Applying Irrigation Water in Circles (vs. squares) Why (briefly) 1)

55 Slides1.90 MB

Applying Irrigation Water in Circles (vs. squares) Why (briefly) 1) Economical 2) Low O & M 3) High Reliability 4) Central Delivery Point

Applying Irrigation Water in Circles (vs. squares) Why it’s a little trickier? In a rectangular system each sprinkler applies water to an Identically sized Area (A) In a circular system the area increases as the radius increases Hence, each sprinkler applies water to a differently sized Area (A) 1 2 1 2 3 A1 A2 A3 A4 3 4 4 A1 A2 A3 A4

How Does this Weigh up on a Typical System? (System Capacity 6 gpm / acre) Circle Area Computations Area π R2 Radius (ft.) Total Area (acres) Spoke Area (acres) Flow Required (gpm) 130 1.2 1.2 7.2 260 4.9 3.7 22.2 390 11.0 6.1 36.6 520 19.5 8.5 51.0 650 30.5 11.0 66.0 780 43.9 13.4 80.4 910 59.7 15.8 94.8 1040 78.0 18.3 109.8 1170 98.7 20.7 124.2 1300 121.8 23.1 138.6 Sprinklers are sized appropriately along length of pivot to maintain uniform applications along linear length of the center pivot machine

How Does this Weigh up on a Typical System? High Pressure

How Does this Weigh up on a Typical System? Medium Pressure

How Does this Weigh up on a Typical System? Low Pressure

Soil / Water Intake Curves 4.0 Intake Rate (in / hr) 3.0 1.0 Family 2.0 0.5 Family 0.3 Family 1.0 0.0 0.0 0.1 0.2 0.3 Time (hrs) 0.4 0.5

Sprinkler Pressure vs. Intake Characteristics Timed Rain Gauge Analysis Thunderstorm Intensity

Sprinkler Pressure vs. Intake Characteristics Timed Rain Gauge Analysis Thunderstorm Intensity Low Medium High Low Medium High

CPNozzle Program New Version Windows Version Similar Inputs Better Visualization Residue Component Estimates Surface Storage and Runoff

CPNOZZLE Important Variables Application Rate Soil Family Field Position of Soil Family Residue Amount Slope Sprinkler Radius of Throw RUN CPNOZZLE

GIS – Toolkit Applications .

CPNOZZLE Example Composite Worksheet Acres Spoke # 1 2 3 4 5 6 7 8 9 10 Family Potential Runoff % 0.3 Weighted Runoff Acres Family Potential Runoff % 0.5 Weighted Runoff Total Weighted Runoff Total Acres Potential Runoff Acres Family Potential Runoff % 1 Weighted Runoff

Irrigation System Design (Some Basic Concepts) Don’t Over - Complicate We Want To Get This FIELD WATER Up Here

Irrigation System Design (Some Basic Concepts) Don’t Over - Complicate We Want To Get This FIELD WATER Up Here

Irrigation System Design (Some Basic Concepts) 2 Important Parameters 1)Flow (most commonly given in gpm) Bucket–Fulls Per Unit Time 2)Pressure or Head (given in psi or ft. of water) Squirting Distance

FLOW DETERMINATION 1) Crop / Soil Requirements a) effective root zone b) soil texture 2) Field Size 3) Water Source Limitations a) physical b) by permit c) other

Crop Requirements (gpm / acre) From NDSU: “Selecting a Sprinkler Irrigation System” Table 1. System Capacity in gallons per minute per acre (gpm/acre) for different soil textures needed to supply sufficient water for each crop in 9 out of 10 years. An application efficiency of 80% and a 50% depletion of available soil water were used for the calculations. -----------------------------------------------------------Root Coarse Loam Zone Sand Fine and Depth and Loamy Sandy Sandy Silt Crop (ft) Gravel Sand Sand Loam Loam Loam -----------------------------------------------------------POTATOES* 2.0 8.2 7.5 7.0 6.4 6.1 5.7 DRY BEANS 2.0 7.9 7.1 6.4 6.1 5.7 5.4 SOYBEANS 2.0 7.9 7.1 6.4 6.1 5.7 5.4 CORN 3.0 7.3 6.6 5.9 5.5 5.3 4.9 SUGARBEETS 3.0 7.3 6.6 5.9 5.5 5.3 4.9 SMALL GRAINS 3.0 7.3 6.6 5.9 5.5 5.3 4.9 ALFALFA 4.0 6.8 5.9 5.6 5.1 5.0 4.5 -----------------------------------------------------------*Adjusted for 40% depletion of available water General Rule 6 gpm / acre

(Crop Requirement) x (Field Size) Flow Requirement EXAMPLE (6 gpm / acre) x (125 acres) 750 gpm (Not Written in Stone but good guidelines to follow) May also be physical or permit demanded constraints on pumping rate which dictate

PRESSURE or HEAD 4 Main Considerations 1) To offset Elevation difference between source and delivery point 2) To compensate for Friction losses in the mainline delivery system 3) System Operational Requirements 4) Other Minor losses

Elevation Difference between water source and point of distribution Vertical distance between pumping water surface and the field delivery point (for center pivots use the highest point in the irrigated field for conservative calculations) Example 50 feet Surface Water Ground Water

Friction Losses Most friction losses in irrigation systems are developed in the system mainline (transmission pipeline) (Significant friction loss also occurs in the pivot itself but Is usually calculated and included as part of the operational pressure requirements) Transmission Pipeline Most often PVC but may also be aluminum, steel or PE

Friction Losses Important factors in the calculation pipe friction loss are: Pipe Inside Diameter (id) Pipe Material Pipe Length Fluid Velocity or Flow Rate Friction loss is typically calculated using one of several common equations: (Hazen Williams equation or Darcy equation)

Friction Losses Hazen Williams Equation H 10.44LQ1.85 C1.85d4.87 Where: H head loss from friction (ft.) L length of pipe (ft.) Q flow (gpm) C friction factor (140 – 150 for PVC pipe higher number means smoother pipe) d inside diameter of pipe (in.)

Friction Losses Hazen Williams Equation H 10.44LQ1.85 C1.85d4.87 Example If 750 gpm is flowing through 1500 feet of new 8 inch ID PVC pipe the friction loss will be {10.44 x (1500) x (750)1.85 } / {(150)1.85 x (8)4.87} 12.3 feet

Operational Pressure Requirements At the Center Pivot Consist of: 1) Pressure necessary to operate sprinklers and regulators satisfactorily (5 psi or greater above rated pressure of regulator) 2) Friction losses incurred in span pipe Calculation is usually combined together with sprinkler package spreadsheet Requirements are commonly given at pivot point location Elevation differences along pivot may also be included Example pivot point requirement: 45 psi @ 750 gpm

Minor Losses The majority of minor losses which will increase the overall head requirement can be caused by: 1) Small friction losses which occur due to fittings and deviations in pipeline alignment 2) Extra losses through pump and suction pipe 3) Friction loss incurred in well tubing 4) Other In large pipeline networks minor losses can be a substantial portion of the total head requirement Typically in irrigation systems minor losses are not a large part of the total head requirement – Often times it is good enough to simply add 5 to 10 feet to the final head calculation as an adjustment for any minor losses which may occur in the system

Example Pressure Totals 1) Elevation Head 50 ft. 2) Friction losses in the mainline delivery system 12.3 ft. 3) System Operational Requirements 45 psi or 104 ft. (2.3 ft. of water 1 psi) 4)Minor losses estimate 10 ft. Total Dynamic Head 176 ft.

PUMP SELECTION Total Dynamic Head (ft.) 225 Full Impellor 10% Trim 85% 20% Trim 176 82% 30% Trim 79% 0 750 Flow (gpm) 1250

PUMP SELECTION Total Dynamic Head (ft.) 225 85% 20% Trim 82% 79% 0 1250 Flow (gpm)

PUMP STUFF 1) Pumps DO NOT make pressure (only flow) The system to which the pump is attached creates resistance to flow (pressure) 2) Pump speed is proportional to output (flow) but the head that a pump can resist is proportional to the square of speed. (which means changing speed changes pump flow reasonably but changes head characteristics a whole bunch) (pump affinity laws) 3) Typically slower running pumps are used for low head - high volume applications. 4) Common speeds for irrigation pumps: 1200 RPM (flood pumps), 1800 RPM (sprinklers with moderate head requirements), 3600 RPM (sprinklers with high head requirements).

POWER REQUIREMENTS Horsepower Required TDH x Q 3954 x n Where n wire to water efficiency (pump efficiency minus a little good first guess is .75) EXAMPLE {(176 ft.) x (750 gpm)} / {3954 x .75} 44.3 hp

CPED PROGRAM 1) Rewritten for use by NRCS in EQIP program 2) Evaluates sprinkler package coefficient of uniformity (must be at least 85% according to NRCS sprinkler standard) 3) Uses pump input parameters to give an entire system evaluation 4) Sprinkler inputs set up similar to OUTLETS program RUN CPED

IRRIGATION WATER MANAGEMENT By the Checkbook Method 1) Treats soil profile as a checkbook 2) Water is the 3) Inputs and outputs are measured or estimated and the balance is tracked throughout the growing season 4) Can be tracked by hand, in a spreadsheet or with other software

Checkbook Account Transfers Evapotranspiration (Withdrawal) Irrigation (Deposit) Soil Profile (Account Balance) Rain (Deposit) Deep Percolation (Withdrawal)

IRRIGATION SCHEDULING by the CHECKBOOK METHOD NDSU software 1) Baled Lotus spreadsheet which tracks soil depletion throughout growing season 2) Estimates crop water use based on daily high temperature input and days past emergence of particular crop 3) Soil available water inputs are entered at setup 4) Contains historical weather record for several sites in ND and MN. 5) Actual soil water measurements can be entered to keep record closer to actual RUN IRRIGATION

EQIP Irrigation Water Management Plan Worksheet Example

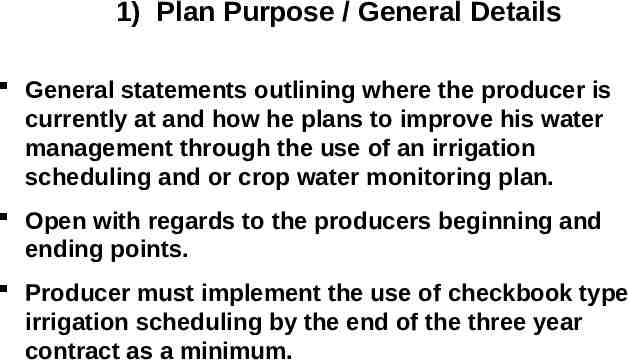

1) Plan Purpose / General Details General statements outlining where the producer is currently at and how he plans to improve his water management through the use of an irrigation scheduling and or crop water monitoring plan. Open with regards to the producers beginning and ending points. Producer must implement the use of checkbook type irrigation scheduling by the end of the three year contract as a minimum.

2) System Capacity / Field Information Flow(gpm) 750 Total Area(acres) 132 System Efficiency(%) 75 Daily Application Rates at efficiency Daily application rate at 100% efficiency (in / day) (0.053) x Flow(gpm) / Area(acres) 100% 0.30 90% 0.27 80% 0.24 70% 0.21

3) Soils Information Farland Grail Stady Bryant Field Acreage 46 44 38 2 Field Percentage 35.4 33.9 29.2 1.5 Irrigation Group 8c 10c 6i 8c Top 1 foot 2.5 2.5 2.5 2.5 Top 2 feet 4.5 4.5 4.5 4.5 Top 3 feet 6.5 6.5 5.5 6.5 Top 4 feet 8.5 8.5 6.0 8.5 Top 5 feet 10 10.5 6.5 10.0 Soil Name Cumulative Available Water to depth (in.)

4) Crop Data 2006 2007 2008 Crop Corn Potato Wheat Full Rooting Depth (ft.) 4.0 2.0 3.5 Suggested MAD (%)* 50 40 50 Avg. Annual Water Use 25.9 23.2 18.8 Est. annual no. days crop water use exceeds system capacity 25 23 18 Year

Rain or Soil Water Dependant System can meet Crop Requirements @ 80% eff. 0.35 0.3 0.25 0.2 0.15 0.1 Date 9/18 9/4 8/21 8/7 7/24 7/10 6/26 6/12 5/29 0.05 0 5/15 Corn ET (in. / day) Robinson, ND Corn Crop Water Use 2000-2004 averages vs. 5.8 GPM / Acre

5) Water Management Plan 2006 2007 2008 Corn Potato Wheat Farland Stady Farland Managed Crop Rooting Depth (ft.) 4.0 2.0 3.0 Managed Available Water Total (in.) 8.5 4.5 6.5 MAD (in.) 4.25 1.8 3.25 Deficit for Rainfall (in.) 0.50 0.1 0.50 Managed Soil Water (in.) 3.75 1.7 2.75 4.25,50 2.70,60 3.25,50 Year Crop Managed Soil Minimum Soil Available Water (in., %)

CSP Irrigation Water Management Evaluation Sheet 1) Evaluates an irrigation system and management scheme for placement/eligibility in the CSP program RUN CSP program

Irrigation Handbook Modifications Located in Section II of EFOTG Chapter 1: Definitions of useful terminiology Chapter 2: Irrigation group classification designations and descriptions (These have changed with this version of the guide) Individual County Soils Classification (in soils section)

Cnty Soils Link

CH 1 link CH 2 link

Electrical Center Pivot Operation 1) 3 Phase Electric Power so that motors can be easily reversed and consequently the machine will reverse directions 2) Motor power is 480 V 3Ph, Control power is 120 V 1Ph 3) Main power supply is delivered to main control panel at pivot point. Control and motor power is delivered to each tower via a 10 or 11 conductor cable mounted on top of span 4) Timer circuit controls last tower, it runs when timer is activated. The rest of the towers play catch up through the use of micro-switches

Electrical Center Pivot Operation

Electrical Center Pivot Operation Last Tower Controlled By Percent Timer

Electrical Center Pivot Operation Next Tower Follows When Micro-switch Triggers

Electrical Center Pivot Operation All Other Towers Follow Similarly

Center Pivot 10 Conductor Span Cable Timer End Gun Forward Reverse Neutral Safety Ground Power Power Power

THE END