MODULE 17 Egress and Fire Protection

73 Slides3.72 MB

MODULE 17 Egress and Fire Protection

Egress and Fire Protection What could make employees need to escape quickly? What are the typical escape routes? What precautions are taken for fire protection and prevention? 2 2006 TEEX

Regulations 29 CFR 1910 Subparts E and L 29 CFR 1926 Subpart F – construction API RP 54 Section 7: Fire Protection and Prevention 6.10: Auxiliary Escape 9.3.10: At least 2 stairways on a drilling rig 3 2006 TEEX

29 CFR 1910 Subpart E Exit Routes, EAPs, and FPPs

1910.34 Coverage Every employer is covered: 1910.34 through 1910.39 apply to workplaces in general industry Except mobile workplaces such as vehicles or vessels Exit routes Emergency action plans 5 2006 TEEX

1910.34(c) Definitions Exit: that portion of an exit route that is generally separated from other areas to provide a protected way of travel to the exit discharge. Exit access: that portion of an exit route that leads to an exit. Exit discharge: the part of the exit route that leads directly outside or to a street, walkway, refuge area, public way, or open space with access to the outside. 6 2006 TEEX

1910.34(c) Definitions Exit route: a continuous and unobstructed path of exit travel from any point within a workplace to a place of safety (including refuge areas). Consists of three parts: The exit access; The exit; and, The exit discharge. Equivalent to “Means of Egress” in the Life Safety Code and most local building and fire codes 7 2006 TEEX

1910.35 Compliance with NFPA 101-2000, Life Safety Code Compliance with the exit route provisions of NFPA 101-2000 will be deemed to be in compliance with the corresponding requirements in § § 1910.34, 1910.36, 1910.37 NFPA 8 2006 TEEX

29 CFR 1910.36 Design and Construction Requirements for Exit Routes

1910.36(a)(1) Basic Requirement An exit route must be a permanent part of the workplace Eat at Ma’s Place 10 No ropes or rope ladde rs 2006 TEEX

1910.36(a)(2) Exit separated by fire resistant materials Construction materials used to separate an exit from other parts of the workplace: 1 hour resistance 3 stories 2 hours resistance 4 stories 1 hour 2 hours 11 2006 TEEX

1910.36(a)(3) Openings into an exit must be limited Openings into an exit: limited to those necessary to allow access to the exit Each opening must be protected by an approved self-closing fire door that remains closed or automatically closes in an emergency 12 2006 TEEX

1910.36(b) The number of exit routes must be adequate At least 2 routes must be available Except for sufficiently small occupancy – see (b)(3) As far away from each other as practical in case one is blocked by fire or smoke More than 2 required if all cannot evacuate through 2 exit routes Life Safety Code can help with this determination 13 2006 TEEX

1910.36(c)(1) Exit Discharge Must lead directly outside or to a street, walkway, refuge area, public way, or open space with access to the outside Exit Discharge Offices Storage Exit access Fabricating shop 14 Discharge Exit 2006 TEEX

1910.36(c)(2) Exit Discharge The street, walkway, refuge area, public way, or open space to which an exit discharge leads must be large enough to accommodate the building occupants likely to use the exit route 15 2006 TEEX

1910.36(c)(3) Exit Discharge Exit stairs that continue beyond the level of the exit discharge must be interrupted at that level by doors, partitions, or other effective means that clearly indicate the direction of travel leading to the exit discharge 16 NOT AN EXIT NOT AN EXI T 2006 TEEX

1910.36(d) Exit door must be unlocked Must be able to open exit route door From the inside at all times Without keys, tools, or special knowledge Panic bar is permissible No device or alarm that could restrict use of route if device fails Mental, penal, correctional facilities: exception with constant supervision & plan 17 2006 TEEX

1910.36(e)(1) A side-hinged exit door must be used A side-hinged door must be used to connect any room to an exit route Must swing out in the direction of exit travel if room is designed for 50 people or room is a high hazard area 18 2006 TEEX

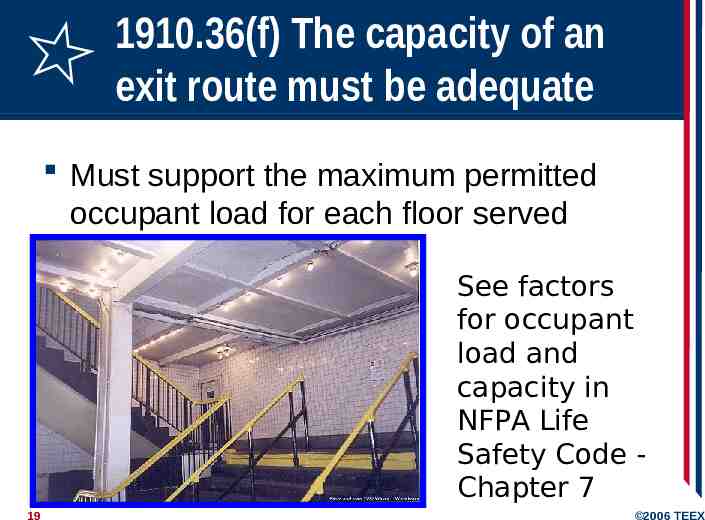

1910.36(f) The capacity of an exit route must be adequate Must support the maximum permitted occupant load for each floor served See factors for occupant load and capacity in NFPA Life Safety Code Chapter 7 19 2006 TEEX

1910.36(f) The capacity of an exit route must be adequate Exit route capacity may not decrease toward exit discharge 20 2006 TEEX

1910.36(g) Exit minimum height and width requirements Ceiling at least 7’6” Any projection from the ceiling 6’8” Exit access 28 inches wide Including all objects projecting into route 7-½ ft. 6 ft.- 8 in. 21 2006 TEEX

1910.36(h) An outdoor exit route is permitted. Same minimum height and width Additional requirements: Guardrails on unenclosed sides Covered if snow or ice likely to accumulate Unless snow removed before hazard Reasonably straight Smooth, solid, level walkways No dead end longer than 20 feet 22 2006 TEEX

29 CFR 1910.37 Maintenance, safeguards, and operational features for exit routes

1910.37(a) The danger to employees must be minimized Exit routes must be kept free of explosive or highly flammable furnishings or decorations No exit route may lead toward high hazard area, unless shielded 24 2006 TEEX

1910.37(a) The danger to employees must be minimized Exit routes free and unobstructed: No materials/equipment may be placed within exit route Exit access must not go through a room that can be locked Safeguards must be kept in working order 25 2006 TEEX

1910.37(b) Lighting and marking must be adequate and appropriate Exit routes adequately lighted Clearly visible and marked by a sign reading "Exit" No decorations or signs that obscure the visibility of exit route door 26 2006 TEEX

1910.37(b) Lighting and marking must be adequate and appropriate If the direction of travel to the exit is not immediately apparent, signs must be posted indicating the direction of travel to the nearest exit Line-of-sight to an exit sign must clearly be visible at all times Way to exit is not apparent 27 2006 TEEX

1910.37(b) Lighting and marking must be adequate and appropriate Each doorway or passage that could be mistaken for an exit must be marked "Not an Exit" or similar designation, or be identified by a sign indicating its actual use (e.g., closet) 28 2006 TEEX

1910.37(b) Lighting and marking must be adequate and appropriate Each exit sign must be illuminated to a surface value of at least five footcandles (54 lux) by a reliable light source and be distinctive in color The word "Exit" in plainly legible letters 6” Letters 3/4 inch thick 29 2006 TEEX

1910.37(d) Exit routes during construction, repairs, or alterations Employees must not occupy a workplace until the exit routes are ready in occupied portion 30 2006 TEEX

1910.37(d) Exit routes during construction, repairs, or alterations Employees must not be exposed to hazards from construction activities that are beyond the normal permissible conditions, or that would impede exiting the workplace 31 2006 TEEX

1910.37(e) Alarm system Alarm system must be installed and maintained in operable condition To warn of fire or other emergencies Unless employees can promptly see or smell fire or hazard in time Must comply with 1910.165 (in Subpart L) 32 2006 TEEX

29 CFR 1910.38 Emergency Action Plans

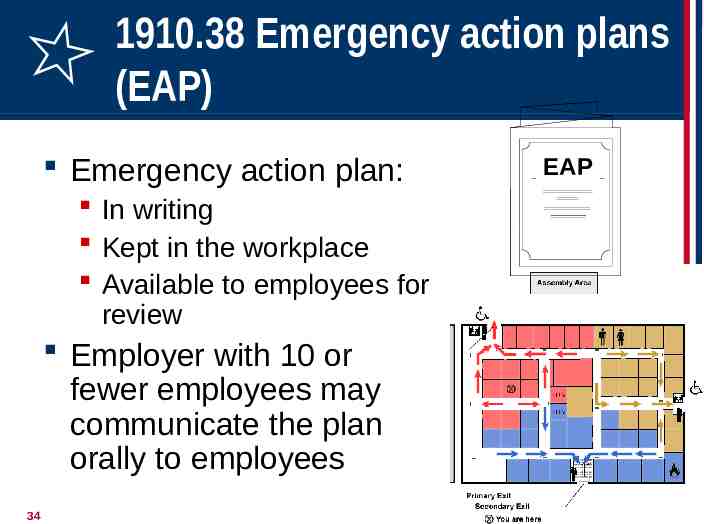

1910.38 Emergency action plans (EAP) Emergency action plan: EAP In writing Kept in the workplace Available to employees for review Employer with 10 or fewer employees may communicate the plan orally to employees 34 2006 TEEX

1910.38(c) Minimum elements of an emergency action plan 1. Procedures for reporting a fire or other emergency 2. Procedures for emergency evacuation, including type of evacuation and exit route assignments 3. Procedures for employees who remain to operate critical plant operations before evacuating 35 2006 TEEX

1910.38(c) Minimum elements of an emergency action plan 4. Procedures to account for all employees after evacuation 5. Procedures to be followed by employees performing rescue or medical duties 6. Name or job title of every employee who may be contacted by employees who need more information about the plan 36 2006 TEEX

Alarms, training, review d. Alarm system must use distinctive signals for each purpose, comply with 1910.165 e. Designate and train employees to assist in safe, orderly evacuation of others f. Review of EAP with each employee: 37 When plan developed or employee assigned When employee’s responsibilities under the plan change When the plan changes 2006 TEEX

29 CFR 1910.39 Fire Prevention Plans

1910.39(b) Written and oral fire prevention plans Any required fire prevention plan must: Must be in writing, Be kept in the workplace, and Be made available to employees for review Employer with 10 or fewer employees may communicate the plan orally to employees 39 2006 TEEX

1910.39(c)(1) Minimum elements of a fire prevention plan List of all major fire hazards Proper handling and storage procedures for hazardous materials Potential ignition sources and their control Type of fire protection equipment necessary to control each major hazard 40 2006 TEEX

1910.39(c)(1) Minimum elements of a fire prevention plan, cont’d Procedures to control accumulations of flammable and combustible waste Maintenance procedures for safeguards on heat-producing equipment to prevent ignition of combustible materials Name or title of employees responsible for maintaining equipment to prevent or control sources of ignition or fires Name or title of employees responsible for control of fuel source hazards 41 2006 TEEX

1910.39(e) Employee information An employer must inform employees upon initial assignment to a job of the fire hazards to which they are exposed. An employer must also review with each employee those parts of the fire prevention plan necessary for selfprotection. 42 2006 TEEX

29 CFR Subpart L Fire Protection

Organization of 1910 Subpart L 44 155 Scope, application, definitions 156 Fire brigades 157 Portable fire extinguishers 158 Standpipe and hose systems 159 Automatic sprinkler systems 160-163 Fixed extinguishing systems 164 Fire detection systems 165 Employee alarm systems 2006 TEEX

29 CFR 1910.155 Scope, Application, and Definitions

Scope and Application Fire brigades, fire suppression equipment, fire detection systems, alarm systems Applies to all employments except maritime, construction, and agriculture 46 2006 TEEX

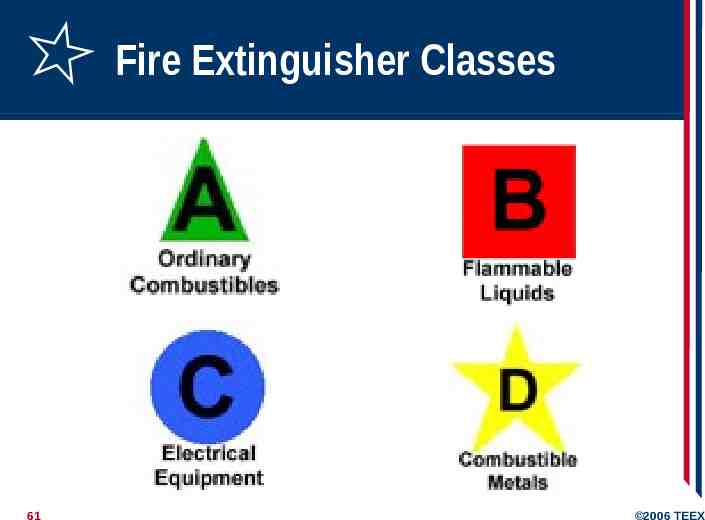

Definitions Class A fire: Ordinary combustible materials Paper Wood Cloth Some rubber and plastic. Class B fire: 47 Flammable or combustible liquids Flammable gases Greases Some rubber and plastic 2006 TEEX

Definitions Class C fire: Energized electrical equipment Employee safety requires nonconductive extinguishing media Class D fire: Combustible metals 48 Magnesium Titanium Zirconium Sodium Lithium Potassium 2006 TEEX

Definitions Dry chemical: small particles of chemicals supplemented for dryness and flow Bicarbonates Potassium chloride Monoammonium phosphate Dry powder: compound used to extinguish or control Class D fires 49 2006 TEEX

Definitions Enclosed structure: Has a roof or ceiling and at least 2 walls May accumulate smoke, toxic gases and heat Foam: Bubbles form a blanket over liquid, sealing combustible vapors Gaseous agent: Diffuses uniformly to extinguish fires 50 2006 TEEX

29 CFR 1910.156 Fire Brigades

Scope and Application Organization, training, PPE Fire brigades established by employer Industrial fire departments Private or contractual fire departments PPE requirements only apply to interior structural firefighting 52 2006 TEEX

Organization and Training Organizational statement available Physical capability No heart disease, epilepsy, or emphysema without physician’s certificate of fitness Training and education Beforehand and frequently enough Examples of quality training programs Special hazards and written procedures 53 2006 TEEX

Firefighting Equipment Maintain and inspect at least annually Portable fire extinguishers and respirators: inspect at least monthly Remove and replace unserviceable or damaged equipment 54 2006 TEEX

Protective clothing For interior structural firefighting Not required for incipient stage firefighting Provide at no cost and assure use Protect head, body, and extremities 55 Foot and leg protection Body protection Hand protection Head, eye, and face protection 2006 TEEX

Respiratory protection devices Provided to and used by fire brigade members Meet 1910.134 as well SCBA requirements 56 2006 TEEX

29 CFR 1910.157 Portable Fire Extinguishers

Scope and application Placement, use, maintenance, testing For portable fire extinguishers to be used by employees inside structures (e) and (f) only if not for employee use Partial exemptions: Policy requiring total evacuation; FPP and EAP; extinguishers not present Only designated employees authorized 58 2006 TEEX

General requirements Provide, mount, locate and identify Readily accessible to employees without possible injury Only approved fire extinguishers No carbon tetrachloride or chlorobromomethane extinguishers Maintain fully charged and operable in designated places 59 2006 TEEX

Selection and distribution Based on fire classes, size of hazard Class A: 75 ft. travel distance to extinguisher, or standpipe Class B: 50 ft. travel distance to extinguisher Class C: Based on pattern for Class A/B Class D: 75 ft. travel distance to extinguishing agent 60 2006 TEEX

Fire Extinguisher Classes 61 2006 TEEX

Inspection, maintenance, and testing Portable extinguishers or hose visually inspected monthly Annual maintenance check – record available Maintenance 6 years after recharge or hydrostatic test for dry chemical extinguishers with 12-year hydrostatic test requirements Alternate equivalent protection during maintenance/recharging 62 2006 TEEX

Hydrostatic testing Performed by trained persons with suitable testing equipment and facilities Test interval given for various types of extinguishers Tested when new evidence of corrosion or mechanical injury Details for various types 63 2006 TEEX

Training and education If employees are to use fire extinguishers, the employer must educate them on principles and hazards EAP-designated employees trained on appropriate equipment Upon employment and at least annually 64 2006 TEEX

Standpipe and hose systems For smaller systems – not Class I Protected against mechanical damage Repaired promptly if damaged Equipment: designed for prompt use Water supply: minimum 100 gal/min Tests and maintenance 65 2006 TEEX

1910.159-163: Sprinklers and Fixed Extinguishing Systems Sprinklers – only if required by OSHA Fixed extinguishing systems Discharge alarms and safeguards Inspection and maintenance PPE for rescue of employees trapped Dry chemical Gaseous agent Water spray and foam 66 2006 TEEX

Fire detection systems Restore to normal condition ASAP after each test or alarm – spares available Maintenance and testing Protect from corrosion, physical impact Do not support by wires or tubing Designed to operate in time, provide a warning Delay only if necessary for immediate safety 67 2006 TEEX

Employee alarm systems All local fire alarm signaling systems used to alert employees Enough warning for emergency action of safe escape Perceived above ambient noise/light Tactile devices when necessary Distinctive and recognizable 68 2006 TEEX

Employee alarm systems Explain to each employee how to report emergencies Establish procedures for emergency alarm Restore to normal condition ASAP after each test or alarm – spares available 69 2006 TEEX

Employee alarm systems Maintain in operating condition except during repairs or maintenance Test for reliability/adequacy every 2 months if unsupervised Back-up means of alarm when out of service Supervised systems notify personnel of deficiencies – test once/year 70 2006 TEEX

Employee alarm systems Manually operated actuation devices (fire alarm pulls) Unobstructed Conspicuous Readily accessible 71 2006 TEEX

API RP 54 Fire Protection on Oil and Gas Well Sites

API RP 54 Requirements Drilling rigs: at least 4 20-pound capacity, Class BC rated fire extinguishers Well servicing rigs: at least 2 20-pound capacity, Class BC rated fire extinguishers Available near all welding Firefighting equipment also includes water hoses and drilling fluid guns 73 2006 TEEX