HAZARDOUS MATERIALS EMPLOYEE TRAINING 2021 EDITION REUSABLE

47 Slides2.76 MB

HAZARDOUS MATERIALS EMPLOYEE TRAINING 2021 EDITION REUSABLE INDUSTRIAL PACKAGING ASSOCIATION (RIPA)

HAZARDOUS MATERIALS EMPLOYEE TRAINING Federal requirements governing hazmat employee training are found in Title 49 of the Code of Federal Regulations (§172.700 ‑172.704) The U.S. Department of Transportation is the primary regulatory agency for container reconditioners, manufacturers and distributors of packagings.

DOT requires “hazmat employers” to WHY TRAINING? train employees whose jobs have an impact on hazardous materials transportation safety (“hazmat employee”) about the recognition, regulation and proper handling of these materials. This definition includes anyone who “reconditions,” “manufacturers, marks, maintains or repairs ” a package or container that may be used for hazmat transportation.

WHY TRAINING (CONTINUED) ? Training is required because you or your employees perform one or more of these tasks: Recondition or manufacture hazmat packaging (examples: drums or IBCs), Mark packagings for hazmat use, Test packagings sold to hazmat shippers.

The DOT training rule applies to – WHO MUST BE TRAINED? Company owners Plant managers Plant workers Repair shop workers Company drivers

HOW OFTEN DO EMPLOYEES HAVE TO BE TRAINED? Every hazmat employee must be trained initially within 90 days of being hired. Recurrent hazmat training must be provided to all covered employees every three (3) years.

TYPES OF HAZMAT TRAINING General Awareness (Including Hazmat “Security Awareness”) Safety & Emergency Training Function-Specific (Including Testing)

Hazardous materials pose risks to safety, health and the environment. Rules for packaging and shipping GENERAL AWARENESS TRAINING hazmats are established by the U.S. Department of Transportation (DOT). Within DOT, the Pipeline and Hazardous Materials Safety Administration is responsible for writing and enforcing most hazmat rules

HAZMAT BASICS The following slides will explain: Non-Bulk, Intermediate Bulk and Bulk Containers Classes of Hazardous Materials DOT Packing Groups Hazard Levels Package Labels Vehicle Placards Shipping Papers

NON-BULK, INTERMEDIATE BULK AND BULK CONTAINERS Non-bulk containers hold 119 gallons or less of liquid hazmat (Example: 55-gallon steel drums). Intermediate Bulk Containers are often referred to as “IBCs”; they typically hold 275 - 330 gallons of hazmat; Bulk containers can hold more than 119 gallons of liquid hazmat. When DOT references “bulk” containers, they usually are talking about tank trucks and rail tank cars.

DOT HAZARD CLASSES (1 – 9)

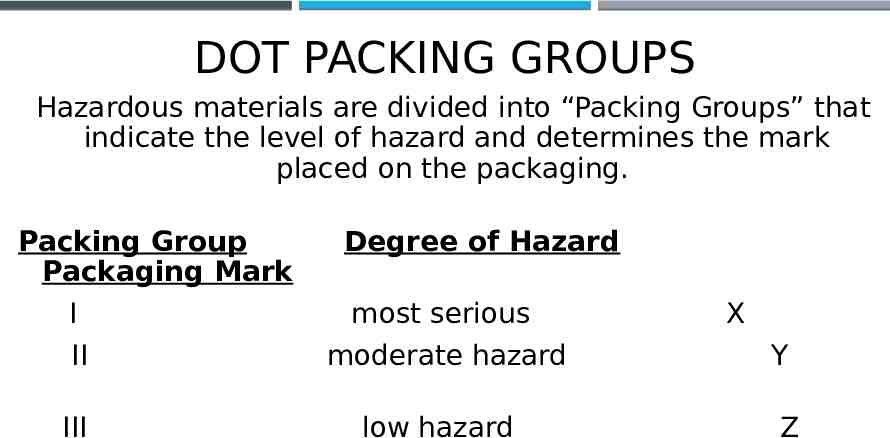

DOT PACKING GROUPS Hazardous materials are divided into “Packing Groups” that indicate the level of hazard and determines the mark placed on the packaging. Packing Group Packaging Mark I II III Degree of Hazard most serious moderate hazard low hazard X Y Z

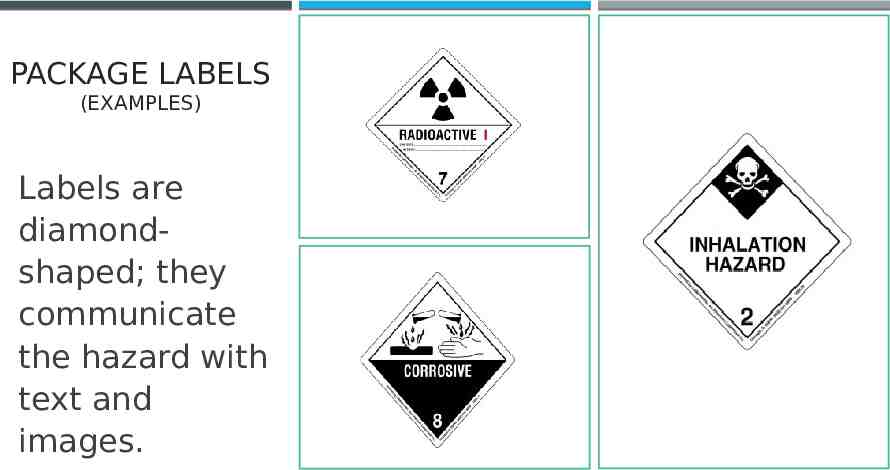

PACKAGE LABELS (EXAMPLES) Labels are diamondshaped; they communicate the hazard with text and images.

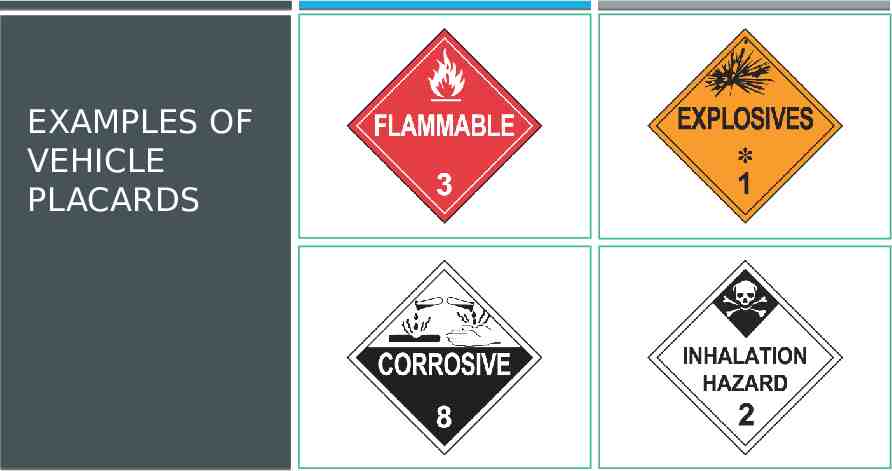

EXAMPLES OF VEHICLE PLACARDS

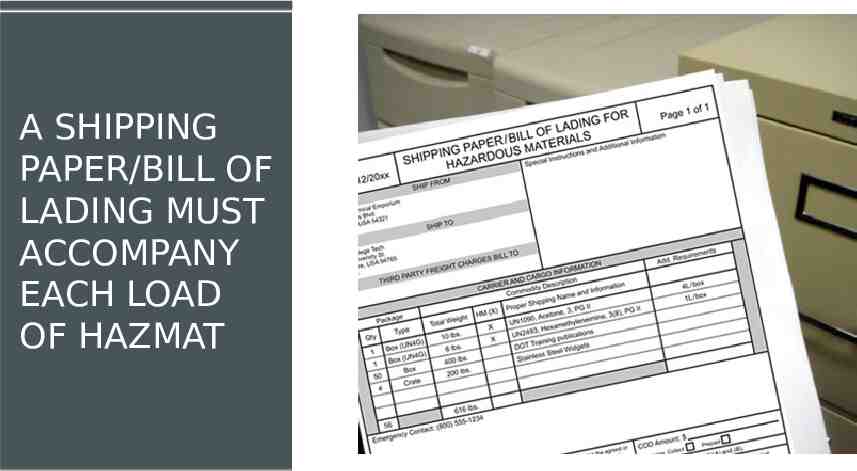

A SHIPPING PAPER/BILL OF LADING MUST ACCOMPANY EACH LOAD OF HAZMAT

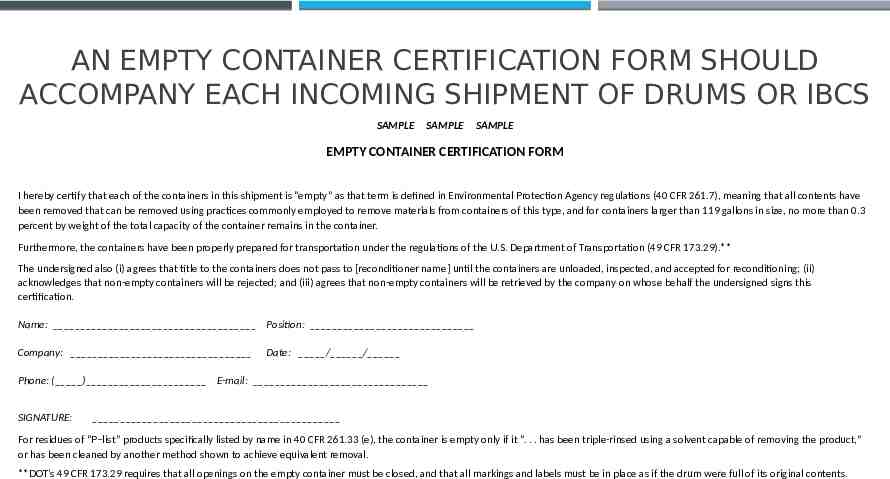

AN EMPTY CONTAINER CERTIFICATION FORM SHOULD ACCOMPANY EACH INCOMING SHIPMENT OF DRUMS OR IBCS SAMPLE SAMPLE SAMPLE EMPTY CONTAINER CERTIFICATION FORM I hereby certify that each of the containers in this shipment is “empty” as that term is defined in Environmental Protection Agency regulations (40 CFR 261.7), meaning that all contents have been removed that can be removed using practices commonly employed to remove materials from containers of this type, and for containers larger than 119 gallons in size, no more than 0.3 percent by weight of the total capacity of the container remains in the container. Furthermore, the containers have been properly prepared for transportation under the regulations of the U.S. Department of Transportation (49 CFR 173.29).** The undersigned also (i) agrees that title to the containers does not pass to [reconditioner name] until the containers are unloaded, inspected, and accepted for reconditioning; (ii) acknowledges that non-empty containers will be rejected; and (iii) agrees that non-empty containers will be retrieved by the company on whose behalf the undersigned signs this certification. Name: Position: Company: Date: / / Phone: ( ) E-mail: SIGNATURE: For residues of “P–list” products specifically listed by name in 40 CFR 261.33 (e), the container is empty only if it “. . . has been triple-rinsed using a solvent capable of removing the product,” or has been cleaned by another method shown to achieve equivalent removal. **DOT’s 49 CFR 173.29 requires that all openings on the empty container must be closed, and that all markings and labels must be in place as if the drum were full of its original contents.

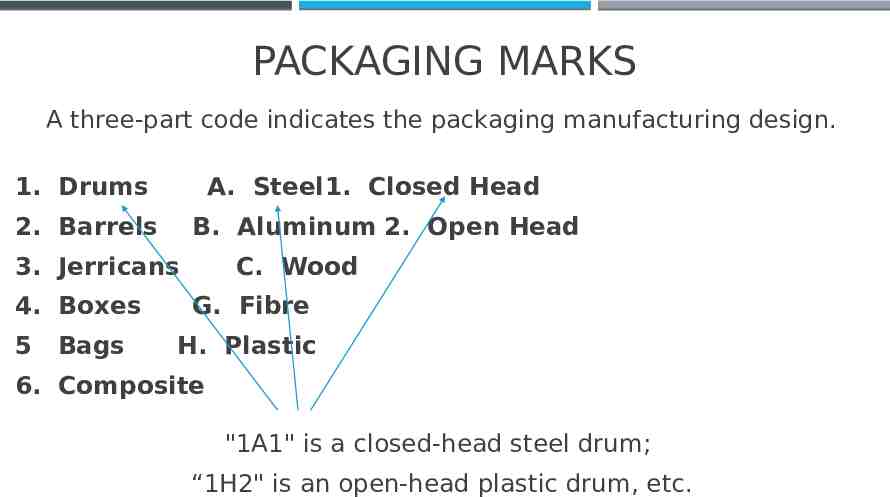

PACKAGING MARKS A three-part code indicates the packaging manufacturing design. 1. Drums A. Steel1. Closed Head 2. Barrels B. Aluminum 2. Open Head 3. Jerricans 4. Boxes 5 Bags C. Wood G. Fibre H. Plastic 6. Composite "1A1" is a closed-head steel drum; “1H2" is an open-head plastic drum, etc.

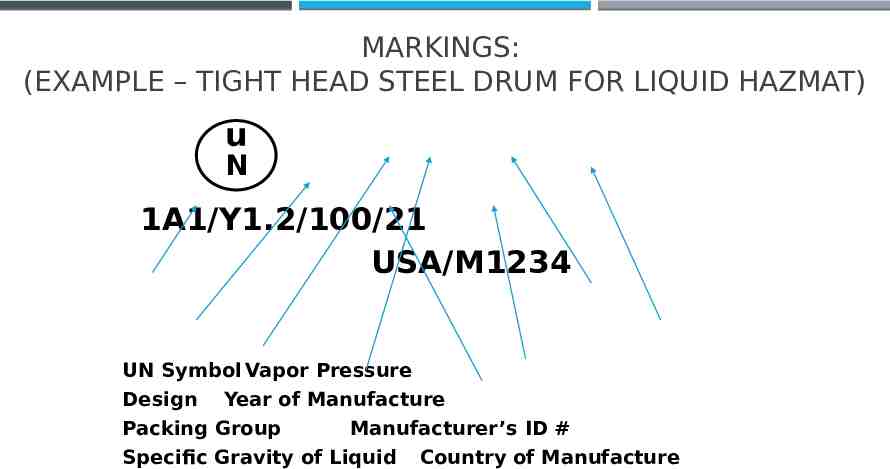

MARKINGS: (EXAMPLE – TIGHT HEAD STEEL DRUM FOR LIQUID HAZMAT) u N 1A1/Y1.2/100/21 USA/M1234 UN Symbol Vapor Pressure Design Year of Manufacture Packing Group Manufacturer’s ID # Specific Gravity of Liquid Country of Manufacture

Instead of marking containers DOT REGISTRATION NUMBERS with their company name and address, manufacturers and reconditioners can obtain a registration number from the U.S DOT. Registered numbers are 4- digits, preceded by an “R” or an “M”. For example: M1234.

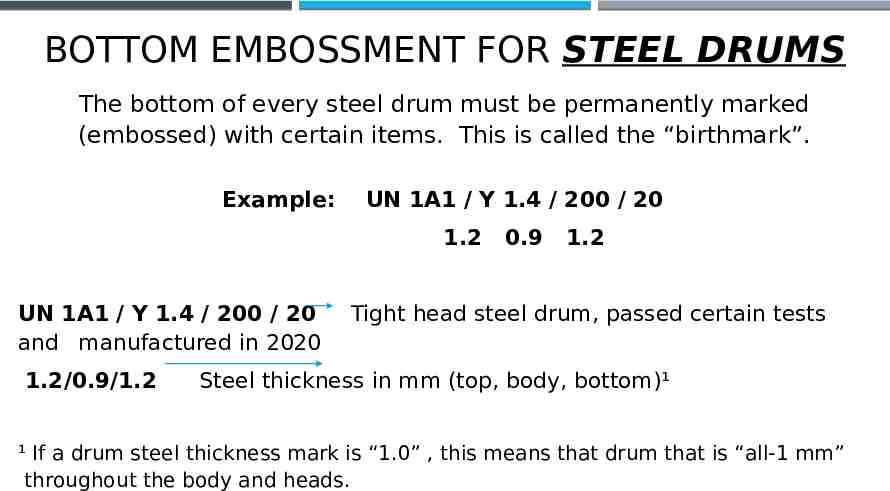

BOTTOM EMBOSSMENT FOR STEEL DRUMS The bottom of every steel drum must be permanently marked (embossed) with certain items. This is called the “birthmark”. Example: UN 1A1 / Y 1.4 / 200 / 20 1.2 UN 1A1 / Y 1.4 / 200 / 20 and manufactured in 2020 1.2/0.9/1.2 0.9 1.2 Tight head steel drum, passed certain tests Steel thickness in mm (top, body, bottom)¹ ¹ If a drum steel thickness mark is “1.0” , this means that drum that is “all-1 mm” throughout the body and heads.

CLOSURE INSTRUCTIONS Manufacturers, reconditioners and distributors of hazmat packagings must provide users (customers) with written instructions on how to properly close the packagings. Reconditioners/distributers can write their own instructions or obtain instructions from the original manufacturers of packagings and closures. RIPA will provide members with sample closure instructions for drums and IBCs upon request.

SAFETY AWARENESS TRAINING Employers are required to give all hazmat employees Safety Awareness Training. For packaging reconditioners and manufacturers, this includes information about: Measures to protect the employee from exposure to hazardous materials, and Procedures for avoiding accidents and handling hazmat incidents (spills) Note: OHSA or EPA workplace training programs may be used to satisfy this requirement

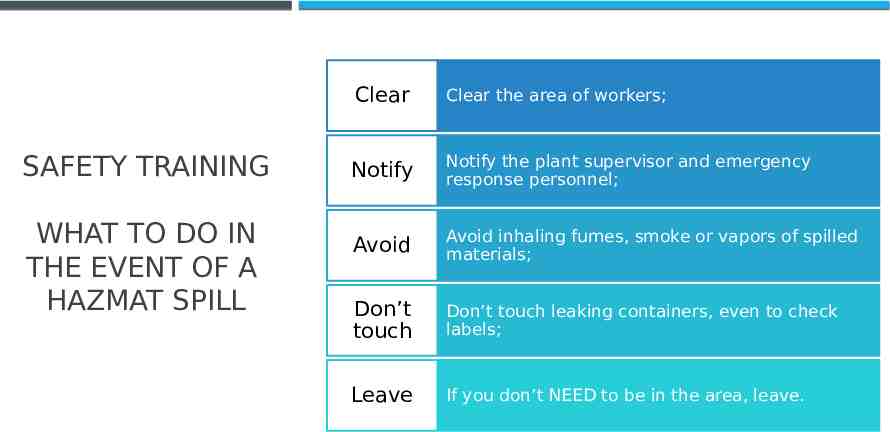

SAFETY TRAINING WHAT TO DO IN THE EVENT OF A HAZMAT SPILL Clear Clear the area of workers; Notify Notify the plant supervisor and emergency response personnel; Avoid Avoid inhaling fumes, smoke or vapors of spilled materials; Don’t touch Don’t touch leaking containers, even to check labels; Leave If you don’t NEED to be in the area, leave.

Offer first aid or obtain professional medical assistance for anyone who may have been injured. Employees should have access to “Safety SAFETY TRAINING: WHAT TO DO IF AN EMPLOYEE IS INJURED Data Sheets” (SDS) which contain first aid information; your employer will instruct you on where these sheets are kept. Some employers post 24-hour phone numbers to call and request that an SDS be sent by fax. In a medical emergency, do not hesitate to call the SDS number or dial 911 for help.

DOT HAZMAT SECURITY AWARENESS (ANTI-TERRORISM) DOT is concerned that certain hazardous materials, in storage or in transport, could be targeted by terrorists for use as lethal and destructive tools. Companies shipping certain highly hazardous materials (e.g. explosives, radiological materials) are required to have written Security Plans to address the risks that someone might attempt to take control of the materials and use them for violent purposes. RIPA members only need to provide employees with basic “security awareness” training.

HAZMAT SECURITY TRAINING FOR RIPA MEMBERS (CONTINUED) Employees must be advised that hazardous materials, hazmat packagings and/or packagings with residues of hazmat could be used by groups or individuals to cause deliberate harm. Employees that suspect someone in the plant or who is a party to any transaction or shipment might be planning malicious use of hazardous materials or hazmat packagings should immediately inform their supervisor.

FUNCTION SPECIFIC TRAINING Know Your Hazmat Responsibilities Specific skills and knowledge are needed to perform certain critical jobs in the plant. These jobs include Leakproofness testing Design type testing (if applicable) Periodic testing and retesting IBCs Post-production container inspection Every employee doing one of these jobs much receive specific training on these tasks. New employees that have not been formally trained, must be supervised.

PRODUCTION TESTING OF DRUMS AND IBCS The level of pressure applied depends on the performance rating of the drum or IBC: X, Y or Z. Generally, the higher the rating (for instance “X”), the higher the pressure used to test. Your employer will instruct you on exactly how to operate the tester at your workstation, e.g. how long to hold pressure, what to do with containers that fail the test, etc. Plants that use pressure differential testers must be sure employees know how to check to determine if the machine is working properly every shift.

“DESIGN-TYPE” TESTING (NON-BULK PACKGINGS) Design type tests are used to qualify (certify) a packaging design as a “UN” packaging for hazmat use. For drums, these tests are: Drop Test Hydrostatic Pressure Test Leakproofness Test Stacking Test Vibration Test

RECORDKEEPIN G: REQUIRED ELEMENTS OF A DESIGN TYPE TEST REPORT Company name and address Test report number; Date of the test report; Manufacturer of the packaging; Description of the packaging which may include drawing(s) or photographs; Maximum capacity of the container; Characteristics of test contents, e.g., viscosity and relative density for liquids; Description of testing procedure and results. Signature of person performing the test

DRUM RECONDITIONING Drum reconditioning includes the following functions: Label removal Cleaning (e.g. washing, furnacing) shot blast (for steel drums) Application of interior lining/exterior paint Leakproofness test Application of UN Mark

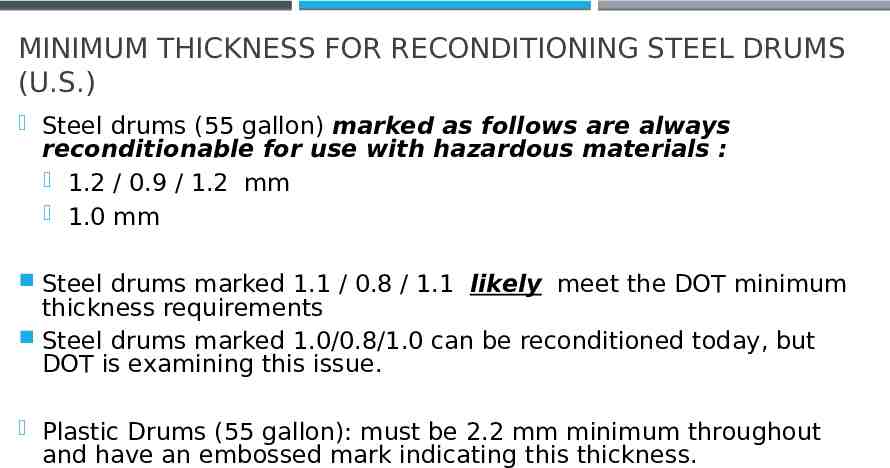

MINIMUM THICKNESS FOR RECONDITIONING STEEL DRUMS (U.S.) Steel drums (55 gallon) marked as follows are always reconditionable for use with hazardous materials : 1.2 / 0.9 / 1.2 mm 1.0 mm Steel drums marked 1.1 / 0.8 / 1.1 likely meet the DOT minimum thickness requirements Steel drums marked 1.0/0.8/1.0 can be reconditioned today, but DOT is examining this issue. Plastic Drums (55 gallon): must be 2.2 mm minimum throughout and have an embossed mark indicating this thickness.

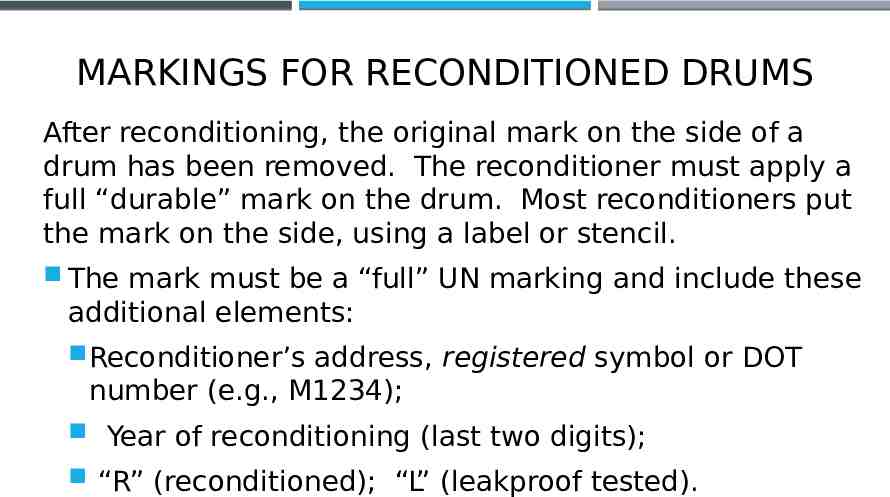

MARKINGS FOR RECONDITIONED DRUMS After reconditioning, the original mark on the side of a drum has been removed. The reconditioner must apply a full “durable” mark on the drum. Most reconditioners put the mark on the side, using a label or stencil. The mark must be a “full” UN marking and include these additional elements: Reconditioner’s address, registered symbol or DOT number (e.g., M1234); Year of reconditioning (last two digits); “R” (reconditioned); “L” (leakproof tested).

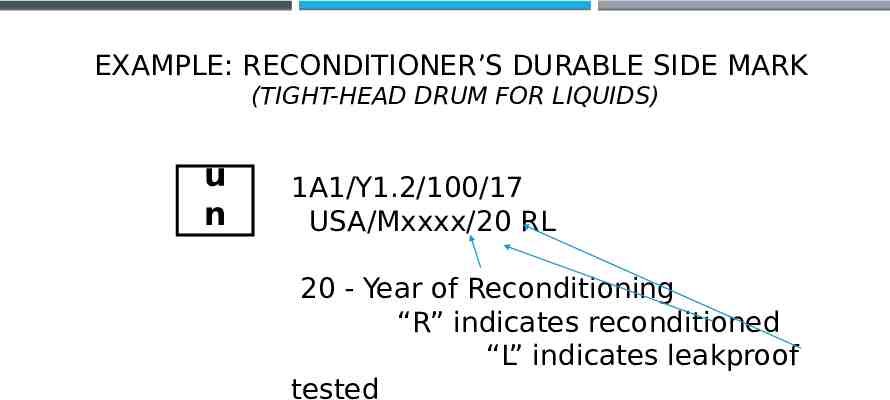

EXAMPLE: RECONDITIONER’S DURABLE SIDE MARK (TIGHT-HEAD DRUM FOR LIQUIDS) u n 1A1/Y1.2/100/17 USA/Mxxxx/20 RL 20 - Year of Reconditioning “R” indicates reconditioned “L” indicates leakproof tested

THERE ARE THREE (3) TYPES OF IBC “REPROCESSIN G” Routine Maintenance Repair Re-manufacturing

FOR A COMPLETE EXPLANATION OF IBC REPROCESSING, DOWNLOAD RIPA’S IBC COMPLIANCE MANUAL: 2020 (WEB SITE) “Routine maintenance” is cleaning and restoration of certain noncontainment parts like legs. Following routine maintenance, a reconditioner must replace the full original mark and add the following marks and perform a “leaktightness” test Country Code (“USA”) Name or symbol or DOT number of the company Example: USA / M1234

COMPOSITE IBC “REPAIR” Replace damaged inner receptacles with ones conforming to the original IBC manufacturer's specification. After replacing the inner receptacle, conduct a leakproofness test on the repaired IBC. Record the date of the test . New replacement inner receptacles come already tested! US DOT issues a Special Permit (SP) to reconditioners that eliminates the need to perform a leakproofness test on a new inner receptacle.

MARKING “REPAIRED” COMPOSITE IBCS Re-apply the original mark Apply a “reprocessing” mark near the original mark with the following elements: Country in which reprocessing took place (“USA”) Name, symbol or “M” number of reprocessor Month/year of leakproofness test Example: USA / M1234 / 01/20

IBC “REMANUFACTURING” OR “CROSS-BOTTLING” IBC “remanufacturing” generally refers to a process by which reconditioners pair a bottle and a cage from different IBC manufacturers. Most reconditioners call this process “cross bottling.” Remanufactured IBCs must pass a full “design-type” test every year. Remanufactured IBCs must be fully marked as if new by the reconditioner.

Some reconditioners will generate as part of operations certain waste that is regulated as hazardous by the U.S. Environmental Protection Agency. SHIPMENTS OFF-SITE OF HAZARDOUS WASTE Reconditioners must either know that the material sent off-site is hazardous waste and manage it properly or test the material for hazardous waste characteristics (by TCLP test). Training, shipping and other rules could apply, depending on volumes.

EMPLOYER RECORDKEEPING FOR TRAINED HAZMAT EMPLOYEES Employers are required by DOT to maintain up-to-date records of hazmat employee training. These records are among the first things that DOT inspectors will ask for when conducting enforcement visits. Make sure your training records include a training certificate and are retained in one file. At least two people at your company should know where this file is kept.

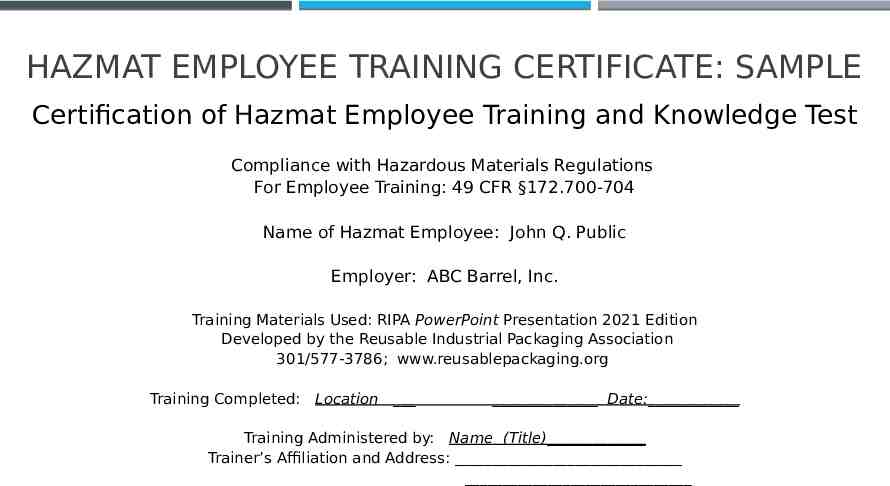

HAZMAT EMPLOYEE TRAINING CERTIFICATE: SAMPLE Certification of Hazmat Employee Training and Knowledge Test Compliance with Hazardous Materials Regulations For Employee Training: 49 CFR §172.700-704 Name of Hazmat Employee: John Q. Public Employer: ABC Barrel, Inc. Training Materials Used: RIPA PowerPoint Presentation 2021 Edition Developed by the Reusable Industrial Packaging Association 301/577-3786; www.reusablepackaging.org Training Completed: Location Date: Training Administered by: Name (Title) Trainer’s Affiliation and Address:

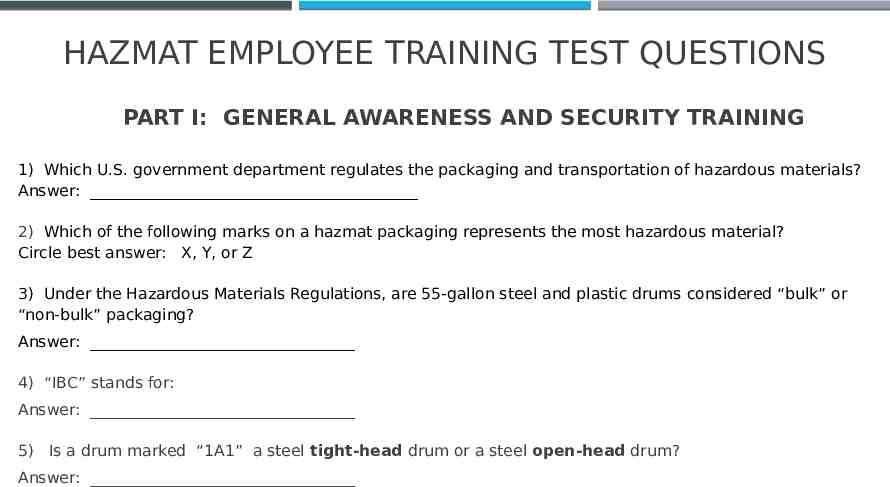

HAZMAT EMPLOYEE TRAINING TEST QUESTIONS PART I: GENERAL AWARENESS AND SECURITY TRAINING 1) Which U.S. government department regulates the packaging and transportation of hazardous materials? Answer: 2) Which of the following marks on a hazmat packaging represents the most hazardous material? Circle best answer: X, Y, or Z 3) Under the Hazardous Materials Regulations, are 55-gallon steel and plastic drums considered “bulk” or “non-bulk” packaging? Answer: 4) “IBC” stands for: Answer: 5) Is a drum marked “1A1” a steel tight-head drum or a steel open-head drum? Answer:

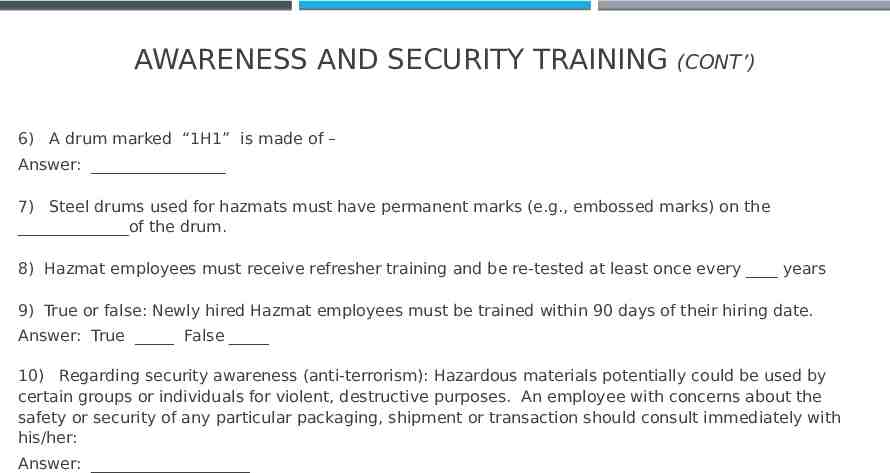

AWARENESS AND SECURITY TRAINING (CONT’) 6) A drum marked “1H1” is made of – Answer: 7) Steel drums used for hazmats must have permanent marks (e.g., embossed marks) on the of the drum. 8) Hazmat employees must receive refresher training and be re-tested at least once every years 9) True or false: Newly hired Hazmat employees must be trained within 90 days of their hiring date. Answer: True False 10) Regarding security awareness (anti-terrorism): Hazardous materials potentially could be used by certain groups or individuals for violent, destructive purposes. An employee with concerns about the safety or security of any particular packaging, shipment or transaction should consult immediately with his/her: Answer:

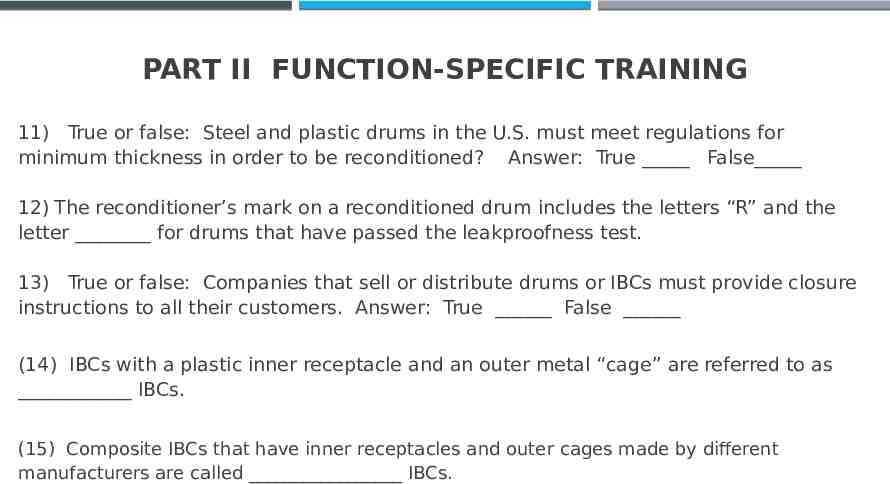

PART II FUNCTION-SPECIFIC TRAINING 11) True or false: Steel and plastic drums in the U.S. must meet regulations for minimum thickness in order to be reconditioned? Answer: True False 12) The reconditioner’s mark on a reconditioned drum includes the letters “R” and the letter for drums that have passed the leakproofness test. 13) True or false: Companies that sell or distribute drums or IBCs must provide closure instructions to all their customers. Answer: True False (14) IBCs with a plastic inner receptacle and an outer metal “cage” are referred to as IBCs. (15) Composite IBCs that have inner receptacles and outer cages made by different manufacturers are called IBCs.

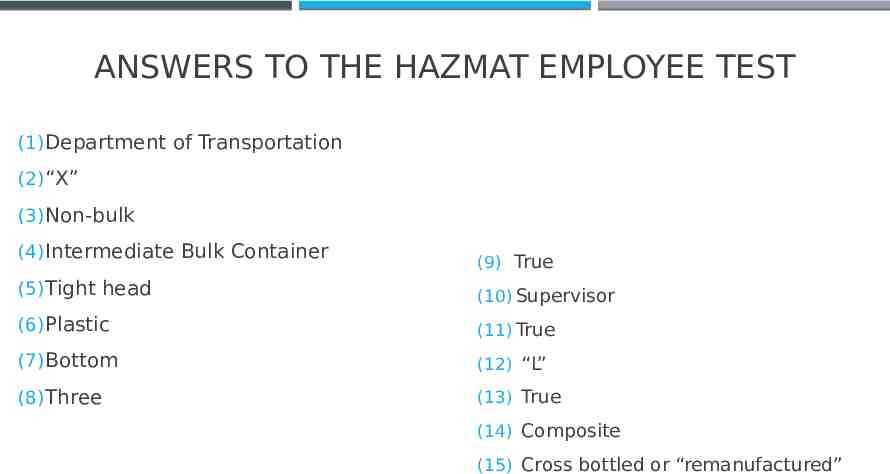

ANSWERS TO THE HAZMAT EMPLOYEE TEST (1) Department of Transportation (2) “X” (3) Non-bulk (4) Intermediate Bulk Container (9) True (5) Tight head (10) Supervisor (6) Plastic (11) True (7) Bottom (12) “L” (8) Three (13) True (14) Composite (15) Cross bottled or “remanufactured”

TRAINING CERTIFICATES Training Certificates are personalized for each attendee. They should go into each attendee’s personnel file with a copy into a facility-wide file for all training records.