AFK10 April 21, 2005

38 Slides3.33 MB

AFK10 April 21, 2005

Structural Study at the NCAT Test Track R. Buzz Powell Dr. David Timm

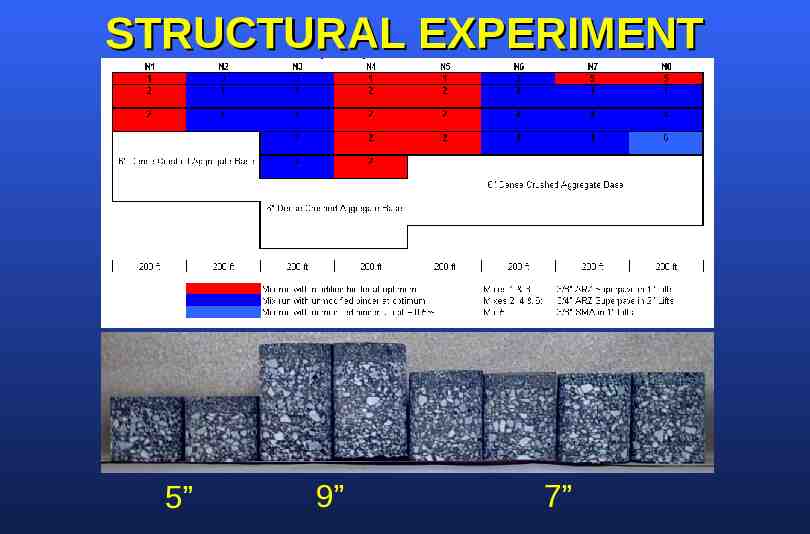

STRUCTURAL EXPERIMENT 5” 9” 7”

Observations 5 inch layers failed about as predicted Some cracking in 7 inch layers Modified sections failed first but not by much Less rutting in modified sections

Based on Test Track Work the Following has been Adopted AL, FL, and NC use more fine-graded mixes FL uses more modified binders AL, OK, and TN have begun to use SMA OK has more confidence in APA AL, GA and TN have increased AC contents

Automated QC Testing Utilization of Automation and Real-Time Testing to Improve QC/QA Procedures For Hot Mix Asphalt Dr. Randy West

QC/QA State of Practice Most HMA requirements for QC are quite complex. QC focus has shifted to the end product and away from controlling the process. Due to the time lag between production and results, hundreds of tons are likely to have been produced, creating a high risk if mix is out of tolerance.

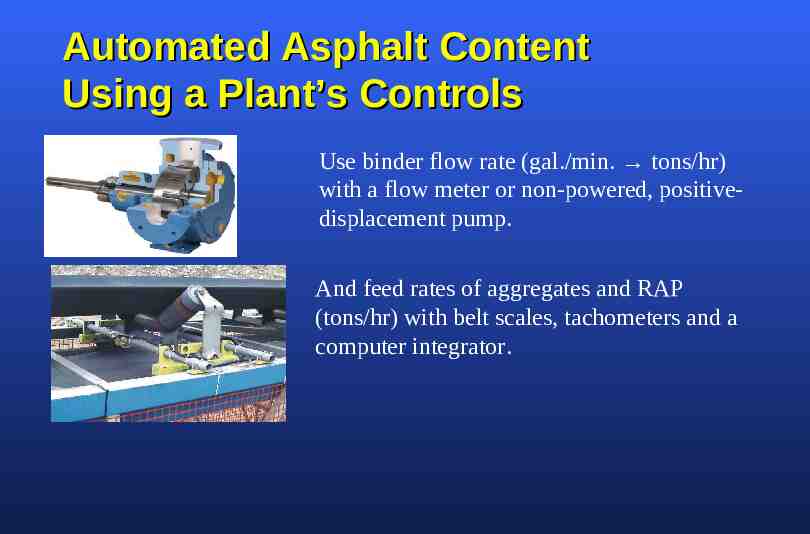

Automated Asphalt Content Using a Plant’s Controls Use binder flow rate (gal./min. tons/hr) with a flow meter or non-powered, positivedisplacement pump. And feed rates of aggregates and RAP (tons/hr) with belt scales, tachometers and a computer integrator.

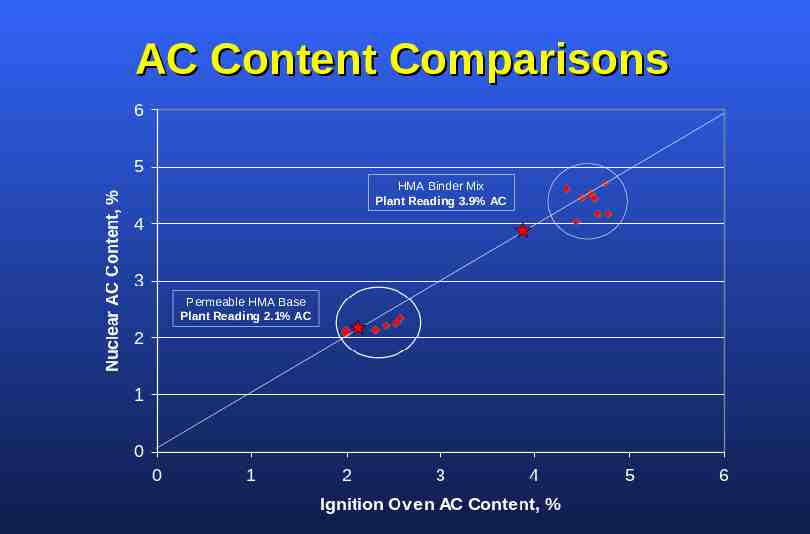

AC Content Comparisons HMA Binder Mix Plant Reading 3.9% AC Permeable HMA Base Plant Reading 2.1% AC

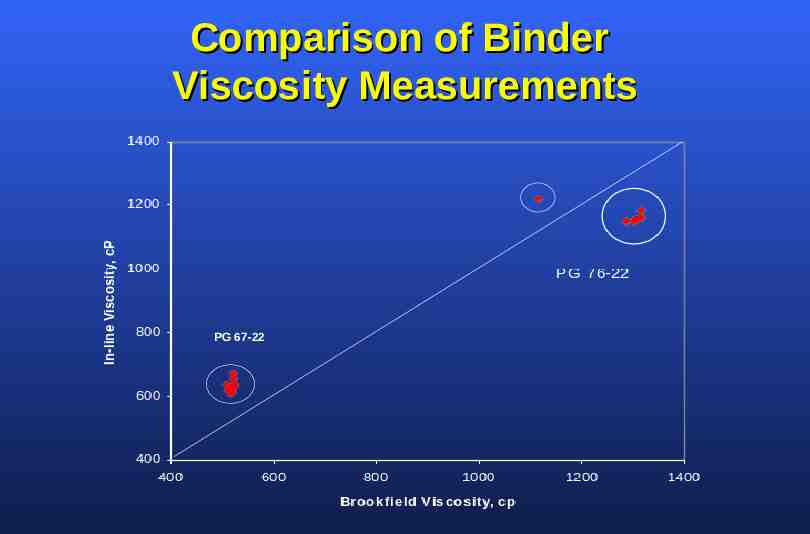

Comparison of Binder Viscosity Measurements PG 67-22

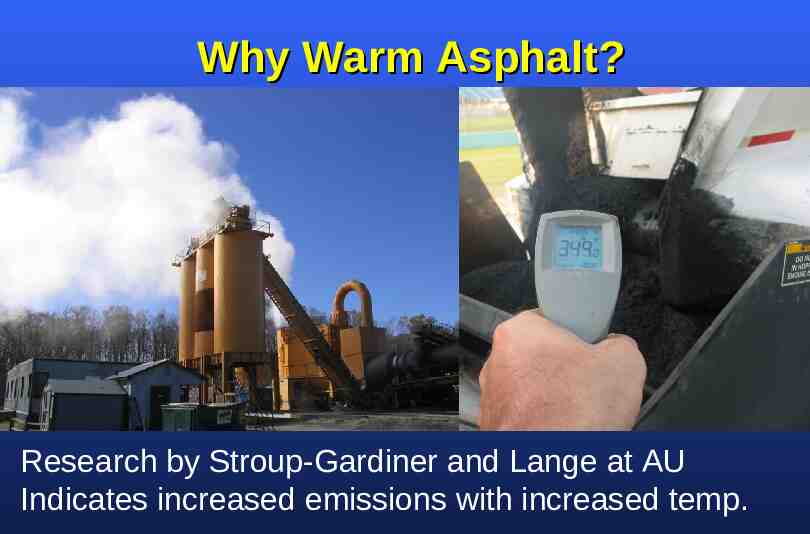

Why Warm Asphalt? Research by Stroup-Gardiner and Lange at AU Indicates increased emissions with increased temp.

We Can Reduce Temperatures Today with No Additives Pre-Superpave – typical compaction temperature 275 F Place Thicker Lifts – NCHRP 9-27 – 3 x NMAS for fine graded – 4 x NMAS for coarse graded Tarp Trucks Drier Aggregate – pave under stockpiles

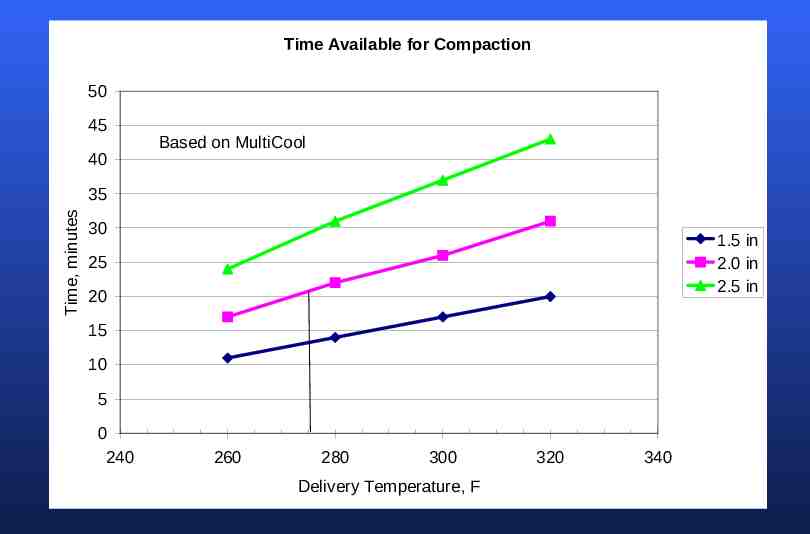

Time Available for Compaction 50 45 40 Based on MultiCool Time, minutes 35 30 1.5 in 2.0 in 2.5 in 25 20 15 10 5 0 240 260 280 300 Delivery Temperature, F 320 340

What are Warm Asphalt Mixes? Several process have been developed to improve mixture workability allowing lower production and laydown temperatures – WAM Foam – Shell/Kolo Veidekke – Zeolite – Eurovia/Hubbard Construction – Sasobit – Sasol Int./Moore and Munger – New processes

AIRFIELD ASPHALT PAVEMENT TEST PROGRAM (AAPTP)

PROCESS FAA Funded in July 2004 Contractor is Auburn University AAPTP Director reports to the College of Engineering not to the Director of NCAT Program size 1.6 million per year WEB Site: www.AAPTP.us

Process Continued Program Coordinating Group – – – – 14 Members – Met in October 2004 Provides overall direction to program Identifies the projects Project Development Panel – – – – Project Director Representative of FAA Representative of DOD Two subject area experts

Initial Projects Adjusting PG Binder Grade Selection Procedures Development of Guidelines for Rubblization Guidance on the Use of Superpave Mix Design Procedures for Airfield Pavements Evaluation of SMA for Airfields

Initial Projects (Cont.) Longitudinal Joint Construction Improved OGFC Evaluate Need and Develop Plan for National Certification of Airport HMA Technicians

Endurance Limit of Hot Mix Asphalt Mixtures to Prevent Fatigue Cracking in Flexible Pavements NCHRP 9-38 Ray Brown Brian Prowell

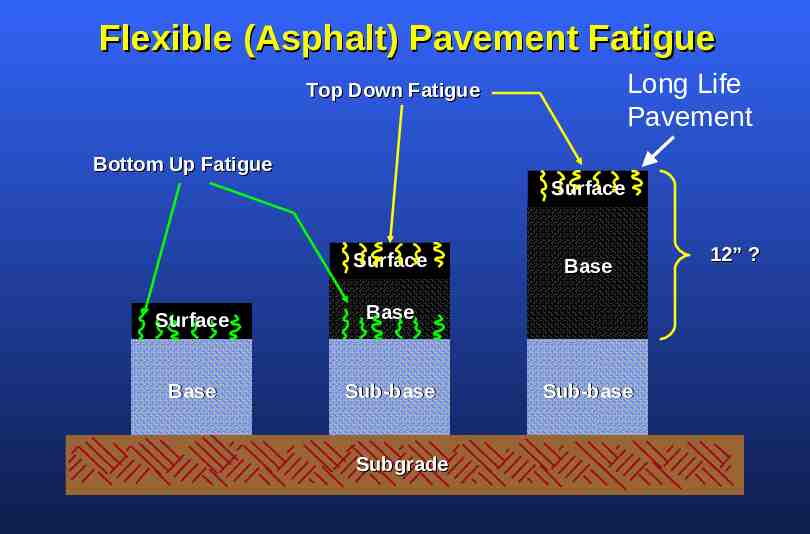

Flexible (Asphalt) Pavement Fatigue Long Life Pavement Top Down Fatigue Bottom Up Fatigue Surface Surface Surface Base Base Sub-base Subgrade Base Sub-base 12” ?

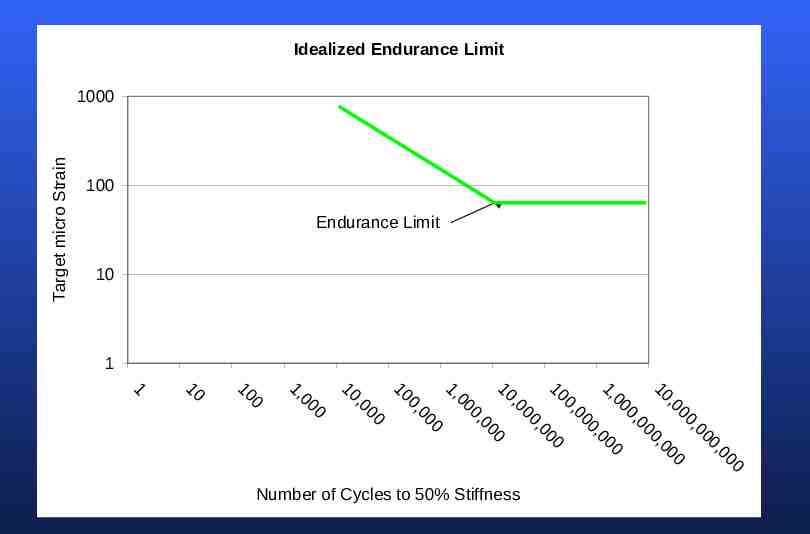

Idealized Endurance Limit Target micro Strain 1000 100 Endurance Limit 10 1 00 ,0 00 ,0 00 0 ,0 00 10 0, 00 0, 00 0 1, 00 0, 00 0, 10 00 ,0 00 ,0 10 0 00 0, 00 1, 0 00 0, 10 00 ,0 10 0 00 1, 0 10 10 1 Number of Cycles to 50% Stiffness

Tire/Pavement Noise

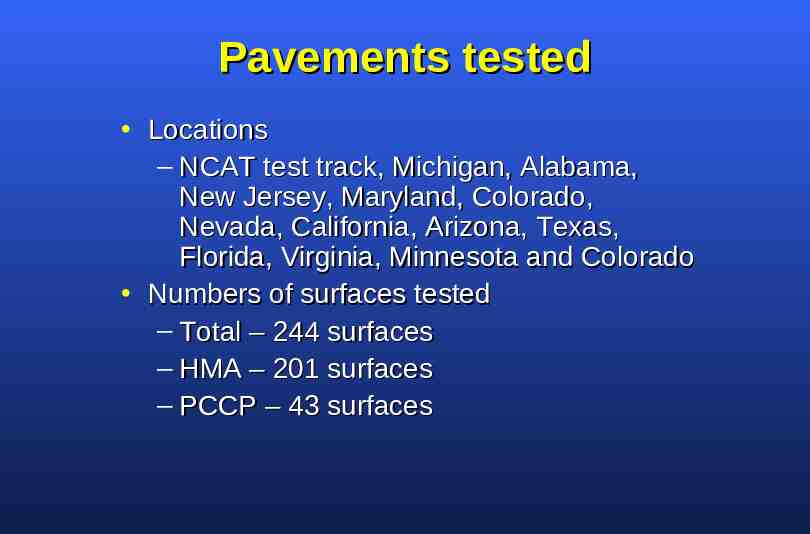

Pavements tested Locations – NCAT test track, Michigan, Alabama, New Jersey, Maryland, Colorado, Nevada, California, Arizona, Texas, Florida, Virginia, Minnesota and Colorado Numbers of surfaces tested – Total – 244 surfaces – HMA – 201 surfaces – PCCP – 43 surfaces

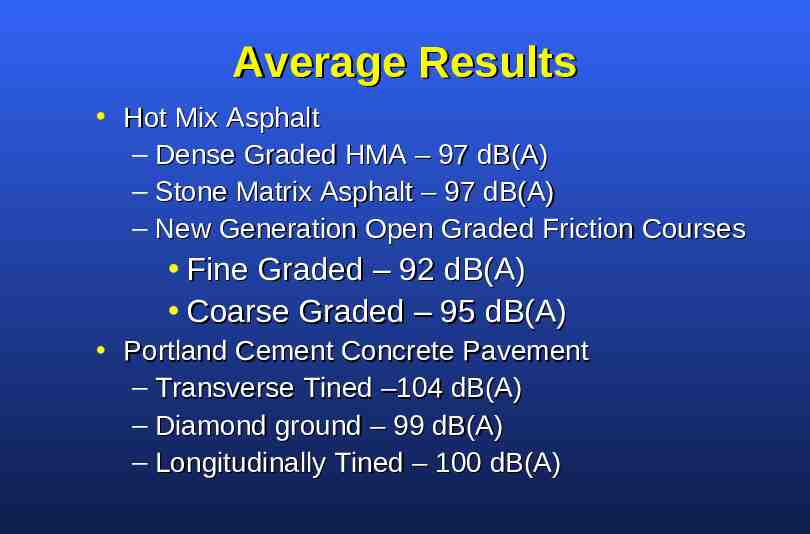

Average Results Hot Mix Asphalt – Dense Graded HMA – 97 dB(A) – Stone Matrix Asphalt – 97 dB(A) – New Generation Open Graded Friction Courses Fine Graded – 92 dB(A) Coarse Graded – 95 dB(A) Portland Cement Concrete Pavement – Transverse Tined –104 dB(A) – Diamond ground – 99 dB(A) – Longitudinally Tined – 100 dB(A)

Bomag’s Asphalt Manager – A First Look Brian D. Prowell

U. S. Demonstration Intelligent compaction forum, sponsored by FHWA, in Auburn, AL December 2004 Testing conducted on BOMAG Asphalt Manager in conjunction with NCHRP 10-65 – Nuclear gage and PQI readings taken after each roller pass – Roller placed in finish position to evaluate use as “testing device”

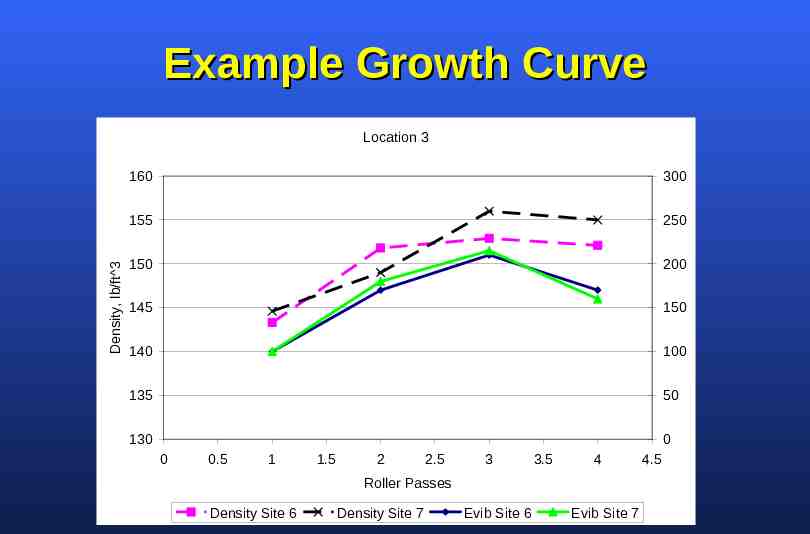

Example Growth Curve Density, lb/ft 3 Location 3 160 300 155 250 150 200 145 150 140 100 135 50 130 0 0 0.5 1 1.5 2 2.5 3 3.5 4 Roller Passes Density Site 6 Density Site 7 Evib Site 6 Evib Site 7 4.5

Evaluation of NDesign for Superpave Mixes

Objectives Evaluate performance of Superpave mixes Compare to performance of Marshall mixes Find same materials/traffic conditions – PG Binders and same aggregates – Similar traffic/ESAL loading Optimize the Superpave NDesign levels

Project Comparisons Age – Marshall - 5.0 years – Superpave - 4.9 years AADT – Marshall - 13,220 – Superpave - 13,971

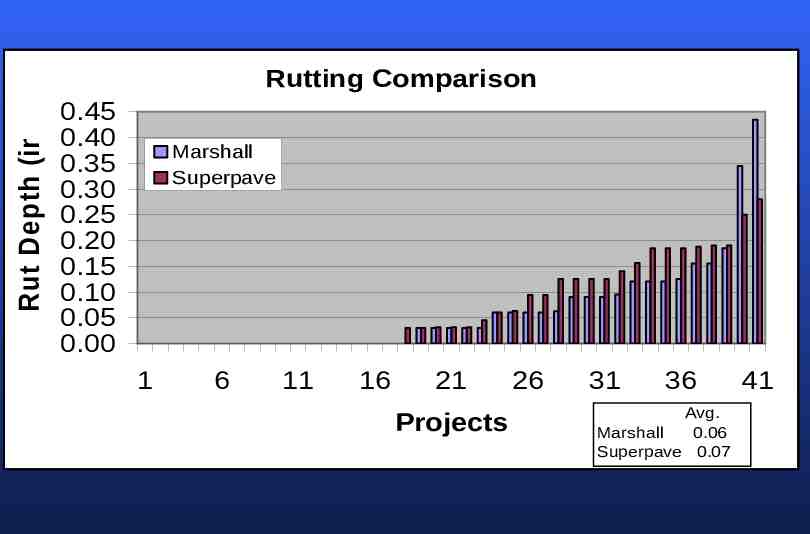

Rut Depth (in) Rutting Comparison 0.45 0.40 0.35 0.30 0.25 0.20 0.15 0.10 0.05 0.00 Marshall Superpave 1 6 11 16 21 Projects 26 31 36 Avg. Marshall 0.06 Superpave 0.07 41

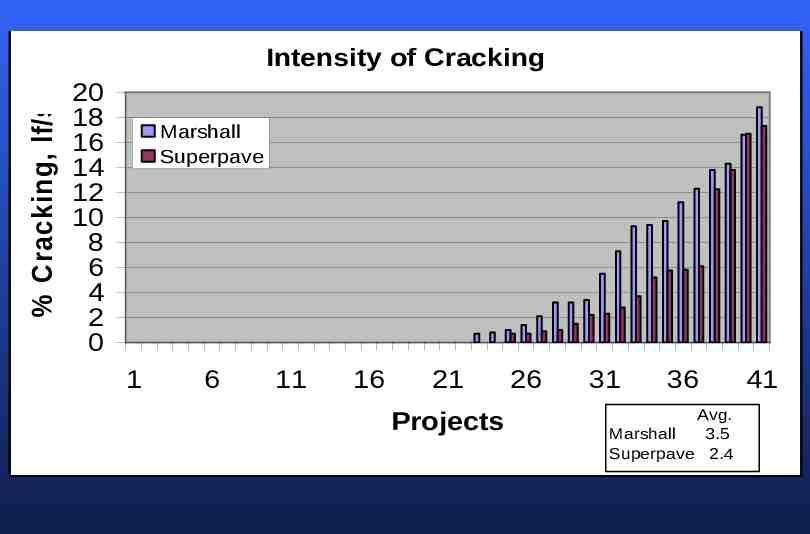

% Cracking, lf/sf Intensity of Cracking 20 18 16 14 12 10 8 6 4 2 0 Marshall Superpave 1 6 11 16 21 Projects 26 31 36 Avg. Marshall 3.5 Superpave 2.4 41

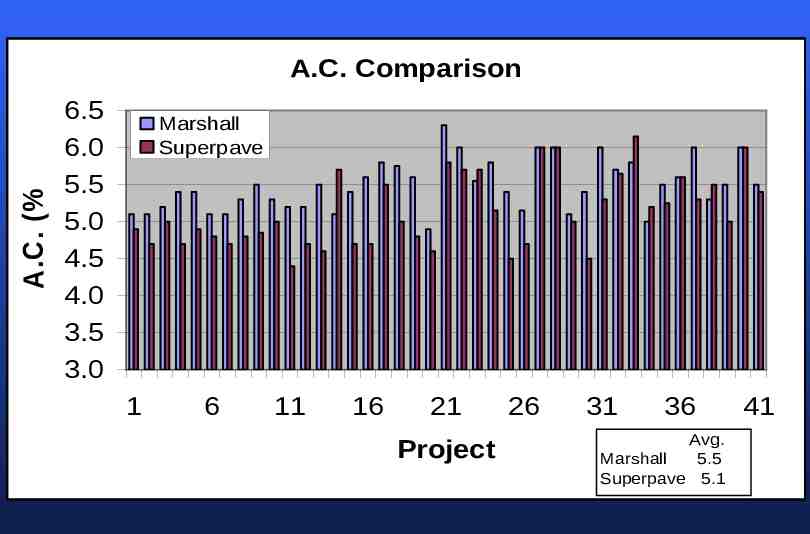

A.C. (%) A.C. Comparison 6.5 6.0 5.5 5.0 4.5 4.0 3.5 3.0 Marshall Superpave 1 6 11 16 21 Project 26 31 36 Avg. Marshall 5.5 Superpave 5.1 41

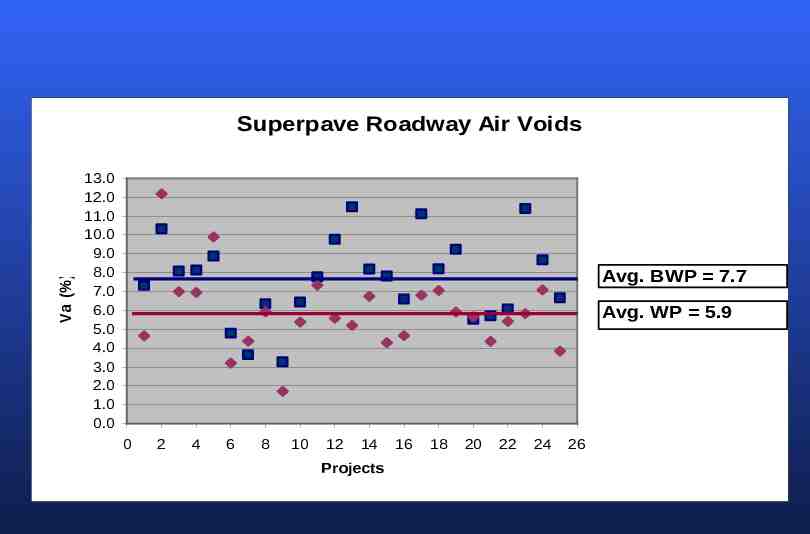

Va (% ) Superpave Roadway Air Voids 13.0 12.0 11.0 10.0 9.0 8.0 7.0 6.0 5.0 4.0 3.0 2.0 1.0 0.0 Avg. BWP 7.7 Avg. WP 5.9 0 2 4 6 8 10 12 14 Projects 16 18 20 22 24 26

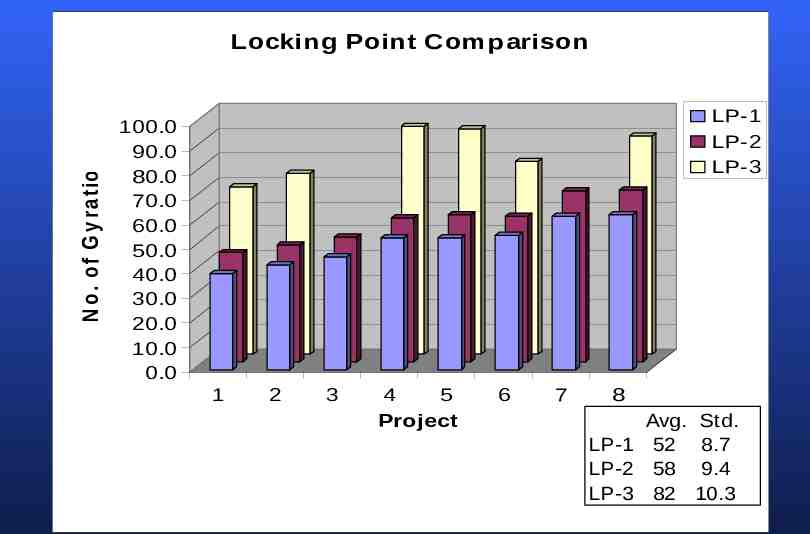

N o . o f G y ra tio n s Locking Point Com parison LP-1 LP-2 LP-3 100.0 90.0 80.0 70.0 60.0 50.0 40.0 30.0 20.0 10.0 0.0 1 2 3 4 5 Project 6 7 8 Avg. LP-1 52 LP-2 58 LP-3 82 Std. 8.7 9.4 10.3

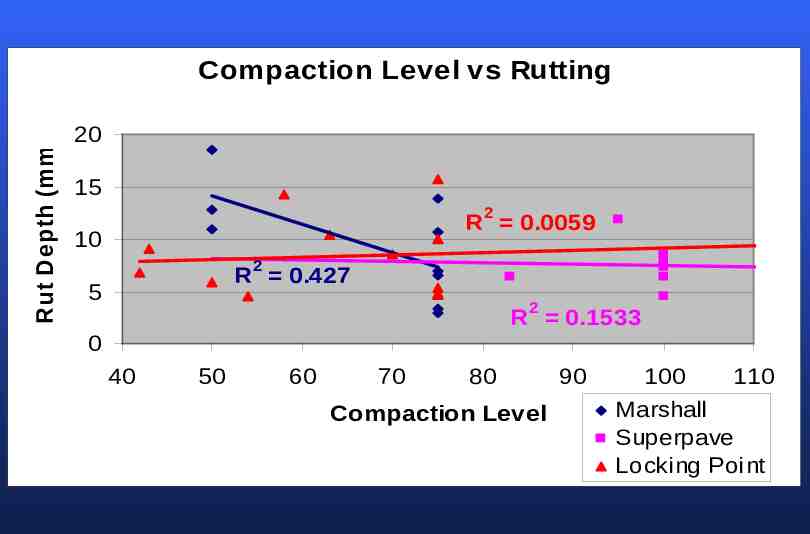

R ut D epth (mm) Compaction Level vs Rutting (without Outlier) 20 15 2 R 0.0059 10 2 R 0.427 5 2 R 0.1533 0 40 50 60 70 80 Compaction Level 90 100 110 Marshall Superpave Locking Point

Thanks