RFID Technology in Supply Chains

34 Slides2.58 MB

RFID Technology in Supply Chains

Diverse Applications Marathon races Airline baggage tracking Electronic security keys Livestock tagging Electronic toll pricing Library Video stores Defense Retailing – Stock levels, prices, expiry dates, remote access of products SCM

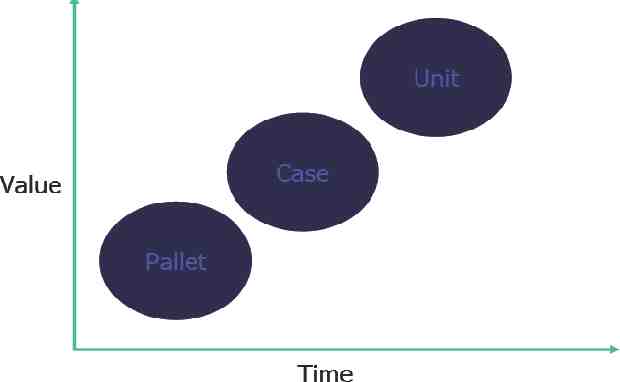

RFID and SCM Dramatic change in the management of supply chains Extraordinary ‘Asset Tracking’ ability Wal-Mart, Target. etc. have their suppliers RFID enabled World-wide demand of RFID tags 1 million FMCGs and Food Processing companies at various levels of RFID implementation – Pallet, Case, Item level

Overview of RFID Readers and Tags capable of transmitting and storing information – Tags – Tag readers – Edge servers – Middleware – Application software

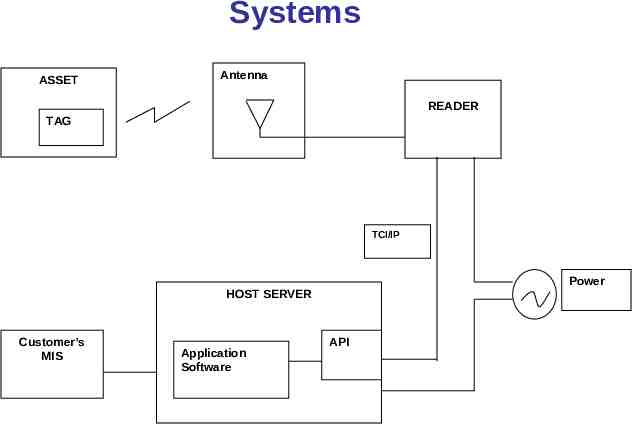

Systems ASSET Antenna READER TAG TCI/IP Power HOST SERVER Customer’s MIS Application Software API

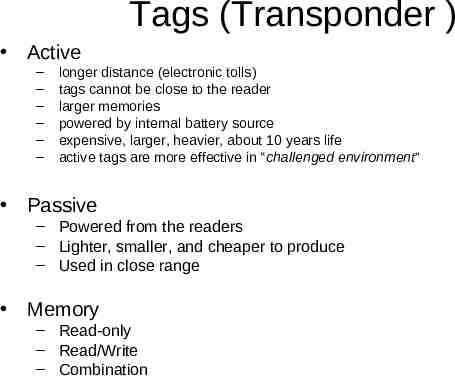

Tags (Transponder ) Active – – – – – – longer distance (electronic tolls) tags cannot be close to the reader larger memories powered by internal battery source expensive, larger, heavier, about 10 years life active tags are more effective in “challenged environment” Passive – Powered from the readers – Lighter, smaller, and cheaper to produce – Used in close range Memory – Read-only – Read/Write – Combination

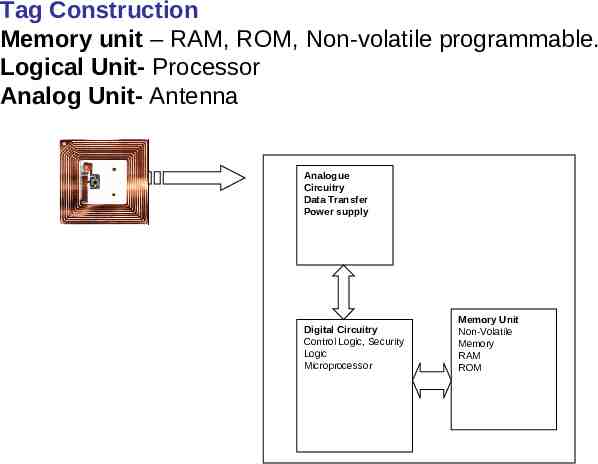

Tag Construction Memory unit – RAM, ROM, Non-volatile programmable. Logical Unit- Processor Analog Unit- Antenna Analogue Circuitry Data Transfer Power supply Digital Circuitry Control Logic, Security Logic Microprocessor Memory Unit Non-Volatile Memory RAM ROM

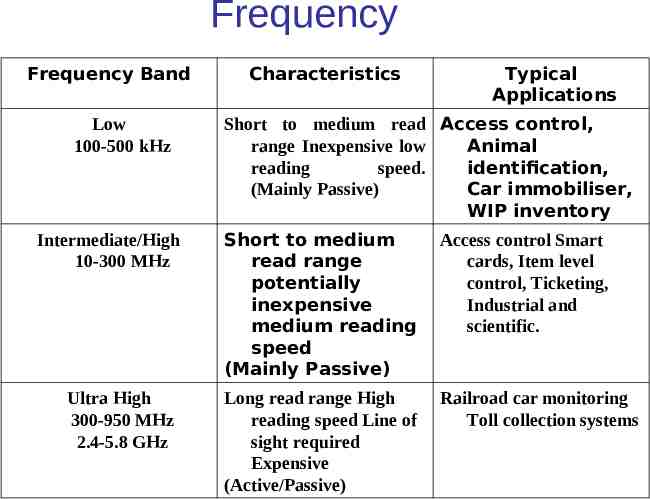

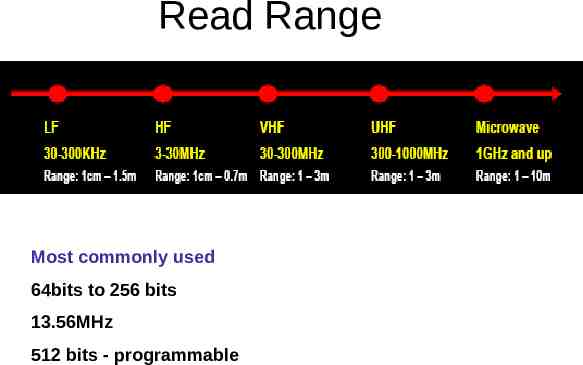

Frequency Frequency Band Low 100-500 kHz Intermediate/High 10-300 MHz Ultra High 300-950 MHz 2.4-5.8 GHz Characteristics Typical Applications Short to medium read Access control, range Inexpensive low Animal reading speed. identification, (Mainly Passive) Car immobiliser, WIP inventory Short to medium read range potentially inexpensive medium reading speed (Mainly Passive) Access control Smart cards, Item level control, Ticketing, Industrial and scientific. Long read range High reading speed Line of sight required Expensive (Active/Passive) Railroad car monitoring Toll collection systems

Read Range Most commonly used 64bits to 256 bits 13.56MHz 512 bits - programmable

Readers Antenna ( orientation, polarization, Protocol) Multi-protocol and Multi-frequency (New) Middleware Reader integration, Data filtering Application Software Filter and process data- feed to customers systems e.g. ERP, CRM, WMS etc.

SCM benefits from RFID Tracking helps in – – – – – – Inventory reduction Increased visibility Improved decision making Improved collaboration amongst the partners Improved pricing Fewer stock-outs Magnitude of benefits – Area of application – Level of application (pallet, case, item)

SCM Benefits from RFID Manufacturing Process – – – – Track the production of the part Instructions to produce Feedback to the ERP system about the status Efficient bottleneck management Distribution Process – – – – Efficient consignment handling Pallets with mixed cases (non-uniform) benefit more Warehouse management Shorter order-to-cash cycle

SCM Benefits from RFID Collaboration – Increased matching of supply and demand – Reduction in bull-whip effect – Improvement in forecasting and demand management Improvement in Inventory Shrinkage – Two percent of total sales is lost in inventory shrinkage Employee theft (48%) Shoplifting (32%) Administrative and paper error (15%) Vendor fraud (5%) Increase in number of empty packets

SCM Benefits from RFID Collaboration – Increased matching of supply and demand – Reduction in bull-whip effect – Improvement in forecasting and demand management Improvement in Inventory Shrinkage – Two percent of total sales is lost in inventory shrinkage Employee theft (48%) Shoplifting (32%) Administrative and paper error (15%) Vendor fraud (5%) Increase in number of empty packets

SCM Benefits from RFID Stockouts – Constitute a major issue in retail industry – Appx. 11% of the top 2000 SKUs are out of stock at any time – 13% for fast moving/promoted goods – RFIDs smart shelves can help to reduce the problem Pricing – Helps in ‘Differential’ and ‘Dynamic’ Pricing

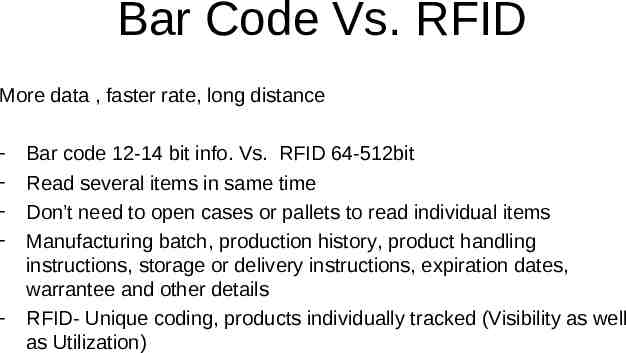

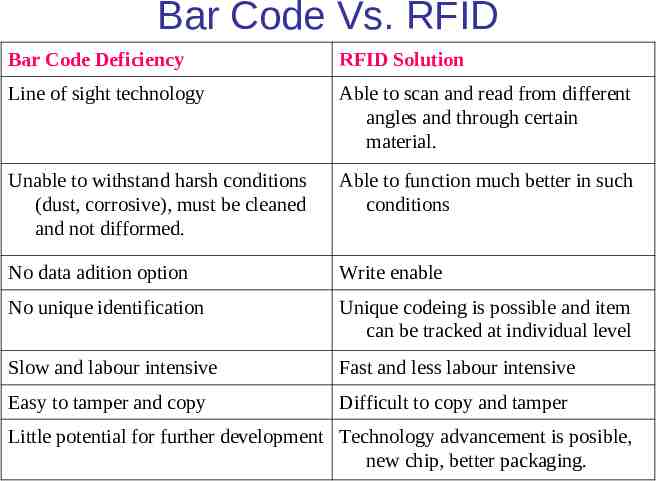

Bar Code Vs. RFID More data , faster rate, long distance - - Bar code 12-14 bit info. Vs. RFID 64-512bit Read several items in same time Don’t need to open cases or pallets to read individual items Manufacturing batch, production history, product handling instructions, storage or delivery instructions, expiration dates, warrantee and other details RFID- Unique coding, products individually tracked (Visibility as well as Utilization)

Bar Code Vs. RFID Bar Code Deficiency RFID Solution Line of sight technology Able to scan and read from different angles and through certain material. Unable to withstand harsh conditions (dust, corrosive), must be cleaned and not difformed. Able to function much better in such conditions No data adition option Write enable No unique identification Unique codeing is possible and item can be tracked at individual level Slow and labour intensive Fast and less labour intensive Easy to tamper and copy Difficult to copy and tamper Little potential for further development Technology advancement is posible, new chip, better packaging.

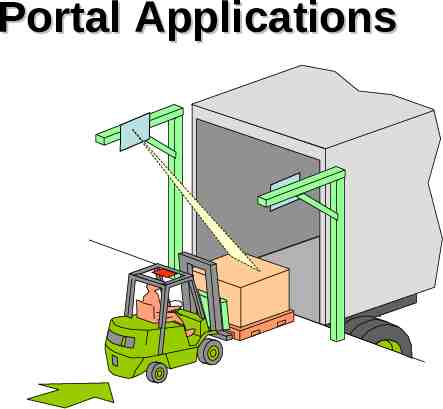

Portal Applications Bill of Lading Material Tracking

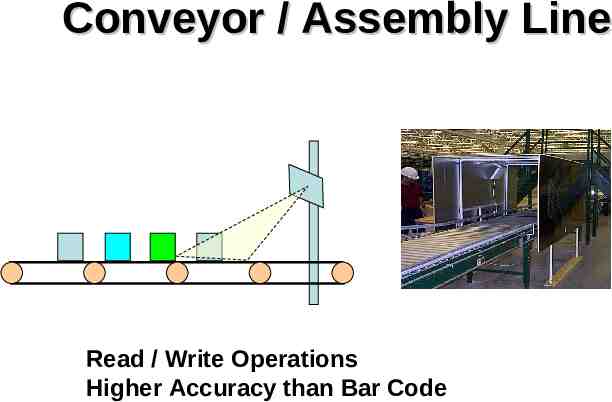

Conveyor / Assembly Line Read / Write Operations Higher Accuracy than Bar Code

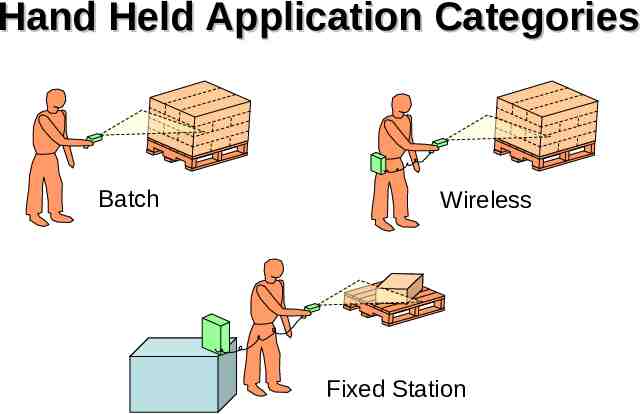

Hand Held Application Categories Batch Wireless Fixed Station

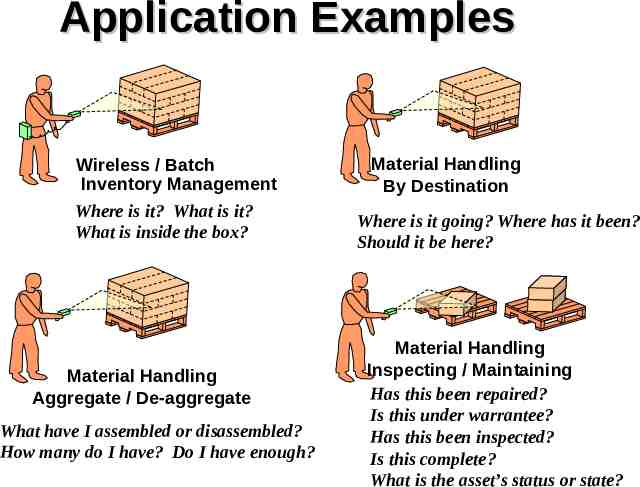

Application Examples Wireless / Batch Inventory Management Where is it? What is it? What is inside the box? Material Handling Aggregate / De-aggregate What have I assembled or disassembled? How many do I have? Do I have enough? Material Handling By Destination Where is it going? Where has it been? Should it be here? Material Handling Inspecting / Maintaining Has this been repaired? Is this under warrantee? Has this been inspected? Is this complete? What is the asset’s status or state?

Shipping Validation Tote/Box/Unit Level Inventory

Reduction In Out-of-stock Smart shelves – Automatic indication out-of-stock, level measurement, wrong item in wrong place, expired product Differentiating items ( slow/fast moving) - Responsive optimizing demand –price - Know customer preference quickly 1% uplift in shelf availability equates to 0.5% sales increase – Reduced out of stocks by approximately 16 percent in 12 stores (wal-mart) Price is displayed on shelves – – Quick, instantaneous price change

Ease Of Real Time Data Sharing RFID will solve the perennial problem of forecasting in apparel industry The easy realtime time data sharing between the store and manufacturrer will bring the flexibility Supplier managed inventory – Wal-Mart P&G

Reverse logistics Unique coding – tracking items individual level after sales even after use Call back any particular batch items- even after retailing buy back offer, replacement offer Environmental issue- disposal – At a recycling plant, parts and materials removed from used appliances must be classified according to items that can be reused, thermally recycled or discarded Product performance review after use

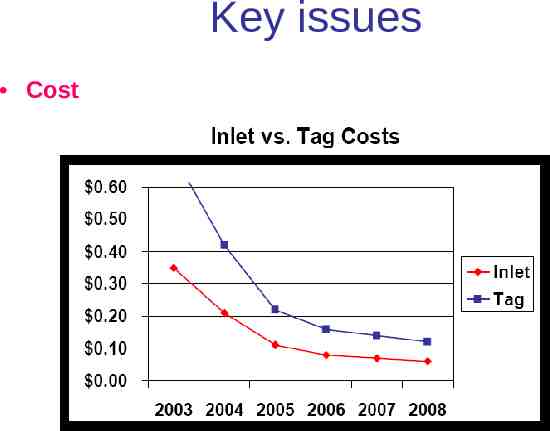

Key issues Cost

Regulation / standardization Why sleeping for 50 years? No standardization till 1999 Regulation – Country specific radio frequency Global SC !!! Auto-ID, Mech Engg. MIT 2003 , technology transferred to EPC global Partially standardized .work in progress

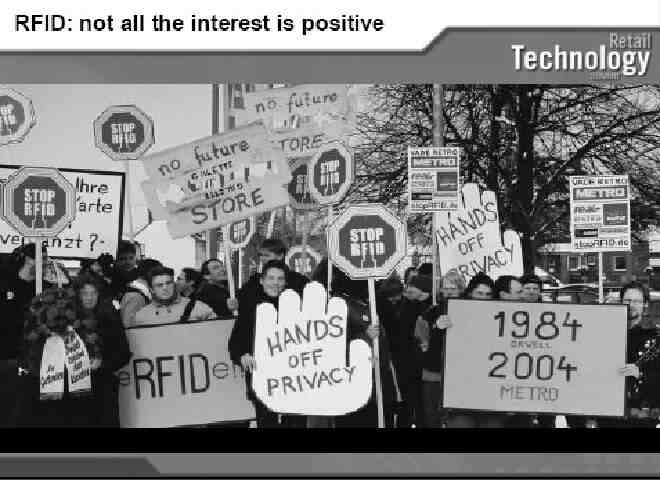

Piping – Privacy issue Embedded tag If tag is not removed If Your information is in wrong hand If somebody rewrite and manipulate or erase the data