Standpipe Fire Systems 29 CFR 1910.158 PPT-124-01 Bureau of

23 Slides862.22 KB

Standpipe Fire Systems 29 CFR 1910.158 PPT-124-01 Bureau of Workers’ Compensation PA Training for Health & Safety (PATHS) 1

Scope This standard applies to all small hose, Class II and Class III Standpipe Systems installed to meet the requirements of a particular OSHA Standard. Exception. This section does NOT apply to Class I Standpipe Systems. PPT-124-01 2

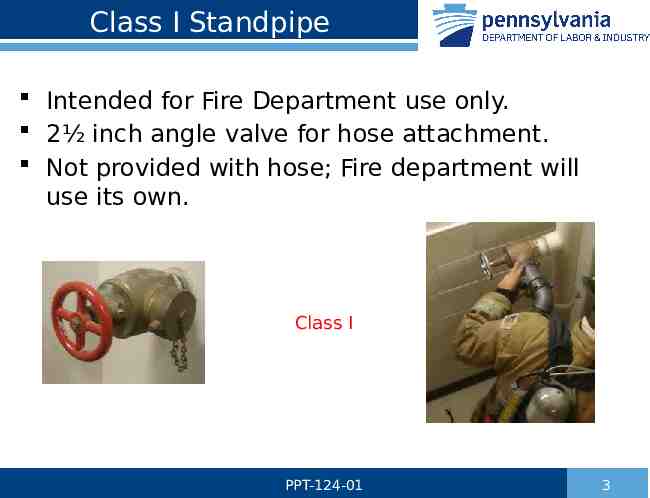

Class I Standpipe Intended for Fire Department use only. 2½ inch angle valve for hose attachment. Not provided with hose; Fire department will use its own. Class I PPT-124-01 3

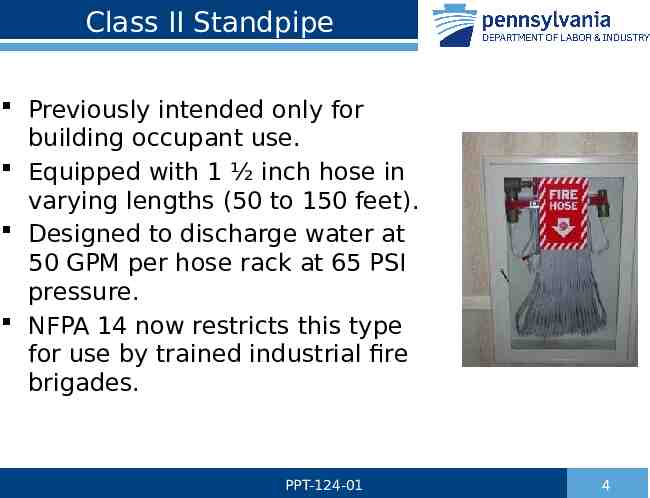

Class II Standpipe Previously intended only for building occupant use. Equipped with 1 ½ inch hose in varying lengths (50 to 150 feet). Designed to discharge water at 50 GPM per hose rack at 65 PSI pressure. NFPA 14 now restricts this type for use by trained industrial fire brigades. PPT-124-01 4

Class III Standpipe 2½ inch angle valve for fire department use and 1½ inch hose rack assembly for industrial fire brigade use. A 2½ inch hose valve with a 2½ inch to 1½ inch reducer and a 1½ inch cap and chain can be used to satisfy the Class III standpipe requirement. Many building codes will require the installation of a Class III standpipe system. This requirement can be met without installing a hose rack assembly. PPT-124-01 5

Protection of Standpipes These shall be located or otherwise protected against mechanical damage. Damaged standpipes shall be repaired promptly. PPT-124-01 6

Equipment o Reels and cabinets are designed to facilitate prompt use. o They must be conspicuously identified. o Cabinets are used only for fire equipment. PPT-124-01 7

Outlets and Connections For Hoses: Located above the floor to avoid being obstructed and be accessible. Use standardized screw threads or provide adapters. PPT-124-01 8

Hose Assure every 1½ inch or smaller hose outlet used is equipped with hose connected and ready for use. In extremely cold climates, hose may be stored in another location provided it is readily available and can be connected when needed. PPT-124-01 9

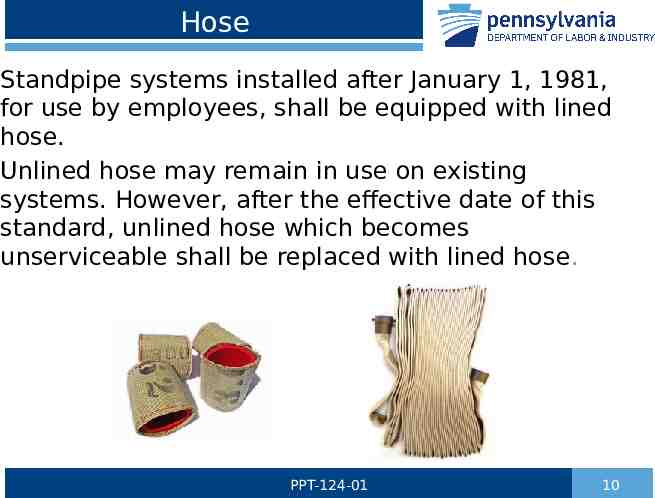

Hose Standpipe systems installed after January 1, 1981, for use by employees, shall be equipped with lined hose. Unlined hose may remain in use on existing systems. However, after the effective date of this standard, unlined hose which becomes unserviceable shall be replaced with lined hose. PPT-124-01 10

Hose Hose of such length that friction loss resulting from water flowing through the hose will not decrease the pressure at the nozzle below a nozzle pressure of 30 psi. The dynamic pressure at the nozzle shall be within the range of 30 psi to 125 psi. PPT-124-01 11

Nozzles Assure standpipe hose is equipped with shut-off type nozzles. No* Yes PPT-124-01 Yes 12

Water Supply The minimum water supply for standpipe and hose systems, which are provided for the use of employees, shall be sufficient to provide 100 gallons per minute for a period of at least thirty (30) minutes (3,000 gallons). PPT-124-01 13

Acceptance Tests Piping of Class II and Class III systems installed after January 1, 1981, including yard piping, is hydrostatically tested for a period of at least 2 hours at not less than 200 psi, Or at least 50 psi in excess of normal pressure when such pressure is greater than 150 psi. PPT-124-01 14

Acceptance Tests Hose on all standpipe systems installed after January 1, 1981, is hydrostatically tested with couplings in place, at a pressure of not less than 200 psi, before it is placed in service. This pressure shall be maintained for at least 15 seconds and not more than one (1) minute during which time the hose shall not leak nor shall any jacket thread break during the test. PPT-124-01 15

Maintenance Assure that water supply tanks are kept filled to the proper level except during repairs. When pressure tanks are used, the employer shall assure that proper pressure is maintained at all times except during repairs. That valves in the main piping connections to the automatic sources of water supply are kept fully open at all times except during repair. PPT-124-01 16

Maintenance Hose systems are inspected at least annually and after each use to assure that all of the equipment and hose are in place, available for use, and in serviceable condition. When the system or any portion thereof is found not to be serviceable, the employer shall remove it from service immediately and replace it with equivalent protection such as extinguishers and fire watches. PPT-124-01 17

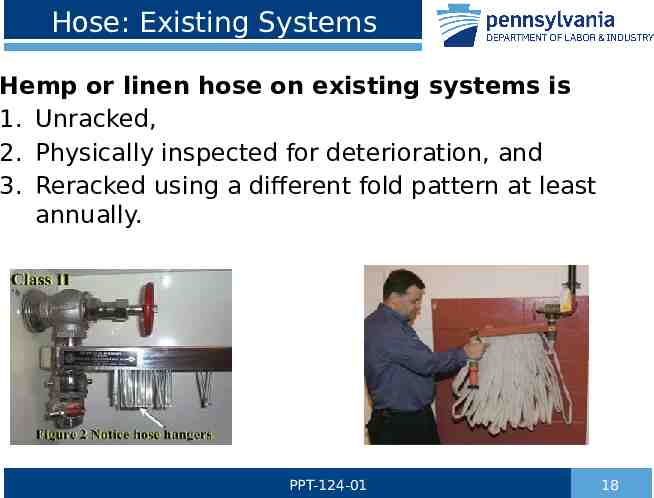

Hose: Existing Systems Hemp or linen hose on existing systems is 1. Unracked, 2. Physically inspected for deterioration, and 3. Reracked using a different fold pattern at least annually. PPT-124-01 18

Hose: Existing Systems Hemp or linen hose on existing systems The employer shall assure that defective hose is replaced in accordance with paragraph (c)(3) (ii) of this section. The employer shall designate trained persons to conduct all inspections required under this section. PPT-124-01 19

Bibliography 29 CFR 1910.158, Standpipe and Hose Systems and Subpart L, Appendix A. 2013 NFPA 14, Standard for the Installation of Standpipe and Hose Systems, National Fire Protection Association, Batterymarch Park, Quincy, MA 02269. PPT-124-01 20

Contact Information Health & Safety Training Specialists 1171 South Cameron Street, Room 324 Harrisburg, PA 17104-2501 (717) 772-1635 [email protected] Like us on Facebook! https://www.facebook.com/BWCPATHS PPT-124-01 21

Questions PPT-124-01 22

Other Suggested Programs The following presentations are also available to supplement your in-house program: Fire Extinguisher Use Industrial Fire Brigade Managing Emergencies Respiratory Protection Please contact us for a full list of other programs available to you free of charge. PPT-124-01 23