Spill Control and Containment Bureau of Workers’ Compensation

87 Slides8.27 MB

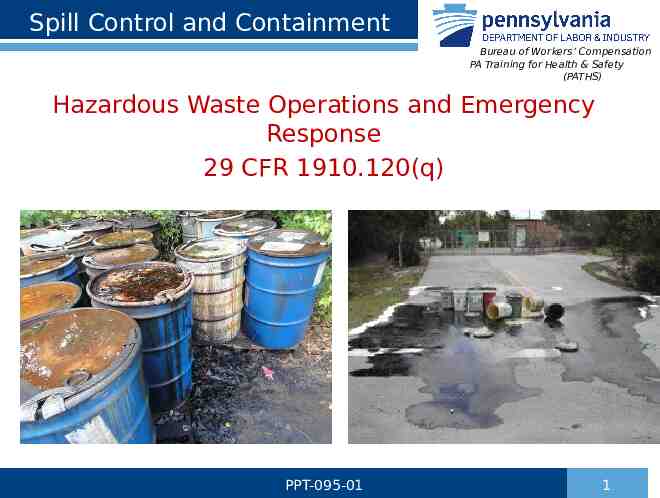

Spill Control and Containment Bureau of Workers’ Compensation PA Training for Health & Safety (PATHS) Hazardous Waste Operations and Emergency Response 29 CFR 1910.120(q) PPT-095-01 1

Introduction The presence of chemicals in today’s society, be it manufacturing, storage, or use situations, may present hazards to persons upon its unplanned release from containment. Even with the myriad regulations governing containers, shipping, and marking, the prudent firm must consider actions should hazardous materials be released. PPT-095-01 2

Topics Containers Hazard Identification Response Actions Emergency Response Zones Mitigation Methods Chemical Control Physical Control PPE Overpacking Decontamination PPT-095-01 3

Containers Various types are used to contain solids, liquids or gases. PPT-095-01 4

Containers Also include transport containers which may be making pick-ups or deliveries to your facility. PPT-095-01 5

Containers Fiberboard and cardboard packaging can also contain hazardous materials. PPT-095-01 6

Containers Can also be processes and vessels containing production materials. Know the valving and shutdown logics for the plant’s processes. PPT-095-01 7

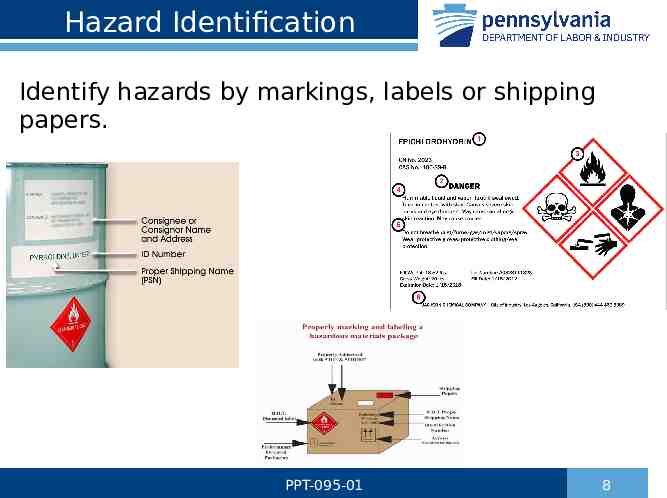

Hazard Identification Identify hazards by markings, labels or shipping papers. PPT-095-01 8

Hazard Identification Once material is identified, other sources may be used to determine spill response actions. PPT-095-01 9

Hazard Identification Identification can also be made in the field with sampling and testing kits. This, however, is timeconsuming. PPT-095-01 10

Hazard Identification Once the material is identified, levels and amounts can be determined by using the correct air monitoring instruments. PPT-095-01 11

Containment: Defined Act or process of containing and/or preventing the expansion of a substance. Purpose: Prevent contaminating surrounding areas Prevent material entering sewers or waterways Reduce contamination of adjacent chemicals Reduce extent of hazard to human life Ensure responders practice A.L.A.R.A. concept (As Low As Reasonably Achievable) PPT-095-01 12

A.L.A.R.A. Concept A concept used during control and clean-up is borrowed from the nuclear industry: The A. L. A. R. A. Concept - “As Low As Reasonably Achievable.” This means that in all actions we should attempt to minimize exposure, contact, and contamination as well as the amount of waste generated by the control operation PPT-095-01 13

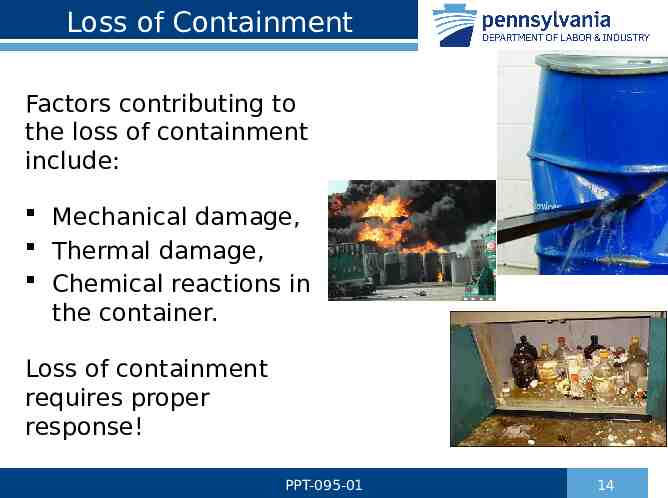

Loss of Containment Factors contributing to the loss of containment include: Mechanical damage, Thermal damage, Chemical reactions in the container. Loss of containment requires proper response! PPT-095-01 14

Types of Contaminants Something which contaminates or “makes impure, unclean, or corrupt by contact; to corrupt; to pollute; to sully; to tarnish; to taint.” Precautions are taken to minimize exposure: Proper size-up of situation Proper PPE Understanding hazards of materials involved Physical state of release and resulting complications. PPT-095-01 15

Solid Release Solid materials easy to recover if kept dry and air movement is minimized. Once wet or damp, adverse reactions may complicate containment. Cover with compatible material to minimize spread. PPT-095-01 16

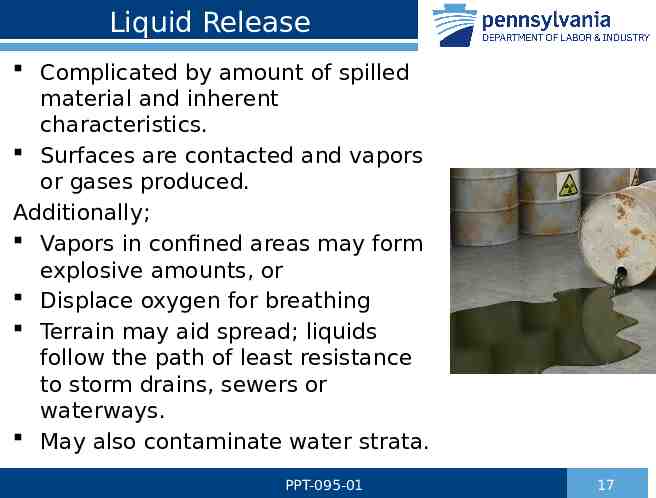

Liquid Release Complicated by amount of spilled material and inherent characteristics. Surfaces are contacted and vapors or gases produced. Additionally; Vapors in confined areas may form explosive amounts, or Displace oxygen for breathing Terrain may aid spread; liquids follow the path of least resistance to storm drains, sewers or waterways. May also contaminate water strata. PPT-095-01 17

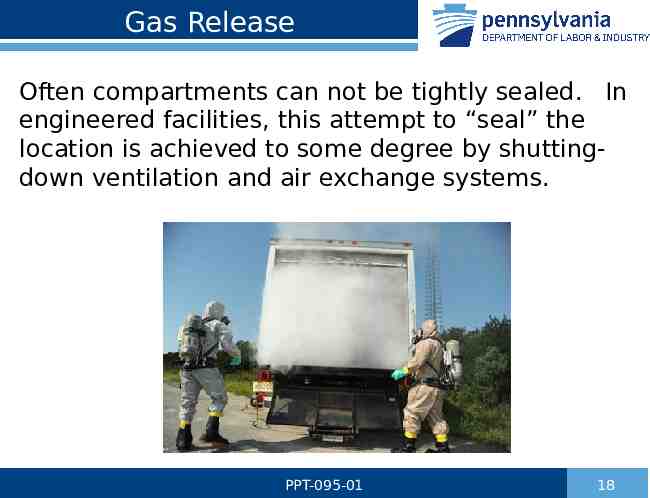

Gas Release Often compartments can not be tightly sealed. In engineered facilities, this attempt to “seal” the location is achieved to some degree by shuttingdown ventilation and air exchange systems. PPT-095-01 18

Types of Damage Thermal Chemical Mechanical PPT-095-01 19

Response Actions Goals of spill response are to: 1. Eliminate additional loss. 2. Prevent further contamination. 3. Avoid unnecessary exposure of workers. 4. Prevent contact with other chemicals. 5. Minimize down-time, loss of stocks, raw materials or finished product. PPT-095-01 20

Proper Response Steps Identify spilled material Size-up incident severity Determine mitigation methods Implement methods PPT-095-01 21

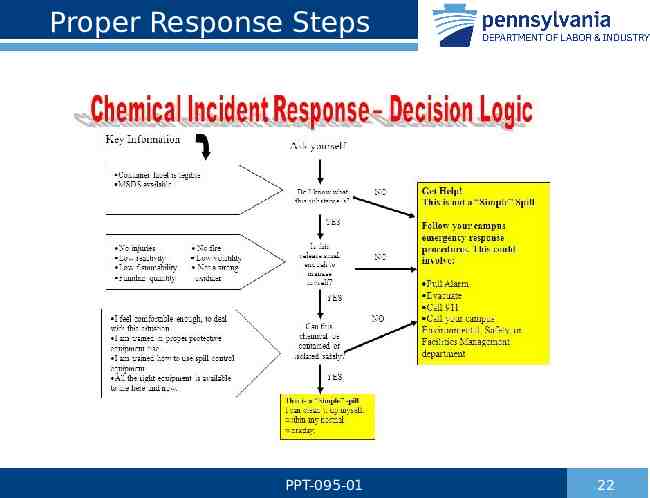

Proper Response Steps PPT-095-01 22

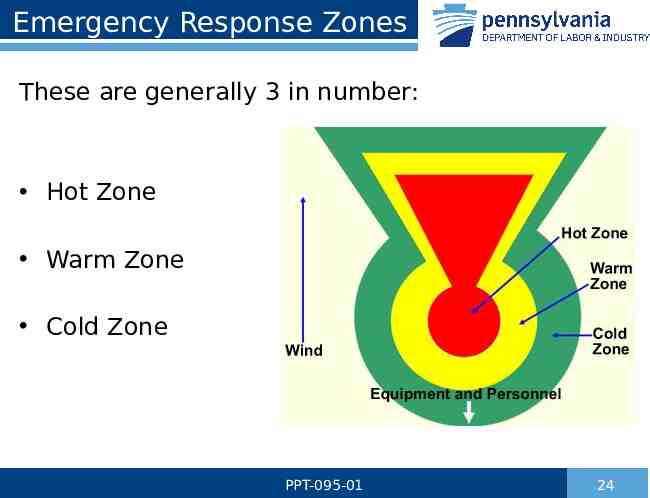

Emergency Response Zones Isolation Release must be isolated against intrusion by unnecessary and untrained persons. During containment operations, the Incident Commander should deny entry to the hazard zone to all but those required to conduct the control operations. Also, such isolation is a guard against contamination of persons, vehicles, and equipment. PPT-095-01 23

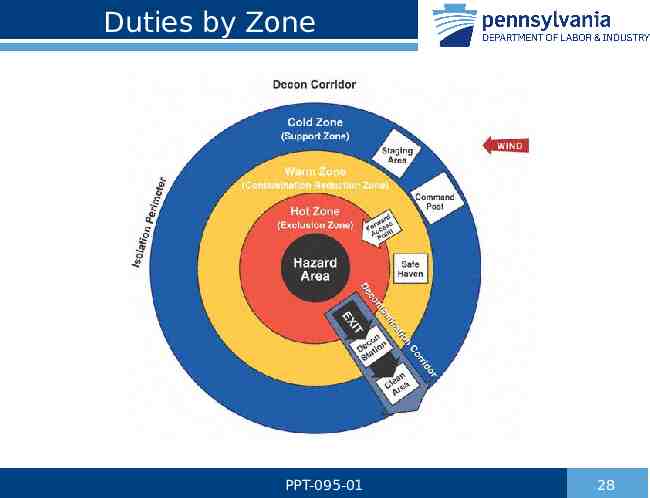

Emergency Response Zones These are generally 3 in number: Hot Zone Warm Zone Cold Zone PPT-095-01 24

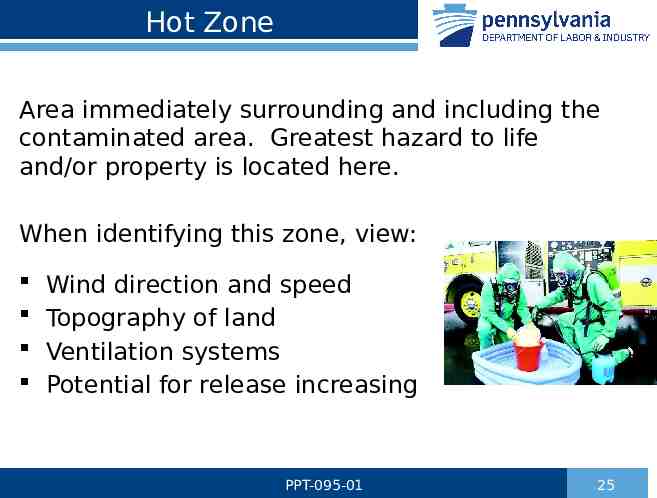

Hot Zone Area immediately surrounding and including the contaminated area. Greatest hazard to life and/or property is located here. When identifying this zone, view: Wind direction and speed Topography of land Ventilation systems Potential for release increasing PPT-095-01 25

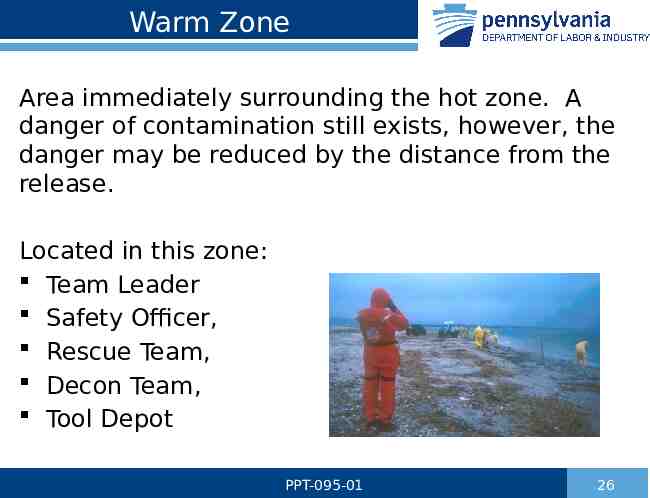

Warm Zone Area immediately surrounding the hot zone. A danger of contamination still exists, however, the danger may be reduced by the distance from the release. Located in this zone: Team Leader Safety Officer, Rescue Team, Decon Team, Tool Depot PPT-095-01 26

Cold Zone Immediately surrounds the Warm Zone. Relatively no danger of contamination or exposure. This is also a buffer zone to insure a safe barrier is maintained around the release. Personnel in this area generally are not required to wear PPE. Located in this zone: Command Post and Incident Commander Support Services and Agencies Staging Area for resources PPT-095-01 27

Duties by Zone PPT-095-01 28

Mitigation Techniques The method by which a substance, once released, is controlled by entry personnel. These are: 1. Chemical Control, and/or 2. Physical Control Sometimes the easiest control method is to tighten the cap on the container. PPT-095-01 29

Chemical Control Diluting: mixing so many parts of a liquid with the challenge liquid to reduce that chemical’s hazards. This can be done with alcohols and other chemicals to reduce their threat. PPT-095-01 30

Chemical Control Neutralization: Mixing an acid with a basic material or base with an acid to return their pH levels toward a reading of 7 (neutral). PPT-095-01 31

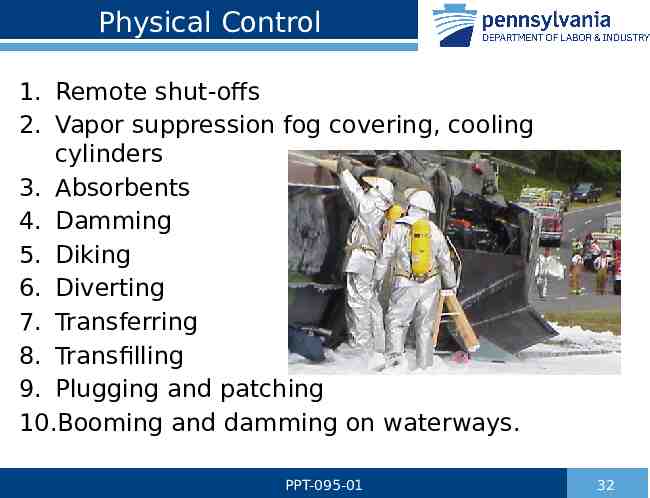

Physical Control 1. Remote shut-offs 2. Vapor suppression fog covering, cooling cylinders 3. Absorbents 4. Damming 5. Diking 6. Diverting 7. Transferring 8. Transfilling 9. Plugging and patching 10.Booming and damming on waterways. PPT-095-01 32

Remote Shut-Offs These exist to shut down processes or pipe-runs to secure product flow. Use flow diagrams in your pre-plan and know the location of these shut-offs prior to an emergency. PPT-095-01 33

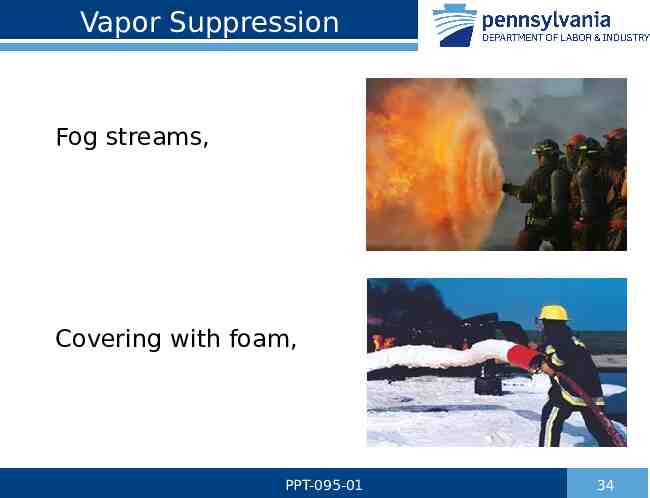

Vapor Suppression Fog streams, Covering with foam, PPT-095-01 34

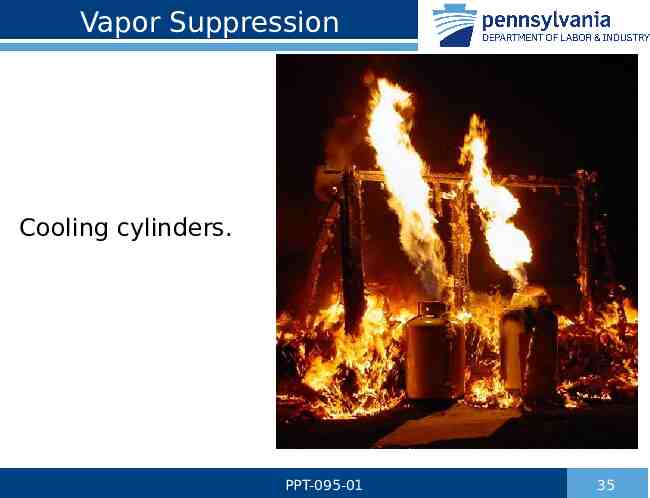

Vapor Suppression Cooling cylinders. PPT-095-01 35

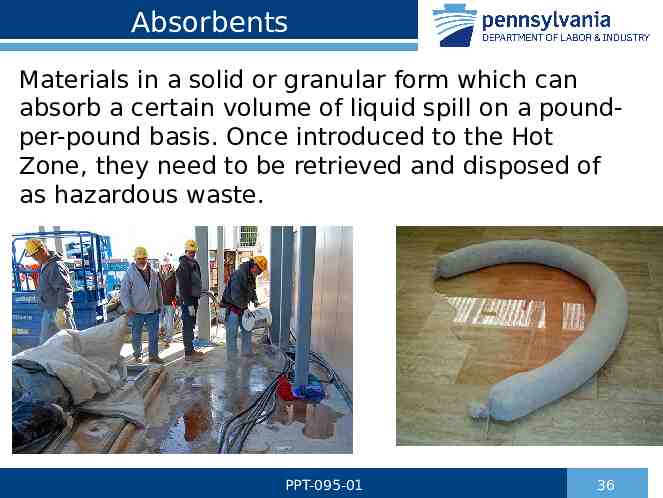

Absorbents Materials in a solid or granular form which can absorb a certain volume of liquid spill on a poundper-pound basis. Once introduced to the Hot Zone, they need to be retrieved and disposed of as hazardous waste. PPT-095-01 36

Damming Involves constructing a downstream impediment to flow. The 2 most often used are the 1) overflow and 2) underflow dam depending on the Specific Gravity (SG) of the liquid flowing. PPT-095-01 37

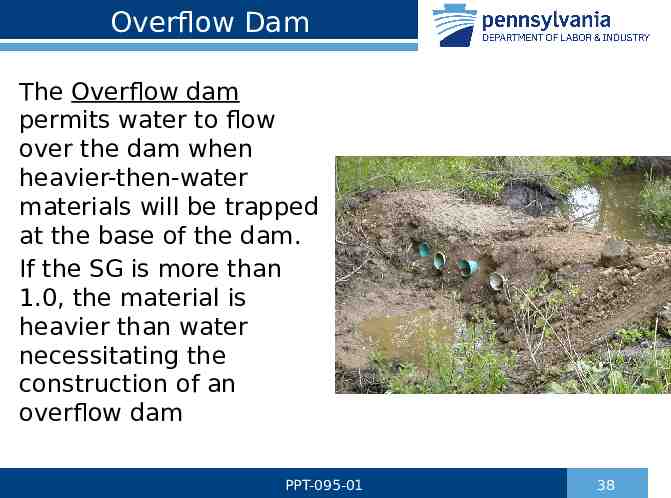

Overflow Dam The Overflow dam permits water to flow over the dam when heavier-then-water materials will be trapped at the base of the dam. If the SG is more than 1.0, the material is heavier than water necessitating the construction of an overflow dam PPT-095-01 38

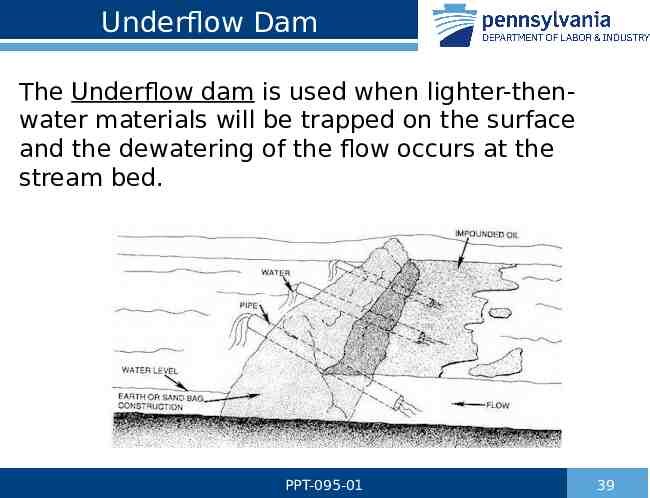

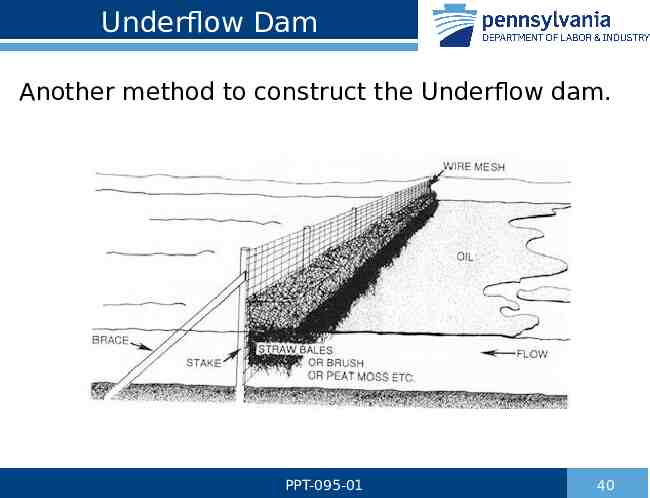

Underflow Dam The Underflow dam is used when lighter-thenwater materials will be trapped on the surface and the dewatering of the flow occurs at the stream bed. PPT-095-01 39

Underflow Dam Another method to construct the Underflow dam. PPT-095-01 40

Diking Placing a physical barrier around the material’s perimeter to prevent its spread. This guards against the intrusion of the material to other products, drains, or the environment Also called Retention Identify potential paths for travel releases before an occurrence! PPT-095-01 41

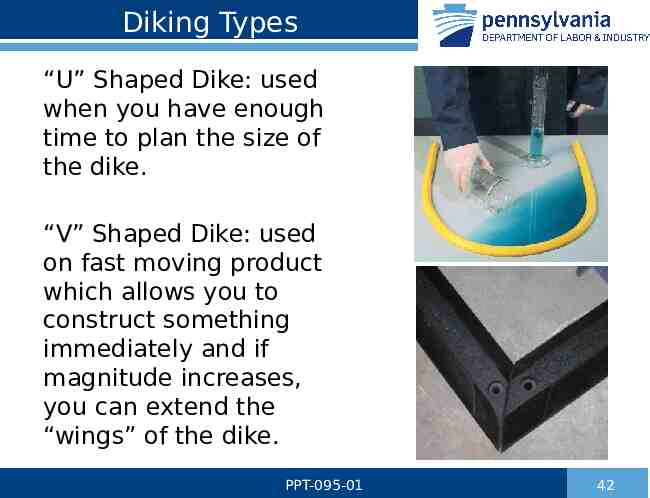

Diking Types “U” Shaped Dike: used when you have enough time to plan the size of the dike. “V” Shaped Dike: used on fast moving product which allows you to construct something immediately and if magnitude increases, you can extend the “wings” of the dike. PPT-095-01 42

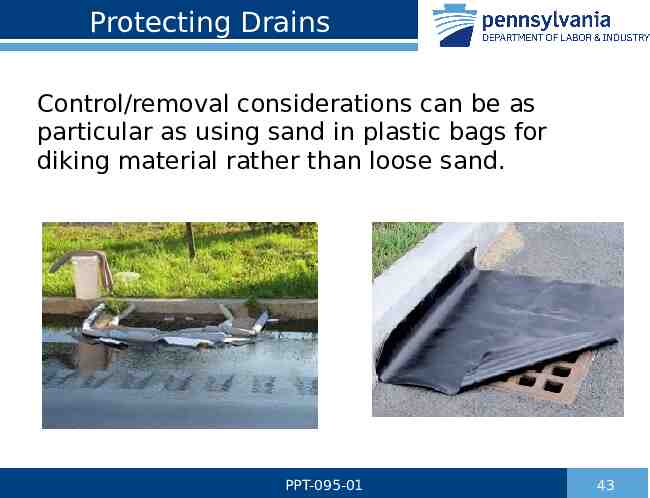

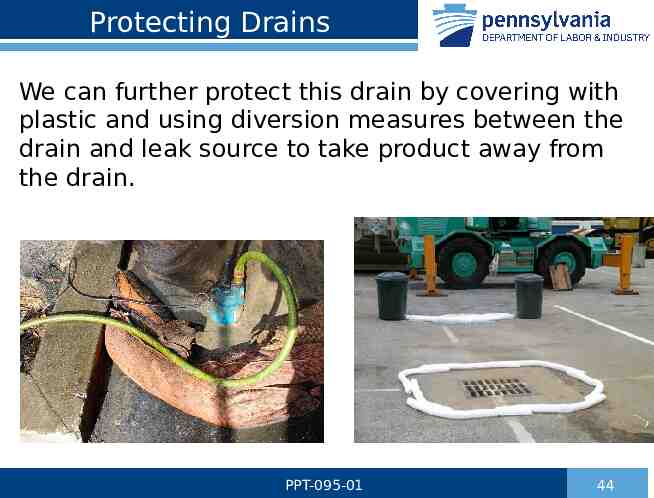

Protecting Drains Control/removal considerations can be as particular as using sand in plastic bags for diking material rather than loose sand. PPT-095-01 43

Protecting Drains We can further protect this drain by covering with plastic and using diversion measures between the drain and leak source to take product away from the drain. PPT-095-01 44

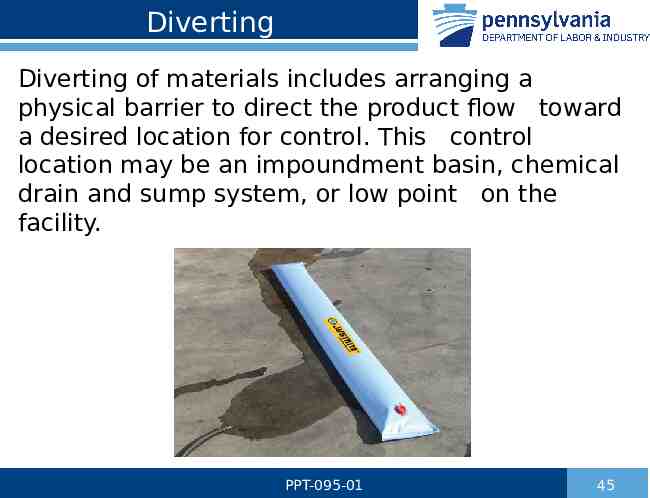

Diverting Diverting of materials includes arranging a physical barrier to direct the product flow toward a desired location for control. This control location may be an impoundment basin, chemical drain and sump system, or low point on the facility. PPT-095-01 45

Transferring Removal of product from its damaged containment to another containment or container. Possible hazards: Characteristics of the material being transferred, Possibility of spillage, Vapor production, Electrical ignition hazard. PPT-095-01 46

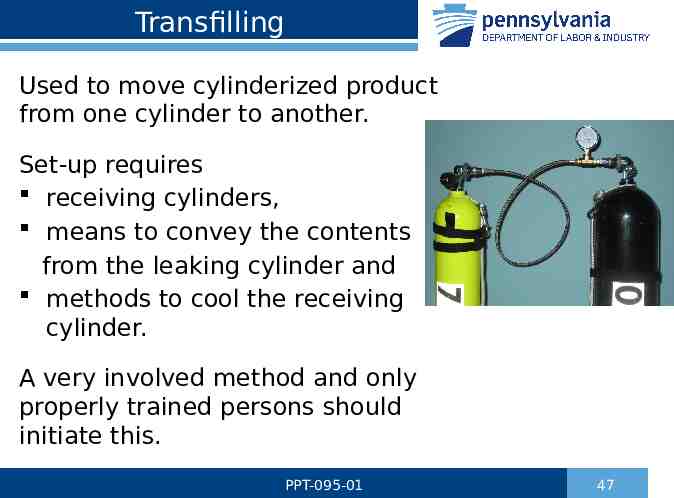

Transfilling Used to move cylinderized product from one cylinder to another. Set-up requires receiving cylinders, means to convey the contents from the leaking cylinder and methods to cool the receiving cylinder. A very involved method and only properly trained persons should initiate this. PPT-095-01 47

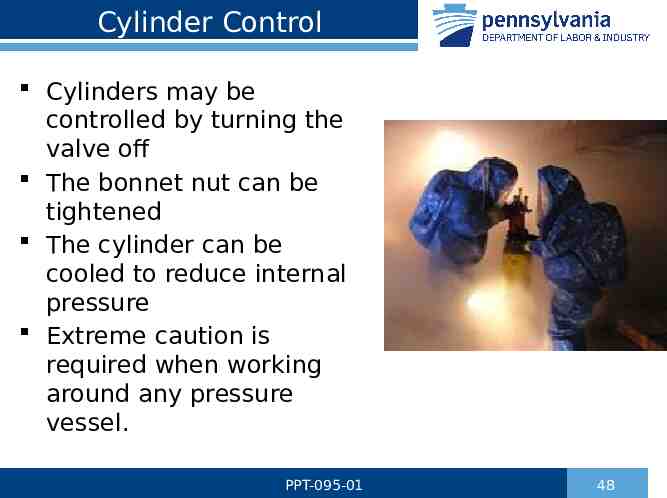

Cylinder Control Cylinders may be controlled by turning the valve off The bonnet nut can be tightened The cylinder can be cooled to reduce internal pressure Extreme caution is required when working around any pressure vessel. PPT-095-01 48

Plugging and Patching Plugging and patching is the use of compatible materials applied to the container to result in either a temporary or permanent seal at the point of damage. PPT-095-01 49

Plugging and Patching Ensure actions are coordinated for safety. PPT-095-01 50

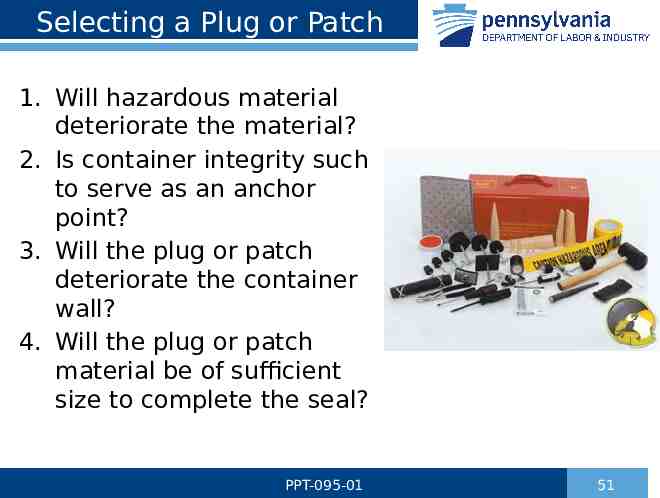

Selecting a Plug or Patch 1. Will hazardous material deteriorate the material? 2. Is container integrity such to serve as an anchor point? 3. Will the plug or patch deteriorate the container wall? 4. Will the plug or patch material be of sufficient size to complete the seal? PPT-095-01 51

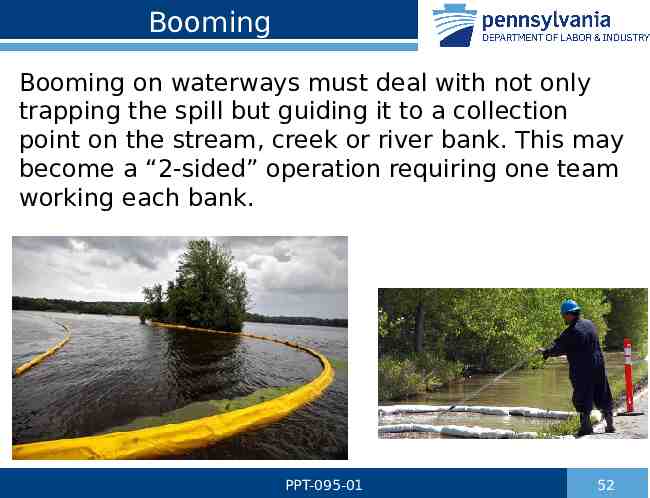

Booming Booming on waterways must deal with not only trapping the spill but guiding it to a collection point on the stream, creek or river bank. This may become a “2-sided” operation requiring one team working each bank. PPT-095-01 52

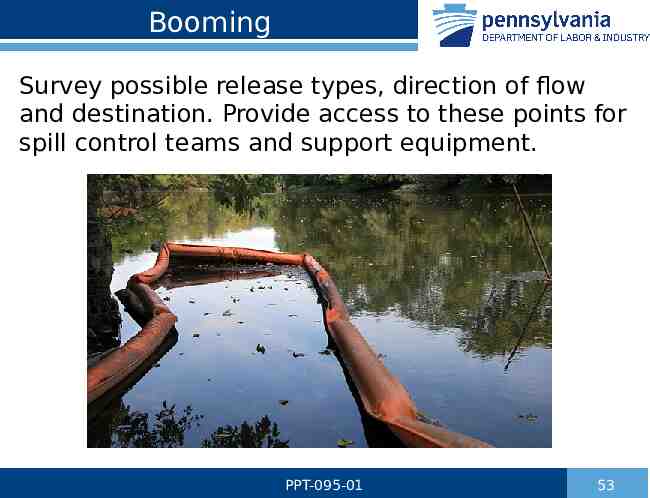

Booming Survey possible release types, direction of flow and destination. Provide access to these points for spill control teams and support equipment. PPT-095-01 53

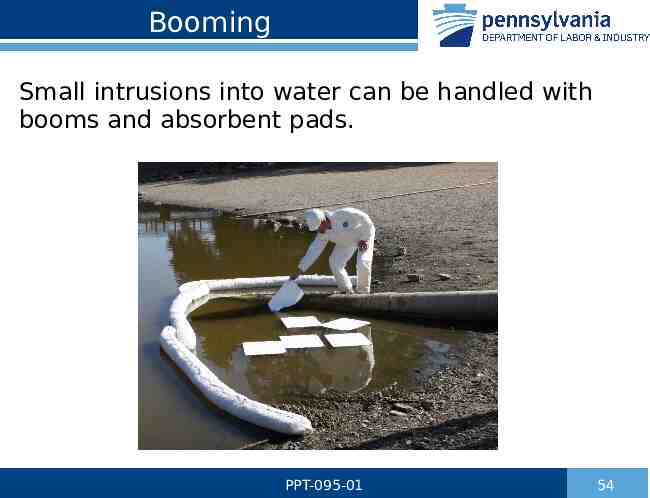

Booming Small intrusions into water can be handled with booms and absorbent pads. PPT-095-01 54

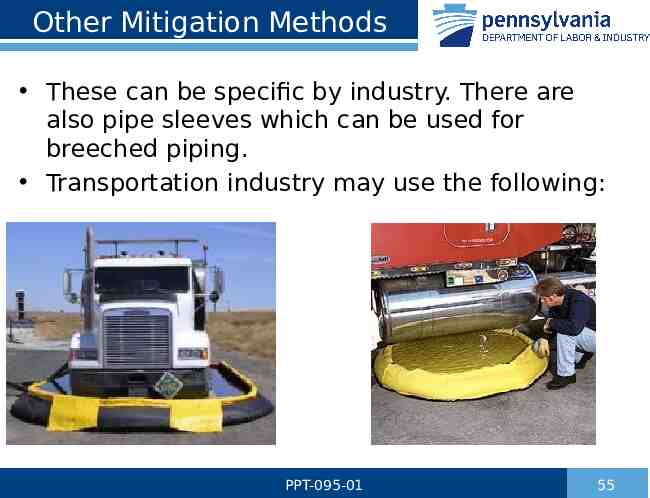

Other Mitigation Methods These can be specific by industry. There are also pipe sleeves which can be used for breeched piping. Transportation industry may use the following: PPT-095-01 55

Responder Levels and Actions Diluting or Neutralizing a spill Specialists or Technicians with Operations support Vapor suppression via fog stream, covering with foam, cooling cylinders. Usually accomplished by Fire Personnel from a distance. PPT-095-01 56

Responder Levels and Actions Physical Control. These can be done remote from the spill, anticipating the direction of flow by Operations level personnel. Remote shut-offs Absorbents Damming Diking Diverting PPT-095-01 57

Responder Levels and Actions Physical Control These may best be handled by Technicians. Transferring Transfilling Plugging and patching Booming and damming on waterways.* PPT-095-01 58

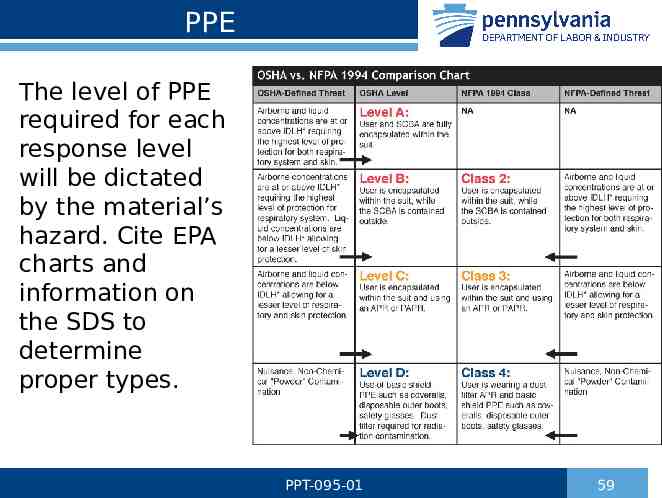

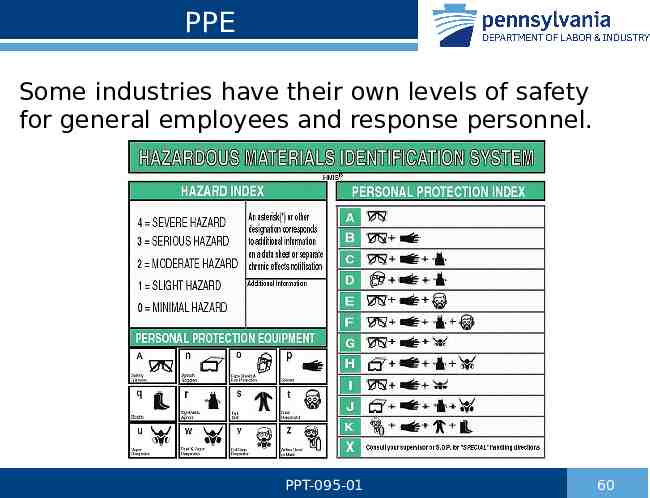

PPE The level of PPE required for each response level will be dictated by the material’s hazard. Cite EPA charts and information on the SDS to determine proper types. PPT-095-01 59

PPE Some industries have their own levels of safety for general employees and response personnel. PPT-095-01 60

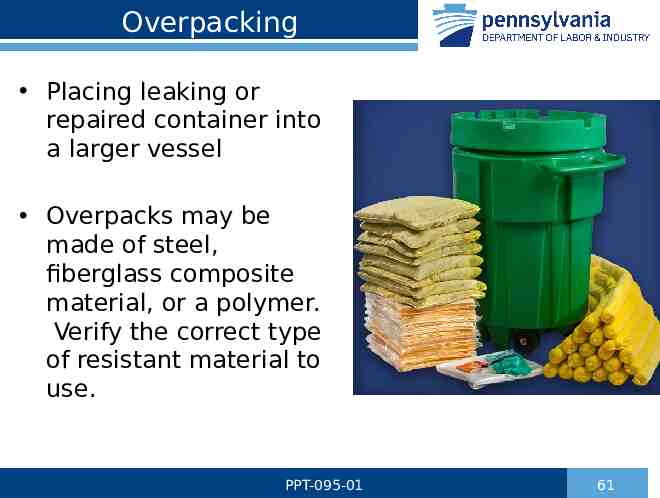

Overpacking Placing leaking or repaired container into a larger vessel Overpacks may be made of steel, fiberglass composite material, or a polymer. Verify the correct type of resistant material to use. PPT-095-01 61

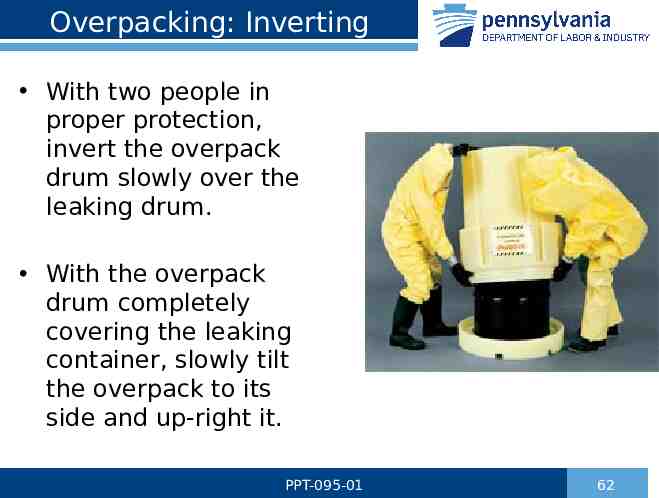

Overpacking: Inverting With two people in proper protection, invert the overpack drum slowly over the leaking drum. With the overpack drum completely covering the leaking container, slowly tilt the overpack to its side and up-right it. PPT-095-01 62

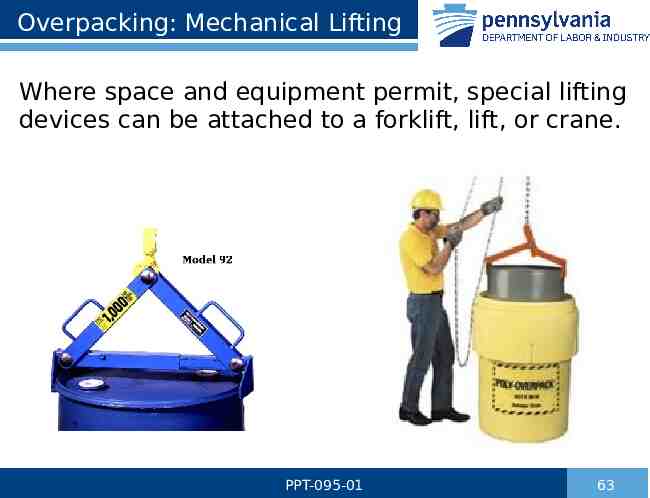

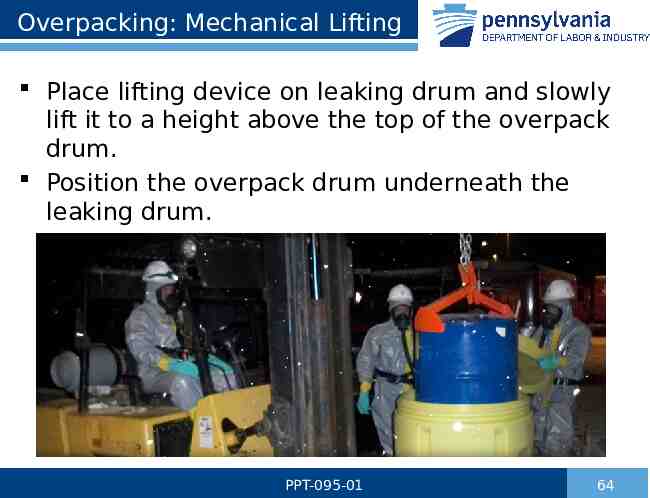

Overpacking: Mechanical Lifting Where space and equipment permit, special lifting devices can be attached to a forklift, lift, or crane. PPT-095-01 63

Overpacking: Mechanical Lifting Place lifting device on leaking drum and slowly lift it to a height above the top of the overpack drum. Position the overpack drum underneath the leaking drum. PPT-095-01 64

Overpacking: Mechanical Lifting Slowly lower the leaking drum into the overpack Place compatible absorbent (shim) material into overpack between the leaking drum. Seal, label, and remove the overpack to a segregated storage point for disposal. PPT-095-01 65

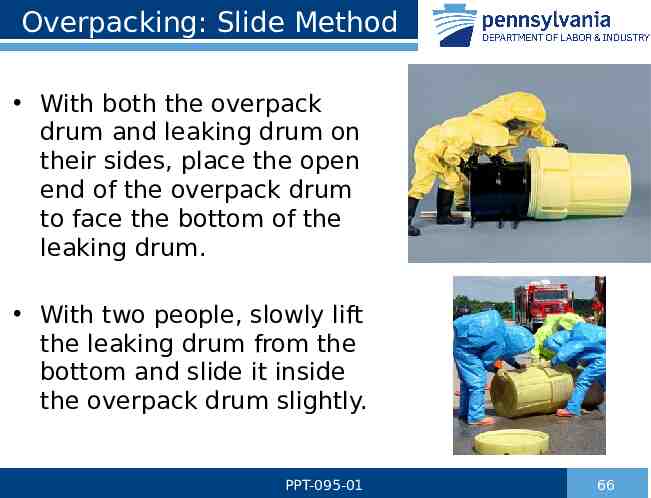

Overpacking: Slide Method With both the overpack drum and leaking drum on their sides, place the open end of the overpack drum to face the bottom of the leaking drum. With two people, slowly lift the leaking drum from the bottom and slide it inside the overpack drum slightly. PPT-095-01 66

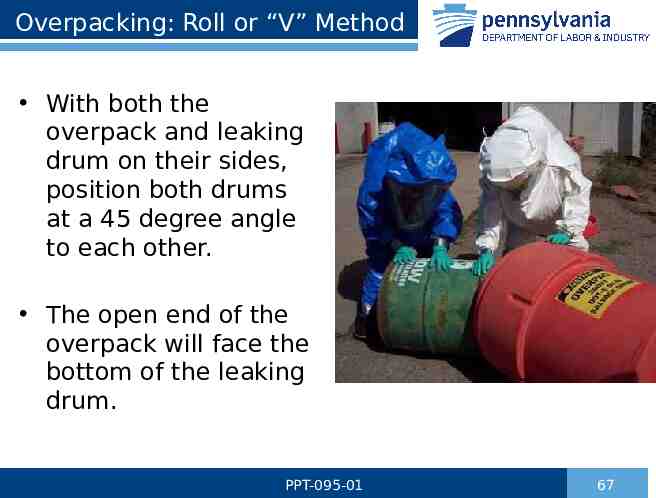

Overpacking: Roll or “V” Method With both the overpack and leaking drum on their sides, position both drums at a 45 degree angle to each other. The open end of the overpack will face the bottom of the leaking drum. PPT-095-01 67

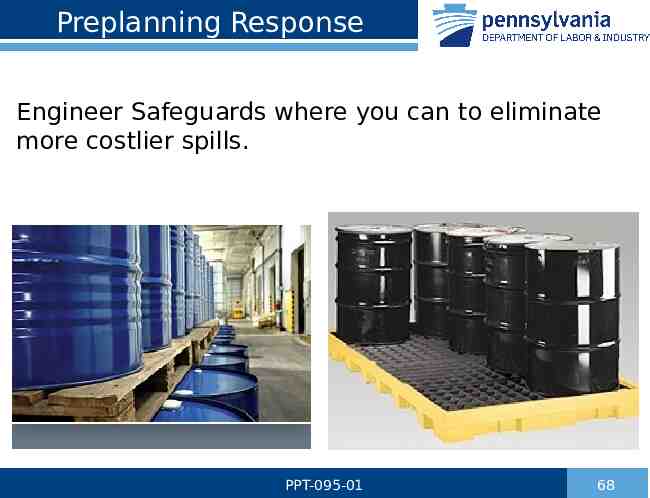

Preplanning Response Engineer Safeguards where you can to eliminate more costlier spills. PPT-095-01 68

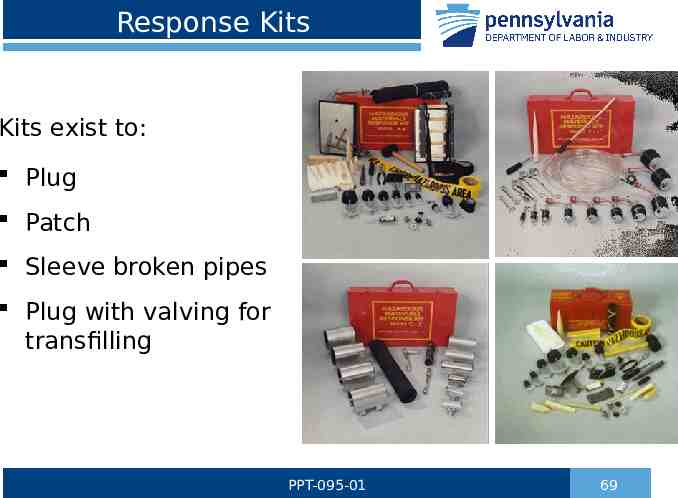

Response Kits Kits exist to: Plug Patch Sleeve broken pipes Plug with valving for transfilling PPT-095-01 69

Response Kits Spill control kits are available for drum spills. Various gallon capacities are also available. PPT-095-01 70

Lab Kits Lab kits exist for lab spills. PPT-095-01 71

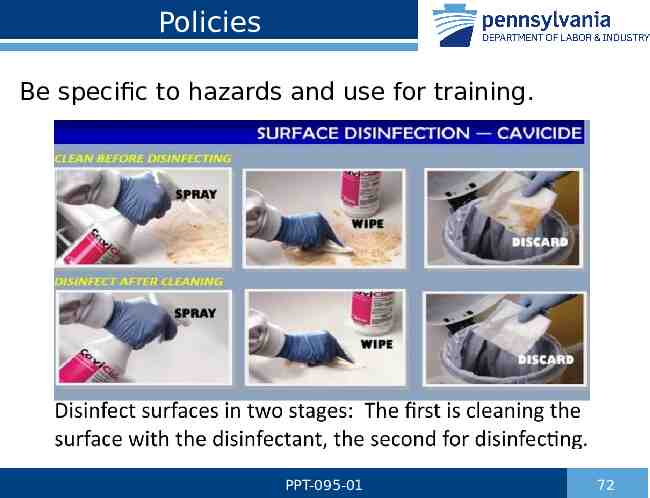

Policies Be specific to hazards and use for training. PPT-095-01 72

Policies For small or nuisance spills. PPT-095-01 73

Policies Larger Operations or Greater Hazard Response PPT-095-01 74

Policies Specialized control operations. PPT-095-01 75

Policies Regulations may not permit you to let a leaking shipment leave your facility. So, you may end up responding to some one else’s incident. Create team policies for such responses. PPT-095-01 76

Removal and Disposal Includes recovery and disposal of a hazardous material (waste). This phase requires careful thought and planning It must also be considered before actions are taken to clean-up a spill. Whatever is introduced to the spill area will then be included as hazardous waste. PPT-095-01 77

Decontamination The completion of any operation will require decontamination of personnel. It may also be required for machines, systems, and other impacted areas. The level of PPE worn will be product-dependent for each work zone and the decon team. PPT-095-01 78

Documentation Proper documentation of the receipt of a hazardous substance and also the disposal of it as a hazardous waste must be in place. Prior contact with a licensed hazardous waste contractor must be accomplished and the mechanism for disposal must be in your contingency plan for an emergency response. PPT-095-01 79

Training Provide training per the standard (29 CFR 1910.120(q)) Use hands-on practical training for simulated situations Train with off-site responders in table top exercises PPT-095-01 80

Self Test 1. Select a facility chemical and the support documents to respond to an incident 2. Determine exposure limits for team 3. Air monitoring required 4. PPE required 5. What level responds? Operations? Technician? Specialist? 6. Spill control actions 7. Decontamination required 8. Documentation and reporting PPT-095-01 81

Summary Determine your need for a spill control team Will it be self-reliant or depend on off-site responders? Partially or totally? Assign team members if you have a team Train your team to the level of response expectations Provide required PPE, spill control equipment, air monitoring equipment as required Determine type of decon and provide that equipment Ensure your program meets safety and regulatory requirements PPT-095-01 82

Bibliography NFPA 471, “Recommended Practice for Responding to Hazardous Material Incidents,” National Fire Protection Association, 1 Batterymarch Park, Quincy, MA 02169-7471. NFPA 472, “Standard for Professional Competence of Responders to Hazardous Material Incidents,” National Fire Protection Association, 1 Batterymarch Park, Quincy, MA 02169-7471. PPT-095-01 83

Bibliography Code of Federal Regulations, 29 CFR 1910120(q) Hazardous Waste Operations and Emergency Response, (HAZWOPER), March 6, 1990. 29 CFR 1910.120, Appendix E Training Curriculum Guidelines, C. Emergency response training, C,b, (1), (2), (3), (4) and (5) Emergency Response Training Manual for Hazardous Materials Technician, Lori P. Andrews, P.E., et.al, Center for Labor Education and Research, Van Nostrand Reinhold, New York, 1992 PPT-095-01 84

Bibliography Neutralization of Corrosive Materials, AFR 71-4, A15, TM 38-250/NAVSUP PUB 505 (Rev)/MCO P4030.19D/DSAM 4145.3/Atch 5/22, March, 1976 (as an example) Hazardous Materials Response Handbook, Jerry Laughlin and David G. Trebisacci, editors, NFPA, 4th Edition, 2002. PPT-095-01 85

Contact Information Health & Safety Training Specialists 1171 South Cameron Street, Room 324 Harrisburg, PA 17104-2501 (717) 772-1635 [email protected] PPT-095-01 86

Other Power Points of Interest You may also wish to view our other Power Points to create your own in-house training program for this topic. Supporting PowerPoint programs include: Basic Air Monitoring HazMat PPE Hazard Communication GHS Hazardous Materials Awareness Hazardous Waste Management Decontamination Find them on our website at www.dli.state.pa.us/PATHS then click Training Resources in the left column. If not on our web, request our list of programs at [email protected] PPT-095-01 87