Proposed Outline for a Course on Digital Supply Chain Management

48 Slides7.15 MB

Proposed Outline for a Course on Digital Supply Chain Management

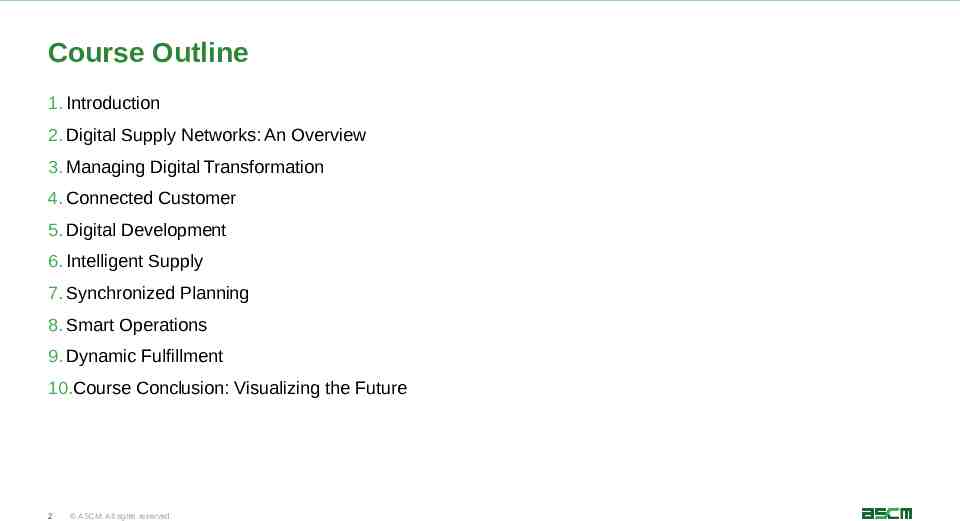

Course Outline 1. Introduction 2. Digital Supply Networks: An Overview 3. Managing Digital Transformation 4. Connected Customer 5. Digital Development 6. Intelligent Supply 7. Synchronized Planning 8. Smart Operations 9. Dynamic Fulfillment 10.Course Conclusion: Visualizing the Future 2 ASCM. All rights reserved.

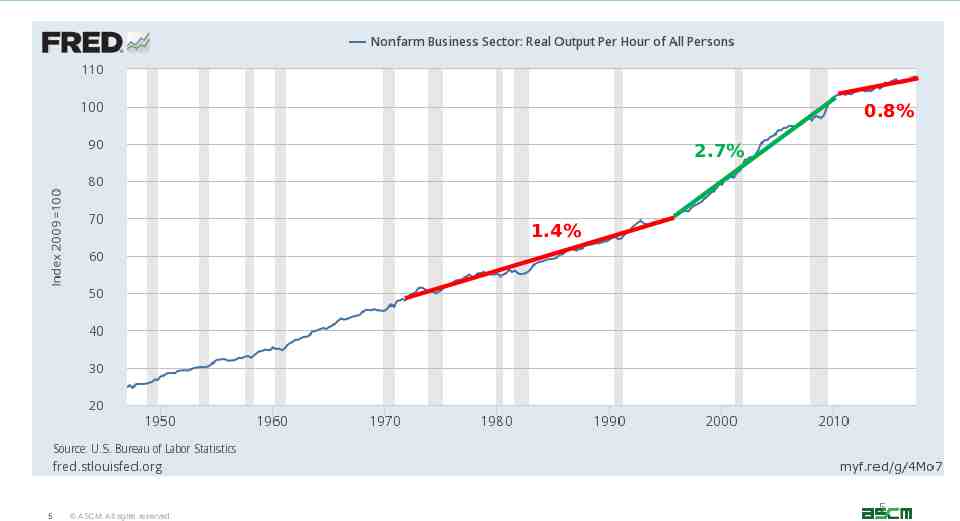

Introduction 1. Learning objectives: a. Understand the goals and structure of this course b. Explain the foundational structure of the DSN framework and its differences from the SCOR model c. Gain a sense of the status quo and state-of-the-art in digital supply chains 2. Core concepts: a. Digitalization (vs digitization) b. DSN, digital thread 3. Supporting content: a. Surveys on level and rate of adoption b. National productivity statistics 3 ASCM. All rights reserved.

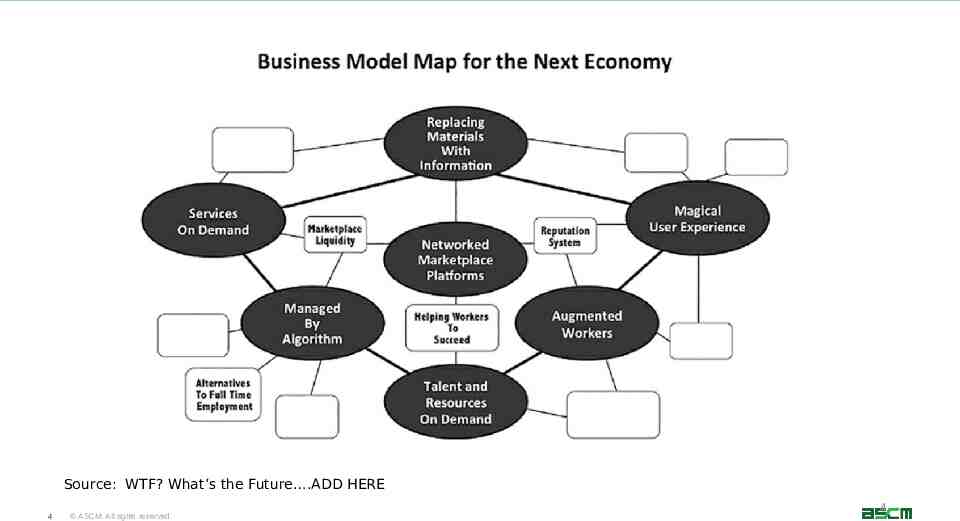

Source: WTF? What’s the Future .ADD HERE 4 ASCM. All rights reserved. 4

0.8% 2.7% 1.4% 5 ASCM. All rights reserved. 5

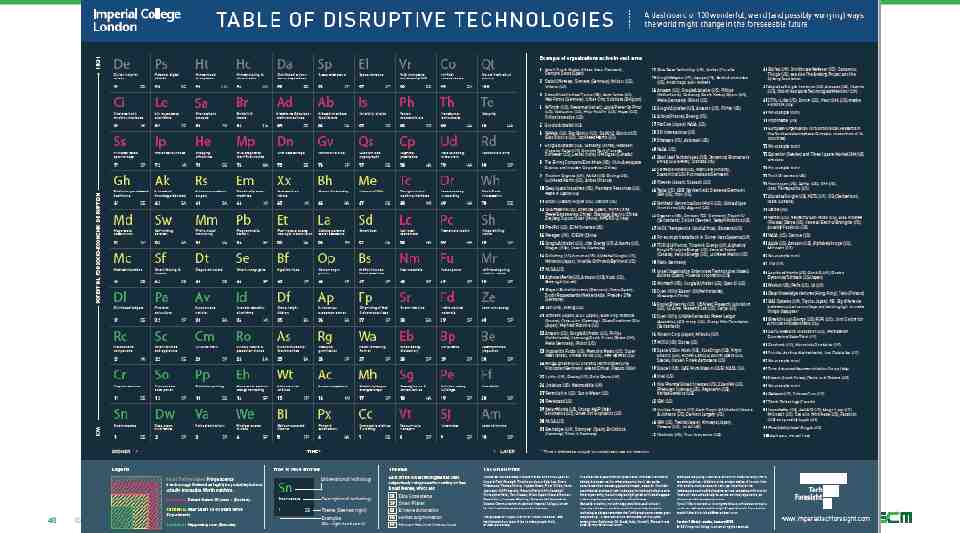

Learning Objectives: What Do Students Need to Know about “Digital” Supply Chains? 1. Understanding of the technology landscape a. Examples of technology solutions b. Organizing framework/Categories of technology 2. Facility with terminology 3. Understanding of opportunities, capabilities enabled by digital technologies 4. Appreciation for scope of change required, implementation challenges, etc. 5. Knowledge of change management best practices 6 ASCM. All rights reserved.

A “scenario” (next two slides) to stimulate interest and discussion of the “digital supply chain” 7 ASCM. All rights reserved.

The Order One morning in the not too distant future, you receive a text message at 7:00 a.m. from your toaster oven as it browns your morning slice of cinnamon bread. The text says that a sensor in the oven has detected that one of the heating elements is about to burn out, and given the predicted remaining useful life of the oven’s other components, it would be best to replace the oven now, rather than to repair it. The text actually came from ODI, your “Online Digital Identity,” which is connected to all your devices. ODI immediately sends you pictures and brief descriptions of 2-3 new toaster oven options and prices. Because ODI has interacted with you for years, observing your toasting habits as well as other aspects of your life, it can select oven styles (size, shape, color) and features (number of heating elements, settings, etc.), that you are likely to find appealing, while also optimizing a value algorithm (benefit/cost). To develop these recommendations, ODI worked with Megazon (an online retailer). It took 15 milliseconds for Megazon’s design engine to receive the design parameters from ODI and respond with recommended configurations. You can select one of the options, or use a drop down menu to add or change any of the features, with immediate price updates. Megazon provides the prices using its demand planning system, which instantly combines information about you (income, location, reward status, and other demographics) with its own internal operating data (e.g., current delivery capacity, forecast of suppliers’ production utilization levels, etc.). Once you are satisfied with a one-of-a-kind toaster oven design and price, ODI places 8 ASCM. All rights reserved.

9 The Response Megazon immediately sends the toaster oven design out for bid to several vendors that have fulfillment centers located within four hours travel time from your home. Each vendor bids on the job using its own “cost-to-serve” intelligent calculator, which incorporates data on the availability of materials and production capacity both in-house and at suppliers. In less than one second, an auction is completed, a vendor, Printhub.com, is selected, and the order is transmitted. At one of Printhub’s fulfillment centers (selected based on proximity and current workload), the order is scheduled by the manufacturing execution system (MES), and 3D printers immediately begin printing unique structural parts for the oven, while robots pull and kit the needed standard components from inventory. By 8:30 a.m., a completed kit is conveyed to an assembly area, where robots assemble, pack, and deliver the oven to the shipping area. It is picked up there by Megazon’s delivery service, either by a drone (air or land) or by one of your neighbors who is making a few extra bucks working for SuperLift home delivery. Megazon’s transportation management system (TMS) chooses the delivery mode and timing based on its evaluation of traffic patterns, availability of drone or driver capacity, and cost. The oven is delivered to your doorstep or nearby lockbox, based on your recorded preference, and a text is sent to you at the moment of delivery. The deliverer also picks up your old oven and delivers it to a nearby refurbishment/recycling center, which happens to be located next door to Printhub’s fulfillment center. ASCM. All rights reserved.

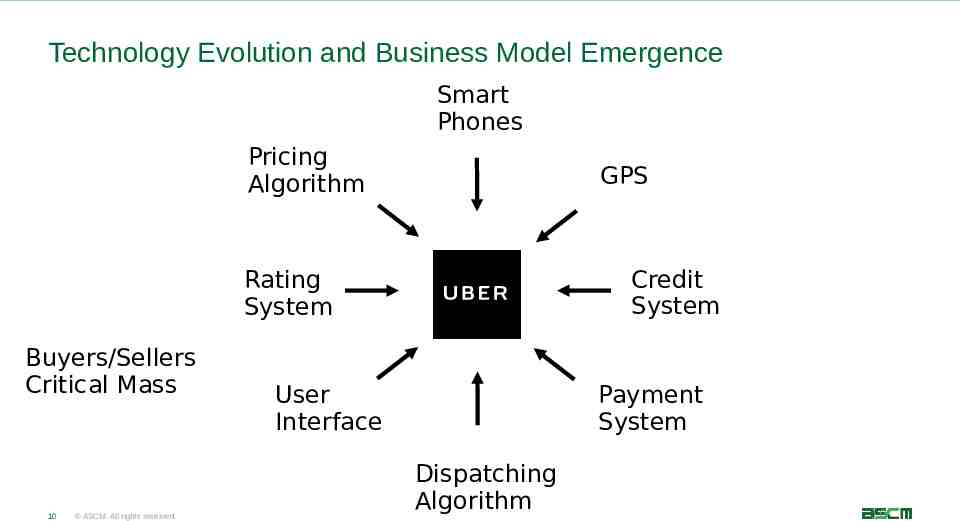

Technology Evolution and Business Model Emergence Smart Phones Pricing Algorithm GPS Credit System Rating System Buyers/Sellers Critical Mass 10 ASCM. All rights reserved. User Interface Payment System Dispatching Algorithm 10

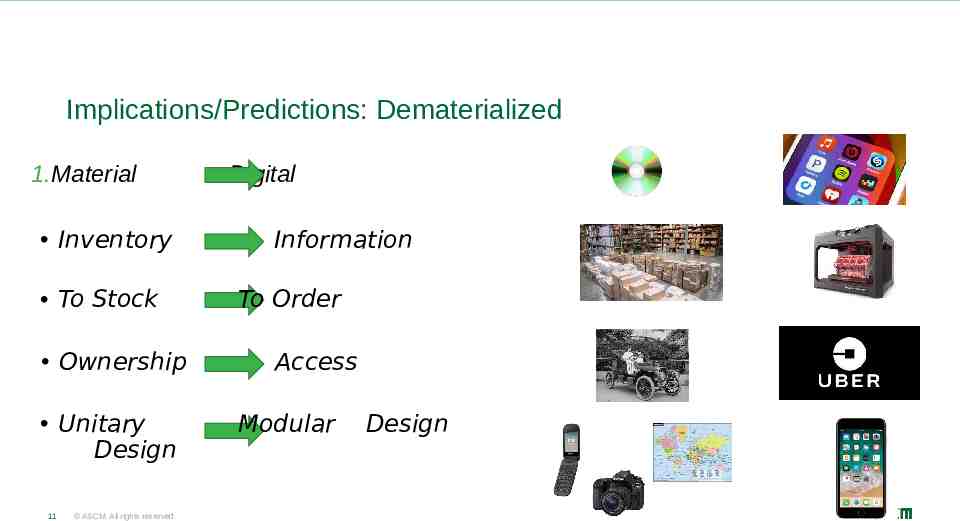

Implications/Predictions: Dematerialized 1.Material Inventory To Stock Ownership Unitary Design 11 ASCM. All rights reserved. Digital Information To Order Access Modular Design

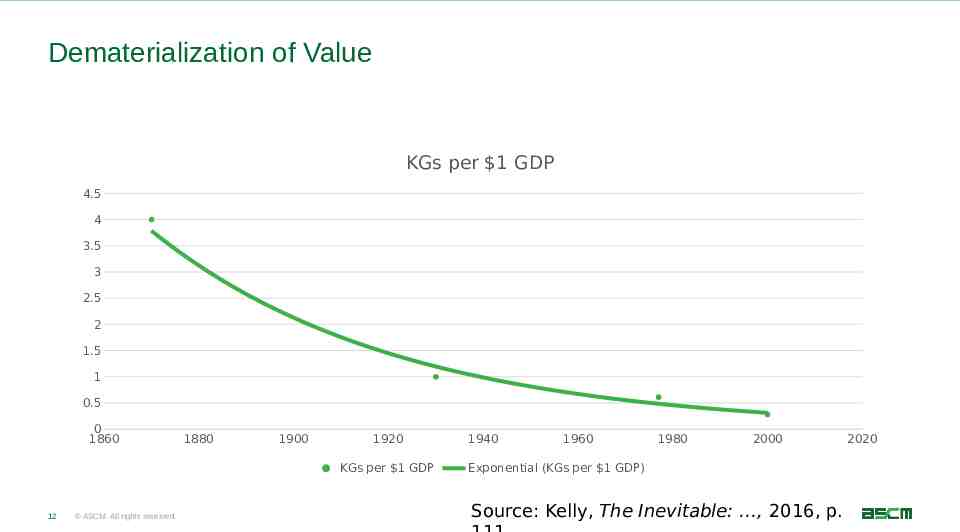

Dematerialization of Value KGs per 1 GDP 4.5 4 3.5 3 2.5 2 1.5 1 0.5 0 1860 1880 1900 1920 KGs per 1 GDP 12 ASCM. All rights reserved. 1940 1960 1980 2000 Exponential (KGs per 1 GDP) Source: Kelly, The Inevitable: , 2016, p. 2020

Implications/Predictions: Service Platforms 1.From product/service design to platform design Sales support Delivery Design FAQs Remote diagnostics Financing Condition monitoring Installation Suggestions/advice Training Loyalty/rewards System integration Community Maintenance Parts 13 Information Consumables Help desk ASCM. All rights reserved.

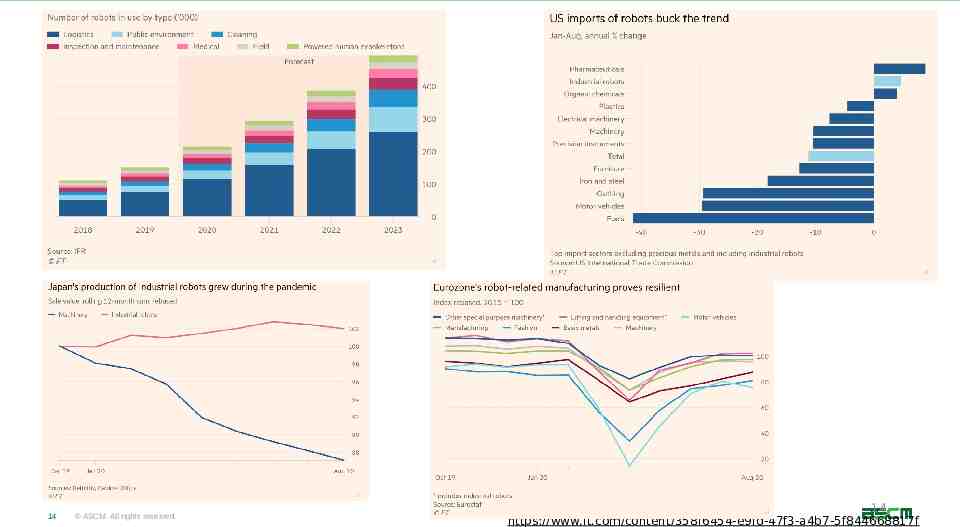

14 ASCM. All rights reserved. 14 https://www.ft.com/content/358f6454-e9fd-47f3-a4b7-5f844668817f

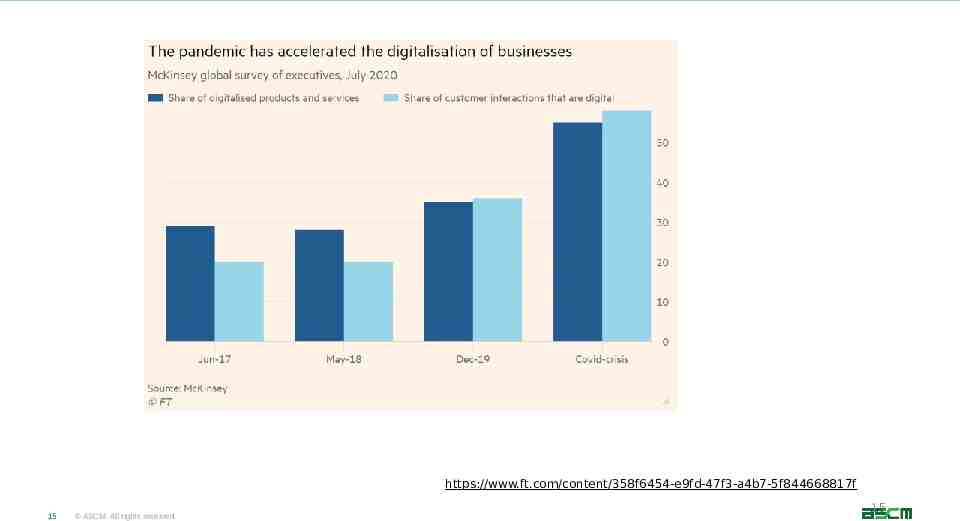

https://www.ft.com/content/358f6454-e9fd-47f3-a4b7-5f844668817f 15 ASCM. All rights reserved. 15

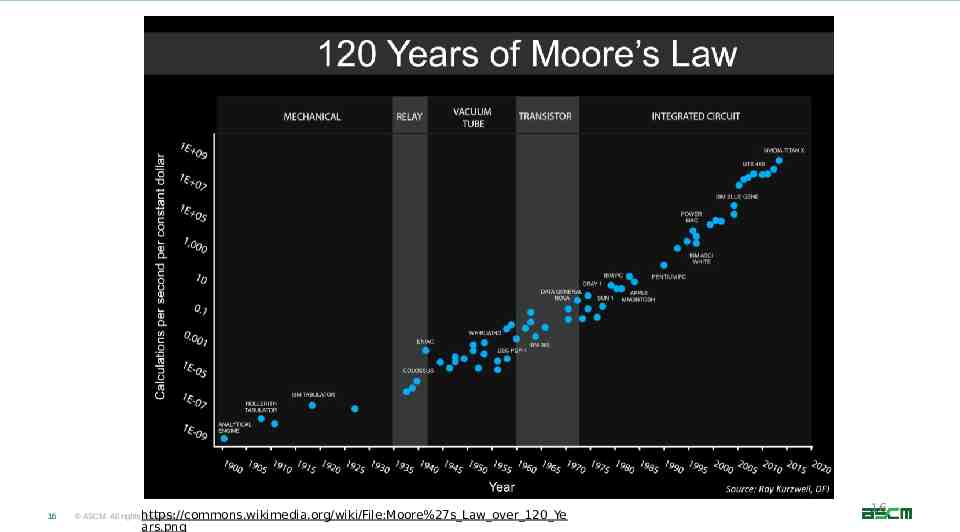

16 ASCM. All rights https://commons.wikimedia.org/wiki/File:Moore%27s Law over 120 Ye reserved. ars.png 16

Digital Supply Networks and the Digital Capabilities Model: An Overview 1. Learning objectives: a. Appreciate the potential value creation that can come from digitalization b. Identify types of technologies enabling SC transformation c. Understand the underlying capabilities that digitalization can enable d. Understand the foundational and crucial role of data 2. Core concepts: a. Instrumented, Integrated (connected), Intelligent b. Always on, on-demand c. Transparent d. Sense, collaborate, optimize, respond (adaptive) e. From chains to networks f. Structured and unstructured data 3. Highlighted technologies: a. Decision support, processing (automation), communication, integration (platform) 17 ASCM. All rights reserved.

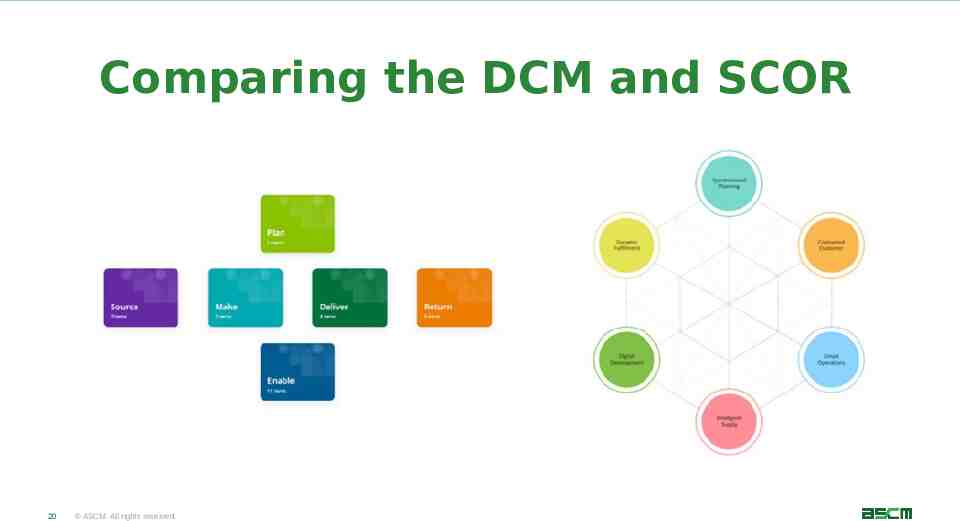

Digital Capabilities Model (DCM) 1. Compare with other “digital supply chain” models e.g., Gartner (slides 24 and 25) 2. DCM content (see file: DSN Capability Model Release 2) a. Digital Disciplines: Sense, Collaborate, Optimize, Respond b. Six Level 1 capabilities; 38 Level 2 capabilities Definitions, examples, personas Positioning in process cycles (journey maps) Maturity levels KPIs 18 ASCM. All rights reserved.

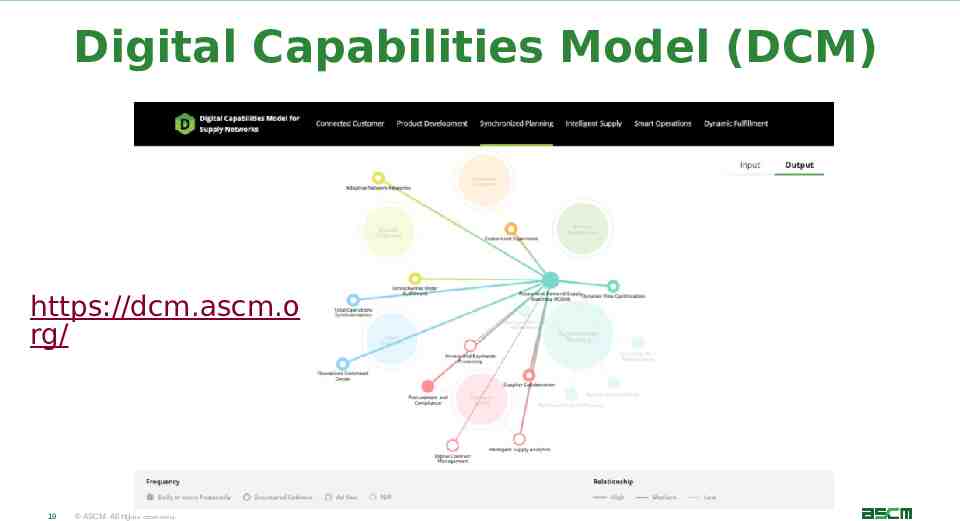

Digital Capabilities Model (DCM) https://dcm.ascm.o rg/ 19 ASCM. All rights reserved.

Comparing the DCM and SCOR 20 ASCM. All rights reserved.

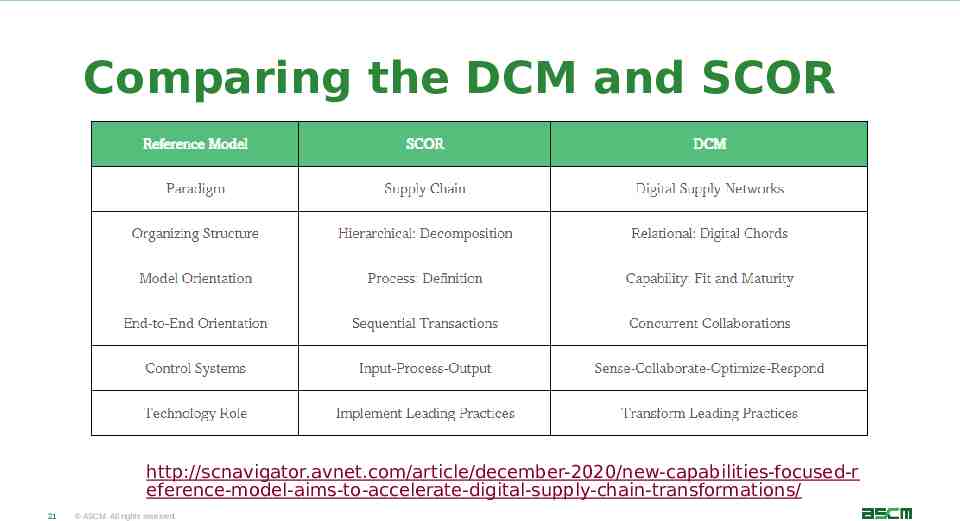

Comparing the DCM and SCOR http://scnavigator.avnet.com/article/december-2020/new-capabilities-focused-r eference-model-aims-to-accelerate-digital-supply-chain-transformations/ 21 ASCM. All rights reserved.

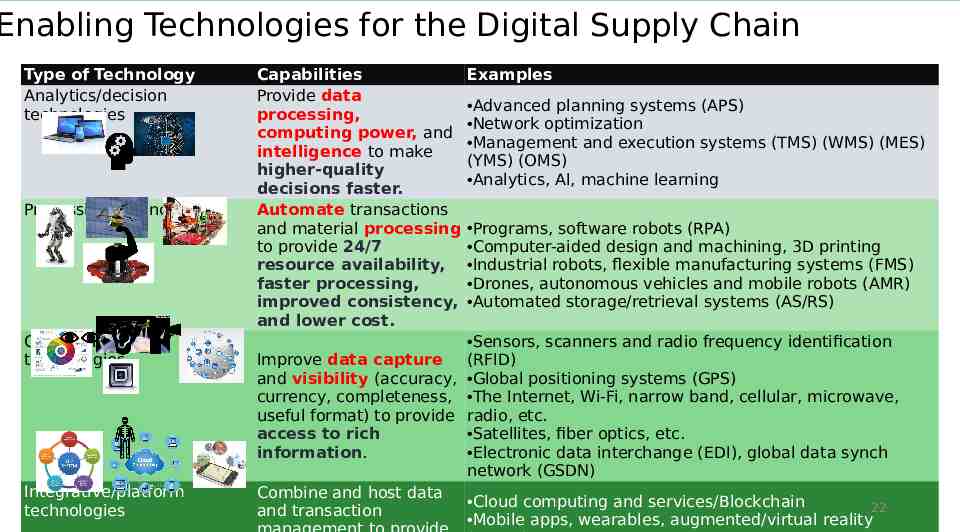

Enabling Technologies for the Digital Supply Chain Type of Technology Analytics/decision technologies Processing technologies Communications technologies Integrative/platform technologies 22 ASCM. All rights reserved. Capabilities Provide data processing, computing power, and intelligence to make higher-quality decisions faster. Automate transactions and material processing to provide 24/7 resource availability, faster processing, improved consistency, and lower cost. Examples Advanced planning systems (APS) Network optimization Management and execution systems (TMS) (WMS) (MES) (YMS) (OMS) Analytics, AI, machine learning Programs, software robots (RPA) Computer-aided design and machining, 3D printing Industrial robots, flexible manufacturing systems (FMS) Drones, autonomous vehicles and mobile robots (AMR) Automated storage/retrieval systems (AS/RS) Sensors, scanners and radio frequency identification Improve data capture (RFID) and visibility (accuracy, Global positioning systems (GPS) currency, completeness, The Internet, Wi-Fi, narrow band, cellular, microwave, useful format) to provide radio, etc. Satellites, fiber optics, etc. access to rich Electronic data interchange (EDI), global data synch information. network (GSDN) Combine and host data Cloud computing and services/Blockchain 22 and transaction Mobile apps, wearables, augmented/virtual reality

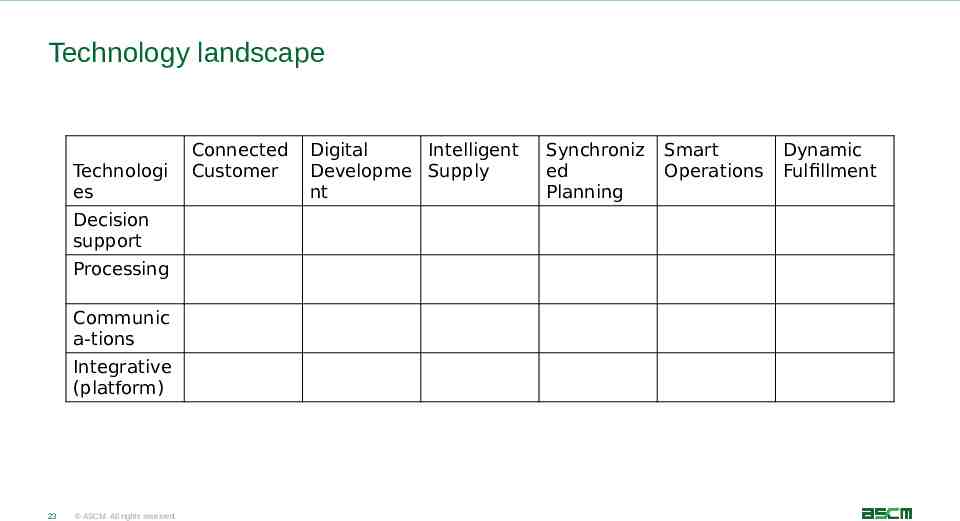

Technology landscape Technologi es Decision support Processing Communic a-tions Integrative (platform) 23 ASCM. All rights reserved. Connected Customer Digital Intelligent Developme Supply nt Synchroniz ed Planning Smart Operations Dynamic Fulfillment

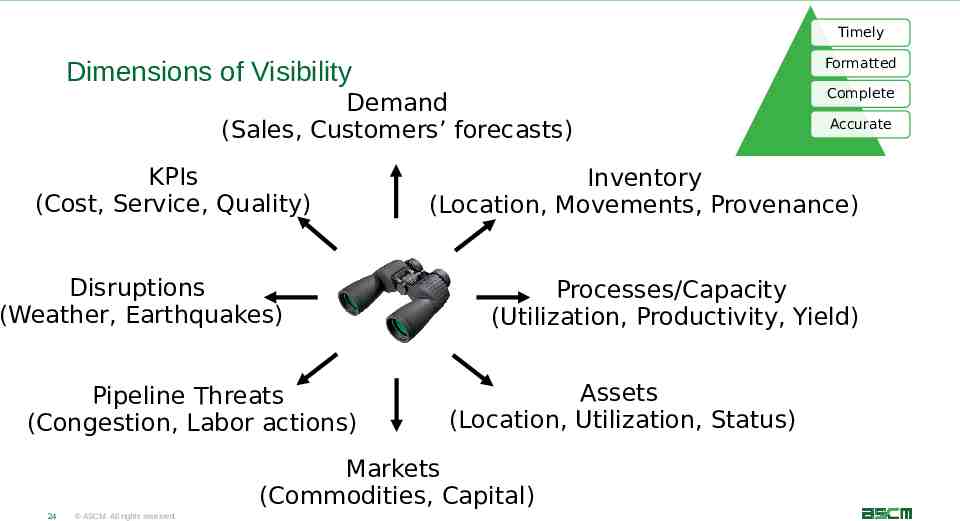

Timely Formatted Dimensions of Visibility Demand (Sales, Customers’ forecasts) KPIs (Cost, Service, Quality) Disruptions (Weather, Earthquakes) Pipeline Threats (Congestion, Labor actions) ASCM. All rights reserved. Accurate Inventory (Location, Movements, Provenance) Processes/Capacity (Utilization, Productivity, Yield) Assets (Location, Utilization, Status) Markets (Commodities, Capital) 24 Complete 24

Managing Digital Transformation 1. Learning objectives: a. Explain the basic elements of a comprehensive roadmap for DT b. Identify the key challenges with and inhibitors of DT c. Understand different organizational structures and approaches d. Appreciate the role of human capital in transformation efforts 2. Core concepts: a. Digital maturity b. Technology readiness 25 ASCM. All rights reserved.

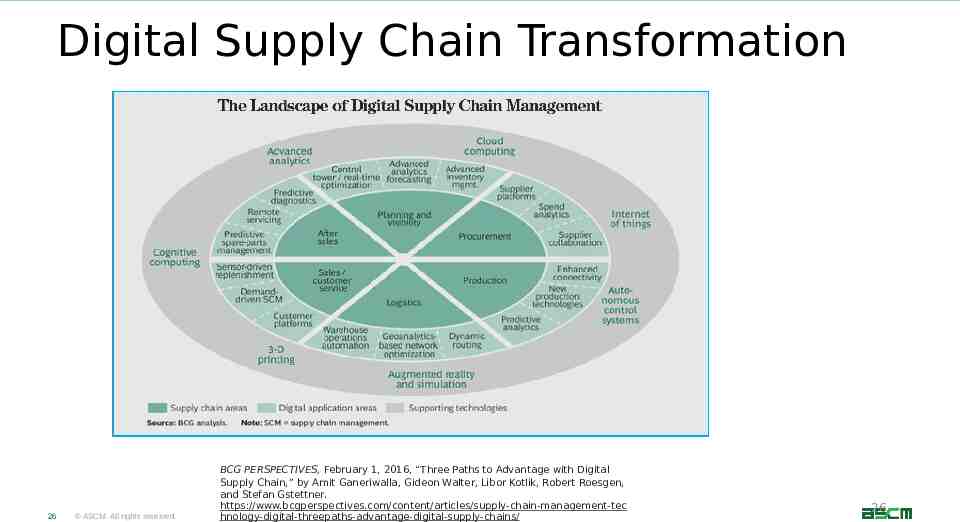

Digital Supply Chain Transformation 26 ASCM. All rights reserved. BCG PERSPECTIVES, February 1, 2016, “Three Paths to Advantage with Digital Supply Chain,” by Amit Ganeriwalla, Gideon Walter, Libor Kotlik, Robert Roesgen, and Stefan Gstettner. https://www.bcgperspectives.com/content/articles/supply-chain-management-tec hnology-digital-threepaths-advantage-digital-supply-chains/ 26

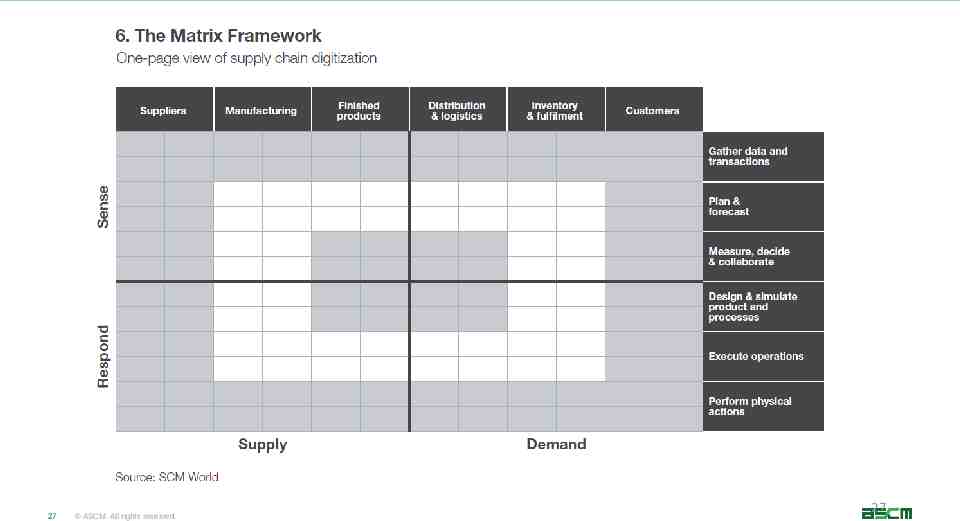

27 ASCM. All rights reserved. 27

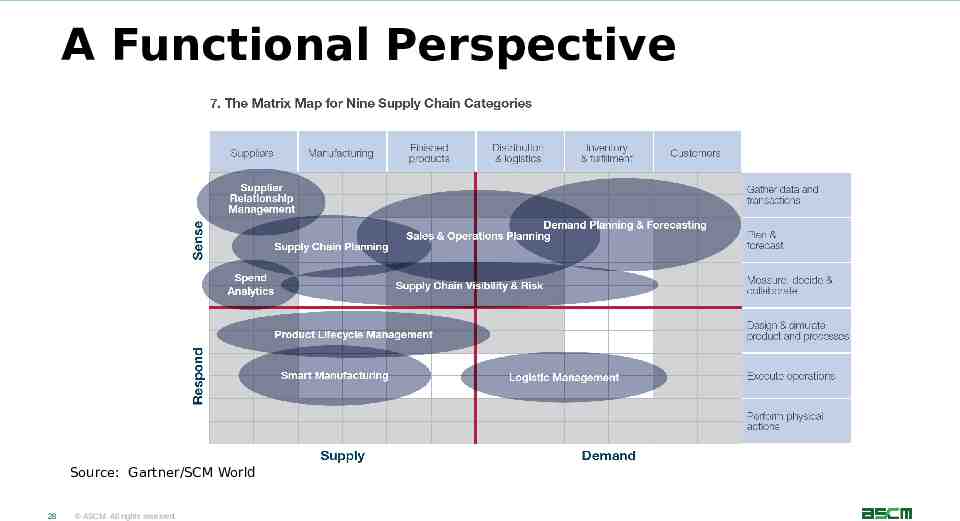

A Functional Perspective Source: Gartner/SCM World 28 ASCM. All rights reserved.

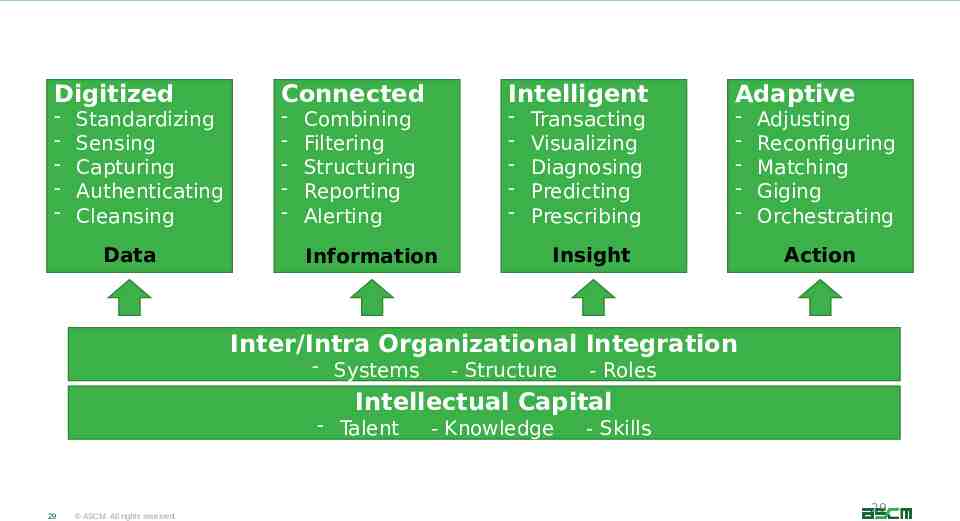

Digitized - Standardizing Sensing Capturing Authenticating Cleansing Data Connected - Intelligent Combining Filtering Structuring Reporting Alerting - Information Transacting Visualizing Diagnosing Predicting Prescribing Adaptive - Insight Adjusting Reconfiguring Matching Giging Orchestrating Action Inter/Intra Organizational Integration - Systems - Structure - Roles Intellectual Capital - Talent 29 ASCM. All rights reserved. - Knowledge - Skills 29

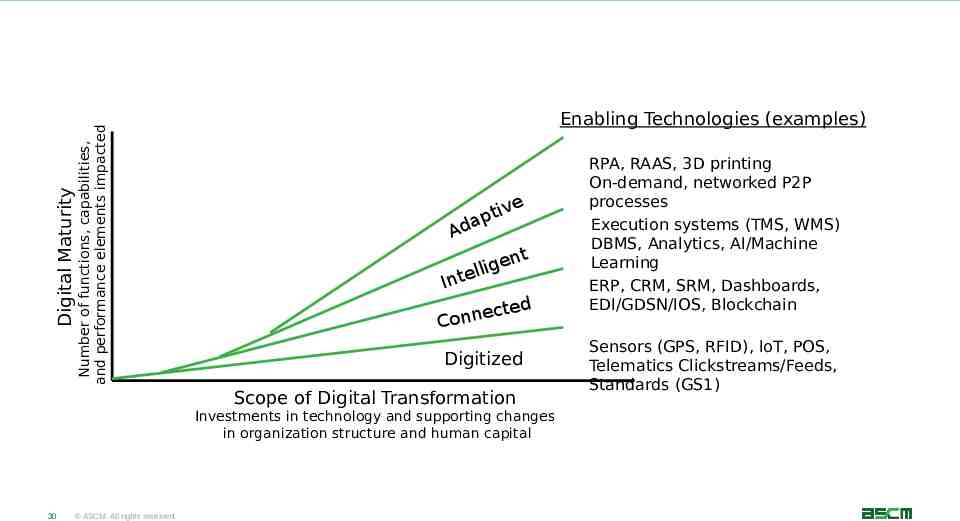

Number of functions, capabilities, and performance elements impacted Digital Maturity Enabling Technologies (examples) iv t p a Ad In e nt e g i l tel ted c e n n Co Digitized Scope of Digital Transformation Investments in technology and supporting changes in organization structure and human capital 30 ASCM. All rights reserved. RPA, RAAS, 3D printing On-demand, networked P2P processes Execution systems (TMS, WMS) DBMS, Analytics, AI/Machine Learning ERP, CRM, SRM, Dashboards, EDI/GDSN/IOS, Blockchain Sensors (GPS, RFID), IoT, POS, Telematics Clickstreams/Feeds, Standards (GS1)

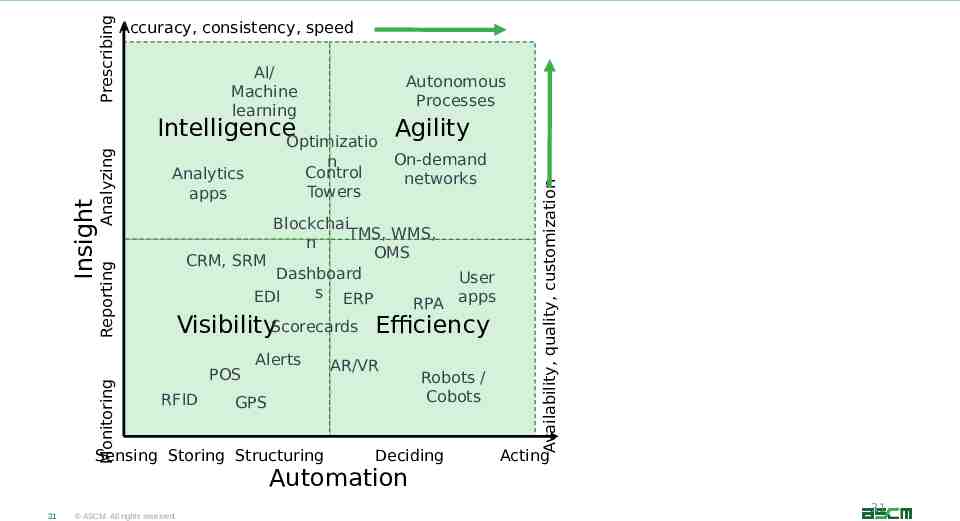

Monitoring Autonomous Processes IntelligenceOptimizatio Agility Blockchai TMS, WMS, n OMS CRM, SRM Dashboard User s ERP EDI RPA apps VisibilityScorecards Efficiency POS RFID Alerts ASCM. All rights reserved. AR/VR GPS Sensing Storing Structuring 31 On-demand networks n Control Towers Analytics apps Robots / Cobots Deciding Automation Availability, quality, customization Prescribing Analyzing AI/ Machine learning Reporting Insight Accuracy, consistency, speed Acting 31

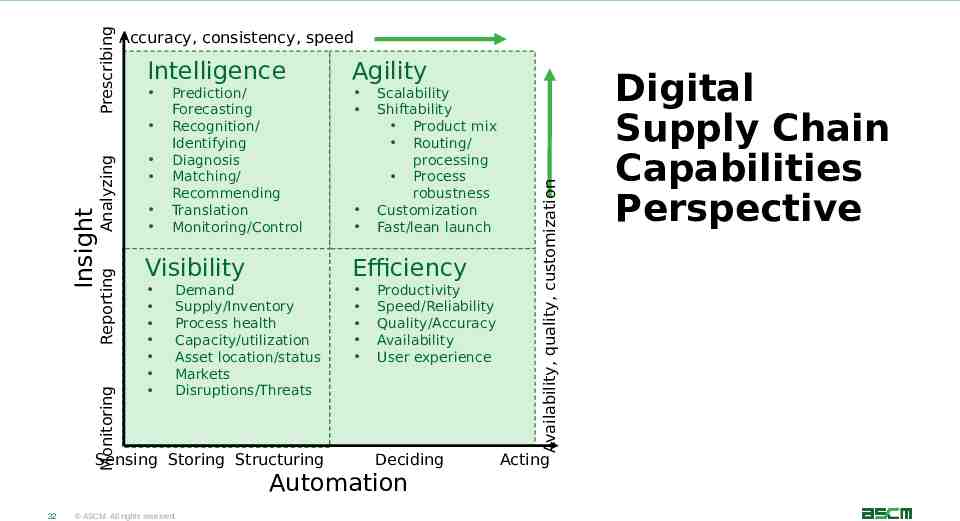

Intelligence Monitoring Reporting Insight Analyzing Prediction/ Forecasting Recognition/ Identifying Diagnosis Matching/ Recommending Translation Monitoring/Control Visibility Demand Supply/Inventory Process health Capacity/utilization Asset location/status Markets Disruptions/Threats ASCM. All rights reserved. Scalability Shiftability Product mix Routing/ processing Process robustness Customization Fast/lean launch Efficiency Sensing Storing Structuring 32 Agility Productivity Speed/Reliability Quality/Accuracy Availability User experience Deciding Automation Availability, quality, customization Prescribing Accuracy, consistency, speed Acting Digital Supply Chain Capabilities Perspective

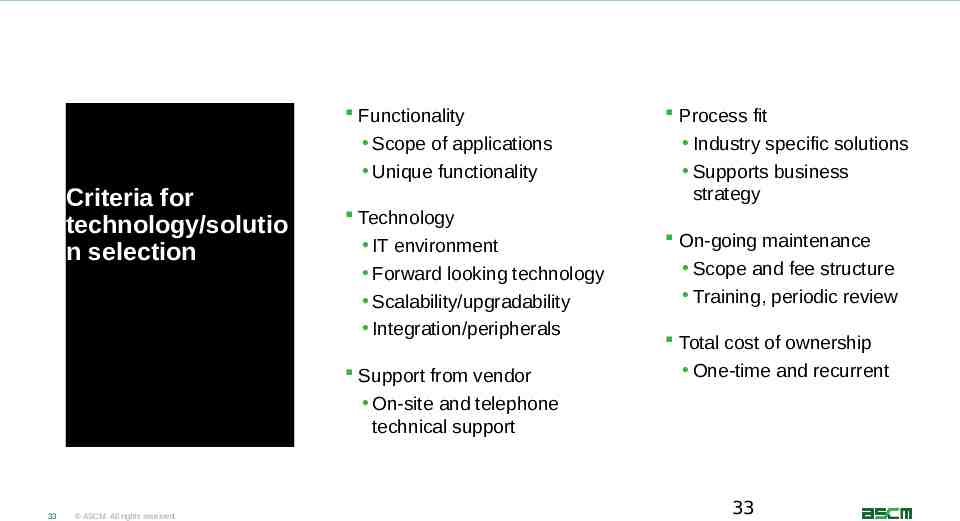

Functionality Scope of applications Unique functionality Criteria for technology/solutio n selection Process fit Industry specific solutions Supports business strategy Technology IT environment Forward looking technology Scalability/upgradability Integration/peripherals Support from vendor On-going maintenance Scope and fee structure Training, periodic review Total cost of ownership One-time and recurrent On-site and telephone technical support 33 ASCM. All rights reserved. 33

Connected Customer 1. Learning objectives: a. Review level 2 capabilities enabling connected customers b. Identify sources of data describing customers’ behaviors c. Describe various technology enabled methods for enhancing customer experience and insights 2. Core concepts: a. Customer engagement b. Evolved levels of “customer service” 3. Highlighted technologies: a. Apps and APIs b. POS systems c. Social media d. IoT in demand chain 34 ASCM. All rights reserved.

Digital Development 1. Learning objectives: a. Review level 2 capabilities enabling digital development b. Understand the value of design-for-X technologies and processes c. Describe different platform-enabled business models 2. Core concepts: a. Platforms, modularity b. Co-development 3. Highlighted technologies: a. 3D printing b. Virtual reality 35 ASCM. All rights reserved.

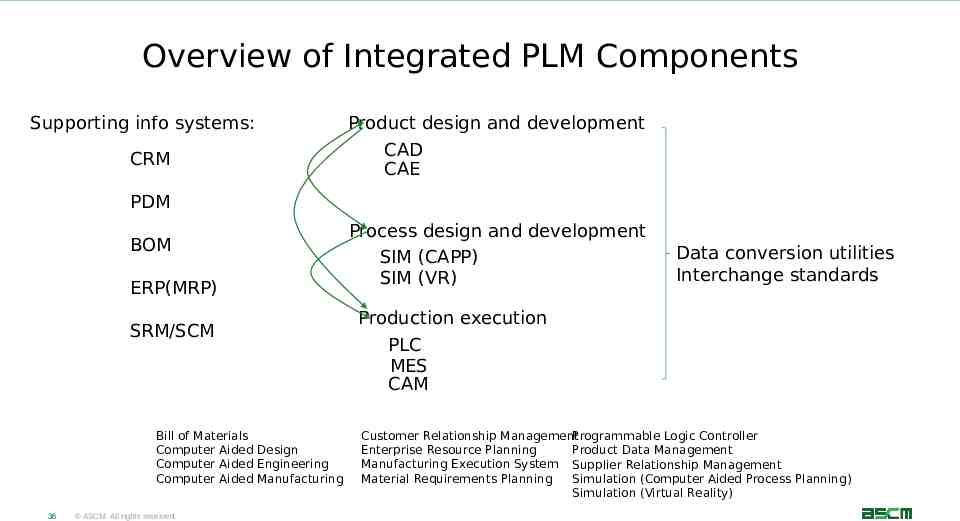

Overview of Integrated PLM Components Supporting info systems: CRM Product design and development CAD CAE PDM BOM ERP(MRP) SRM/SCM Bill of Materials Computer Aided Design Computer Aided Engineering Computer Aided Manufacturing 36 ASCM. All rights reserved. Process design and development SIM (CAPP) SIM (VR) Data conversion utilities Interchange standards Production execution PLC MES CAM Customer Relationship Management Programmable Logic Controller Enterprise Resource Planning Product Data Management Manufacturing Execution System Supplier Relationship Management Material Requirements Planning Simulation (Computer Aided Process Planning) Simulation (Virtual Reality)

Intelligent Supply 1. Learning objectives: a. Review level 2 capabilities enabling intelligent supply b. Understand how digitalization enables intelligent and adaptive sourcing c. Describe how automation and connectivity improve procurement operations d. Examine technology-enabled risk detection and mitigation capabilities 2. Core concepts: a. Visibility and transparency b. Supply risk 3. Highlighted technologies: a. EDI b. GIS, alert systems 37 ASCM. All rights reserved.

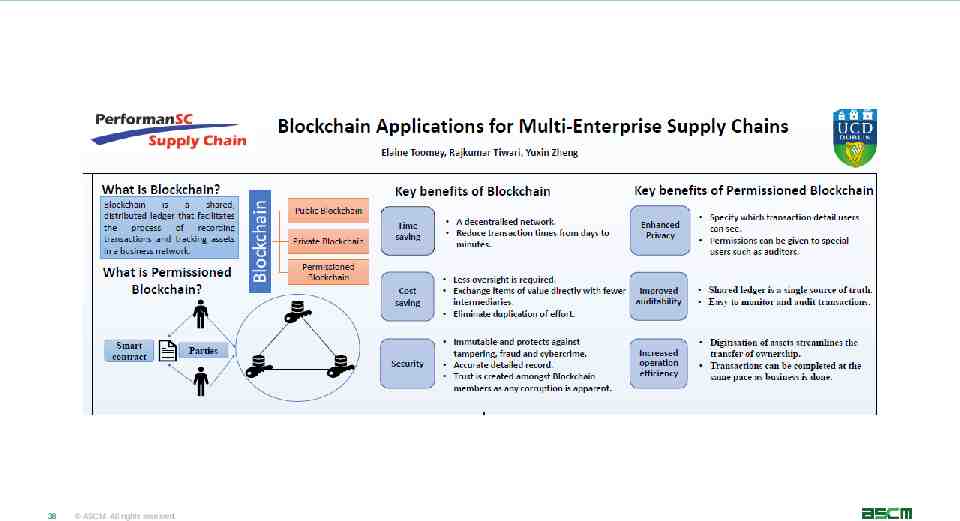

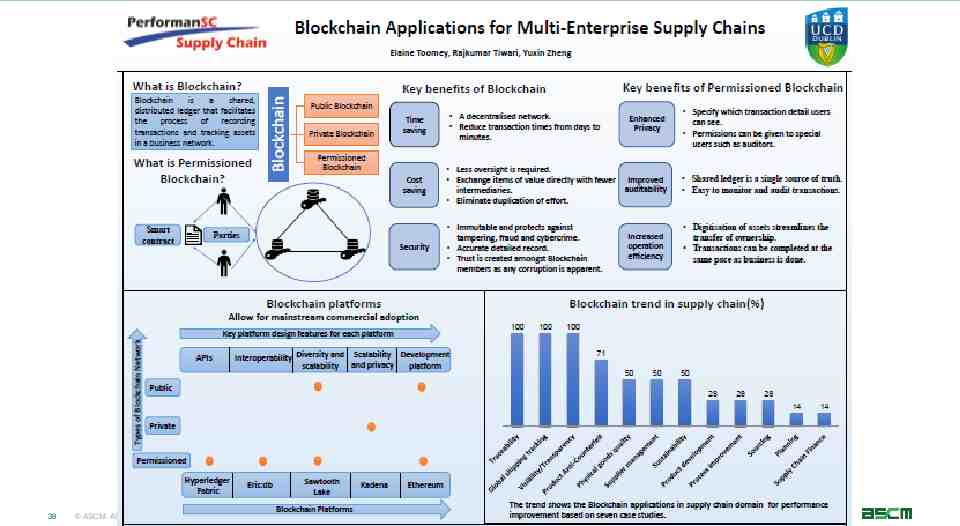

38 ASCM. All rights reserved.

39 ASCM. All rights reserved.

40 ASCM. All rights reserved.

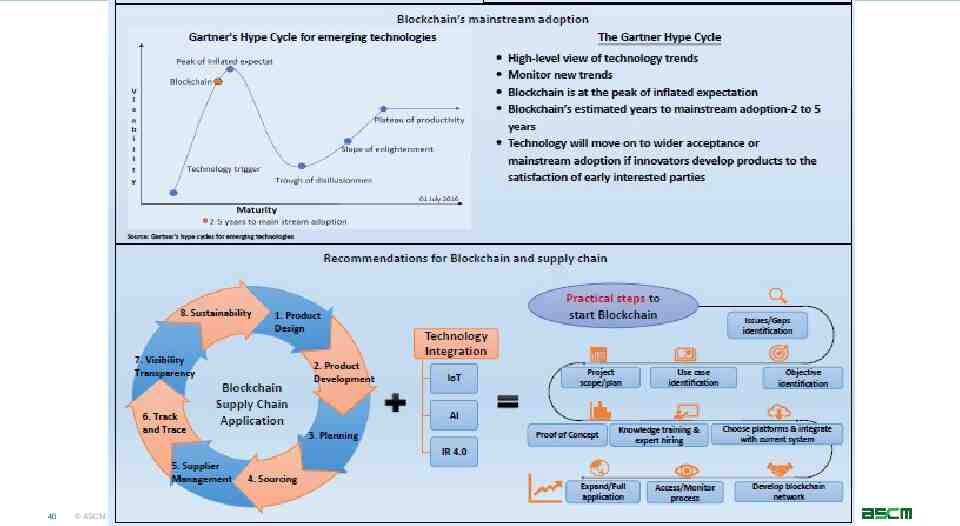

Synchronized Planning 1. Learning objectives: a. Review level 2 capabilities enabling synchronized planning b. Differentiate between strategic, tactical, and operational planning objectives and time frames c. Understand the challenges of developing accurate, complete, current, usefully formatted data to support planning d. Explain how data capture and processing technologies can be used to synchronize and optimize planning 2. Core concepts: a. Concurrent planning b. Digital twin, control towers, etc. 3. Highlighted technologies: a. Blockchain b. Cloud computing c. IoT in supply chain d. AI/Machine learning 41 ASCM. All rights reserved.

Smart Operations 1. Learning objectives: a. Review level 2 capabilities enabling smart operations b. Understand the pros and cons of process automation 2. Core concepts: a. On-demand production 3. Highlighted technologies: a. Additive manufacturing b. Process monitoring 42 ASCM. All rights reserved.

Dynamic Fulfillment 1. Learning objectives: a. Review level 2 capabilities enabling dynamic fulfillment and support b. Describe evolving fulfillment expectations and modes c. Examine alternative technology-enabled models for after sales support 2. Core concepts: a. Fulfillment centers versus distribution centers b. Amazon effect, last mile c. Omni-channel 3. Highlighted technologies: a. Warehouse automation (robots, drones, conveyances) b. Transportation automation (drones, automated vehicles, augmented reality) c. On-demand (gig) capacity apps 43 ASCM. All rights reserved.

Course Conclusion: Visualizing the Future 1. Learning objectives: a. Review key learnings and frameworks b. Develop a vision for digital supply networks today, tomorrow, and in 2050 2. Core concepts: 3. Highlighted technologies: a. Nano-tech b. Augmented humans c. Virtual personal assistants (on-line identities) d. Advanced AI e. Supply Chain as a Service (SCaaS) 44 ASCM. All rights reserved.

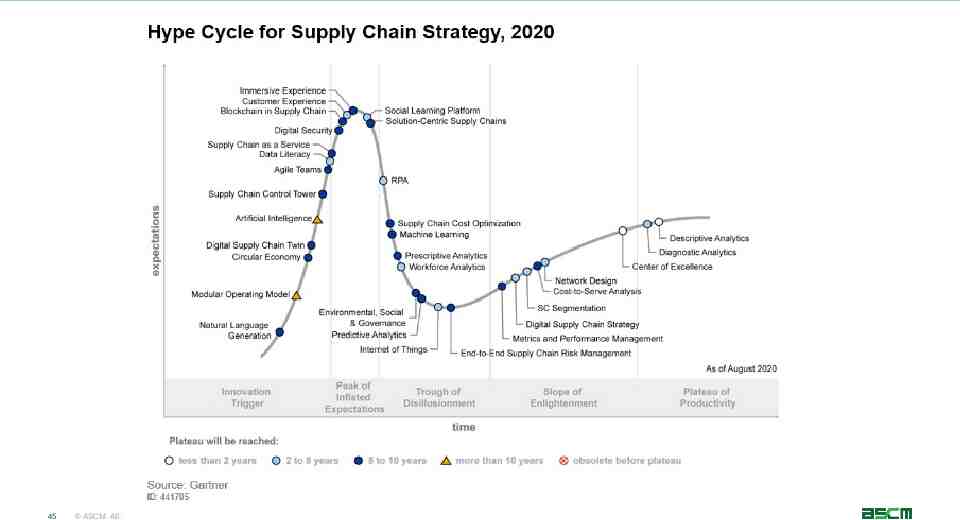

45 ASCM. All rights reserved.

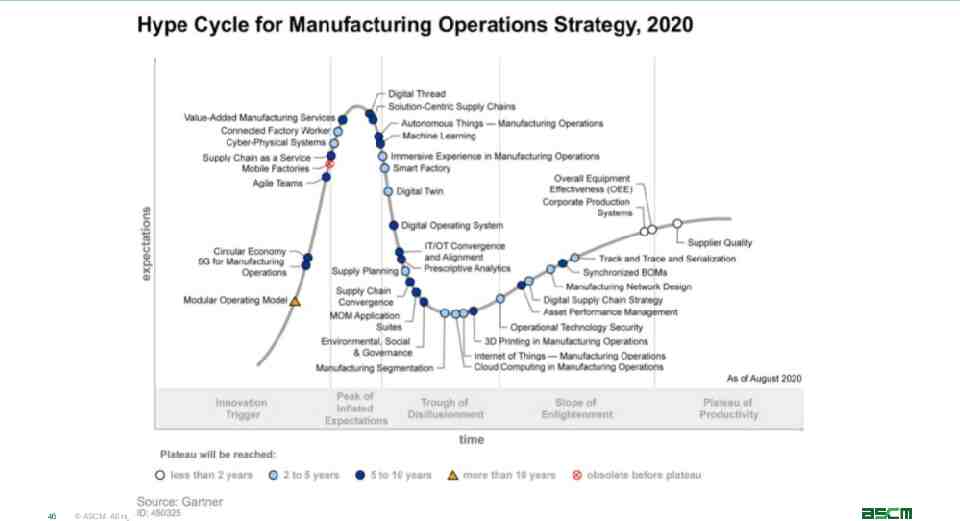

46 ASCM. All rights reserved.

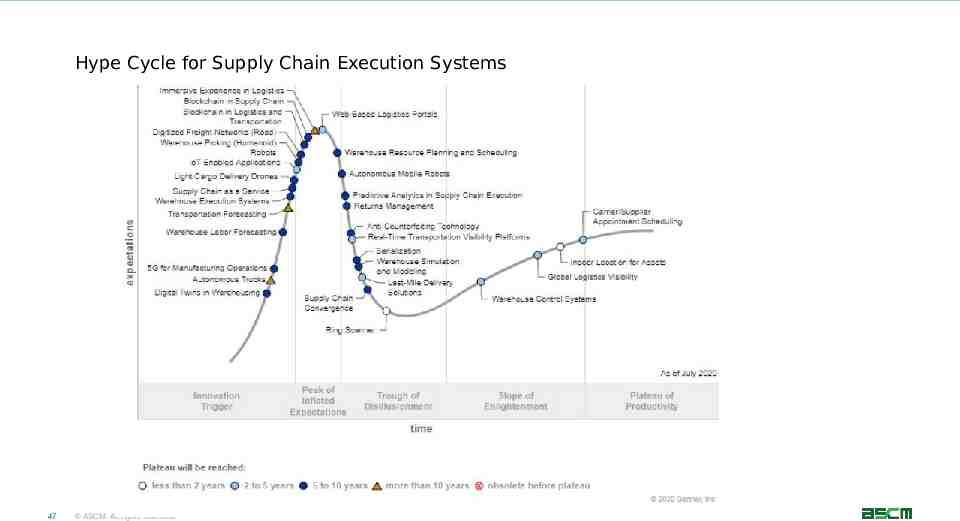

Hype Cycle for Supply Chain Execution Systems 47 ASCM. All rights reserved.

48 ASCM. All rights reserved.