Hazard Control Technologies, Inc. & Energetech, LLC Presents

66 Slides3.10 MB

Hazard Control Technologies, Inc. & Energetech, LLC Presents

F-500 “Micelle Encapsulator Technology” The new chemistry in fire, vapor, and contamination control

Who is Hazard Control Technologies ?

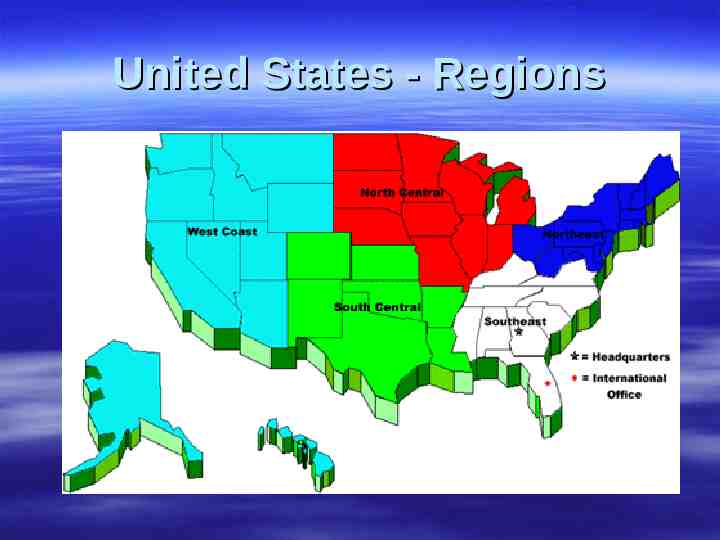

Hazard Control Technologies (HCT) World Headquarters (Atlanta, GA) – General Administrative – Sales and Marketing – Engineering and Design Services – Customer Field Support Services – Manufacturing Worldwide Distributor Organization Web-site – http://www.hct-world.com

United States - Regions

ISO 9001: 2000 Quality System Registration International Organization of Standards; supported by 120 countries Assures consistent, reproducible, and traceable quality and reliability of the design, manufacturing process, and product Registered through FM Approvals, a division of FM Global (recognized leader in fire protection industry) Only 7.6% of U.S. companies are ISO 9001 registered

What is F-500 ?

F-500 F-500 is a multi-purpose Class A & B fire suppression and flammable liquid spill control agent. F-500 is listed on the US EPA NCP product schedule.{National Contingency Plan} F-500 emerging technology is classified under a new NFPA standard currently being developed. – Water Additives for Fire Suppression and vapor Mitigation

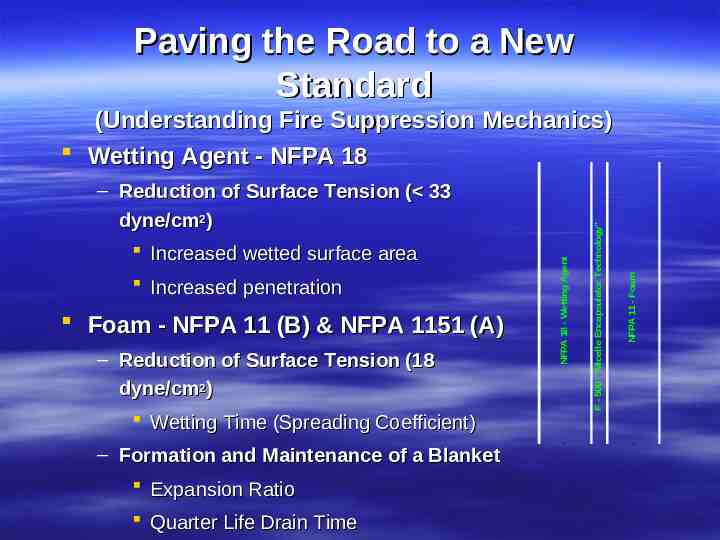

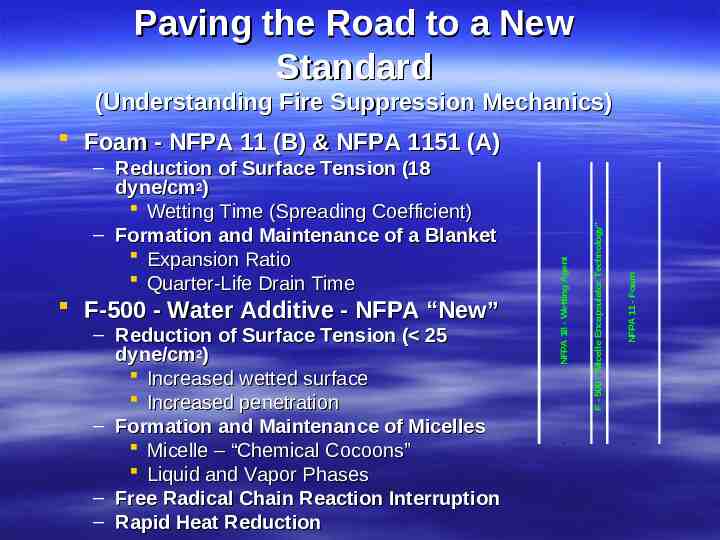

Paving the Road to a New Standard Foam - NFPA 11 (B) & NFPA 1151 (A) – Reduction of Surface Tension (18 dyne/cm2) Wetting Time (Spreading Coefficient) – Formation and Maintenance of a Blanket Expansion Ratio Quarter Life Drain Time NFPA 11 - Foam Increased penetration F - 500 "Micelle Encapsulator Technology" – Reduction of Surface Tension ( 33 dyne/cm2) Increased wetted surface area NFPA 18 - Wetting Agent (Understanding Fire Suppression Mechanics) Wetting Agent - NFPA 18

Paving the Road to a New Standard (Understanding Fire Suppression Mechanics) – Reduction of Surface Tension ( 25 dyne/cm2) Increased wetted surface Increased penetration – Formation and Maintenance of Micelles Micelle – “Chemical Cocoons” Liquid and Vapor Phases – Free Radical Chain Reaction Interruption – Rapid Heat Reduction NFPA 11 - Foam F-500 - Water Additive - NFPA “New” F - 500 "Micelle Encapsulator Technology" – Reduction of Surface Tension (18 dyne/cm2) Wetting Time (Spreading Coefficient) – Formation and Maintenance of a Blanket Expansion Ratio Quarter-Life Drain Time NFPA 18 - Wetting Agent Foam - NFPA 11 (B) & NFPA 1151 (A)

Historical Development of Water Additives Technical Committee 1997 - Foam Technical Committee oversaw both – NFPA 11 – Foam – NFPA 18 – Wetting Agents 1997-1998 - HCT Solicited NFPA Standards Council that a new group of agents exist whose fire suppression mechanics are different and do not fall into either category 1999 - NFPA Standards Council formed new Technical Committee – Water Additives for Fire Control and Vapor Mitigation

F-500 Water Additive Characteristics F-500 is not a Foam !!! F-500 Does not rely of the formation and maintenance of a foam blanket Superior Heat Reduction (******) Superior Penetration Capabilities Superior Smoke Reduction Ideal agent for 3-dimensional type applications

F-500 Applications Fire Extinguishment – Class A Fires – Class B Fires Polar Solvents Non-Polar Solvents Fire Extinguishers Surface Washing, Soil Washing / Bio Remediation Enhancement Hazardous Spill Control Vapor Suppression

F-500 Class A Fire - Applications Wood / Paper Cotton Hay / Straw / Grain Coal Coconut Fiberglass Plastics (PVC, HDPE, Etc.) Rubber Tires

F-500 Class B Fire - Applications Non-Polar Solvents (Hydrocarbons) – Gasoline / Diesel – Jet A / JP4 / JP5 / JP8 – Crude / Oils Polar Solvents – Isopropyl Alcohol – Methanol – Methyl Ethyl Ketone – MTBE Rubber Tires

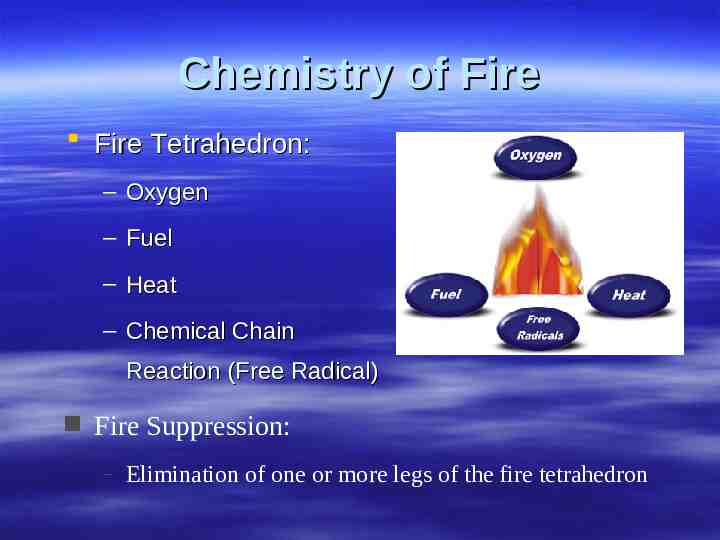

Chemistry of Fire Fire Tetrahedron: – Oxygen – Fuel – Heat – Chemical Chain Reaction (Free Radical) Fire Suppression: – Elimination of one or more legs of the fire tetrahedron

Fire Suppression Mechanics for Class A and B Fires Foam – – Surface Tension Reduction Formation and Maintenance of a Blanket Oxygen F-500 – – – Surface Tension Reduction Formation and Maintenance of Micelles Interrupt Free Radical Chain Reaction Fuel Heat Free Radical F-500 works simultaneously on three legs of the fire tetrahedron

F-500 Fire Suppression Mechanics Surface Tension Reduction – Reduce from 72 dynes/cm to less than 33 dynes/cm – Increases wetted surface area and penetration – Acts as a carrier of the F-500 molecules that form micelles Micelle Formation and Maintenance Interruption of Chemical Chain Reaction

High Surface Tension Illustration Example of High Surface Tension – Waxed Car – The water on the right has beaded up due to the high surface tension of the water molecule. Conversely, F-500 reduces the surface tension

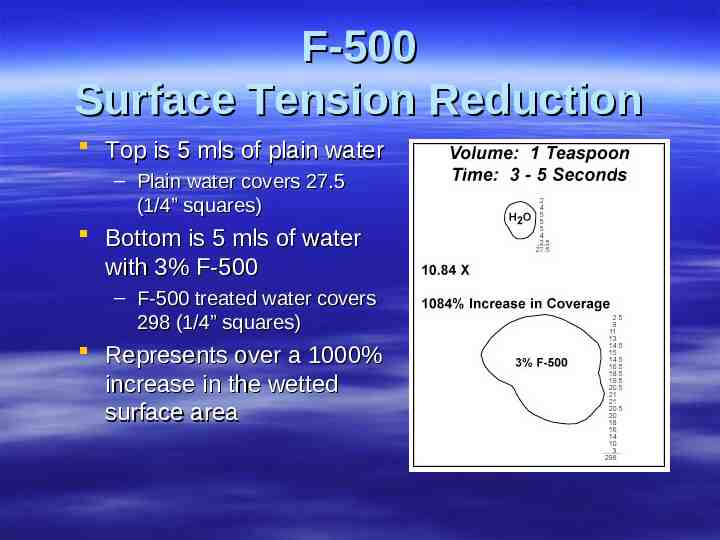

F-500 Surface Tension Reduction Top is 5 mls of plain water – Plain water covers 27.5 (1/4” squares) Bottom is 5 mls of water with 3% F-500 – F-500 treated water covers 298 (1/4” squares) Represents over a 1000% increase in the wetted surface area

F-500 Extinguishment Power If: – One (1) gallon of plain water equals one (1) fire extinguishment unit Then: – One (1) gallon of water with F-500 equals twenty (20) to thirty (30) fire extinguishment units Why twenty (20) to thirty (30) ?

Application to a Fire Materials have pores like the pores in your skin – – – – – Coal Wood Cotton Paper Steel In addition to 10 times the wetted surface area F-500’s reduced surface tension allows penetration into the pores One contributing factor to rapid reduction of heat

Fire Tetrahedron Components * * ** * * * * Free Radicals Oxygen Heat Fuel

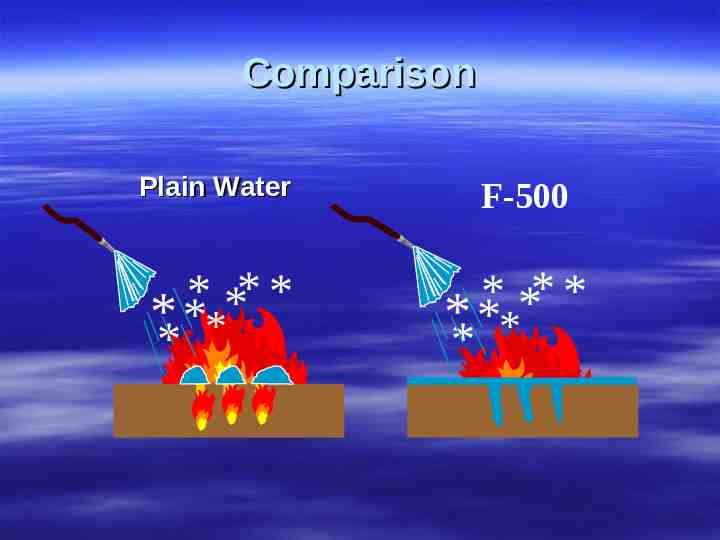

Comparison Plain Water * * * * ** ** F-500 * * * * ** **

Comparison Plain Water * * * * ** ** F-500 * * * * ** **

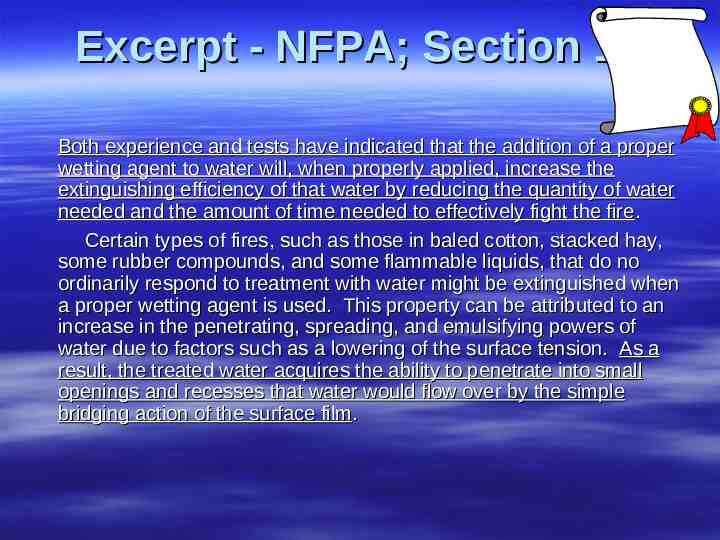

Excerpt - NFPA; Section 18 Both experience and tests have indicated that the addition of a proper wetting agent to water will, when properly applied, increase the extinguishing efficiency of that water by reducing the quantity of water needed and the amount of time needed to effectively fight the fire. Certain types of fires, such as those in baled cotton, stacked hay, some rubber compounds, and some flammable liquids, that do no ordinarily respond to treatment with water might be extinguished when a proper wetting agent is used. This property can be attributed to an increase in the penetrating, spreading, and emulsifying powers of water due to factors such as a lowering of the surface tension. As a result, the treated water acquires the ability to penetrate into small openings and recesses that water would flow over by the simple bridging action of the surface film.

F-500 Fire Suppression Mechanics Surface Tension Reduction Micelle Formation and Maintenance – Amphipathic Molecule – F-500 molecules align to form a “chemical cocoon” around hydrocarbon molecules Interruption of Free Radical Chain Reaction

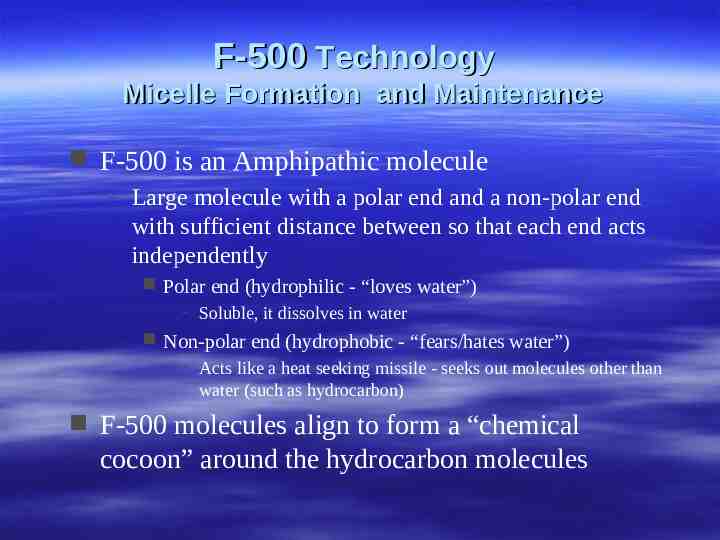

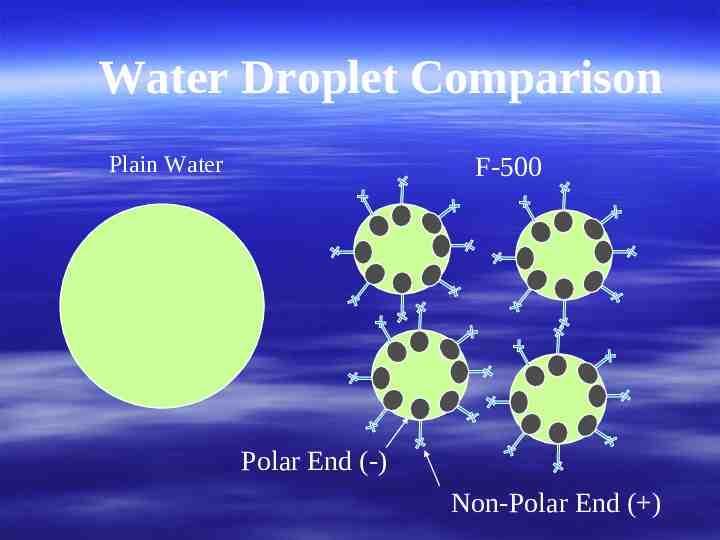

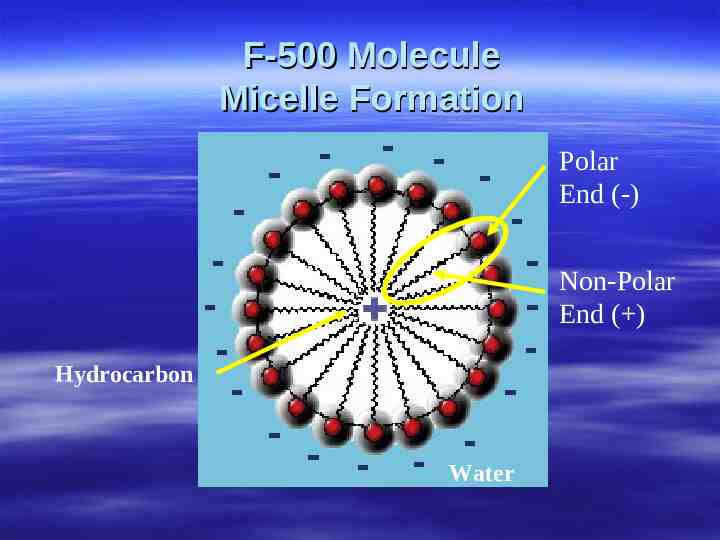

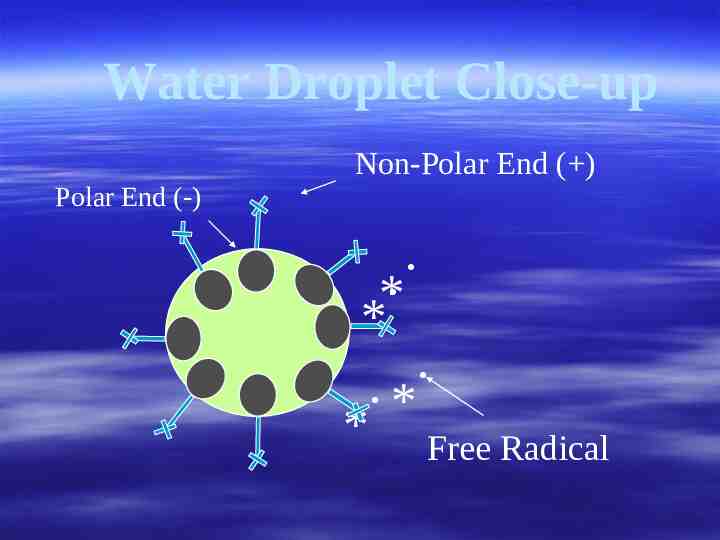

F-500 Technology Micelle Formation and Maintenance F-500 is an Amphipathic molecule – Large molecule with a polar end and a non-polar end with sufficient distance between so that each end acts independently Polar end (hydrophilic - “loves water”) – Non-polar end (hydrophobic - “fears/hates water”) – Soluble, it dissolves in water Acts like a heat seeking missile - seeks out molecules other than water (such as hydrocarbon) F-500 molecules align to form a “chemical cocoon” around the hydrocarbon molecules

Water Droplet Comparison Plain Water F-500 Polar End (-) Non-Polar End ( )

F-500 Molecule Micelle Formation Polar End (-) Non-Polar End ( ) Hydrocarbon Water

Introduction of Micelles * * * * * *

F-500 Fire Suppression Mechanics Surface Tension Reduction Micelle Formation and Maintenance Interruption of Free Radical Chain Reaction – F-500 high molecular weight molecule absorbs energy – F-500 inhibits coalescence of free radicals Reduction of smoke

Water Droplet Close-up Non-Polar End ( ) Polar End (-) . .* * . .* * Free Radical

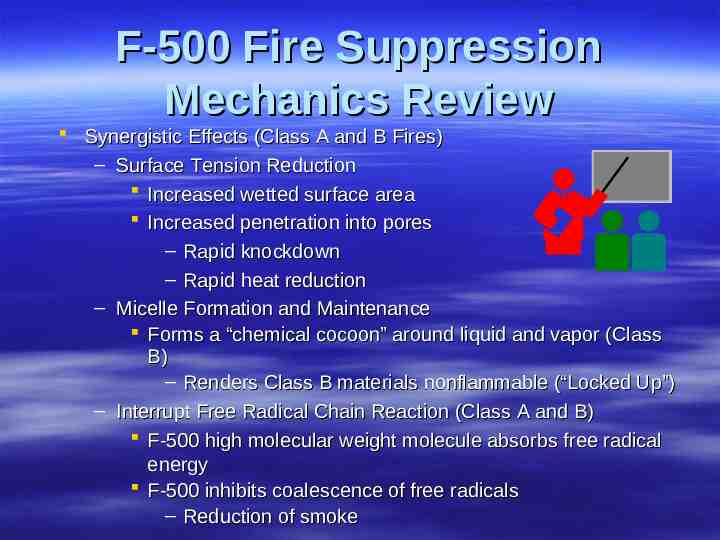

F-500 Fire Suppression Mechanics Review Synergistic Effects (Class A and B Fires) – Surface Tension Reduction Increased wetted surface area Increased penetration into pores – Rapid knockdown – Rapid heat reduction – Micelle Formation and Maintenance Forms a “chemical cocoon” around liquid and vapor (Class B) – Renders Class B materials nonflammable (“Locked Up”) – Interrupt Free Radical Chain Reaction (Class A and B) F-500 high molecular weight molecule absorbs free radical energy F-500 inhibits coalescence of free radicals – Reduction of smoke

F-500 Features and Benefits “ The New Standard ”

F-500 “The Engineered Advantage” UL listed for Class A & B Fast extinguishment time Rapid heat reduction Smoke dissipation / Increase in visibility Eliminates vapors

F-500 Equipment and Application Procedures F-500 has been examined and found to comply with the applicable requirements in the Standard for Foam Equipment and Liquid Concentrates, UL 162 – F-500 is listed for use in standard foam equipment eductors (in-line, by-pass, etc.) proportioners (on board, around the pump, etc.) premix F-500 is UL listed for Class A and Class B fires at 1%, 3%, and 6% . F-500 can be used with both fresh and salt water – Corrosion effect of salt water would apply if used with salt water

F-500 “The Engineered Advantage” UL listed for Class A & B Fast extinguishment time Rapid heat reduction Smoke dissipation / Increase in visibility Eliminates vapors

Fast Extinguishment Time Less liability and risk to firefighters, owners, and insurance companies Less economical losses to the owner – When fire burns it causes damage Uses less Product and Water – Product and Water use is a function of extinguishment time Less clean-up cost Less wear and tear on equipment Independently documented by: – Major Oil Company / Reno Fire Dept.

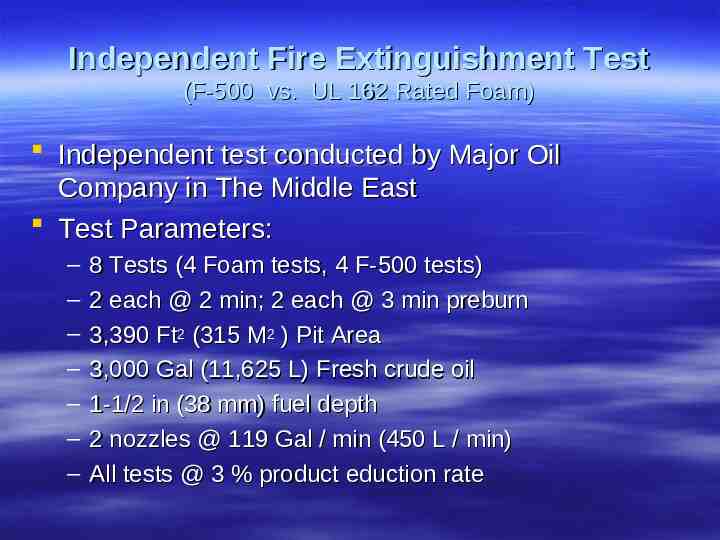

Independent Fire Extinguishment Test (F-500 vs. UL 162 Rated Foam) Independent test conducted by Major Oil Company in The Middle East Test Parameters: – – – – – – – 8 Tests (4 Foam tests, 4 F-500 tests) 2 each @ 2 min; 2 each @ 3 min preburn 3,390 Ft2 (315 M2 ) Pit Area 3,000 Gal (11,625 L) Fresh crude oil 1-1/2 in (38 mm) fuel depth 2 nozzles @ 119 Gal / min (450 L / min) All tests @ 3 % product eduction rate

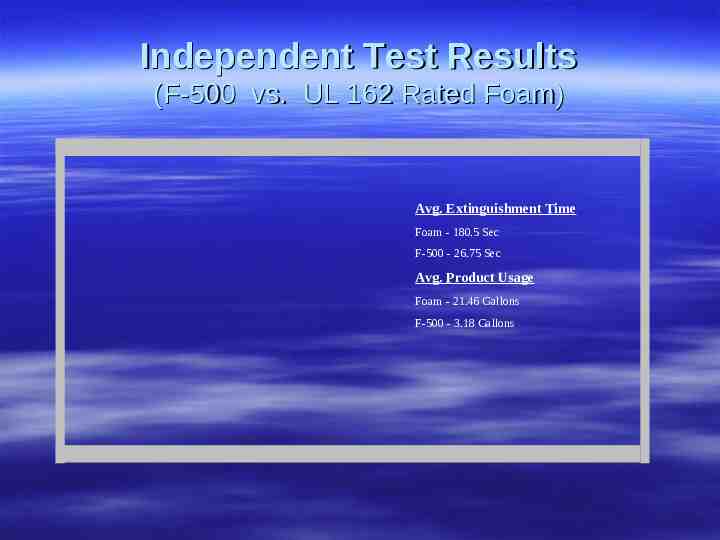

Independent Test Results (F-500 vs. UL 162 Rated Foam) Avg. Extinguishment Time Foam - 180.5 Sec F-500 - 26.75 Sec Avg. Product Usage Foam - 21.46 Gallons F-500 - 3.18 Gallons

F-500 “The Engineered Advantage” UL listed for Class A & B Fast extinguishment time Rapid heat reduction Smoke dissipation / Increase in visibility Eliminates vapors

Fire Fact Heat and Smoke – Eliminates #1 cause of death 80% of fire related fatalities are related to heat and/or smoke inhalation

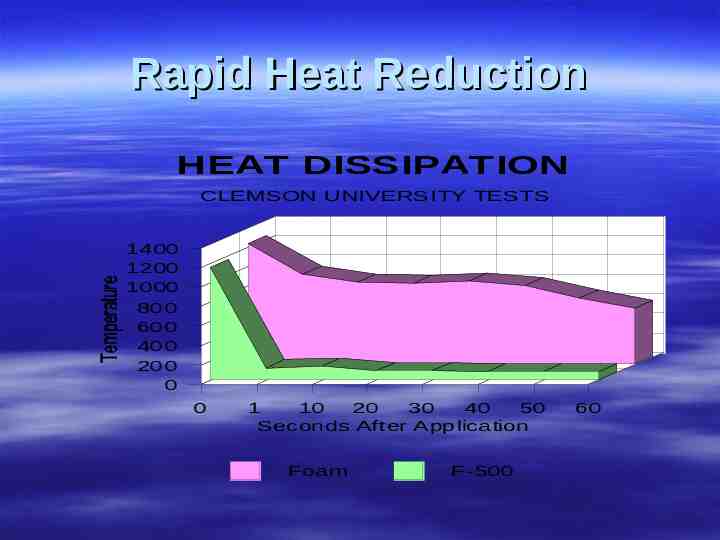

Rapid Heat Reduction HEAT DISSIPATION CLEMSON UNIVERSITY TESTS 1400 1200 1000 800 600 400 200 0 0 1 10 20 30 40 50 Seconds After App lication Foam F-500 60

Rapid Heat and Smoke Reduction Benefits Heat – Reduces the chance of spontaneous combustion of surrounding infrastructure – Allows closer, more aggressive and safer attack of the fire Faster extinguishment time Reduces heat exhaustion and injury

F-500 “The Engineered Advantage” UL listed for Class A & B Fast extinguishment time Rapid heat reduction Smoke dissipation / Increase in visibility Eliminates vapors

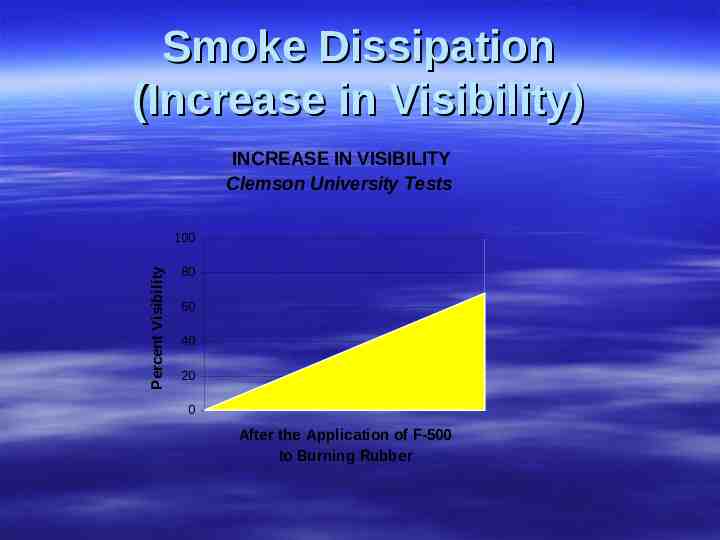

Smoke Dissipation (Increase in Visibility) INCREASE IN VISIBILITY Clemson University Tests Percent Visibility 100 80 60 40 20 0 After the Application of F-500 to Burning Rubber

Rapid Heat and Smoke Reduction Benefits Smoke – 68% increase in visibility provides a safer, more visual attack of the fire Can see potential life-threatening hazards Allows closer, more aggressive and safer attack of the fire – Tests show a 97% reduction of airborne toxic particulates of incomplete combustion – Reduced soot formation Indicates interruption of free radical chain reaction

F-500 “The Engineered Advantage” UL listed for Class A & B Fast extinguishment time Rapid heat reduction Smoke dissipation / Increase in visibility Eliminates vapors

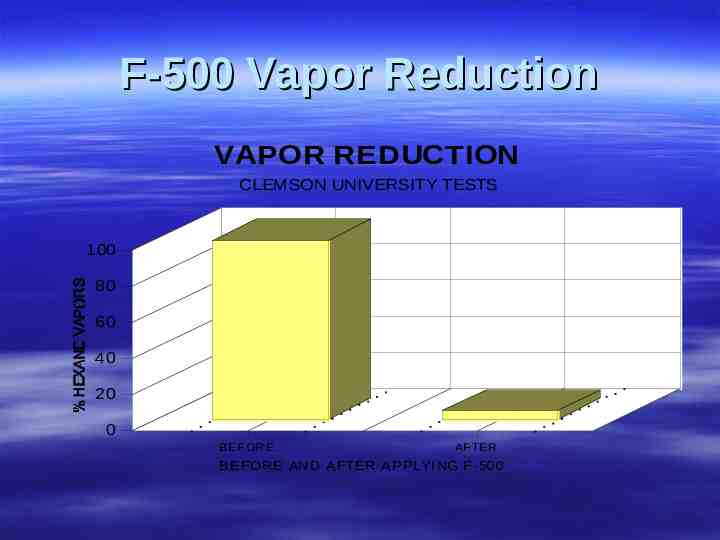

F-500 Vapor Reduction VAPOR REDUCTION CLEMSON UNIVERSITY TESTS 100 80 60 40 20 0 BEF OR E AF TER BEFO RE AN D AFTER APPLYI NG F -500

Rapid Vapor Mitigation F-500 “locks up” vapors Reduces explosion hazard Renders flammable liquids nonflammable Reduces burnback and flashover Shortens down time in tank cleaning operations Increases safety in firefighting, spill control, and tank cleaning Environmentally beneficial to ozone

F-500 “Engineered Environmental Advantages” Noncorrosive Nontoxic Nonhazardous 100% Fully Biodegradable

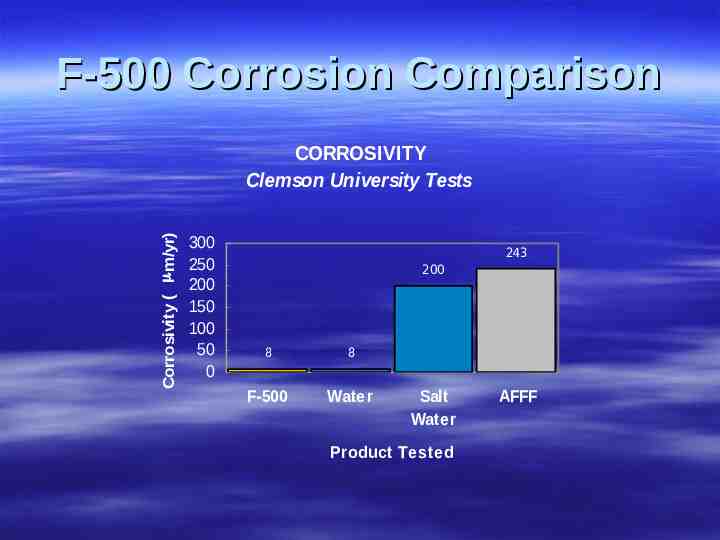

F-500 Corrosion Comparison Corrosivity ( m m/yr) CORROSIVITY Clemson University Tests 300 250 200 150 100 50 0 243 200 8 8 F-500 Water Salt Water Product Tested AFFF

F-500 Corrosion Benefits F-500 has no more corrosive effect on equipment than plain water F-500 is 30 times less corrosive than currently manufactured AFFF F-500 actually acts as a lubricant and cleaning agent to equipment Less corrosion damage to surrounding infrastructure

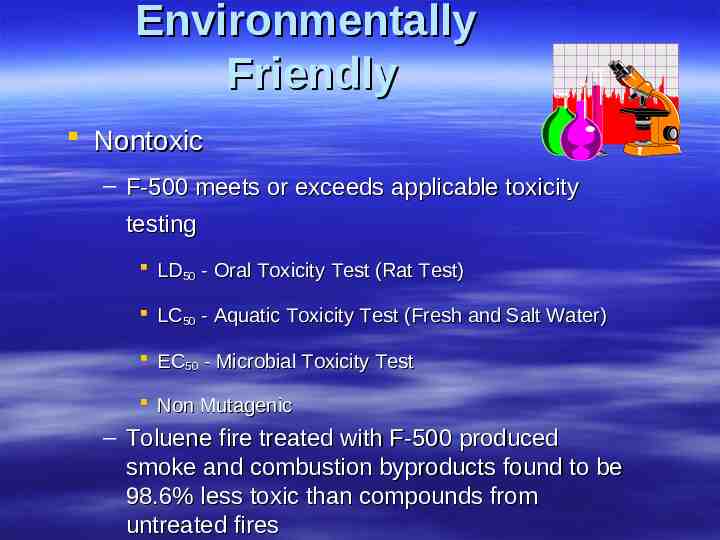

Environmentally Friendly Nontoxic – F-500 meets or exceeds applicable toxicity testing LD50 - Oral Toxicity Test (Rat Test) LC50 - Aquatic Toxicity Test (Fresh and Salt Water) EC50 - Microbial Toxicity Test Non Mutagenic – Toluene fire treated with F-500 produced smoke and combustion byproducts found to be 98.6% less toxic than compounds from untreated fires

Environmentally Friendly Nonhazardous – F-500 contains no ingredients reportable under the Superfund Amendment and Reauthorization Act (SARA) Title III, Section 313 of 40 CFR-372 or the Comprehensive Environmental Response, Compensation, and Liability Act (CERCLA) as of July 1, 1995 – F-500 is discarded as non-hazardous waste under RCRA CFR-261 Biodegradable – 100% fully biodegradable – F-500 BOD is 87% less and COD is 80% less than the AR-AFFF Environmentally Responsive Formulation

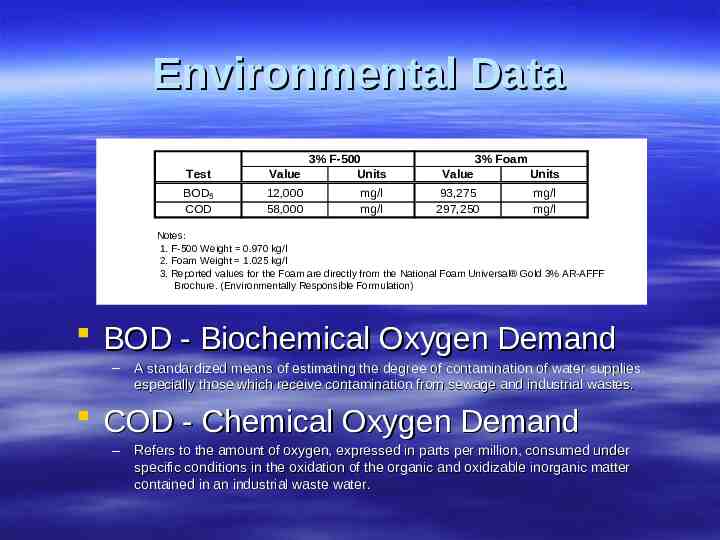

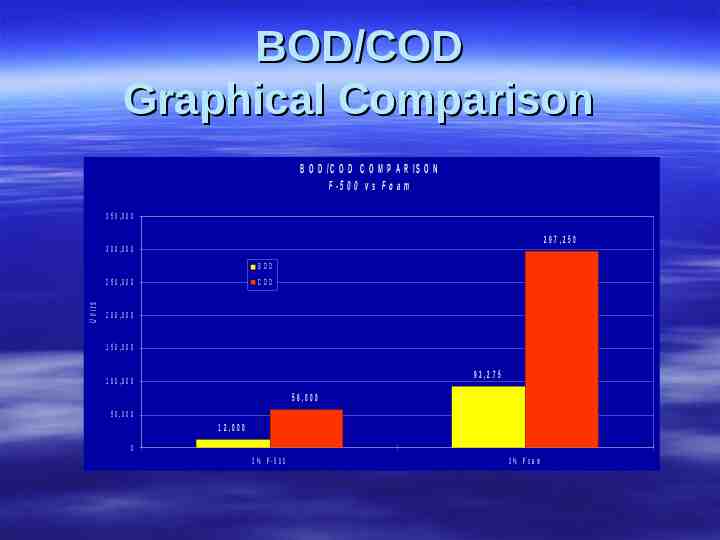

Environmental Data Test 3% F-500 Value Units BOD5 COD 12,000 58,000 mg/l mg/l 3% Foam Value Units 93,275 297,250 mg/l mg/l Notes: 1. F-500 Weight 0.970 kg/l 2. Foam Weight 1.025 kg/l 3. Reported values for the Foam are directly from the National Foam Universal Gold 3% AR-AFFF Brochure. (Environmentally Responsible Formulation) BOD - Biochemical Oxygen Demand – A standardized means of estimating the degree of contamination of water supplies, especially those which receive contamination from sewage and industrial wastes. COD - Chemical Oxygen Demand – Refers to the amount of oxygen, expressed in parts per million, consumed under specific conditions in the oxidation of the organic and oxidizable inorganic matter contained in an industrial waste water.

BOD/COD Graphical Comparison B O D /C O D C O M P A R IS O N F -5 0 0 v s F o a m 3 5 0 ,0 0 0 2 9 7 ,2 5 0 3 0 0 ,0 0 0 BOD U n its 2 5 0 ,0 0 0 COD 2 0 0 ,0 0 0 1 5 0 ,0 0 0 9 3 ,2 7 5 1 0 0 ,0 0 0 5 8 ,0 0 0 5 0 ,0 0 0 1 2 ,0 0 0 0 3% F-500 3% Foam

F-500 Growing Market Acceptance Municipal Fire Department Market – Class A & B Fire Suppression Applications – Class B Spill Control Applications Power Companies (Fixed Systems & Handline) – Coal Handling Systems (PRB Coal) – Turbines / Generator / Boiler / Transformers Petro-Chemical – – – – Class B Spill Control Applications Tank Cleaning & Devaporization Pipeline Cleaning & Devaporization Soil Washing

F-500 Growing Market Acceptance Rubber Tire Industry (Fixed Systems & Handline) – – – Production Lines & Areas Warehouse Storage Scrap Pile Storage Paper Industry (Fixed Systems & Handline) – Raw Material Stock Piles – Recycling Stock Piles – Hydraulic Pit Press Areas – Warehouse Storage Military – Structural Fire Fighting – Spill Control

F-500 Economical Advantages Fastest knockdown capability in the industry – Uses less product than foam – Less clean-up cost – Limits liquidated fire damage Demo Test Results Case Histories

The New Technology in Fire Protection FOAM UL 162 Test Protocols F-500 Being Developed by NFPA Technical Committee

Field Support Training: – Hazard Control Technologies, Inc. offer field training to client personnel in the safe, effective use of F-500 products and assist in the integration of our product into your existing training regimen. Technical: – Members of NFPA and sit on several technical committees.

F-500 “The New Standard” UL listed for existing foam equipment Fast extinguishment time Rapid heat and smoke dissipation Increase in visibility Eliminates vapors Noncorrosive Nontoxic Nonhazardous 100% biodegradable

Bottom Line If you’re not using F-500 you’re just playing with fire !!!

Distributor Contact Information ENERGETECH, LLC 7427 S. Main St. Midvale, UT 84047 (801) 566-5678 (800) 972-1736