What’s After Nanotechnology? Developing the Army’s Future Materials

25 Slides6.75 MB

What’s After Nanotechnology? Developing the Army’s Future Materials Dr. David M. Stepp U.S. Army Research Office Materials Science Division [email protected] (919) 549-4329, DSN 832-4329, FAX (919) 549-4399 http://www.aro.army.mil 2 March 2005

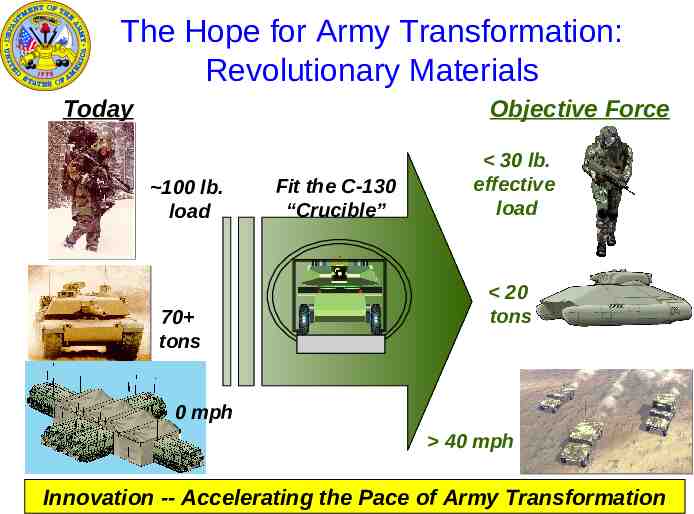

The Hope for Army Transformation: Revolutionary Materials Today Objective Force 100 lb. load 70 tons Fit the C-130 “Crucible” 30 lb. effective load 20 tons 0 mph 40 mph Innovation -- Accelerating the Pace of Army Transformation

Outline Basic Research Definition U.S. Army Research Office Overview – Types of Basic Research Awards – Major Focus Areas DoD Nanotechnology Definition Nanotechnology and Lightweight Materials What’s After Nanotechnology? – Optimized Materials Design – Bio-hybrids – Improved Technology Transfer

Basic Research Defined (DoD 7000.14-R) Basic research is systematic study directed toward greater knowledge or understanding of the fundamental aspects of phenomena and of observable facts without specific applications towards processes or products in mind. It includes all scientific study and experimentation directed toward increasing fundamental knowledge and understanding in those fields of the physical, engineering, environmental and life sciences related to long-term national security needs. It is farsighted high payoff research that provides the basis for technological progress. Basic research may lead to: (a) subsequent applied research and advanced technology developments in Defense-related technologies, and (b) new and improved military functional capabilities in areas such as

Basic Research Refined Needs Driven Research Opportunity Driven Research Lightweight Armor Materials Amorphous Metals Ultra-lightweight Structures Computational Materials Science Lightweight Power Sources Unique Characterization Tools Combat ID/IFF Microstructure Quantification Foamed Materials Self-healing Materials

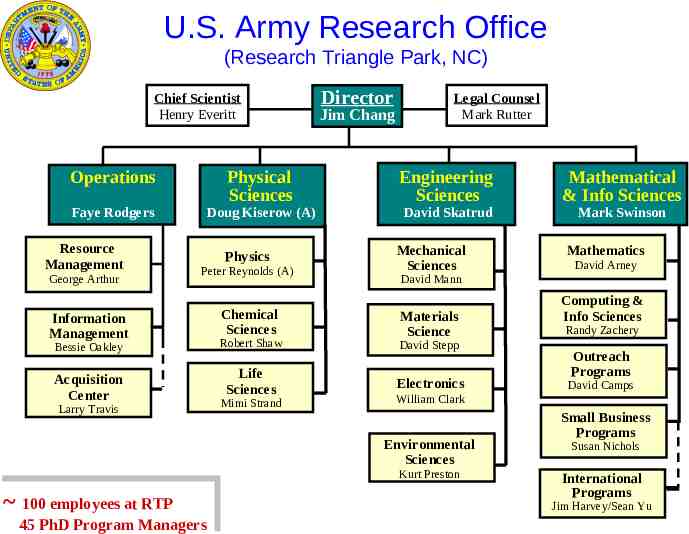

U.S. Army Research Office (Research Triangle Park, NC) Chief Scientist Henry Everitt Operations Faye Rodgers Resource Management George Arthur Director Jim Chang Legal Counsel Mark Rutter Physical Sciences Engineering Sciences Physics Peter Reynolds (A) Mechanical Sciences Chemical Sciences Materials Science Doug Kiserow (A) Information Management Bessie Oakley Acquisition Center Larry Travis David Skatrud David Stepp Life Sciences Electronics Kurt Preston 45PhD PhDProgram ProgramManagers Managers 45 Mathematics David Arney Computing & Info Sciences Randy Zachery Outreach Programs David Camps William Clark Environmental Sciences 100employees employeesatatRTP RTP 100 Mark Swinson David Mann Robert Shaw Mimi Strand Mathematical & Info Sciences Small Business Programs Susan Nichols International Programs Jim Harvey/Sean Yu

ARO Basic Research Awards http://www.aro.army.mil ARO’s Broad Agency Announcement Single Investigator Program ( 100k / year for 3 years) Conference / Symposium / Workshop Grants ( 5k for 12 months) Short Term Innovative Research, STIR (up to 50k for 9 months) Young Investigator Program, YIP ( 50k / year for 3 years) HBCU/MI Program ( 100k / year for 3 years) Multidisciplinary Research Program of the University Research Initiative, MURI ( 1M / year for 5 years) DoD Experimental Program to Stimulate Competitive Research, DEPSCoR ( 350k for 3 years) Defense University Research Instrumentation Program, DURIP ( 200k for 12 months) Small Business Innovative Research, SBIR ( 70k for 6 months 50k for 4 months 730k for 24 months) Small Business Technology Transfer, STTR (with “research institute” partner) ( 100k for 6 months 750k for 24 months) Externally Funded Programs

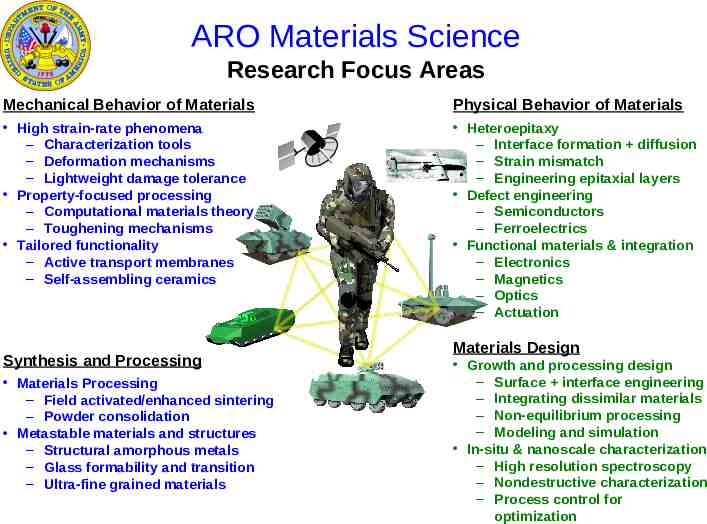

ARO Materials Science Research Focus Areas Mechanical Behavior of Materials Physical Behavior of Materials High strain-rate phenomena – Characterization tools – Deformation mechanisms – Lightweight damage tolerance Property-focused processing – Computational materials theory – Toughening mechanisms Tailored functionality – Active transport membranes – Self-assembling ceramics Heteroepitaxy – Interface formation diffusion – Strain mismatch – Engineering epitaxial layers Defect engineering – Semiconductors – Ferroelectrics Functional materials & integration – Electronics – Magnetics – Optics – Actuation Synthesis and Processing Materials Processing – Field activated/enhanced sintering – Powder consolidation Metastable materials and structures – Structural amorphous metals – Glass formability and transition – Ultra-fine grained materials Materials Design Growth and processing design – Surface interface engineering – Integrating dissimilar materials – Non-equilibrium processing – Modeling and simulation In-situ & nanoscale characterization – High resolution spectroscopy – Nondestructive characterization – Process control for optimization

DoD Nanotechnology Defined DoD nanotechnology programs are distinguished from those of other federal agencies in that the program activities are simultaneously focused on scientific and technical merit and on potential relevance to DoD. The overall technical objective of these programs is to develop understanding and control of matter at dimensions of approximately 1 to 100 nanometers, where the physical, chemical, and biological properties may differ in fundamental and valuable ways from those of individual atoms, molecules, or bulk matter. The overall objective for DoD relevance is to discover and exploit unique phenomena at these dimensions to enable novel applications enhancing war fighter and battle systems capabilities.

Nanotechnology and Lightweight Materials http://www.physics.umd.edu/robot/feynm/fphoto.html Courtesy AIP Niels Bohr Library Richard P. Feynman (1918-88)

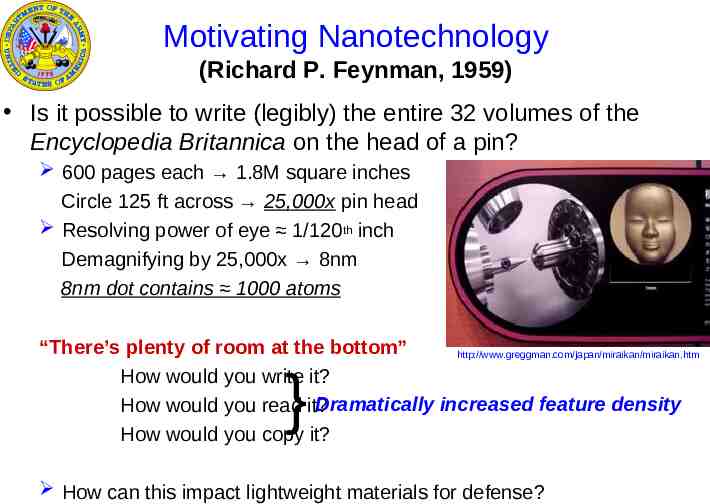

Motivating Nanotechnology (Richard P. Feynman, 1959) Is it possible to write (legibly) the entire 32 volumes of the Encyclopedia Britannica on the head of a pin? 600 pages each 1.8M square inches Circle 125 ft across 25,000x pin head Resolving power of eye 1/120th inch Demagnifying by 25,000x 8nm 8nm dot contains 1000 atoms “There’s plenty of room at the bottom” http://www.greggman.com/japan/miraikan/miraikan.htm How would you write it? Dramatically increased feature density How would you read it? How would you copy it? } How can this impact lightweight materials for defense?

Nanotechnology and Lightweight Materials? Strengths Unprecedented functional materials and functional structures Feature densities (and surface areas) Weight savings from reduced size of components “Inserting” function into proven structural materials Degradation resistance, surface-area-based enhancements Features can be engineered below critical defect size Multifunctional materials Some enhancement from atomic-scale optimization, simulation Most likely for highest-end applications (incremental)

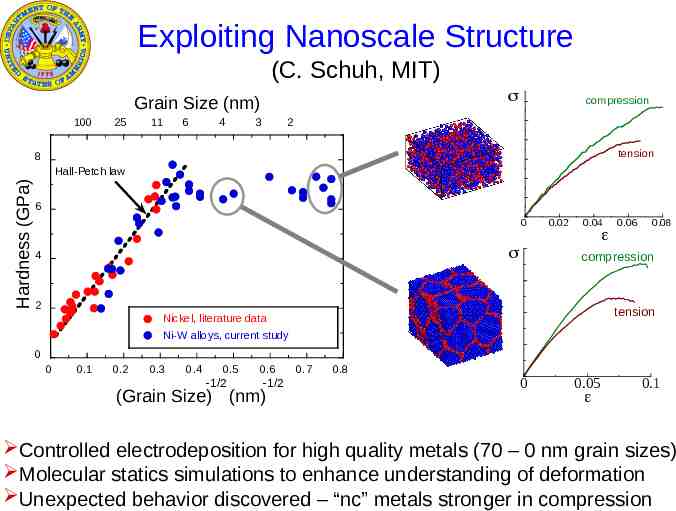

Exploiting Nanoscale Structure (C. Schuh, MIT) Grain Size (nm) 100 25 11 6 4 3 compression 2 tension 8 Hardness (GPa) Hall-Petch law 6 0 4 0.02 0.04 0.06 0.08 compression 2 tension Nickel, literature data Ni-W alloys, current study 0 0 0.1 0.2 0.3 0.4 0.5 -1/2 0.6 -1/2 (Grain Size) (nm) 0.7 0.8 0 0.05 0.1 Controlled electrodeposition for high quality metals (70 – 0 nm grain sizes) Molecular statics simulations to enhance understanding of deformation Unexpected behavior discovered – “nc” metals stronger in compression

"This isn't right. This isn't even wrong." http://www.geocities.com/ilian73/pauli.html Wolfgang Pauli (1900-1958)

Nanotechnology and Lightweight Materials? Weaknesses Excessive funding Prolific “forced” nanotechnology focus in research proposals Over-hyped and misleading results (esp. athletic equipment) Relative improvements to substandard materials Non-falsifiable hypotheses Mechanical properties and extrapolating to design values Micro/nano -scale testing does not correlate with bulk Reliability and repeatability problematic Material scale-up highly problematic Processing control, variations, and durability Nanotubes

Example: Actual Military Requests “Injectable” training Localized fluency in all languages; seamlessly blend into any cultural environment Example: “Tactical neural nano-implant” Integrated self-protection capabilities Indestructibility; appear to be standard regional dress Example: “Carbon nanotube armor” Sensors and communications Extend all senses; be able to detect stress or unusual behavior Example: “Sensory enhancing nanobots” Shape shift materials Ability to blend with any environment Example: “Nano-fabrics that self heal, self clean, and adopt color and texture of surroundings”

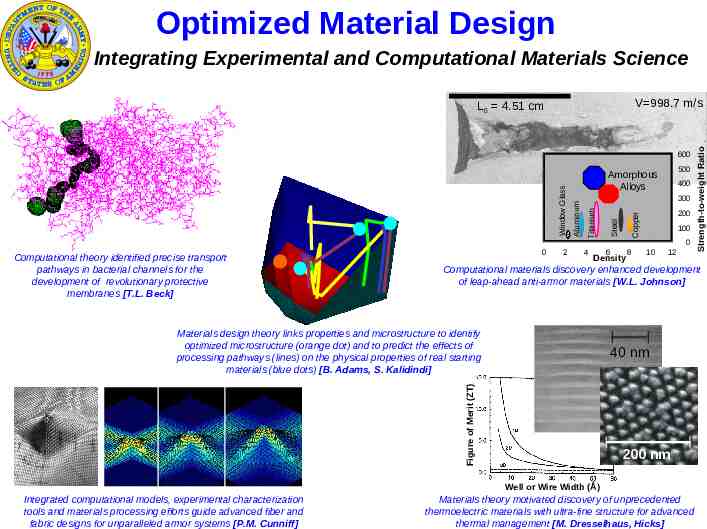

Optimized Material Design Integrating Experimental and Computational Materials Science Computational theory identified precise transport pathways in bacterial channels for the development of revolutionary protective membranes [T.L. Beck] 0 2 500 Amorphous Alloys 400 300 4 6 200 Copper Steel Titanium Aluminum Window Glass 600 Density 8 100 0 10 12 Computational materials discovery enhanced development of leap-ahead anti-armor materials [W.L. Johnson] Materials design theory links properties and microstructure to identify optimized microstructure (orange dot) and to predict the effects of processing pathways (lines) on the physical properties of real starting materials (blue dots) [B. Adams, S. Kalidindi] Figure of Merit (ZT) 40 nm 200 nm Well or Wire Width (Ǻ) Integrated computational models, experimental characterization tools and materials processing efforts guide advanced fiber and fabric designs for unparalleled armor systems [P.M. Cunniff] Strength-to-weight Ratio V 998.7 m/s L0 4.51 cm Materials theory motivated discovery of unprecedented thermoelectric materials with ultra-fine structure for advanced thermal management [M. Dresselhaus, Hicks]

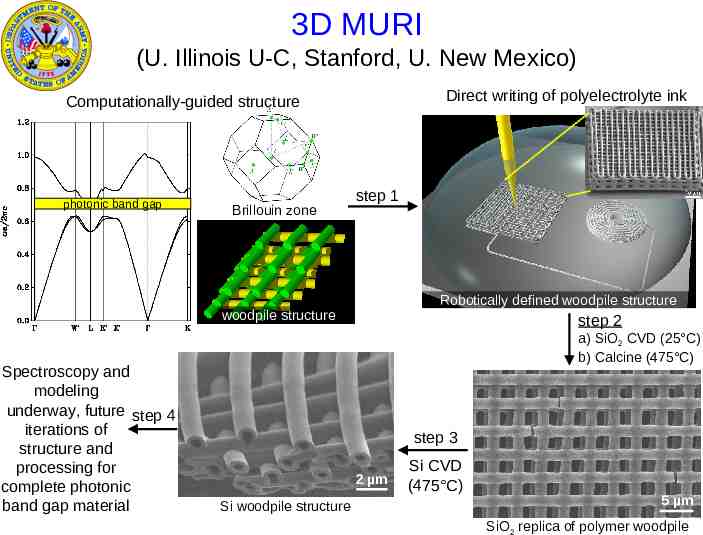

3D MURI (U. Illinois U-C, Stanford, U. New Mexico) Direct writing of polyelectrolyte ink Computationally-guided structure photonic band gap Brillouin zone step 1 Robotically defined woodpile structure woodpile structure Spectroscopy and modeling underway, future step 4 iterations of structure and processing for complete photonic band gap material step 2 a) SiO2 CVD (25 C) b) Calcine (475 C) step 3 2 µm Si woodpile structure Si CVD (475 C) 5 µm SiO2 replica of polymer woodpile

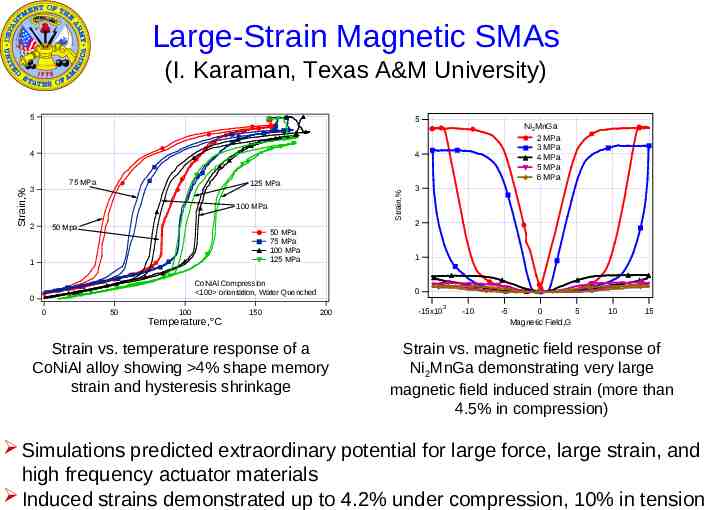

Large-Strain Magnetic SMAs (I. Karaman, Texas A&M University) 5 5 4 75 MPa 3 125 MPa Strain,% Strain,% 4 Ni2MnGa 2 MPa 3 MPa 4 MPa 5 MPa 6 MPa 100 MPa 2 50 Mpa 50 MPa 75 MPa 100 MPa 125 MPa 1 0 50 100 Temperature, C 150 2 1 CoNiAl Compression 100 orientation, Water Quenched 0 3 0 200 Strain vs. temperature response of a CoNiAl alloy showing 4% shape memory strain and hysteresis shrinkage -15x10 3 -10 -5 0 5 Magnetic Field,G 10 15 Strain vs. magnetic field response of Ni2MnGa demonstrating very large magnetic field induced strain (more than 4.5% in compression) Simulations predicted extraordinary potential for large force, large strain, and high frequency actuator materials Induced strains demonstrated up to 4.2% under compression, 10% in tension

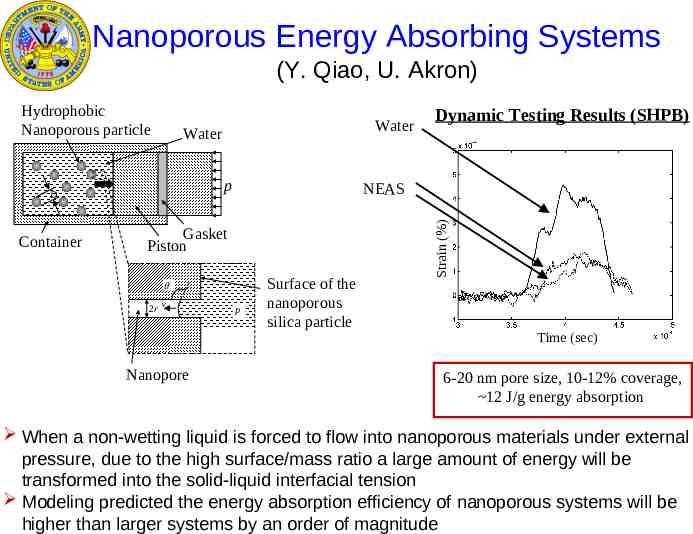

Nanoporous Energy Absorbing Systems (Y. Qiao, U. Akron) Water p D Container Water NEAS Gasket Piston 2r v Nanopore Dynamic Testing Results (SHPB) p Surface of the nanoporous silica particle Strain (%) Hydrophobic Nanoporous particle Time (sec) 6-20 nm pore size, 10-12% coverage, 12 J/g energy absorption When a non-wetting liquid is forced to flow into nanoporous materials under external pressure, due to the high surface/mass ratio a large amount of energy will be transformed into the solid-liquid interfacial tension Modeling predicted the energy absorption efficiency of nanoporous systems will be higher than larger systems by an order of magnitude

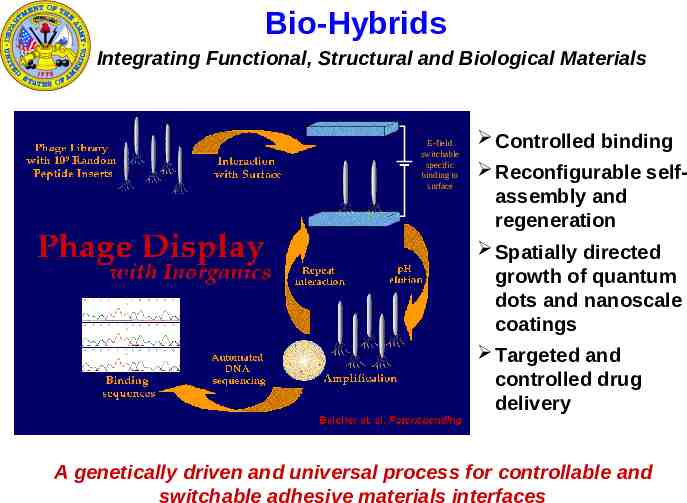

Bio-Hybrids Integrating Functional, Structural and Biological Materials E-field switchable specific binding to surface Controlled binding Reconfigurable selfassembly and regeneration Spatially directed growth of quantum dots and nanoscale coatings Targeted and controlled drug delivery A genetically driven and universal process for controllable and switchable adhesive materials interfaces

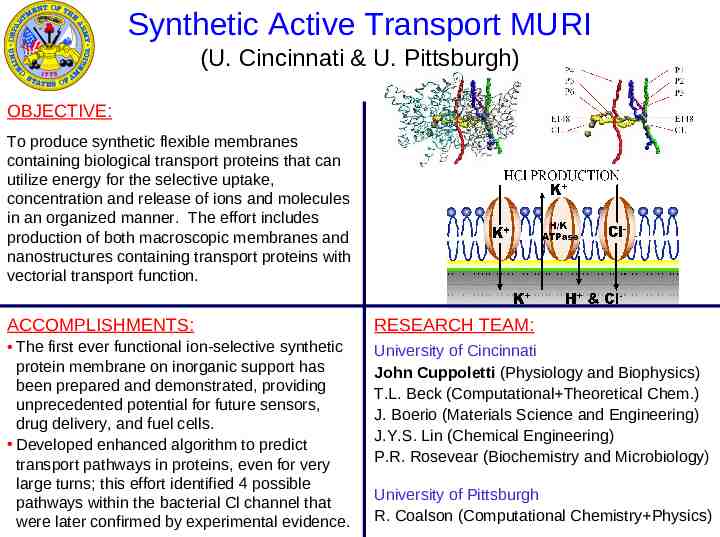

Synthetic Active Transport MURI (U. Cincinnati & U. Pittsburgh) OBJECTIVE: To produce synthetic flexible membranes containing biological transport proteins that can utilize energy for the selective uptake, concentration and release of ions and molecules in an organized manner. The effort includes production of both macroscopic membranes and nanostructures containing transport proteins with vectorial transport function. ACCOMPLISHMENTS: RESEARCH TEAM: The first ever functional ion-selective synthetic protein membrane on inorganic support has been prepared and demonstrated, providing unprecedented potential for future sensors, drug delivery, and fuel cells. Developed enhanced algorithm to predict transport pathways in proteins, even for very large turns; this effort identified 4 possible pathways within the bacterial Cl channel that were later confirmed by experimental evidence. University of Cincinnati John Cuppoletti (Physiology and Biophysics) T.L. Beck (Computational Theoretical Chem.) J. Boerio (Materials Science and Engineering) J.Y.S. Lin (Chemical Engineering) P.R. Rosevear (Biochemistry and Microbiology) University of Pittsburgh R. Coalson (Computational Chemistry Physics)

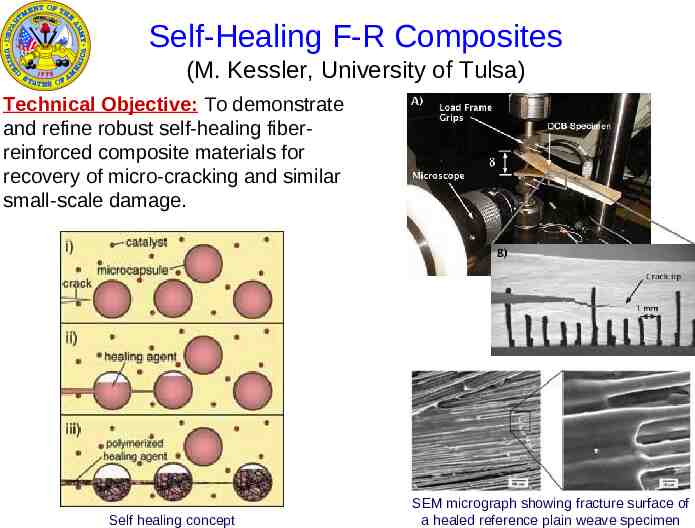

Self-Healing F-R Composites (M. Kessler, University of Tulsa) Technical Objective: To demonstrate and refine robust self-healing fiberreinforced composite materials for recovery of micro-cracking and similar small-scale damage. Self healing concept SEM micrograph showing fracture surface of a healed reference plain weave specimen

Improving Technology Transfer Nanomanufacturing to enable scaled-up, reliable, cost effective manufacturing of nanoscale materials, structures, devices, and systems; the development and integration of ultra-miniaturized top-down processes and increasingly complex bottom-up or self-assembly processes. Small Business Innovative Research (SBIR) Small Business Technology Transfer (STTR) Manufacturing Technology (MANTECH) program Industry partnerships? Spiral development? “Preliminary” field testing?

[email protected] http://www.aro.army.mil Basic Research and the U.S. Army Research Office – Farsighted high-payoff research – Needs driven and opportunity driven basic research efforts Nanotechnology and Lightweight Materials – Tremendous potential for enhancing functionality – Beware non-falsifiable hypotheses, esp. for mechanical/structural apps. What’s After Nanotechnology – Optimized Materials Design? – Bio-hybrids? – Improved Technology Transfer