Industrial Hygiene Risk Assessments By Kelsey Smith

30 Slides3.51 MB

Industrial Hygiene Risk Assessments By Kelsey Smith

Abstract High-quality aluminum auto part coating requires significant amounts of paint and solvents. Conventional air spray guns are the standard spray equipment used to apply coatings in the automotive refinishing industry. The health risk assessment based on the automotive coating operation will focus on a probability of harm rather than the actual health outcomes, which may be diagnosed years after the exposure. Varieties of health risk assessment tools will be presented. Participants will take away a downloadable Industrial Hygiene Risk Assessment tool which successfully identifies the hazards associated with spray painting operations.

Industrial Hygiene Risk Assessment Introduction IH is a very dynamic and complex discipline. It is difficult to describe where IH starts and ends in the occupational safety, health and environmental (SH&E) field. With a great deal of overlap in the field, there are no clear professional boundaries for the IH practice. For instance, occupational ergonomics is considered within the industrial hygiene domain, yet many safety and engineering professionals work in this area. Environmental concerns are often addressed by industrial hygienist. And some professionals are charged with coordinating all SH&E efforts. There is considerable debate in the professional IH community regarding the practice of IH Risk Assessment. Health risk assessment, Exposure Assessment, Exposure Risk Assessment and Management (ERAM), are all terms used by IH professionals to refer to IH risk and its assessment. It should be noted that exposure assessment does not equal a true Risk Assessment. 01/30/2023 3

New Standards and IH Risk Assessment New standards and a rapidly changing profession require proper alignment of traditional IH risk assessment models with the methodologies described in the standards. The risk assessment process is well defined in the American National Standard, ANSI Z 10-2012, Occupational Health and Safety Management Systems, by the following statement taken from its Appendix F, Risk Assessment: “Risk Assessment is the process to determine the level of risk based on the likelihood the hazard will cause an injury or disease, and the severity of the injury or disease that may result. When a hazard is identified and discussion takes place concerning its potential for harm and the probability an injurious incident or exposure can occur, a risk assessment has been made.” (ANSI, AIHA, & ASSE, 2012, page 47) For the purposes of this presentation we’ll primarily use definitions and risk assessment processes described in ANSI Z10, the International Standards Organization’s ISO 31000/ANSI Z690 series and ANSI Z590.3-2011, Prevention through Design standards. 01/30/2023 4

Fundamental Concepts In 2002, AIHA published a white paper on Risk Assessment and Risk Management. The paper outlined AIHA’s policy on the practice of human health risk assessment techniques in regulatory decision-making, development of public health policy, and in the allocation of government and private sector resources to occupational and environmental issues (AIHA, 2002). AIHA “supports the use of an iterative approach to the assessment process in which relatively simple techniques are used initially to identify the potential magnitude of the health risk, followed by more sophisticated analyses as needed.” 01/30/2023 5

Fundamental Concepts Health Risk Rating - One of the techniques used to identify the potential magnitude of the health risk is the “Health Risk Rating” methodology described in Chapter 6 of AIHA’s Exposure Assessment Strategy (Ignacio & Bullock, 2006). Mulhausen, Damiano, and Pullen (2006b) defined Health Risk Rating (HRR) as a function of the potential health effect caused by the agent and the potential exposure. HRR is calculated based on the Equation below where Health Effect Rating is a semi-quantitative numerical rating. Health Risk Rating Formula 01/30/2023 6

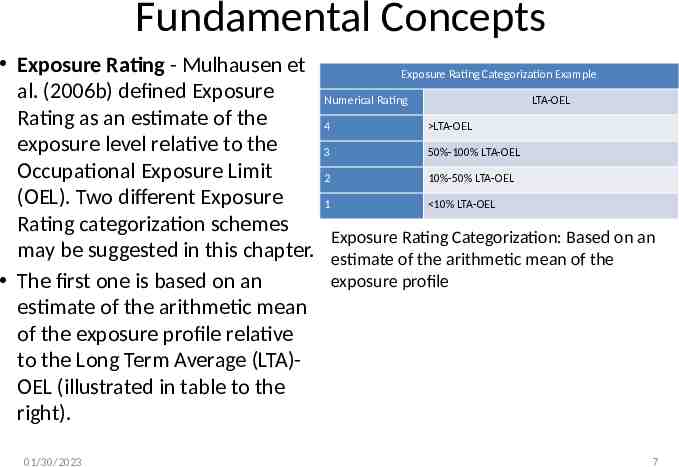

Fundamental Concepts Exposure Rating - Mulhausen et Exposure Rating Categorization Example al. (2006b) defined Exposure Numerical Rating LTA-OEL Rating as an estimate of the 4 LTA-OEL exposure level relative to the 3 50%-100% LTA-OEL Occupational Exposure Limit 2 10%-50% LTA-OEL (OEL). Two different Exposure 1 10% LTA-OEL Rating categorization schemes Exposure Rating Categorization: Based on an may be suggested in this chapter. estimate of the arithmetic mean of the The first one is based on an exposure profile estimate of the arithmetic mean of the exposure profile relative to the Long Term Average (LTA)OEL (illustrated in table to the right). 01/30/2023 7

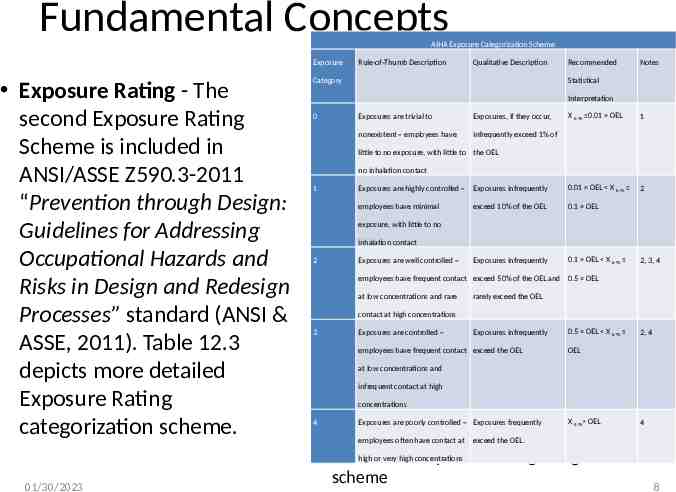

Fundamental Concepts AIHA Exposure Categorization Scheme Exposure Exposure Rating - The second Exposure Rating Scheme is included in ANSI/ASSE Z590.3-2011 “Prevention through Design: Guidelines for Addressing Occupational Hazards and Risks in Design and Redesign Processes” standard (ANSI & ASSE, 2011). Table 12.3 depicts more detailed Exposure Rating categorization scheme. 01/30/2023 Rule-of-Thumb Description Qualitative Description Category Recommended Notes Statistical Interpretation 0 X 0.95 0.01 OEL 1 Exposures are highly controlled – Exposures infrequently 0.01 OEL X 0.95 2 employees have minimal exceed 10% of the OEL 0.1 OEL Exposures infrequently 0.1 OEL X 0.95 Exposures are trivial to Exposures, if they occur, nonexistent – employees have infrequently exceed 1% of little to no exposure, with little to the OEL no inhalation contact 1 exposure, with little to no inhalation contact 2 Exposures are well controlled – 2, 3, 4 employees have frequent contact exceed 50% of the OEL and 0.5 OEL at low concentrations and rare rarely exceed the OEL contact at high concentrations 3 Exposures are controlled – Exposures infrequently employees have frequent contact exceed the OEL 0.5 OEL X 0.95 2, 4 OEL at low concentrations and infrequent contact at high concentrations 4 Exposures are poorly controlled – Exposures frequently employees often have contact at X 0.95 OEL 4 exceed the OEL. high or12.3, very high concentrations Table. Exposure Rating categorization scheme 8

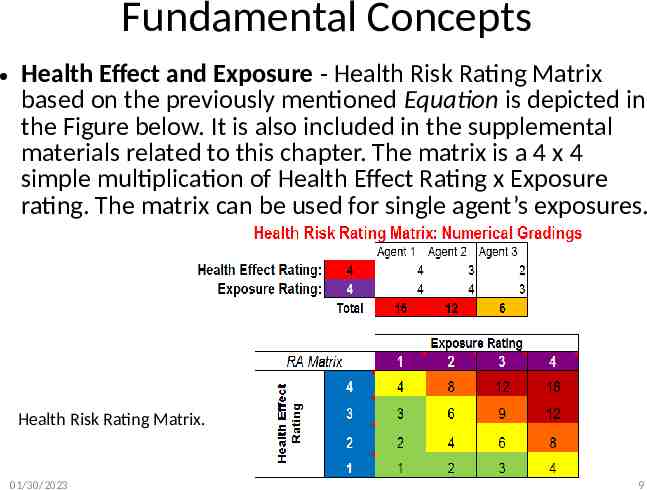

Fundamental Concepts Health Effect and Exposure - Health Risk Rating Matrix based on the previously mentioned Equation is depicted in the Figure below. It is also included in the supplemental materials related to this chapter. The matrix is a 4 x 4 simple multiplication of Health Effect Rating x Exposure rating. The matrix can be used for single agent’s exposures. Health Risk Rating Matrix. 01/30/2023 9

Fundamental Concepts Alternate Health Risk Ranking Systems COSHH Essentials - One technique used to identify the potential magnitude of the health risk is the Control of Substances Hazardous to Health Regulations’ COSHH Essentials online tool. ART - “The Advanced REACH Tool (ART) version 1.5 incorporates a mechanistic model of inhalation exposure and a statistical facility to update the estimates with measurements selected from an in-built exposure database or the user’s own data. Stroffenmanager - The Stoffenmanager is a generic tool, initially developed for small and medium size business to support them in assessing, prioritizing and controlling risks from chemicals at the workplace. It provides support for companies and EHS professionals in performing a risk assessment and controlling exposure by taking proper risk management measures. 01/30/2023 10

Fundamental Concepts Health Risk Assessments and Prioritization The health risk assessment should focus on a probability of harm rather than the actual health outcomes, which may be diagnosed years after the exposure. Varieties of simple health risk assessment tools are available. Qualitative risk assessment matrix, as described in ANSI Z10 – 2012 Appendix F, can be used for initial risk assessment. Numerical risk assessment method can also be utilized. To demonstrate semi-quantitative IH risk assessment I’ll present the following case study. 01/30/2023 11

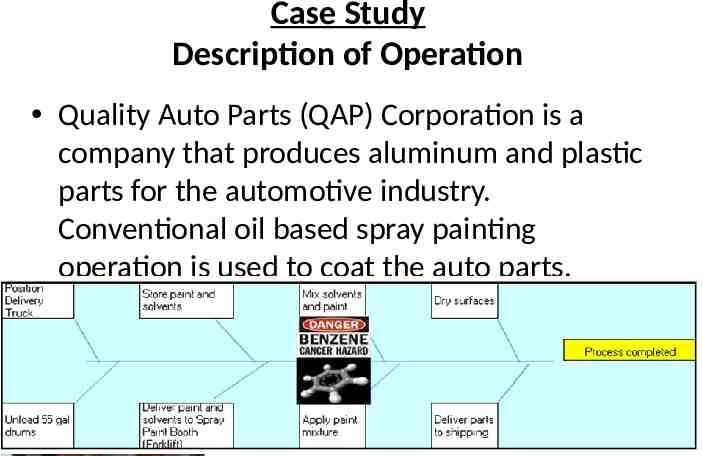

Case Study Description of Operation Quality Auto Parts (QAP) Corporation is a company that produces aluminum and plastic parts for the automotive industry. Conventional oil based spray painting operation is used to coat the auto parts.

Case Study Description of Operation The company stores oil based paint in 55 gal. drums in the storage room. Flammable solvents are also stored in the storage room. The solvents contain up to 5% of Benzene. The paint and the solvents drums are moved with a forklift truck to the conventional spray booth. (OSHA Forklift S&H Topic)

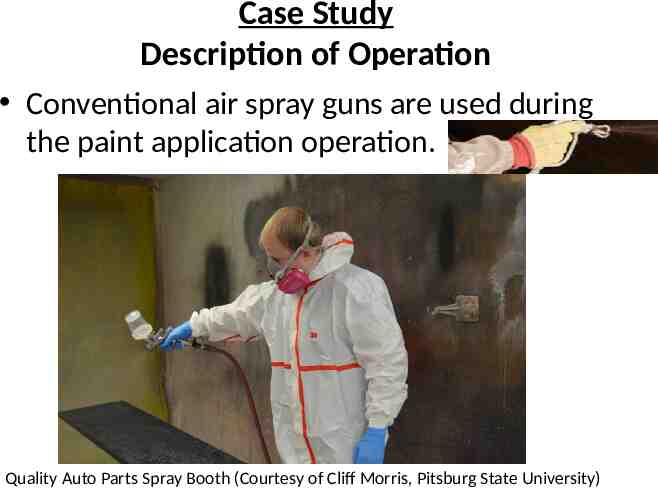

Case Study Description of Operation Conventional air spray guns are used during the paint application operation. Quality Auto Parts Spray Booth (Courtesy of Cliff Morris, Pitsburg State University)

Case Study Description of Operation Personal Protective Equipment (PPE) is the preferred method of control, since it is the cheapest option. Current state of the process: The coating operators are using only N95 or P100 respirators and safety glasses. Not surprisingly, the safety glasses are “coated” with paint after just 10 min. of use. Naturally, the spray paint operators are complaining that they can’t see very well the parts and the Quality Control (QC) manager determined that only 72% of the parts are coated properly.

Case Study Description of Operation Quality Auto Parts Spray Painting Operation (Courtesy of Cliff Morris, Pitsburg State University)

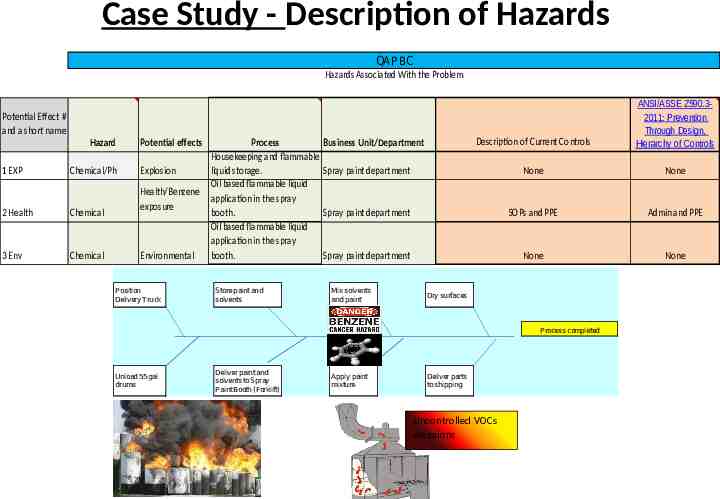

Case Study - Description of Hazards QAP BC Hazards Associated With the Problem Description of Current Controls ANSI/ASSE Z590.32011: Prevention Through Design, Hierarchy of Controls Spray paint department None None Spray paint department SOPs and PPE Admin and PPE Spray paint department None None Potential Effect # and a short name Hazard 1 EXP Chemical/Ph 2 Health Chemical 3 Env Chemical Potential effects Explosion Health/Benzene exposure Environmental Position Delivery Truck Process Housekeeping and flammable liquid storage. Oil based flammable liquid application in the spray booth. Oil based flammable liquid application in the spray booth. Store paint and solvents Business Unit/Department Mix solvents and paint Dry surfaces Process completed Unload 55 gal drums Deliver paint and solvents to Spray Paint Booth (Forklift) Apply paint mixture Deliver parts to shipping Uncontrolled VOCs emissions

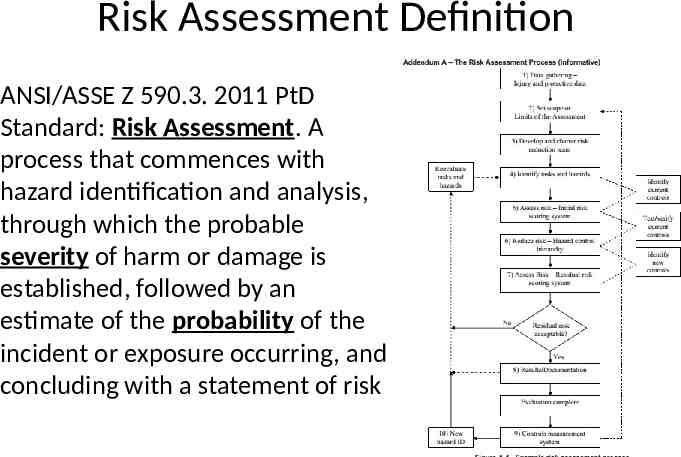

Risk Assessment Definition ANSI/ASSE Z 590.3. 2011 PtD Standard: Risk Assessment. A process that commences with hazard identification and analysis, through which the probable severity of harm or damage is established, followed by an estimate of the probability of the incident or exposure occurring, and concluding with a statement of risk

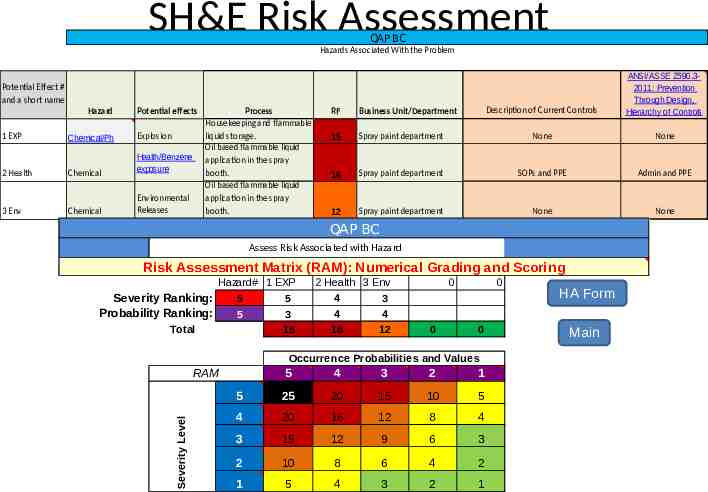

SH&E Risk Assessment QAP BC Hazards Associated With the Problem Description of Current Controls ANSI/ASSE Z590.32011: Prevention Through Design, Hierarchy of Controls Spray paint department None None 16 Spray paint department SOPs and PPE Admin and PPE 12 Spray paint department None None Potential Effect # and a short name Hazard Chemical/Ph 2 Health Chemical 3 Env Chemical Explosion Health/Benzene exposure Environmental Releases Process Housekeeping and flammable liquid storage. Oil based flammable liquid application in the spray booth. Oil based flammable liquid application in the spray booth. RF Business Unit/Department 15 QAP BC Assess Risk Associated with Hazard Risk Assessment Matrix (RAM): Numerical Grading and Scoring Hazard# 1 EXP Severity Ranking: 5 5 Probability Ranking: 5 3 Total 15 2 Health 3 Env 4 3 4 4 16 12 0 0 0 0 Occurrence Probabilities and Values RAM Severity Level 1 EXP Potential effects 5 4 3 2 1 5 25 20 15 10 5 4 20 16 12 8 4 3 15 12 9 6 3 2 10 8 6 4 2 1 5 4 3 2 1 HA Form Main

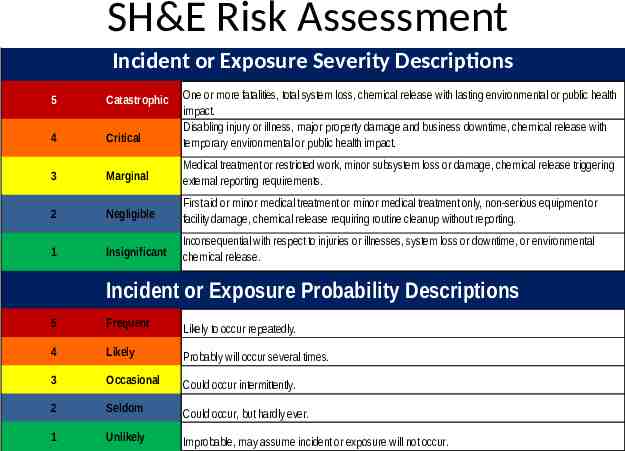

SH&E Risk Assessment Incident or Exposure Severity Descriptions 5 Catastrophic 4 Critical One or more fatalities, total system loss, chemical release with lasting environmental or public health impact. Disabling injury or illness, major property damage and business downtime, chemical release with temporary environmental or public health impact. 3 Marginal Medical treatment or restricted work, minor subsystem loss or damage, chemical release triggering external reporting requirements. 2 Negligible First aid or minor medical treatment or minor medical treatment only, non-serious equipment or facility damage, chemical release requiring routine cleanup without reporting. 1 Insignificant Inconsequential with respect to injuries or illnesses, system loss or downtime, or environmental chemical release. Incident or Exposure Probability Descriptions 5 Frequent Likely to occur repeatedly. 4 Likely Probably will occur several times. 3 Occasional Could occur intermittently. 2 Seldom Could occur, but hardly ever. 1 Unlikely Improbable, may assume incident or exposure will not occur.

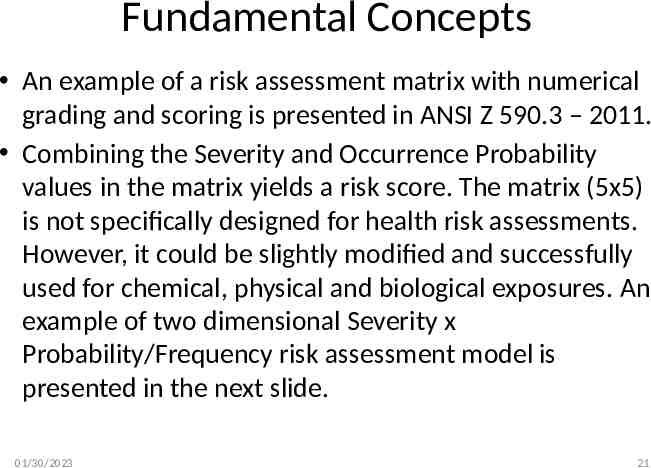

Fundamental Concepts An example of a risk assessment matrix with numerical grading and scoring is presented in ANSI Z 590.3 – 2011. Combining the Severity and Occurrence Probability values in the matrix yields a risk score. The matrix (5x5) is not specifically designed for health risk assessments. However, it could be slightly modified and successfully used for chemical, physical and biological exposures. An example of two dimensional Severity x Probability/Frequency risk assessment model is presented in the next slide. 01/30/2023 21

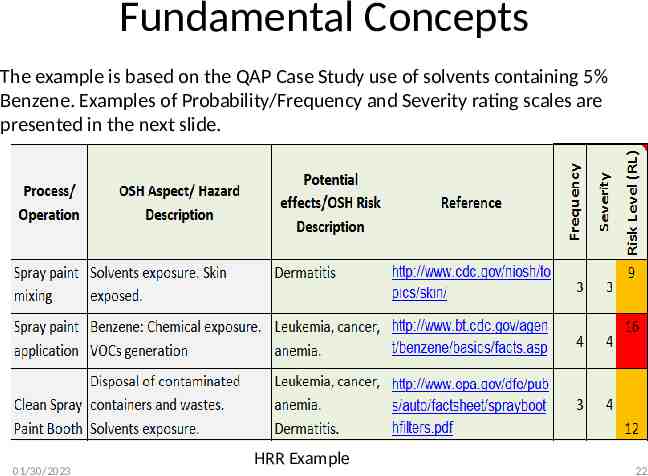

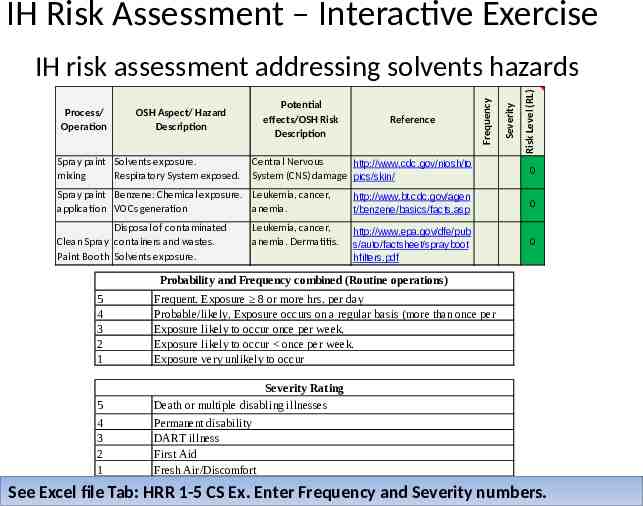

Fundamental Concepts The example is based on the QAP Case Study use of solvents containing 5% Benzene. Examples of Probability/Frequency and Severity rating scales are presented in the next slide. 01/30/2023 HRR Example 22

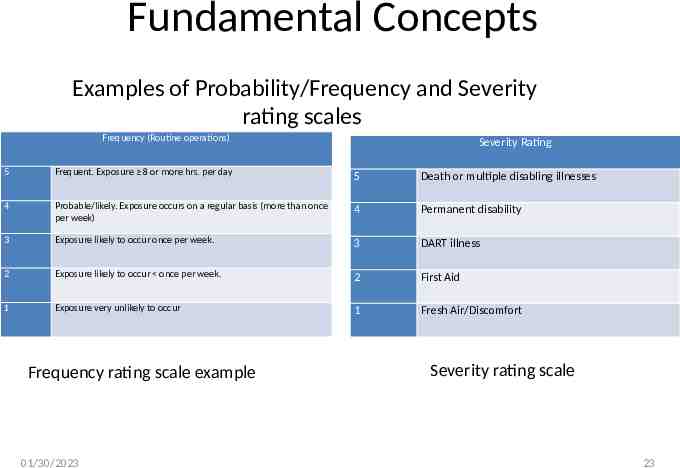

Fundamental Concepts Examples of Probability/Frequency and Severity rating scales Frequency (Routine operations) Severity Rating 5 Frequent. Exposure 8 or more hrs. per day 5 Death or multiple disabling illnesses 4 Probable/likely. Exposure occurs on a regular basis (more than once per week) 4 Permanent disability 3 Exposure likely to occur once per week. 3 DART illness 2 Exposure likely to occur once per week. 2 First Aid 1 Exposure very unlikely to occur 1 Fresh Air/Discomfort Frequency rating scale example 01/30/2023 Severity rating scale 23

IH Risk Assessment – Interactive Exercise Spray paint Solvents exposure. mixing Respiratory System exposed. Reference Central Nervous http://www.cdc.gov/niosh/to System (CNS) damage pics/skin/ Risk Level (RL) Potential effects/OSH Risk Description OSH Aspect/ Hazard Description Severity Process/ Operation Frequency IH risk assessment addressing solvents hazards 0 Spray paint Benzene: Chemical exposure. Leukemia, cancer, application VOCs generation anemia. http://www.bt.cdc.gov/agen t/benzene/basics/facts.asp 0 Disposal of contaminated Clean Spray containers and wastes. Paint Booth Solvents exposure. http://www.epa.gov/dfe/pub s/auto/factsheet/sprayboot hfilters.pdf 0 Leukemia, cancer, anemia. Dermatitis. Probability and Frequency combined (Routine operations) 5 4 3 2 1 Frequent. Exposure 8 or more hrs. per day Probable/likely. Exposure occurs on a regular basis (more than once per Exposure likely to occur once per week. Exposure likely to occur once per week. Exposure very unlikely to occur 5 Severity Rating Death or multiple disabling illnesses 4 3 2 1 Permanent disability DART illness First Aid Fresh Air/Discomfort See Excel file Tab: HRR 1-5 CS Ex. Enter Frequency and Severity numbers.

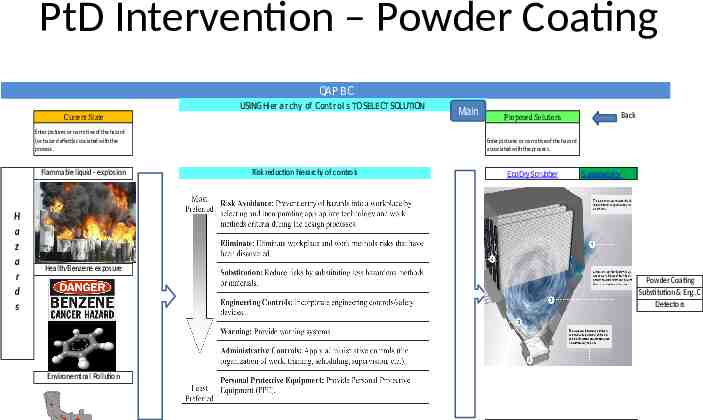

PtD Intervention – Powder Coating QAP BC USING Hier a r chy of Cont r ol s TO SELECT SOLUTION Current State Enter pictures or narrative of the hazard (or hazard effect)associated with the process. Flammable liquid - explosion H a z a r d s Main Back Proposed Solutions Enter pictures or narrative of the hazard associated with the process. Risk reduction hierarchy of controls EcoDryScrubber Sustainability Health/Benzene exposure Powder Coating Substitution & Eng. C Detectors Environemtnal Pollution

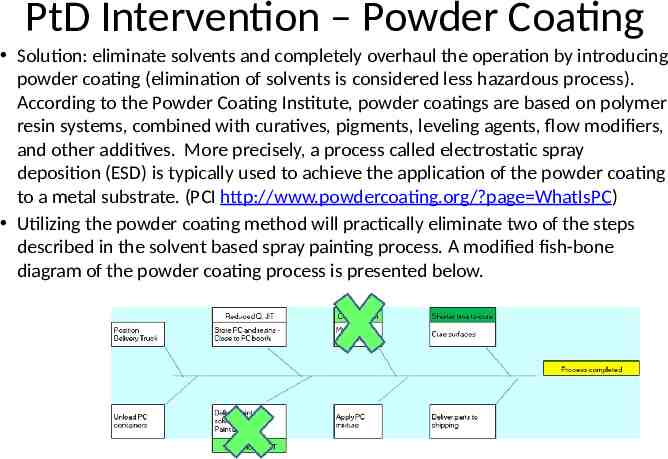

PtD Intervention – Powder Coating Solution: eliminate solvents and completely overhaul the operation by introducing powder coating (elimination of solvents is considered less hazardous process). According to the Powder Coating Institute, powder coatings are based on polymer resin systems, combined with curatives, pigments, leveling agents, flow modifiers, and other additives. More precisely, a process called electrostatic spray deposition (ESD) is typically used to achieve the application of the powder coating to a metal substrate. (PCI http://www.powdercoating.org/?page WhatIsPC) Utilizing the powder coating method will practically eliminate two of the steps described in the solvent based spray painting process. A modified fish-bone diagram of the powder coating process is presented below.

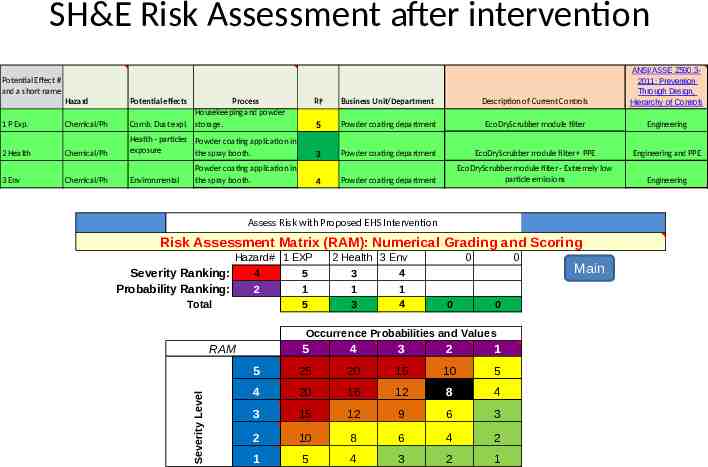

SH&E Risk Assessment after intervention RF Business Unit/Department Description of Current Controls ANSI/ASSE Z590.32011: Prevention Through Design, Hierarchy of Controls 5 Powder coating department EcoDryScrubber module filter Engineering Potential Effect # and a short name Potential effects 1 P Exp. Chemical/Ph Process Housekeeping and powder Comb. Dust expl. storage. 2 Health Chemical/Ph Health - particles Powder coating application in exposure the spray booth. 3 Powder coating department EcoDryScrubber module filter PPE Engineering and PPE 3 Env Chemical/Ph Environmental Powder coating application in the spray booth. 4 Powder coating department EcoDryScrubber module filter - Extremely low particle emissions Engineering Assess Risk with Proposed EHS Intervention Risk Assessment Matrix (RAM): Numerical Grading and Scoring Severity Ranking: Probability Ranking: Total Hazard# 1 EXP 4 5 2 1 5 2 Health 3 Env 3 4 1 1 3 4 0 0 0 0 Occurrence Probabilities and Values RAM Severity Level Hazard 5 4 3 2 1 5 25 20 15 10 5 4 20 16 12 8 4 3 15 12 9 6 3 2 10 8 6 4 2 1 5 4 3 2 1 Main

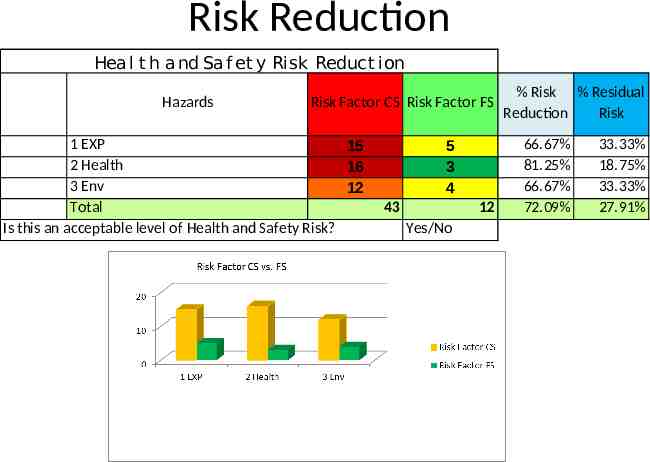

Risk Reduction Hea l t h a nd Sa f et y Risk Reduct ion Hazards Risk Factor CS Risk Factor FS 1 EXP 15 2 Health 16 3 Env 12 Total Is this an acceptable level of Health and Safety Risk? 5 3 4 43 12 Yes/No % Risk % Residual Reduction Risk 66.67% 81.25% 66.67% 72.09% 33.33% 18.75% 33.33% 27.91%

Summary The tools and methods discussed in this presentation represent a summary of some of the methods used in IH Risk Assessment and Management process. These methodologies present IH risk assessment (RA) process in a systemic and easy to read format highlighting the priorities. The proposed use of RA Tools for IH interventions relies on professional judgment and semi-quantitative decision-making in order to assess the significance of hazards and assign a HRR number to each task or process. Utilizing semi-quantitative methods for IH risk assessments helps in prioritizing recommendations for reducing risks. 01/30/2023 29

Questions? IH Risk Assessment tools link: http://centralspace.ucmo.edu/handle/123456789/464