CHAPTER 53 CompressionIgnition Engines

47 Slides2.10 MB

CHAPTER 53 CompressionIgnition Engines

Introduction Compression-ignition engines are fuel-efficient engines that run on diesel fuel. – Easily adapted to alternative fuels – Reputation for being slow and noisy, and emitting smoke – Modern diesel engines are quiet, efficient, and powerful with reduced emissions.

Market Forces and Technology (1 of 3) History of diesel – During the 1970s oil crisis, diesel cars became popular. – Despite shortcomings, diesel engines are a staple because of the high cost of fuel. – Firmer tailpipe emission standards and robust economy resulted in improvements in diesel technology beginning around 1997.

Market Forces and Technology (2 of 3) Emissions advantage – Since 1988, “soot” emissions have been reduced by 83%; oxides of nitrogen by 63%. – Hydrocarbon, carbon monoxide, and carbon dioxide emissions have been reduced. – Additional gains will come from cleaner, low-sulfur petro-diesel fuel or synthetic and biodiesel fuels. – EPA has mandated cleaner air and enacted emission regulations.

Market Forces and Technology (3 of 3) Public perceptions – Even before regulations, OEMs were converting diesel engine platforms from in-line injection systems to common rail. – Both trucks and light passenger vehicles have benefited from clean diesel technology. Models from Volkswagen, Chevy, Ford, Dodge – Many service providers now offer drive-through diesel vehicle service and repair. Increased demand for skilled technicians

Compression-Ignition Engine Fundamentals (1 of 9) With gas engines, ignition occurs when spark plug fires. With compressionignition engines, it occurs when fuel is injected into the combustion chamber.

Compression-Ignition Engine Fundamentals (2 of 9) Four-stroke diesel engines – Cycle includes: Intake stroke Compression stroke (ignition occurs near its end) Power stroke Exhaust stroke

Compression-Ignition Engine Fundamentals (3 of 9) A B C D The four-stroke cycle. A. Intake. B. Compression. C. Power. D. Exhaust.

Compression-Ignition Engine Fundamentals (4 of 9) Four-stroke diesel engines (cont’d) – Cycle requires two full revolutions of the crankshaft. – Volumetric efficiency (VE) is the amount of fresh air taken into the cylinder on the intake stroke at a given rpm in relation to the space in the cylinder at engine standstill. Aspirated engines have less than 100% VE. Super- or turbocharged engines can have 100% VE.

Compression-Ignition Engine Fundamentals (5 of 9) Four-stroke diesel engines (cont’d) – Engine layout uses both direct and indirect fuel injection designs.

Compression-Ignition Engine Fundamentals (6 of 9) Four-stroke diesel engines (cont’d) – Direct injection: Fuel is injected directly into the combustion chamber.

Compression-Ignition Engine Fundamentals (7 of 9) Four-stroke diesel engines (cont’d) – Indirect injection: Fuel is sprayed into a robust, hot antechamber in the cylinder head (called a prechamber).

Compression-Ignition Engine Fundamentals (8 of 9) Two-stroke diesel engines – Perform all events of a four-stroke engine with two piston strokes and one crankshaft revolution

Compression-Ignition Engine Fundamentals (9 of 9) Two-stroke diesel engines (cont’d) – The intake air blower is driven by the crankshaft. – Turbochargers are sometimes used to improve VE. – Scavenging ensures efficient removal of hot exhaust gases from the cylinder and replacement with fresh air.

The Three Phases of Combustion Once fuel is injected it goes through three phases. – Ignition delay/lag period – Flame spread – Direct burning

Compression-Ignition Engine Components (1 of 18) Engine upper/lower end – The cylinder block provides the framework, strength, and structure for the engine. Houses the crankshaft, connecting rods, pistons, camshaft, lifters, bearing, and timing gears Additional components can be included or attached to the block. Made of cast iron Block skirt extends below crankshaft centerline for extra strength

Compression-Ignition Engine Components (2 of 18) Engine upper/lower end (cont’d) – Cylinder block (cont’d) All major components are in exact alignment. Cylinder bores have removable sleeves (liners) for easier replacement during repair. Cylinder head attaches to block at cylinder bore opening and seals the cylinders.

Compression-Ignition Engine Components (3 of 18) Engine upper/lower end (cont’d) – Cylinder heads house the valves, injectors, and glow plugs. Most are cast iron. Single or multiple heads can be used. Components include rocker arms or a rocker shaft. Some engines also have a camshaft in the cylinder head (overhead cam engine).

Compression-Ignition Engine Components (4 of 18) Diesel engine passages – Diesel engines have passages cast or machined into the cylinder head and block for cooling and lubrication.

Compression-Ignition Engine Components (5 of 18) Diesel engine passages (cont’d) – The combustion chamber may be formed into the piston crown in various shapes and sizes. Different than gas engines because of reduced area above piston at TDC and the way that compression ignition occurs – Fuel injectors are mounted on the cylinder head, reaching into the precombustion chamber (indirect injection) or main chamber (direct). Fuel is atomized and injected as a fine mist.

Compression-Ignition Engine Components (6 of 18) Diesel valves and components – Intake and exhaust valves allow air to enter and exhaust gases to exit.

Compression-Ignition Engine Components (7 of 18) Diesel valves and components (cont’d) – Valves usually run parallel to the centerline of a diesel engine. – Small four-stroke engines usually have two valves per cylinder (intake valve is larger). – In typical two-stroke engines, no need for intake valves because air entering the cylinders is pressurized by a blower or compressor.

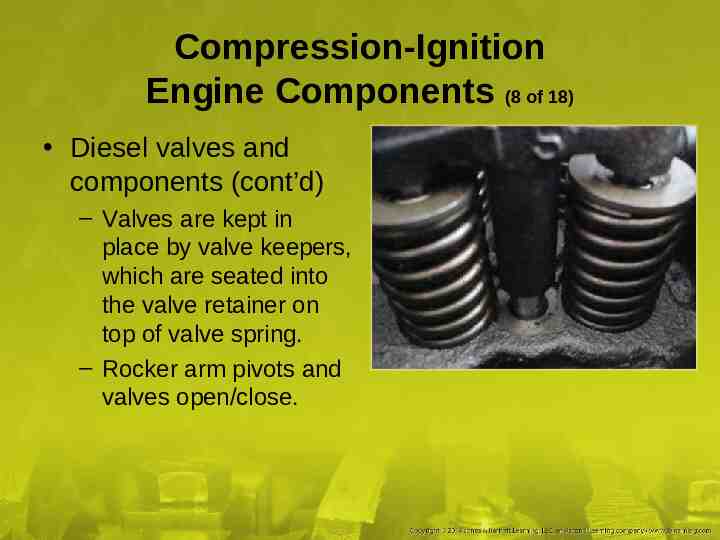

Compression-Ignition Engine Components (8 of 18) Diesel valves and components (cont’d) – Valves are kept in place by valve keepers, which are seated into the valve retainer on top of valve spring. – Rocker arm pivots and valves open/close.

Compression-Ignition Engine Components (9 of 18) Diesel valves and components (cont’d) – Overhead valves are driven by a system of pushrods with the following components: Camshaft Lifters Pushrods Rocker arms Valves

Compression-Ignition Engine Components (10 of 18) Diesel valves and components (cont’d) – Some small high-speed diesel engines use one or more camshafts located in the cylinder head. – The camshaft keeps the valves operating in the right timing sequence.

Compression-Ignition Engine Components (11 of 18) Crankshaft/camshaft relationship – Timing between pistons and valves is critical to avoid engine self-destruction. – In a four-stroke engine, the crankshaft makes two complete revolutions per cycle, during which valves must open and close once. – The camshaft must rotate at half the speed of the crankshaft.

Compression-Ignition Engine Components (12 of 18) Crankshaft/camshaft relationship (cont’d) – Correct timing can be achieved by gears, chains and sprockets, or a toothed belt and sprockets (timing gears). – When timing chains or belts are used with sprockets, the number of cogs on the driving crankshaft sprocket is matched to the driven sprocket.

Compression-Ignition Engine Components (13 of 18) Camshaft drives – Camshafts can be driven by the crankshaft through different methods. A B A. Timing gears. B. Timing chain and sprockets.

Compression-Ignition Engine Components (14 of 18) Camshaft drives (cont’d) – Gears are most reliable, but present design and placement challenge because they mesh together; they are also noisy. – Timing chains allow more flexibility in placement and design, but like gears must be lubricated, properly tensioned, and sealed inside the engine. – Timing belts are most flexible in terms of design and placement, but are the least reliable.

Compression-Ignition Engine Components (15 of 18) Diesel crankshaft – Converts the reciprocating movement of the pistons into rotating movement that transmits power through the transmission and final drive unit of the vehicle

Compression-Ignition Engine Components (16 of 18) Diesel crankshaft (cont’d) – Crankshaft shape is unusual. Main bearing journals are centered through the shaft. Rod bearing journals are offset from the centerline on throws. As piston is forced down, it pushes down on the rod journal and crankshaft throw through the connecting rod.

Compression-Ignition Engine Components (17 of 18) Diesel crankshaft (cont’d) – Crankshafts must balance uneven forces in engine from power strokes and offset pressures. Counterweights balance and offset forces applied by pistons. They keep rotating components in balance and help crankshaft turn smoothly.

Compression-Ignition Engine Components (18 of 18) Diesel crankshaft (cont’d) – Crankshaft bearings are critical to proper operation. Main bearings support the crankshaft in the block and lubricate surface for main bearing journals. Connecting rod bearings support the connecting rods as the crankshaft turns and lubricate connecting rod journals. – Lateral movement of the crankshaft is stopped by thrust bearings, which can be part of or separate from a main bearing.

The Flywheel (1 of 7) Stores torsional energy from the power stroke and gives it back to the crankshaft so it can keep turning A diesel engine flywheel.

The Flywheel (2 of 7) Dual-mass flywheels (DMFs) – DMF eliminates excessive transmission gear rattle, reduces gear change/shift effort, and increases fuel economy. – Two types: One is made up of a primary and secondary flywheel with a series of torsion springs and cushions; a friction ring alleviates damage from torque load. Other incorporates planetary gearing; designed for engines with stronger vibrations in the lower rpm range.

The Flywheel (3 of 7) Dual-mass flywheels (cont’d) – Used for light-duty diesel trucks with manual transmissions and higher performance luxury vehicles. – Construction relocates damper from the driven disc to the engine flywheel. – Designed to provide maximum isolation of the frequency below the engine’s operating rpm – Most effective during engine start-up and shutdown

The Flywheel (4 of 7) Diesel engine pistons – Modern pistons are made of aluminum alloys that can withstand stress from extreme heat and pressure. – Many factors determine the design and shape of a piston.

The Flywheel (5 of 7) Diesel engine pistons (cont’d) – Direct injection engines have an almost flat surface on the cylinder head, and almost all of the combustion chamber is shaped in the crown of the piston.

The Flywheel (6 of 7) Diesel engine pistons (cont’d) – Engines with indirect injection usually have flatter piston heads and may include valve pockets. Valve pockets are small indentations that provide clearance when at TDC.

The Flywheel (7 of 7) Diesel engine pistons (cont’d) – Pistons must seal in pressure and temperature from combustion. – Sealing is done with piston rings.

Summary (1 of 6) The five events common to all internal combustion engines are intake, compression, ignition, power, and exhaust. A four-stroke cycle engine completes the intake, compression, power, and exhaust strokes in two revolutions of the crankshaft. A two-stroke cycle engine completes the intake, compression, power, and exhaust strokes in one revolution of the crankshaft.

Summary (2 of 6) The diesel fuel system consists of a lift pump, a fuel filter and water separator, a fuel injection pump, and high-pressure lines and nozzle holder assemblies. Today’s engines use high-pressure common rail injection systems to meet rigid emission standards.

Summary (3 of 6) Three phases of combustion are ignition delay period, flame spread, and direct burning. Diesel engine components are exposed to higher operating temperatures, pressures, and forces than gasoline engine components.

Summary (4 of 6) Both four-stroke and two-stroke diesel engines have passages cast in the head to carry oil for lubrication and water for cooling. Direct and indirect fuel injection systems are two basic designs of fuel delivery control. Fuel injected directly into the combustion chamber is called direct injection.

Summary (5 of 6) Fuel injected into a separate chamber in the cylinder head is called indirect injection. Intake and exhaust valves are used in an engine to provide a means for fresh air to enter and exhaust gases to exit the cylinder. Scavenging is the removal of hot exhaust gases from the cylinder and the refilling of it with fresh air.

Summary (6 of 6) The crankshaft converts the reciprocating movement of the pistons into rotating movement that transmits power through the transmission and final drive unit of the vehicle.

Credits Unless otherwise indicated, all photographs and illustrations are under copyright of Jones & Bartlett Learning.