stock on Order Replen. Policy Replenishment Plan Safety Stock Stock on Order Let’s investigate the impact of Demand, Supply and Lead-time variability on the ability to optimise stock and service levels through the supply chain

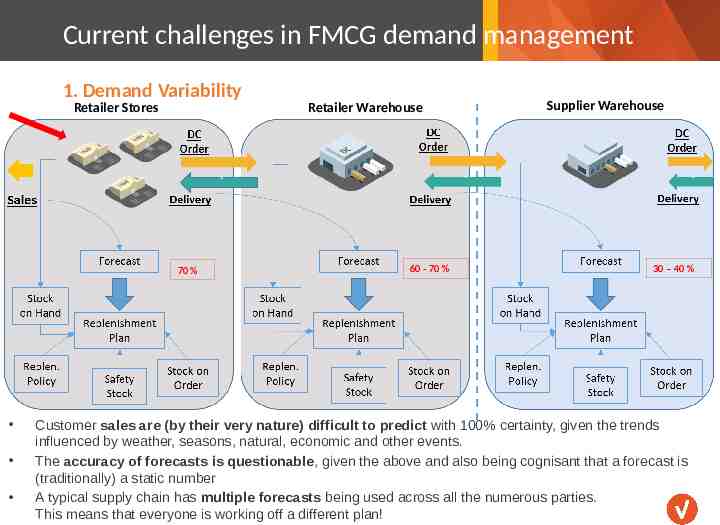

Current challenges in FMCG demand management 1. Demand Variability Retailer Stores 70 % Retailer Warehouse 60 - 70 % Supplier Warehouse 30 – 40 % Customer sales are (by their very nature) difficult to predict with 100% certainty, given the trends influenced by weather, seasons, natural, economic and other events. The accuracy of forecasts is questionable, given the above and also being cognisant that a forecast is (traditionally) a static number A typical supply chain has multiple forecasts being used across all the numerous parties. This means that everyone is working off a different plan!

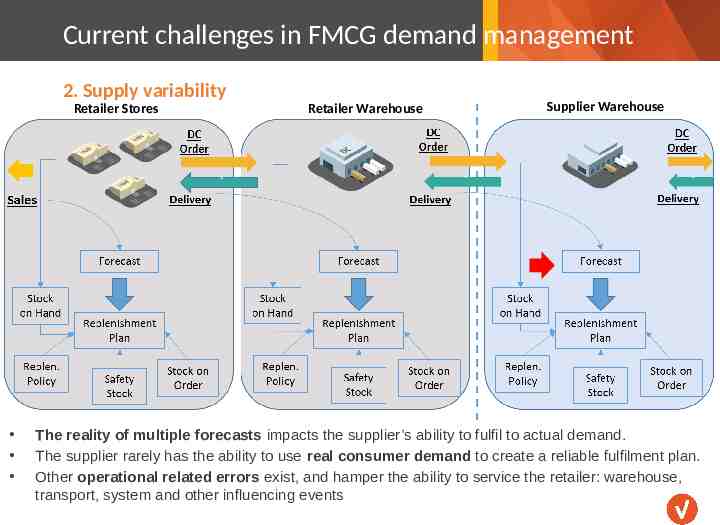

Current challenges in FMCG demand management 2. Supply variability Retailer Stores Retailer Warehouse Supplier Warehouse The reality of multiple forecasts impacts the supplier’s ability to fulfil to actual demand. The supplier rarely has the ability to use real consumer demand to create a reliable fulfilment plan. Other operational related errors exist, and hamper the ability to service the retailer: warehouse, transport, system and other influencing events

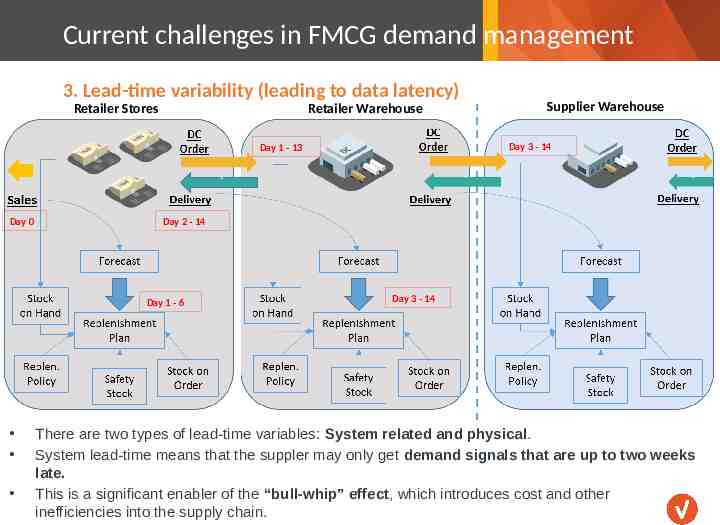

Current challenges in FMCG demand management 3. Lead-time variability (leading to data latency) Retailer Warehouse Retailer Stores Day 3 - 14 Day 1 - 13 Day 0 Day 2 - 14 Day 1 - 6 Supplier Warehouse Day 3 - 14 There are two types of lead-time variables: System related and physical. System lead-time means that the suppler may only get demand signals that are up to two weeks late. This is a significant enabler of the “bull-whip” effect, which introduces cost and other inefficiencies into the supply chain.

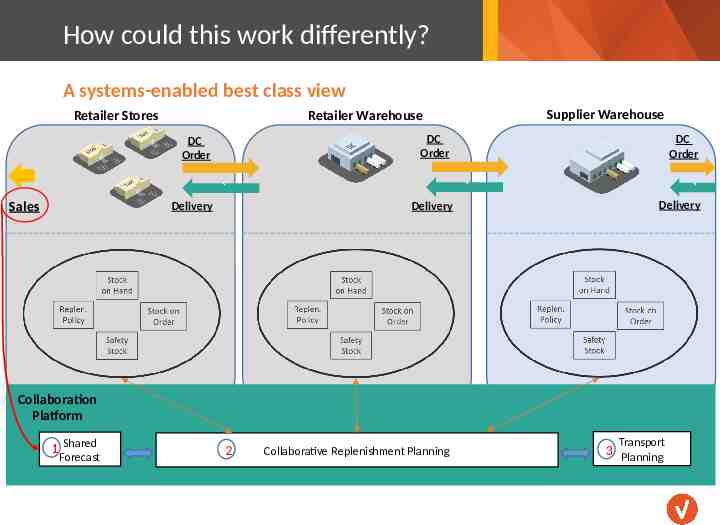

How could this work differently? A systems-enabled best class view DC Order DC Order Delivery DC Order Sales Supplier Warehouse Retailer Warehouse Retailer Stores Delivery Delivery Collaboration Platform 1 Shared Forecast 2 Collaborative Replenishment Planning Transport 3 Planning

Technology-enabled collaboration How should technology make this all happen? Create visibility for all parties (Responsiveness) Real time visibility to the total demand, supply, and capacity picture to be more responsive to changes in demand, available capacity, and supply continuity issues. Promote Process Orchestration (Effectiveness) Provide the ability to manage and automate complex supply chain processes across multiple tiers of partners, driving shared value and common metrics. Reduce Information Latency (Speed) Create the ability to plan, execute, and make decisions from real time information shared across the supply chain. Data Synchronization (Accuracy) All partners working off of the same demand, supply, and capacity information. A single version of the truth. Single Version of the Truth (Transparency) Ability to work together to identify root causes and operational process improvements increasing productivity, efficiency, and perfect order performance.

Agenda 1. 2. 3. 4. Introduction and Objectives Supply Chain Collaboration: Definitions What supply chain problem are we trying to solve? Collaboration and Integrated Demand Planning: “As-Is” versus “Best-in-Class” 5. So where should local FMCG players start?

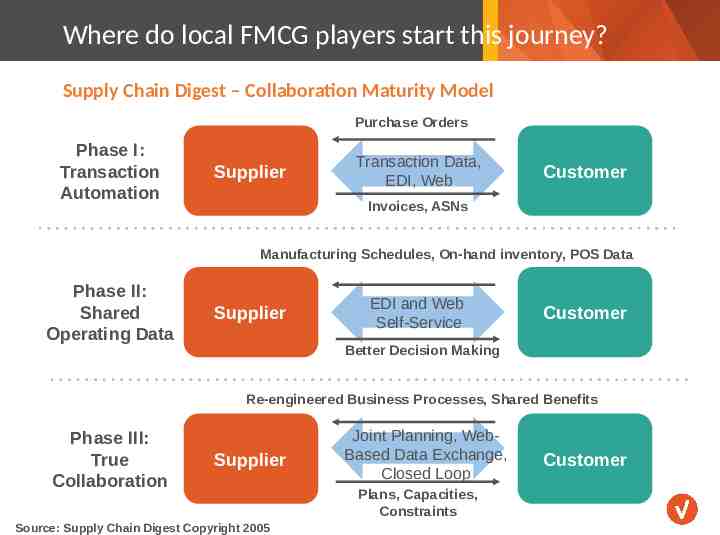

Where do local FMCG players start this journey? Supply Chain Digest – Collaboration Maturity Model Purchase Orders Phase I: Transaction Automation Supplier Transaction Data, EDI, Web Customer Invoices, ASNs Manufacturing Schedules, On-hand inventory, POS Data Phase II: Shared Operating Data Supplier EDI and Web Self-Service Customer Better Decision Making Re-engineered Business Processes, Shared Benefits Phase III: True Collaboration Supplier Source: Supply Chain Digest Copyright 2005 Joint Planning, WebBased Data Exchange, Closed Loop Plans, Capacities, Constraints Customer

www.resolvesp.com 47 Landmarks Ave, Samrand resolvesp [email protected] 076 573 8096 @resolve sp