UNCLASSIFIED SUPERVISOR SAFETY TRAINING UNCLASSIFIED

59 Slides1.71 MB

UNCLASSIFIED SUPERVISOR SAFETY TRAINING UNCLASSIFIED

UNCLASSIFIED How we got here PL 91-596 Executive Order 12196 DODI 6055-1 29 CFR 1960 NAVMC 5100.8 MCO 5100.29C UNCLASSIFIED

UNCLASSIFIED PUBLIC LAW 91-596 (1) provide safe and healthful places and conditions of employment, consistent with the standards set under section 6; (2) acquire, maintain, and require the use of safety equipment, personal protective equipment, and devices reasonably necessary to protect employees; (3) keep adequate records of all occupational accidents and illnesses for proper evaluation and necessary corrective action. UNCLASSIFIED

UNCLASSIFIED Executive Order 12196 Extended the OSH Act to all federal agencies, except uniquely military equipment, systems, and operations. UNCLASSIFIED

UNCLASSIFIED 29 CFR 1960 “OSHA Basic Elements for Federal individuals”, includes further provisions to ensure a safe and healthful working environment for Federal individuals. DODI 6055.1 Takes preceding laws and applies them to the military. UNCLASSIFIED

UNCLASSIFIED MARINE CORPS OSH PROGRAM The Marine Corps Safety Program and the Marine Corps Occupational Safety and Health Policy Order narrows down the preceding regulations as they apply to the Marine Corps. – NAVMC DIR 5100.8 – Marine Corps OSH Program Manual – MCO 5100.8 – Marine Corps OSH Policy Order There are numerous other safety order’s and policies that address specific hazard areas and safety programs. These will be discussed later. UNCLASSIFIED

UNCLASSIFIED NAVMC DIR 5100.8 Marine Corps OSH Program Manual Applicability: – Active & Reserve Components – Civilians – Sister Services stationed on installation – Contractors - If Supervised by the government and the government has the responsibility or the means to UNCLASSIFIED correct mishap causes or mitigate/eliminate hazards

UNCLASSIFIED MCO 5100.29C Marine Corps Safety Program Purpose: – Prescribe policy, responsibilities, and procedures to safeguard and preserve Marine Corps resources worldwide, to include civilians, sister services, contractors (limited) against mishaps. – Establishes RM (MCO 3500.27B) as the Marine Corps’ principle risk reduction methodology and assures regulatory and statutory compliance. – Provides for public safety incident to Marine Corps operations and activities. UNCLASSIFIED

UNCLASSIFIED Safety Program Conflicts When standards in Marine Corps publications conflict with a legal standard (OSH Act) or provide a lower degree of protection, the more stringent standard will apply. UNCLASSIFIED

UNCLASSIFIED INDUSTRIAL HYGIENE SURVEYS WHAT IT COVERS: Task Analysis Engineering Controls Administrative Controls Personal Protective Equipment (PPE) requirements Chemical Identification Exposure Levels UNCLASSIFIED

UNCLASSIFIED Supervisor Responsibilities UNCLASSIFIED

UNCLASSIFIED Supervisor Responsibilities 1. Set the example 2. Identify risks and ensure employees are aware how to mitigate them 3. Perform inspections 4. Acknowledge safety behavior by abating reported hazards 5. Report and investigate all mishaps 6. Train your employees 7. Train yourself UNCLASSIFIED

UNCLASSIFIED 1. Set the Example Supervisors set the tone! “Don’t worry about wearing your eye protection, the boss NEVER wears his!” UNCLASSIFIED

UNCLASSIFIED 2. Identify risks “I didn’t know that the liquid was flammable!” RISK PRINCIPLES 1. Accept risks when benefits outweigh costs 2. Accept no unnecessary risk 3. Anticipate and manage risk by planning 4. Make risk decisions at the right level UNCLASSIFIED

UNCLASSIFIED Risk Identification Techniques Risk Management (RM) – Principle method for Marines per MCO 5100.29C Job Hazard Assessment (JHA) – Performed by supervisors – Evaluates each task in the work place – Updated when new processes or tools enter the work place Industrial Hygiene Surveys (IH) – Performed by medical personnel – Every 2 years UNCLASSIFIED

UNCLASSIFIED RM is a process not a program! It must become an inherent way of doing business UNCLASSIFIED

UNCLASSIFIED 1. Identify Hazards 2. Assess Hazards 3. Make Risk Decisions 4. Implement Controls 5. Supervise UNCLASSIFIED

Benefits UNCLASSIFIED RM Improved mission effectiveness Reduction in mishaps UNCLASSIFIED

UNCLASSIFIED Joint Risk Assessment Matrix UNCLASSIFIED

UNCLASSIFIED JOB HAZARD/SAFETY ANALYSIS UNCLASSIFIED

UNCLASSIFIED Job Hazard Analysis Technique that focuses on job tasks as a way to identify hazards before they occur. – It focuses on the relationship between the worker, the task, the tools, and the work environment. – After you identify uncontrolled hazards, you will take steps to eliminate or reduce them to an acceptable risk level. UNCLASSIFIED

UNCLASSIFIED Value of Job Hazard Analysis Elimination and prevention of mishaps – Reduced injuries and worker’s compensation costs – Increased productivity Tool for training new individuals UNCLASSIFIED

UNCLASSIFIED Performing a Job Hazard Analysis 1 . Choose a Job 2 . List Job Tasks 4 . Recommen d Changes 3. Determine Hazards UNCLASSIFIED

UNCLASSIFIED Job Tasks Example Changing a Flat Tire To Much information Pull off road Put car in “park” Set brake Activate emergency flashers Open door Get out of car Walk to trunk Put key in lock Open trunk Remove jack Remove Spare tire UNCLASSIFIED

UNCLASSIFIED Job Tasks Example Changing a Flat Tire Not enough information Park car Take off flat tire Put on spare tire Drive away UNCLASSIFIED

UNCLASSIFIED Job Tasks Example Changing a Flat tire Just Right Park car, set brake Remove jack & tire from trunk Loosen lug nuts Jack up car Remove tire Set new tire Jack down car UNCLASSIFIED Tighten lug nuts Store tire & jack

UNCLASSIFIED Work Observation Tips Select experienced worker(s) who will cooperate and participate in the JHA process. Explain purpose of JHA Observe the individual perform the job and write down basic steps Completely describe each step Note deviations (Very Important!) Search for Hazards – Produced by Work – Produced by Environment Repeat job observation as many times as necessary to identify all hazards UNCLASSIFIED

UNCLASSIFIED Job Hazard Analysis Review Why or when should I review my job hazard analysis? Change in physical conditions – Tools, material, layout, or location Change in work procedure Illness or injuries Periodic review UNCLASSIFIED

UNCLASSIFIED Job Hazard Analysis (JHA) Location (e.g., Station, Department) Bldg 204, Special Staff Office Title of Employee Performing Task Multi-Imaging Graphics Artist & Photographer, Admin Support Clerk Work Center (Division or branch, etc.) Specific Task Analyzed Public Affairs Office Grommet Machine Required &/or Recommended Personal protective Equipment to Perform the Task Eye Protection Completed By (Name & Title) Mary Richards, Admin Support Clerk Reviewed By (Name & Title) William Booker, Public Affairs Officer Sequence of Basic Task Steps Grommet pressing Potential Hazard or Accident Smash/pinch fingers in grommet parts. Flying debris. Strain arm or back. Concurrence X NonConcurrence Recommended Action to Prevent Accident or Eliminate Hazard -Inspect Grommet Machine to ensure it is functioning properly prior to use. -Ensure fingers are clear of press. Wear proper PPE (Eye Protection). - Use proper posture and techniques. -Attend Ergonomics/Back injury prevention training. EXAMPLE UNCLASSIFIED No. Of Employees Involved 3

UNCLASSIFIED Safety Inspections Responsibility # 3 UNCLASSIFIED

UNCLASSIFIED WHY CONDUCT SAFETY INSPECTIONS? IDENTIFY POTENTIAL HAZARDS ESTABLISH A GOOD ABATEMENT PLAN UNCLASSIFIED

UNCLASSIFIED MCO 5100.29C Host-Tenant Relationships: – Tenant commands will adhere to the host’s safety standards or the more stringent standard. UNCLASSIFIED

UNCLASSIFIED Requirements ALL WORKPLACES SHALL BE INSPECTED AT LEAST ANNUALLY. HIGH HAZARD AREAS MORE FREQUENTLY BASED ON ASSESSMENT OF EXPOSURE. PER MCO 5100.29 UNCLASSIFIED

UNCLASSIFIED Inspection Types (NAVMC 5100.8, DepO 5100.16F) QUALIFIED INSPECTOR EMPLOYEE REP. Annually High Hazard Unannounced Daily Monthly Continuous IMMINENT DANGER FOLLOW-UP Supervisor USR Employees UNCLASSIFIED ACCOMPANIED IN/OUT BRIEF WRITTEN RPT.

UNCLASSIFIED SAFETY INSPECTIONS IMMINENT DANGER SITUATIONS SHALL BE BROUGHT TO THE IMMEDIATE ATTENTION OF SUPERVISORY PERSONNEL FOR NECESSARY PROMPT ACTION UNCLASSIFIED

UNCLASSIFIED MOST FREQUENT VIOLATIONS Electrical : Receptacles Circuit breaker box Extension Cords Energy Control (Lockout/Tag out) Emergency Lighting Inoperable Exits locked/Not Marked Fire Extinguishers not inspected HAZMAT (Improper storage, SDS) Housekeeping (Slips, Trips, Falls) UNCLASSIFIED

UNCLASSIFIED ENTERPRISE SAFETY APPLICATION MANAGEMENT SYSTEM (ESAMS) UNCLASSIFIED

UNCLASSIFIED MARINE CORPS INSTALLATIONS COMMAND POLICY LETTER 1-16 UNCLASSIFIED

UNCLASSIFIED HAZARD REPORTING AND ABATEMENT Responsibility # 4 UNCLASSIFIED

UNCLASSIFIED HAZARD ABATEMENT (NAVMC 5100.8, DepO 5100.16F) Hazard: exposure or vulnerability to injury, loss, etc Hazardous Conditions may be identified and reported through any means by any person for any workplace. Abate: To eliminate/reduce a hazard by coming into compliance with applicable standards or enacting equivalent protection through: Elimination (immediate), Protection (engineering, admin. procedures, PPE), Projects (long term). UNCLASSIFIED

UNCLASSIFIED Reporting an unsafe hazard Encourage oral notification to supervisor FIRST In lieu of oral notification, an employee may file a written report with the unit or installation safety office – – Report may be anonymous Upon receipt of report, the safety office shall notify the supervisor through the appropriate chain of command. An employee may file an informal report anonymously through the “any mouse” box. – Any mouse boxes are maintained by individual units UNCLASSIFIED

UNCLASSIFIED Reprisals Reprisal against employees for submitting hazard reports is prohibited! Allegations of reprisal to civilian personnel for such participation shall be filed in accordance with existing grievance procedures Military personnel shall use the request mast process UNCLASSIFIED

UNCLASSIFIED NAVMC 11401 UNSAFE OR UNHEALTHFUL WORKING CONDITION NAVMC 11401 REV. 7-98. 1. I believe a condition exists which is a safety or health hazard to Marine Corps personnel or property. (check one) Civilian: Military: Employee Representative: Other: 2. Does this hazard immediately threaten life or health? Yes No 3. Building, worksite, or other location where you believe the unsafe or unhealthful condition exists. 4. Supervisor (if known) at this location is: and phone number is: 5. Briefly describe hazard: 6. Number of employees exposed to or threatened by hazard: 7. If known, list any safety or health standard which you believe may apply to this condition. 8. To your knowledge, has this condition been reported to, discussed with, or brought to the attention of a supervisor? Yes No 9. If yes, please give the results, including any efforts by management to correct the condition. 10. Name (optional): Phone number (Optional): 11. If you are a representative of employees, provide name of your organization. Case Number: (Filled in by Installation or Unit Safety Office) Figure 9-1. -- NAVMC 11401, Unsafe or Unhealthful Working Condition. UNCLASSIFIED

UNCLASSIFIED Report of Unsafe/Unhealthful Working Conditions Once an unsafe/unhealthful working condition has been reported, supervisors should: Supervisors will investigate all written and oral complaints – – Provide a written response within 15 days to originator If unable to resolve within 5 days, contact installation safety office. Installation safety office will provide written response within 15 days – If anonymity was requested, the response should be posted on or near the hazardous process that prompted the complaint. Supervisors will make employees aware of the reporting procedures! Supervisors will refrain from interfering with this hazard reporting process and from discriminating against employees who use the process! UNCLASSIFIED

UNCLASSIFIED NAVOSH Deficiency Notice NAVMC 11400 Written for workplace hazards with a RAC 1, 2, or 3 that can not be corrected immediately. Must be signed by Commander/Division /Department Head The official in charge of the operation shall take prompt action to correct the hazard. A copy of the notice must be posted in the area of the hazard until the hazard has been corrected. The posted notice should be updated as necessary to accurately reflect the status of the abatement action and interim controls. JT Buffoon Division Supervisor UNCLASSIFIED SH O V NA IENCY IC F E E D TIC O N

UNCLASSIFIED Mishap Investigation and Reporting Responsibility # 5 UNCLASSIFIED

UNCLASSIFIED MISHAP INVESTIGATION & REPORTING (OPNAVINST 5102.1D) (MCO P5102.1B) Mishap: Any unplanned or unexpected event causing Personnel Injury Occupational Illness Death Property Loss Explosion Supervisor Commander Safety Investigation Board (SIB) Military on and off duty Civilians on duty UNCLASSIFIED

UNCLASSIFIED Mishap Classes Class A Mishap The resulting total cost of reportable material property damage is 2,000,000 or more; or an injury or occupational illness results in a fatality or permanent total disability. Class B Mishap The resulting total cost of reportable material property damage is 500,000 or more, but less than 2,000,000; or an injury or occupational illness results in permanent partial disability; or three or more personnel are inpatient hospitalized. Class C Mishap The resulting total cost of reportable material property damage is 50,000 or more, but less than 500,000; a non-fatal injury that causes any loss of time from work beyond the day or shift on which it occurred, or a non-fatal illness or disease that causes loss of time from work or disability at any time (lost time case). UNCLASSIFIED

UNCLASSIFIED Immediate Notification Incidents For Class A/B – Commanders must notify their first flag officer, CMC (SD), and NSC within 8 hours by phone or email. UNCLASSIFIED

UNCLASSIFIED 7-8-Day Brief Ensure all serious mishaps (Class A and B) are briefed to the first general officer in the CoC within 7 days, providing the circumstances surrounding the mishap and the steps taken to prevent a recurrence The first general officer will brief their CoC and the ACMC on or before the 8 th day following a serious mishap Also includes any incident that may bring discredit to the Marine Corps or draws media attention UNCLASSIFIED

UNCLASSIFIED Safety Investigation Board (SIB) SIB is required for all class A & B mishaps Lt Col or higher presides as senior member If more than one command is involved the senior officer will be the investigating commander Conducted separately from JAG investigations UNCLASSIFIED

UNCLASSIFIED MISHAP REPORTING MATRIX The following mishaps are to be investigated by a Safety Investigation Board (SIB) and reported via WESS or naval message in the SIREP format MISHAP SEVERITY APPLICABLE PERSONNEL REPORT REQUIRED DEADLINE Class A: Fatality. PTD – Permanent Total Disability. Property Damage 2M. Other: Fatality as result of medical event within 1 hour of PFA/PFT/PRT. Training-related fatality. All afloat Class A mishaps involving collision, fire, grounding and flooding. All Class B and C explosive mishaps, all ordnance impacting off range and all live fire mishaps. Selected other mishaps. On-Duty DOD Civilian Employees and Contractors under DOD Supervision. WESS or SIREP Message 30 Days UNCLASSIFIED On-Duty Military. On-Base Military.

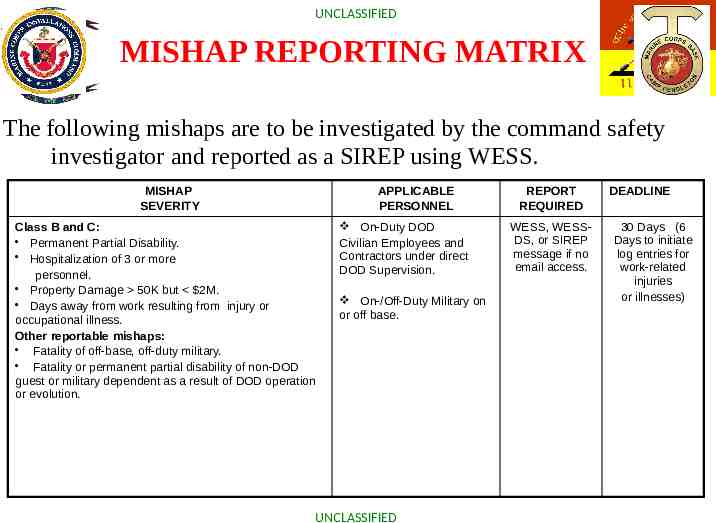

UNCLASSIFIED MISHAP REPORTING MATRIX The following mishaps are to be investigated by the command safety investigator and reported as a SIREP using WESS. MISHAP SEVERITY APPLICABLE PERSONNEL Class B and C: Permanent Partial Disability. Hospitalization of 3 or more personnel. Property Damage 50K but 2M. Days away from work resulting from injury or occupational illness. Other reportable mishaps: Fatality of off-base, off-duty military. Fatality or permanent partial disability of non-DOD guest or military dependent as a result of DOD operation or evolution. On-Duty DOD Civilian Employees and Contractors under direct DOD Supervision. On-/Off-Duty Military on or off base. UNCLASSIFIED REPORT REQUIRED WESS, WESSDS, or SIREP message if no email access. DEADLINE 30 Days (6 Days to initiate log entries for work-related injuries or illnesses)

UNCLASSIFIED MISHAP REPORTING MATRIX The following hazards, in addition to those to be brought to outside attention, are to be reported as a HAZREP using WESS. MISHAP SEVERITY Electrical shock afloat from a design deficiency (no injury). Man-overboard mishaps underway with no injury. All identified hazards where information is valuable if shared with community of interest or all Navy/Marine Corps. APPLICABLE PERSONNEL On-Duty Military and Civilian Employees UNCLASSIFIED REPORT REQUIRED HAZREP using WESS, WESSDS or HAZREP message in no email access DEADLINE None

UNCLASSIFIED Training Requirements UNCLASSIFIED

UNCLASSIFIED EMPLOYEE OSH TRAINING (NAVMC 5100.8, DepO 5100.16F) "SUPERVISORS will ensure personnel under their direct supervision are sufficiently trained to.“ Identify, protect from, and eliminate hazards Be knowledgeable of safety program requirements Initially Specialized New Employees New Process Updating Procedures Employee Performance Non-Routine Tasks UNCLASSIFIED

UNCLASSIFIED HEALTH SURVEILLANCE (NAVMC 5100.8, DepO 5100.16F, MCO 6260.1D) The following Programs require one or a combination of: Surveillance, Monitoring, Training, or Reporting, depending on the hazards involved. SUPERVISORS must ensure that they and their employees meet these Program requirements when applicable to their work places. Hearing Conservation - MCO 6260.1E Sight Conservation - NAVMC 5100.8 Asbestos Control Program - MCO P5100.1B Radiation Safety - MCO 5104.3B Laser Safety - MCO P5104.1B Respiratory Protection – NAVMC DIR 5100.8 UNCLASSIFIED

UNCLASSIFIED Questions? UNCLASSIFIED

UNCLASSIFIED Review References – NAVMC DIR 5100.8 – MCO 5100.29A Supervisor Responsibilities Set the example Identify risks and ensure employees are aware how to mitigate them Perform inspections Acknowledge safety behavior by abating reported hazards Report and investigate all mishaps Train your employees Train yourself UNCLASSIFIED