Marcus Thomson, Director of Innovation and Prosperity Office August

37 Slides9.35 MB

Marcus Thomson, Director of Innovation and Prosperity Office August 17, 2017

Agenda 1. About CEMI 2. Why MODCC? 3. What is MODCC? 4. Where is MODCC headed? a. Vision b. Obstacles c. Plan

About CEMI

About CEMI: The following slides show our: 1) Team 2) Vision 3) Collaborators 4) Strategic Initiatives

The CEMI Team VERN DRYLIE R&D PROGRAM DIRECTOR OF ENVIRONMENT & SUSTAINABILITY PAT DUBREUIL R&D PROGRAM DIRECTOR UDMN THEME LEADER DAMIEN DUFF VICE-PRESIDENT GEOSCIENCE & GEOTECHNICAL R&D UDMN THEME LEADER COURTNEY FOLZ COMMUNICATIONS COORDINATOR SHERRY GREASLEY VICE PRESIDENT OPERATIONS BRIAN JONES VICE PRESIDENT BUSINESS INNOVATION SHANNON KATARY NATALIE LAFLEUR-ROY DIRECTOR OF MARKETING FINANCE AND OPERATIONS AND COMMUNITY RELATIONS DIANE LEPAGE UDMN ADMINISTRATIVE COORDINATOR ERIC MAAG UDMN COMMERCIALIZATION DIRECTOR DOUGLAS MORRISON PRESIDENT AND CEO UDMN NETWORK DIRECTOR CHAIR IN HOLISTIC MINING PRACTICES CHARLES NYABEZE DIRECTOR OF BUSINESS DEVELOPMENT HARVEY PARSONS EMERITUS TECHNICAL ADVISOR KIRK RODGERS VICE PRESIDENT – MINE PRODUCTIVITY MARCUS THOMSON DIRECTOR, INNOVATION AND PROSPERITY OFFICE BORA UGURGEL UDMN MANAGING DIRECTOR DAVID VITONE PROJECT MANAGER MIKE RICHER IT ADMINISTRATOR

Develop new mines Sustain existing mines, & Improve environmental performance.

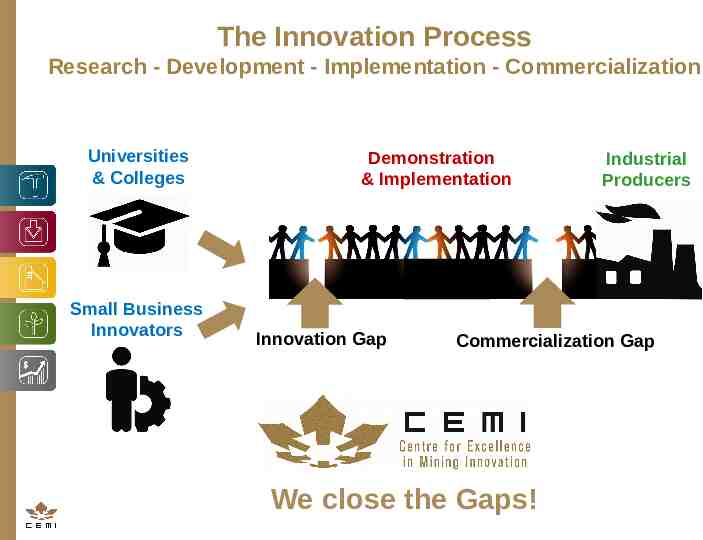

The Innovation Process Research - Development - Implementation - Commercialization Universities & Colleges Small Business Innovators Demonstration & Implementation Innovation Gap Industrial Producers Commercialization Gap We close the Gaps!

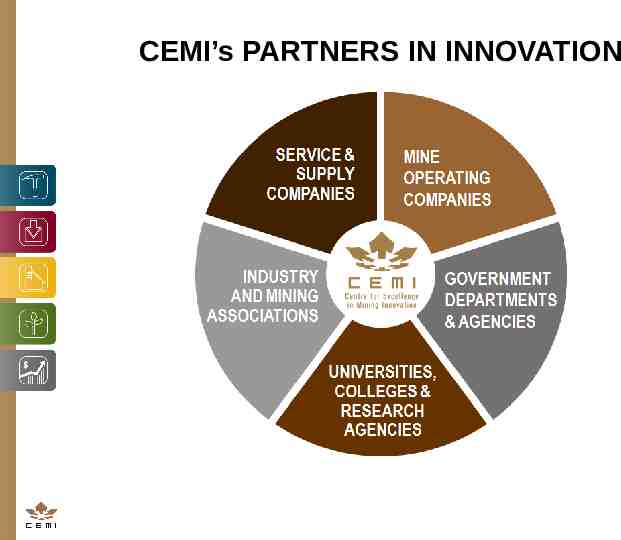

CEMI’s PARTNERS IN INNOVATION

CEMI’s COLLABORATORS IN INNOVATION

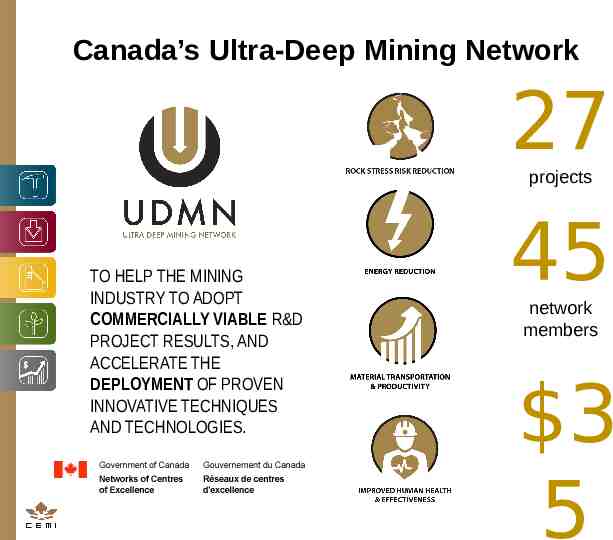

Canada’s Ultra-Deep Mining Network 27 projects TO HELP THE MINING INDUSTRY TO ADOPT COMMERCIALLY VIABLE R&D PROJECT RESULTS, AND ACCELERATE THE DEPLOYMENT OF PROVEN INNOVATIVE TECHNIQUES AND TECHNOLOGIES. 45 network members 3 5

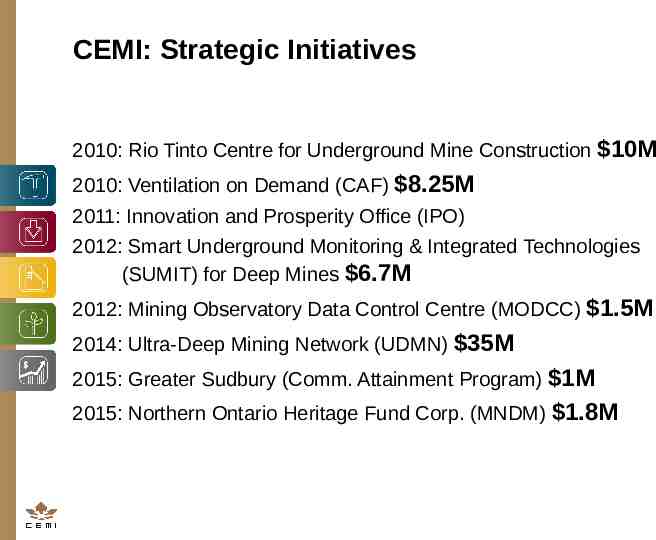

CEMI: Strategic Initiatives 2010: Rio Tinto Centre for Underground Mine Construction 10M 2010: Ventilation on Demand (CAF) 8.25M 2011: Innovation and Prosperity Office (IPO) 2012: Smart Underground Monitoring & Integrated Technologies (SUMIT) for Deep Mines 6.7M 2012: Mining Observatory Data Control Centre (MODCC) 1.5M 2014: Ultra-Deep Mining Network (UDMN) 35M 2015: Greater Sudbury (Comm. Attainment Program) 1M 2015: Northern Ontario Heritage Fund Corp. (MNDM) 1.8M

Why MODCC?

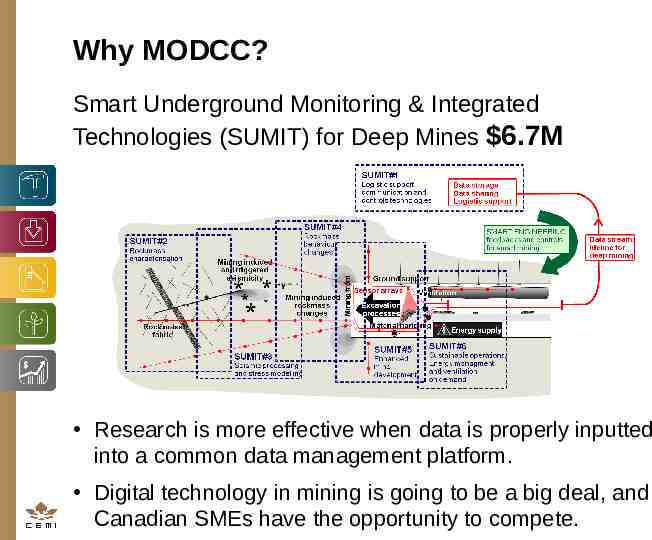

Why MODCC? Smart Underground Monitoring & Integrated Technologies (SUMIT) for Deep Mines 6.7M Research is more effective when data is properly inputted into a common data management platform. Digital technology in mining is going to be a big deal, and Canadian SMEs have the opportunity to compete.

What is MODCC?

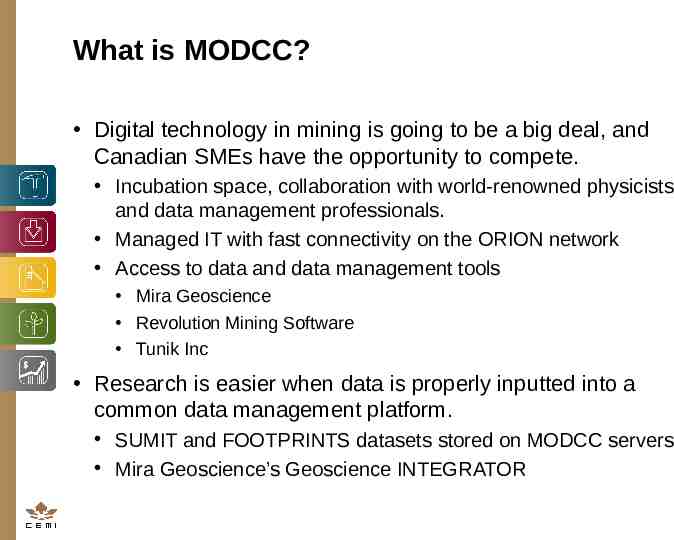

What is MODCC? Digital technology in mining is going to be a big deal, and Canadian SMEs have the opportunity to compete. Incubation space, collaboration with world-renowned physicists and data management professionals. Managed IT with fast connectivity on the ORION network Access to data and data management tools Mira Geoscience Revolution Mining Software Tunik Inc Research is easier when data is properly inputted into a common data management platform. SUMIT and FOOTPRINTS datasets stored on MODCC servers Mira Geoscience’s Geoscience INTEGRATOR

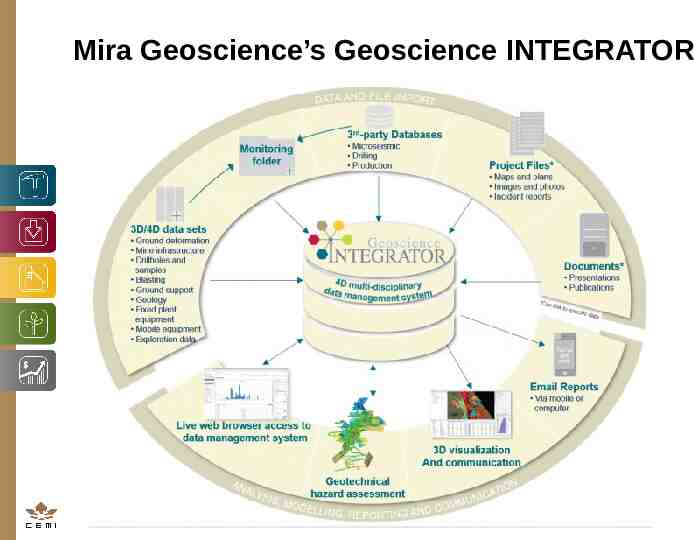

Mira Geoscience’s Geoscience INTEGRATOR

Where is MODCC headed?

Where is MODCC headed? Vision Artificial Intelligence for mining Obstacles Clean, Contextual Mining Data Plan Digital demonstration use case with mining companies Resources for small-to-medium companies Strategy for MODCC

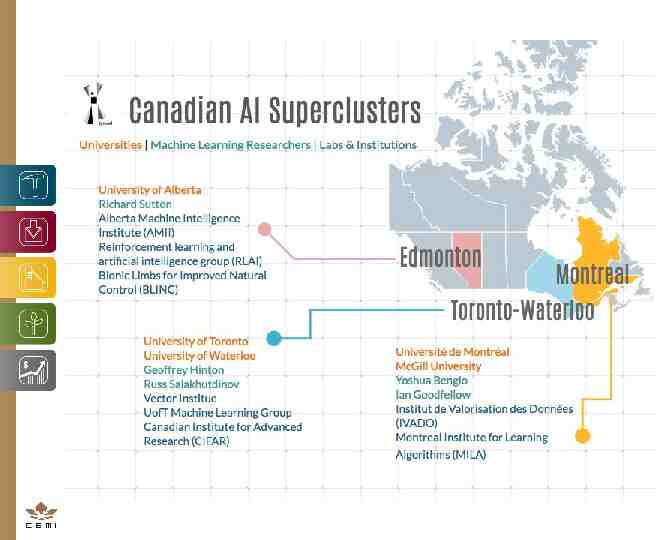

Vision: Artificial Intelligence in Mining

Artificial Intelligence The AI industry is projected to grow from 8.2B in 2013 to 70B by 2020, with a disruptive effect between US 14 to 33 trillion. http://fortune.com/2016/06/03/tech-ceos-artificial-intelligence/ Estimates are that half of the global workforce will be replaced by AI driven technology over the next 15 years. https://s3.amazonaws.com/uploads.massively.ai/tmp%2Faiconference%2FAIReport In 2013, only 1% of all data collected by mining companies was used. http://www.mckinsey.com/industries/metals-and-mining/our-insights/how-digital-innovation-can -improve-mining-productivity

Obstacles: Clean, Contextual Mining Data

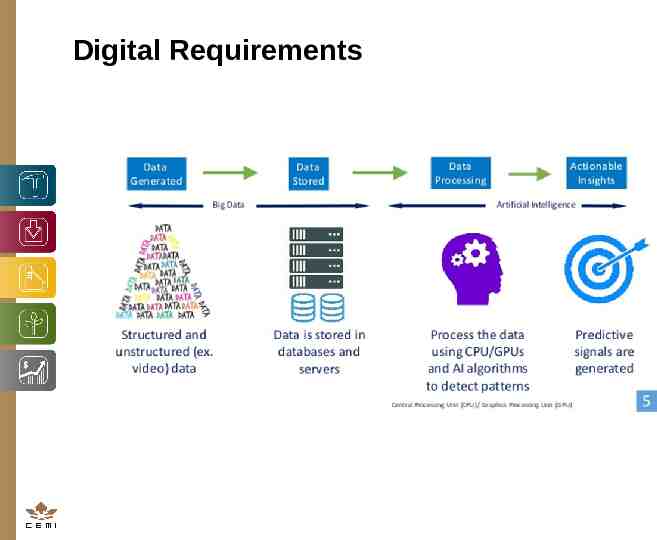

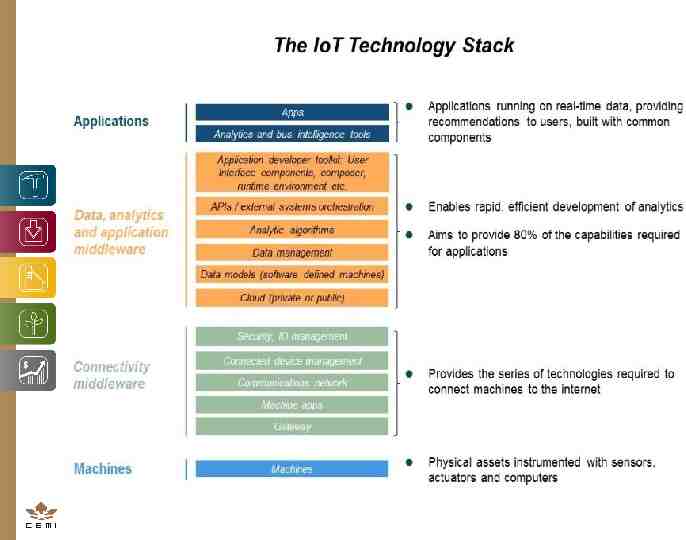

Digital Requirements

Plan: Smart Mining Demonstration Program

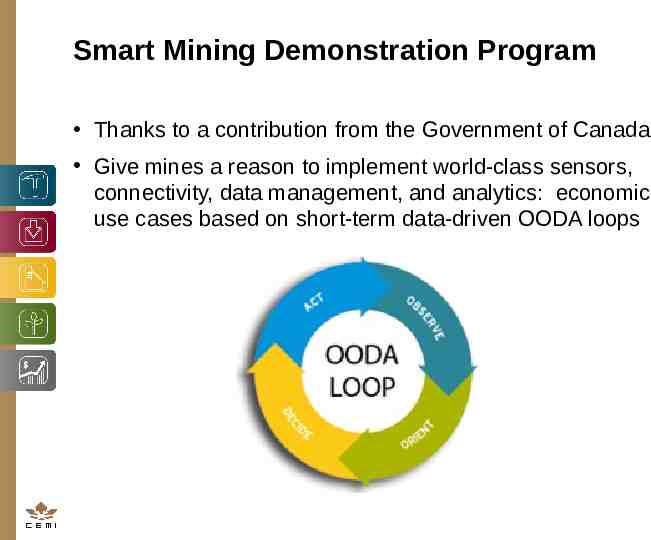

Smart Mining Demonstration Program Thanks to a contribution from the Government of Canada Give mines a reason to implement world-class sensors, connectivity, data management, and analytics: economic use cases based on short-term data-driven OODA loops

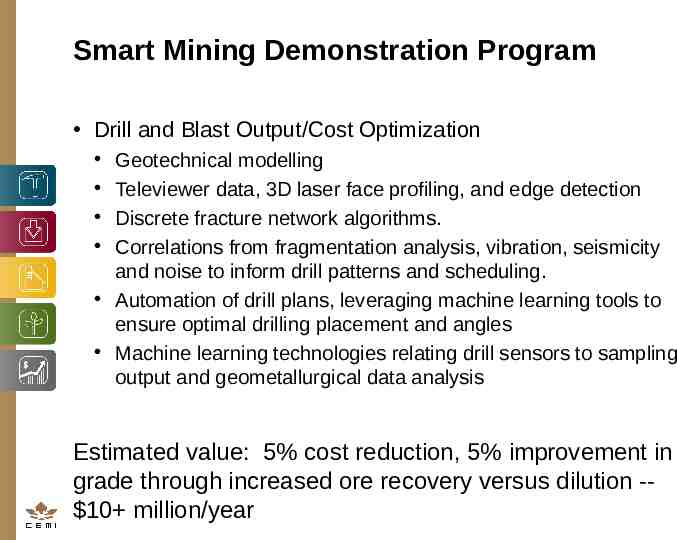

Smart Mining Demonstration Program Drill and Blast Output/Cost Optimization Geotechnical modelling Televiewer data, 3D laser face profiling, and edge detection Discrete fracture network algorithms. Correlations from fragmentation analysis, vibration, seismicity and noise to inform drill patterns and scheduling. Automation of drill plans, leveraging machine learning tools to ensure optimal drilling placement and angles Machine learning technologies relating drill sensors to sampling output and geometallurgical data analysis Estimated value: 5% cost reduction, 5% improvement in grade through increased ore recovery versus dilution - 10 million/year

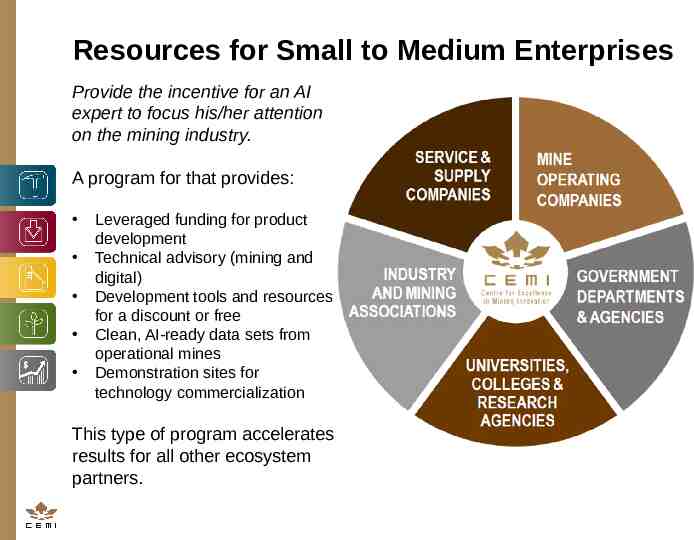

Resources for Small to Medium Enterprises Provide the incentive for an AI expert to focus his/her attention on the mining industry. A program for that provides: Leveraged funding for product development Technical advisory (mining and digital) Development tools and resources for a discount or free Clean, AI-ready data sets from operational mines Demonstration sites for technology commercialization This type of program accelerates results for all other ecosystem partners.

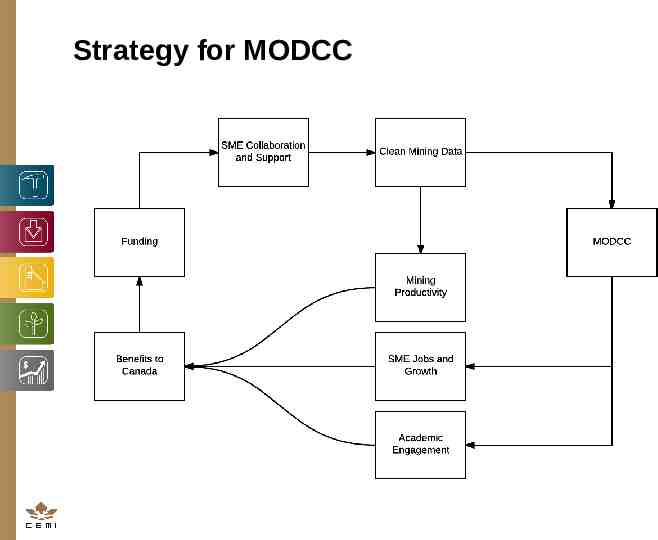

Strategy for MODCC