Integrated Product, Process and Production Engineering Dr. Richard

40 Slides898.00 KB

Integrated Product, Process and Production Engineering Dr. Richard A. Wysk Leonhard Chair in Engineering The Pennsylvania State University University Park, PA 16827 [email protected] http://www.engr.psu.edu/cim

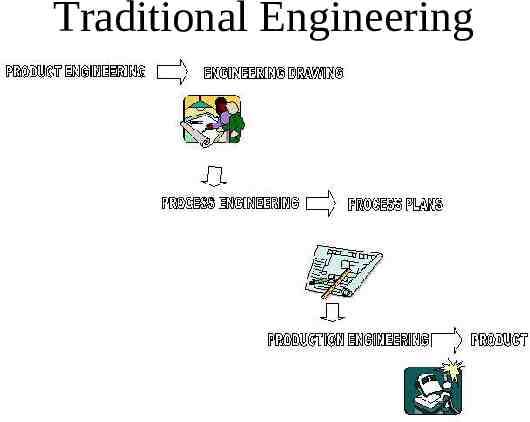

Traditional Engineering

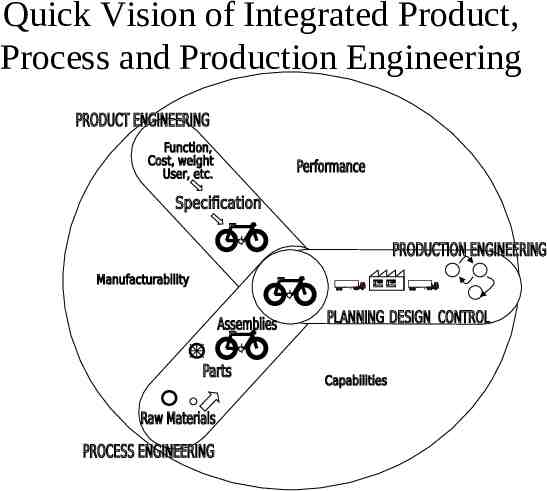

Quick Vision of Integrated Product, Process and Production Engineering

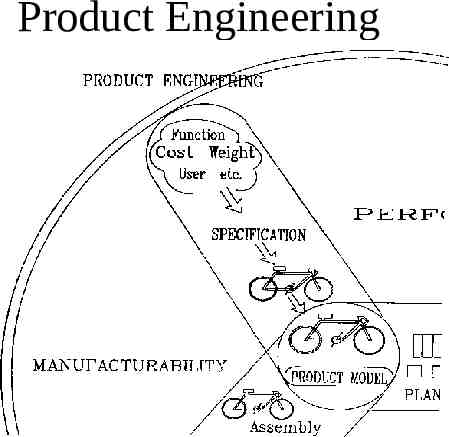

Product Engineering

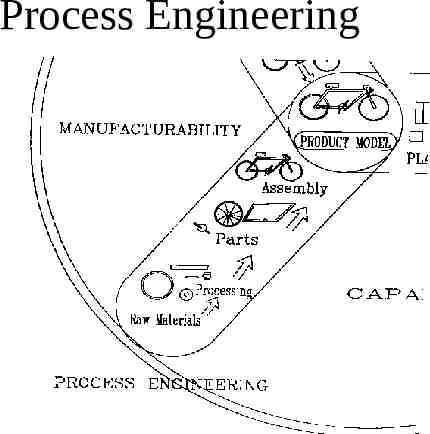

Process Engineering

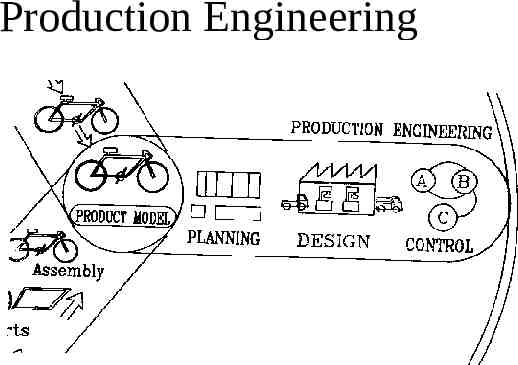

Production Engineering

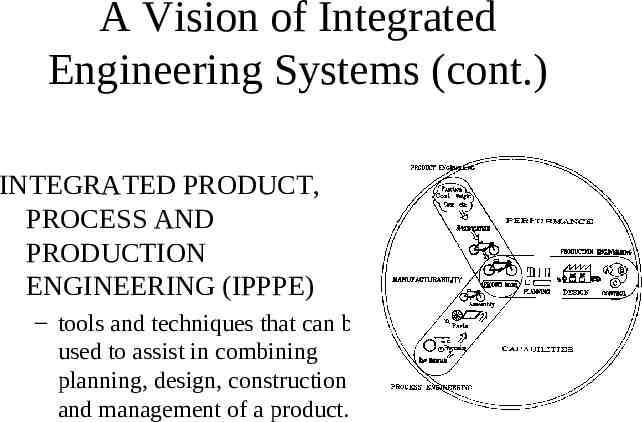

A Vision of Integrated Engineering Systems (cont.) INTEGRATED PRODUCT, PROCESS AND PRODUCTION ENGINEERING (IPPPE) – tools and techniques that can be used to assist in combining planning, design, construction and management of a product.

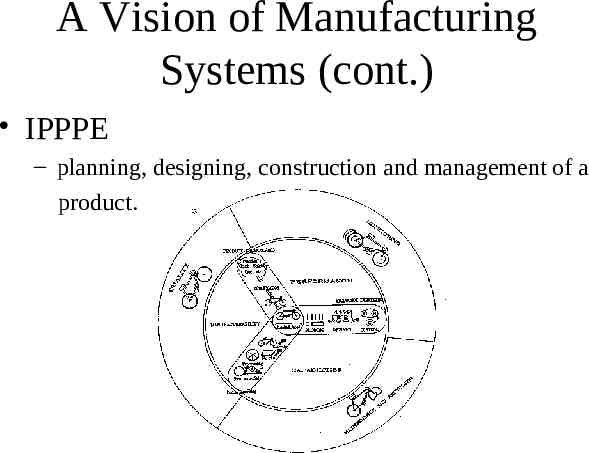

A Vision of Manufacturing Systems (cont.) IPPPE – planning, designing, construction and management of a product.

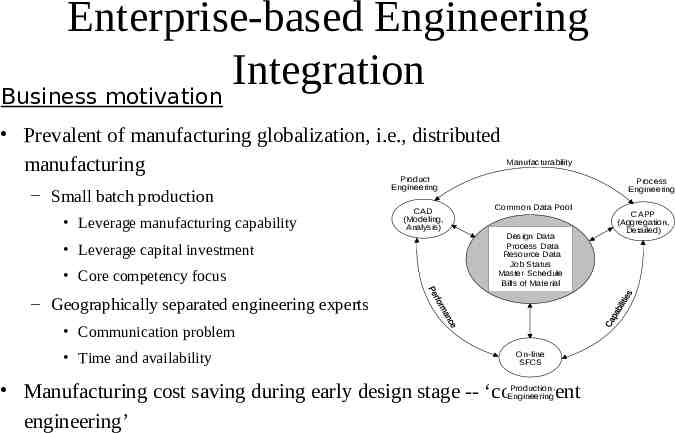

Enterprise-based Engineering Integration Business motivation Prevalent of manufacturing globalization, i.e., distributed manufacturing – Small batch production Leverage manufacturing capability Leverage capital investment Core competency focus Manufacturability Product Engineering CAD (Modeling, Analysis) Process Engineering Common Data Pool Design Data Process Data Resource Data Job Status Master Schedule Bills of Material – Geographically separated engineering experts Communication problem Time and availability On-line SFCS Manufacturing cost saving during early design stage -- ‘concurrent engineering’ Production Engineering CAPP (Aggregation, Detailed)

The Acid Test

Instance specific solutions Group Technology Parametric/feature-based modeling (most existing applications) CAPP DFx

How do we work on generic solutions? We’re all going In different directions!!!

Product Engineering Tools include: CAD, FEM, Dynamic simulations, Good instance specific remedies

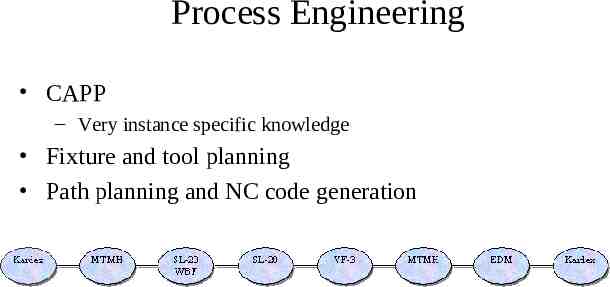

Process Engineering CAPP – Very instance specific knowledge Fixture and tool planning Path planning and NC code generation

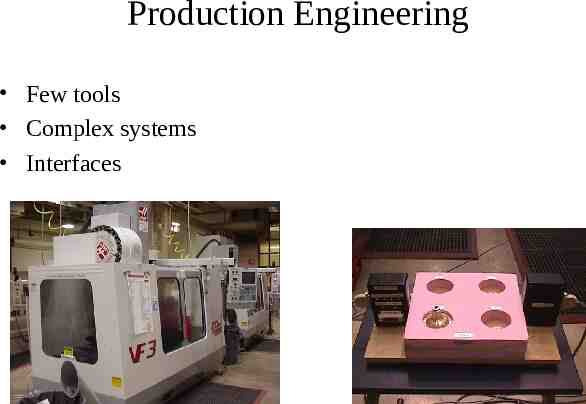

Production Engineering Few tools Complex systems Interfaces

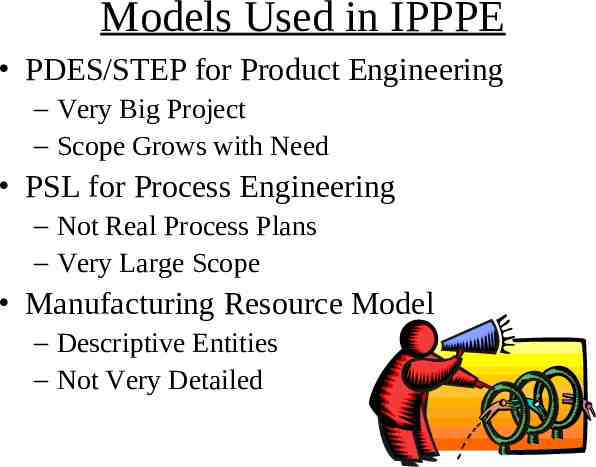

Models Used in IPPPE PDES/STEP for Product Engineering – Very Big Project – Scope Grows with Need PSL for Process Engineering – Not Real Process Plans – Very Large Scope Manufacturing Resource Model – Descriptive Entities – Not Very Detailed

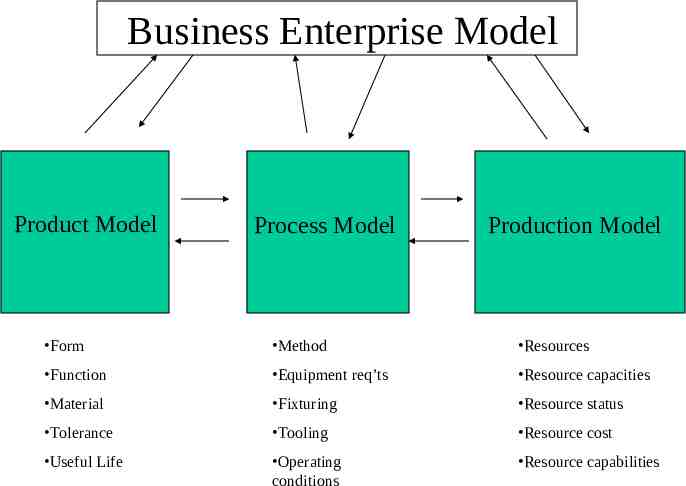

Business Enterprise Model Product Model Process Model Production Model Form Method Resources Function Equipment req’ts Resource capacities Material Fixturing Resource status Tolerance Tooling Resource cost Useful Life Operating conditions Resource capabilities

IPPPE Directions Geographically Separated Engineering Activities Best Practice Only Time Compressed Horizons Open Access (Data and Manufacturing) Intelligent Access to Non-Expert Domains

Geographically Separated Engineering Web Connected Translators and Interpreters to/from Other Domains Software Assistants (or Agents) into Non-Expert Areas Use Best Method to Produce Design Use Best Manufacturing System/Practice to Produce Product Immediate Awareness of Capital Critical Constraints

Best Practice Only Domain Prejudice Dominates Process Engineering Hybrid Manufacturing – We Seldom Use A Single Manufacturing Technique DFx (DFx)

Time Compressed Horizons and Open Access “Better Late than Never” Has Become “Better Never Be Late” – Manage All of Your Resources Carefully Immediate Access to Supplier Critical Activities Well Informed Early Decision Making

Intelligent Access to Non-Expert Domains Critical Size and Tolerance Constraints Should be Available to the Product Engineer Non-Traditional Methods – Domain Prejudice (Powdered Process) Software (Intelligent) Agents Span Various Domains

Some Examples Resource Independent Process Plans Control from IPPPE

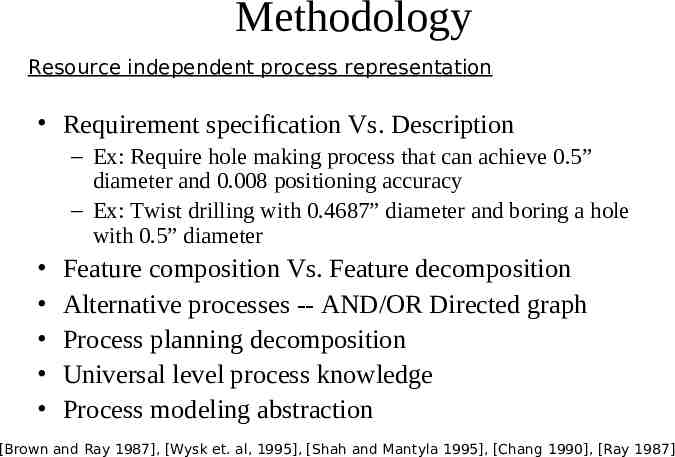

Methodology Resource independent process representation Requirement specification Vs. Description – Ex: Require hole making process that can achieve 0.5” diameter and 0.008 positioning accuracy – Ex: Twist drilling with 0.4687” diameter and boring a hole with 0.5” diameter Feature composition Vs. Feature decomposition Alternative processes -- AND/OR Directed graph Process planning decomposition Universal level process knowledge Process modeling abstraction [Brown and Ray 1987], [Wysk et. al, 1995], [Shah and Mantyla 1995], [Chang 1990], [Ray 1987]

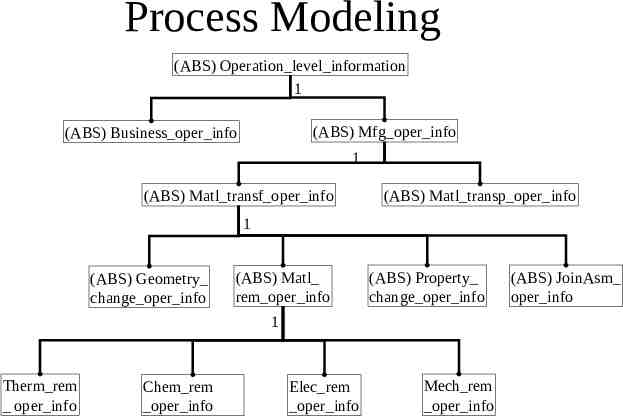

Process Modeling (ABS) Operation level information 1 (ABS) Mfg oper info (ABS) Business oper info 1 (ABS) Matl transf oper info (ABS) Matl transp oper info 1 (ABS) Geometry change oper info (ABS) Matl rem oper info (ABS) Property change oper info 1 Therm rem oper info Chem rem oper info Elec rem oper info Mech rem oper info (ABS) JoinAsm oper info

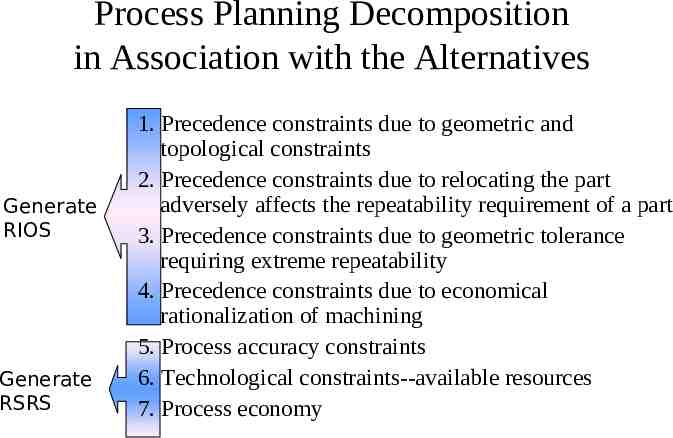

Process Planning Decomposition in Association with the Alternatives Generate RIOS Generate RSRS 1. Precedence constraints due to geometric and topological constraints 2. Precedence constraints due to relocating the part adversely affects the repeatability requirement of a part 3. Precedence constraints due to geometric tolerance requiring extreme repeatability 4. Precedence constraints due to economical rationalization of machining 5. Process accuracy constraints 6. Technological constraints--available resources 7. Process economy

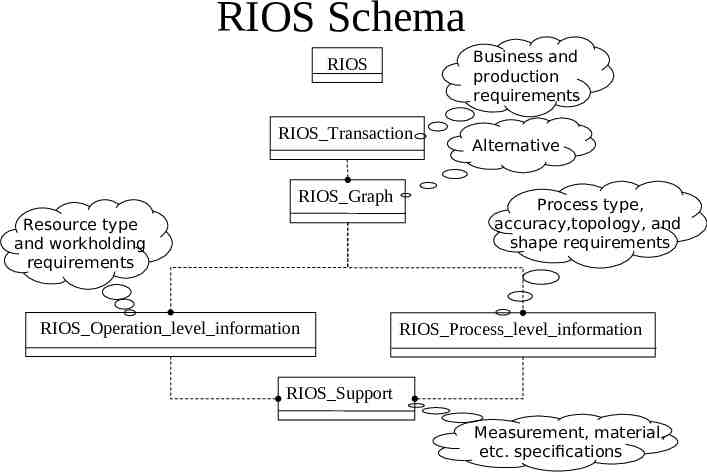

RIOS Schema Business and production requirements RIOS RIOS Transaction RIOS Graph Resource type and workholding requirements RIOS Operation level information Alternative Process type, accuracy,topology, and shape requirements RIOS Process level information RIOS Support Measurement, material, etc. specifications

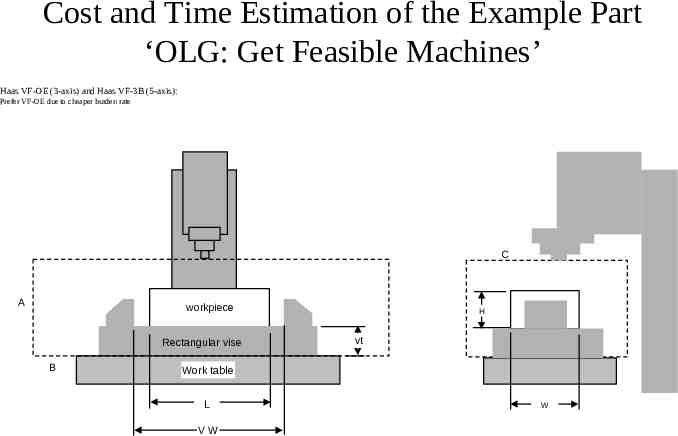

Cost and Time Estimation of the Example Part ‘OLG: Get Feasible Machines’ Haas VF-OE (3-axis) and Haas VF-3B (5-axis): Prefer VF-OE due to cheaper burden rate C A workpiece Rectangular vise B H vt Work table L VW W

Automatic Generation of Simulation Models from Neutral Libraries: An Example Young-Jun Son, University of Arizona Albert T. Jones, NIST Richard A. Wysk, Penn State University

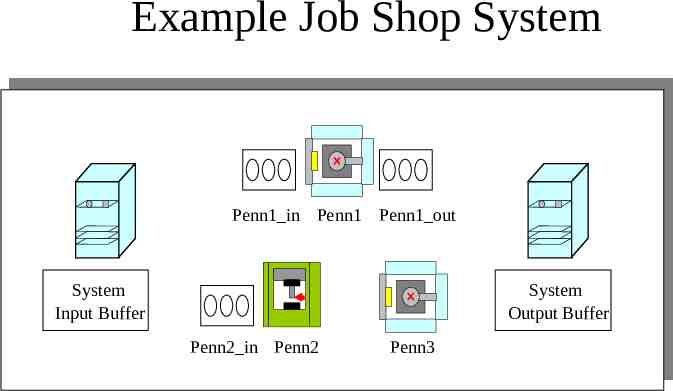

Example Job Shop System Penn1 in Penn1 Penn1 out System Input Buffer System Output Buffer Penn2 in Penn2 Penn3

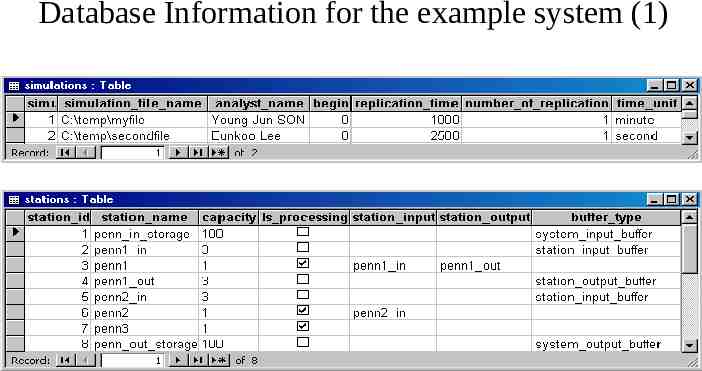

Database Information for the example system (1)

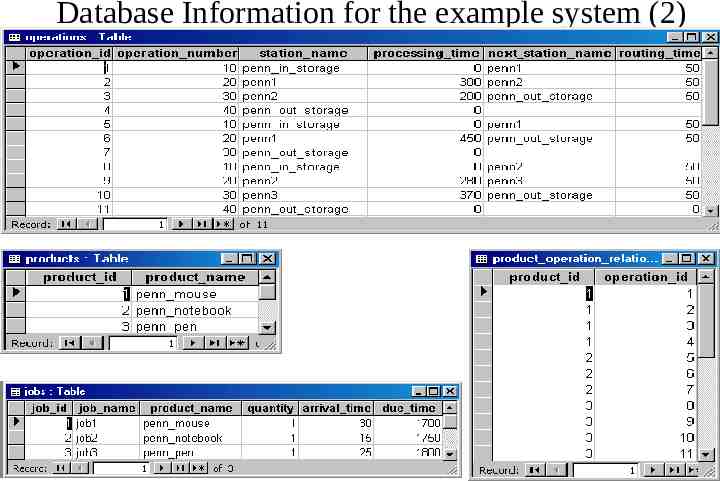

Database Information for the example system (2)

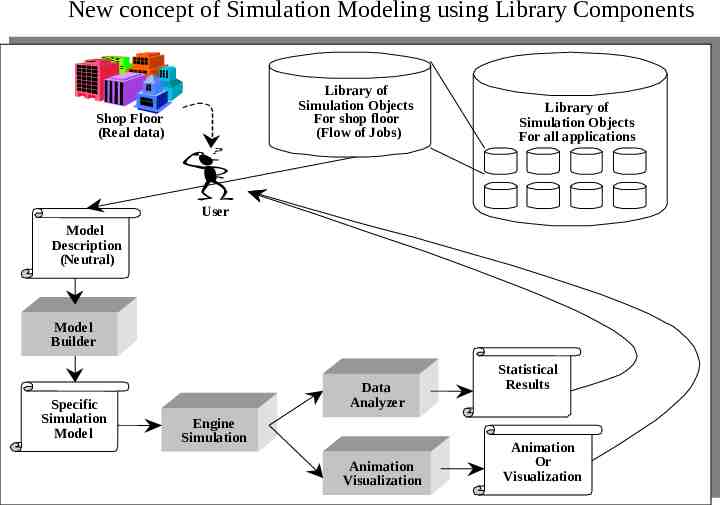

New concept of Simulation Modeling using Library Components Library of Simulation Objects For shop floor (Flow of Jobs) Shop Floor (Real data) Library of Simulation Objects For all applications User Model Description (Neutral) Model Builder Specific Simulation Model Data Analyzer Engine Simulation Animation Visualization Statistical Results Animation Or Visualization

Two Translators (Model Builders) Arena 3.01 ProModel 4.2 Model builders in Visual Basic 6.0 – Microsoft Access 8.0 Object Library – DAO (Data Access Object) 3.5 Library – Arena Object Library – ProModel 1.0 Type Library

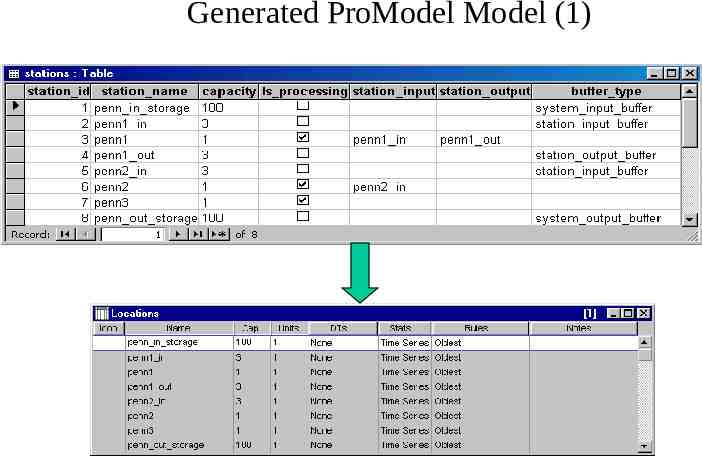

Generated ProModel Model (1)

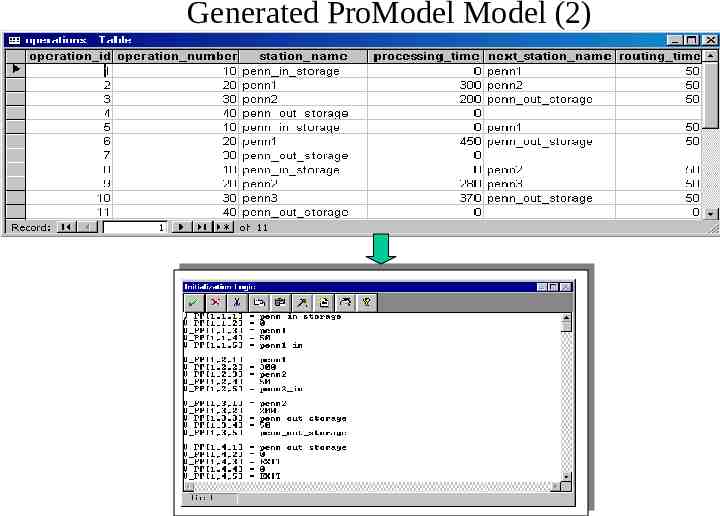

Generated ProModel Model (2)

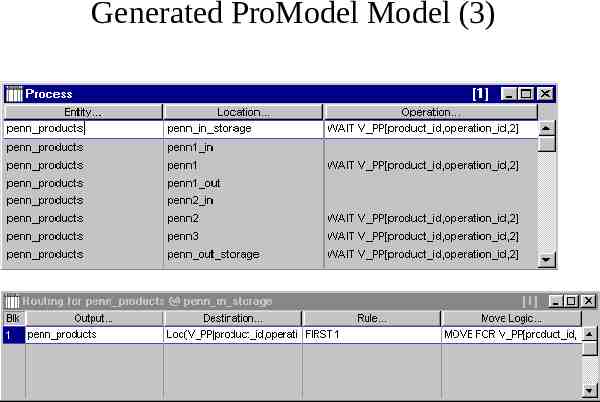

Generated ProModel Model (3)

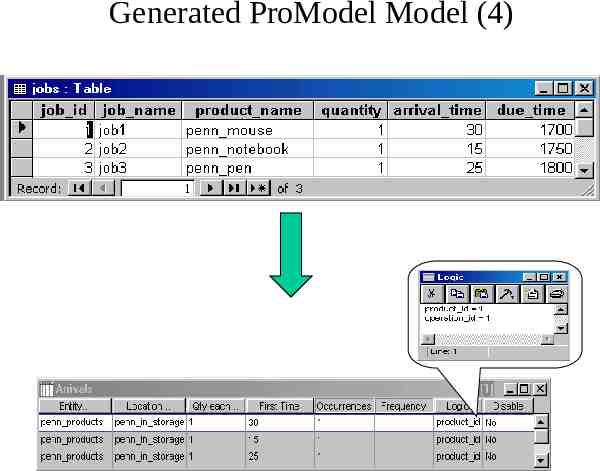

Generated ProModel Model (4)

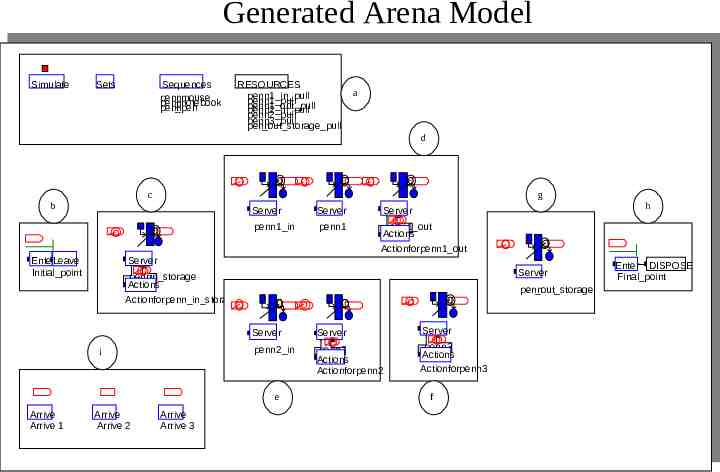

Generated Arena Model Simulate Sets Sequences penn mouse penn notebook penn pen RESOURCES penn1 in pull penn1 pull penn1 out pull penn2 in pull penn2 pull penn3 pull penn out storage pull a d c g b EnterLeave Initial point h Server Server Server penn1 in penn1 penn1 out Actions Actionforpenn1 out Server Server penn in storage Actions penn out storage Actionforpenn in storage i Server Server Server penn2 in penn2 Actions Actionforpenn2 penn3 Actions Actionforpenn3 e Arrive Arrive 1 Arrive Arrive 2 Arrive Arrive 3 f Enter DISPOSE Final point

Summary Manufacturing systems are getting more complicated Manufacturing is becoming a Broad Area Activity Communication issues have increased Integration is key