Risk Analysis in Design and Construction of a Hydropower Station

39 Slides3.57 MB

Risk Analysis in Design and Construction of a Hydropower Station Svana Helen Björnsdóttir, PhD candidate 4th European STAMP Workshop ZHAW, Zürich, 13.-15. Sept. 2016

INTRODUCTION S.H.Bjornsdottir Stiki/Reykjavik University 2

Aim of Research Seek a generic risk analysis methodology that can be used in different disciplines Case Study: Hydropower project – one of six – Examine currently used risk analysis methodology – Apply STAMP/STPA to investigate whether it can be used as a basis for a generic risk analysis methodology – Evaluate and compare S.H.Bjornsdottir Stiki/Reykjavik University 3

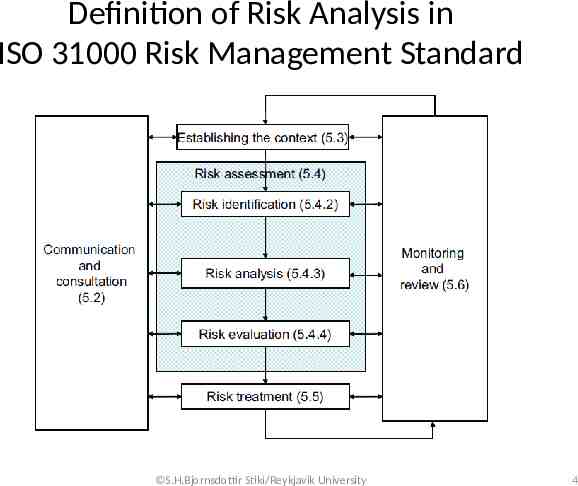

Definition of Risk Analysis in ISO 31000 Risk Management Standard S.H.Bjornsdottir Stiki/Reykjavik University 4

Main Research Question What is a generic risk analysis methodology that can be applied in different disciplines? S.H.Bjornsdottir Stiki/Reykjavik University 5

Research Sub-Questions What is a risk analysis methodology? What are the commonalities of risk analysis methodologies in different disciplines? What are the requirements for a generic risk analysis methodology? Can STAMP/STPA fulfill these requirements? S.H.Bjornsdottir Stiki/Reykjavik University 6

ICELAND NATIONAL POWER COMPANY LANDSVIRKJUN S.H.Bjornsdottir Stiki/Reykjavik University 7

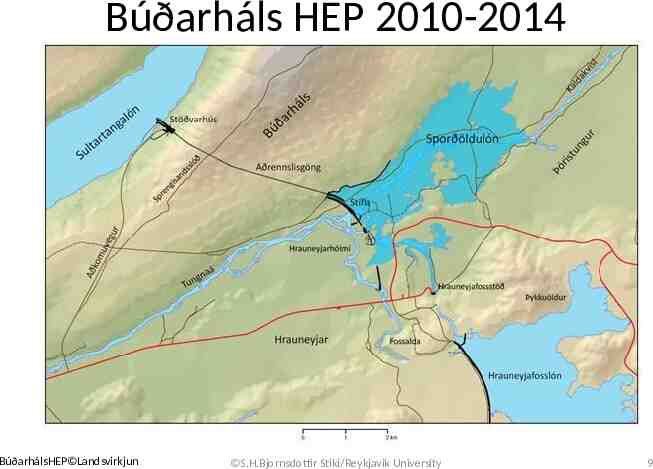

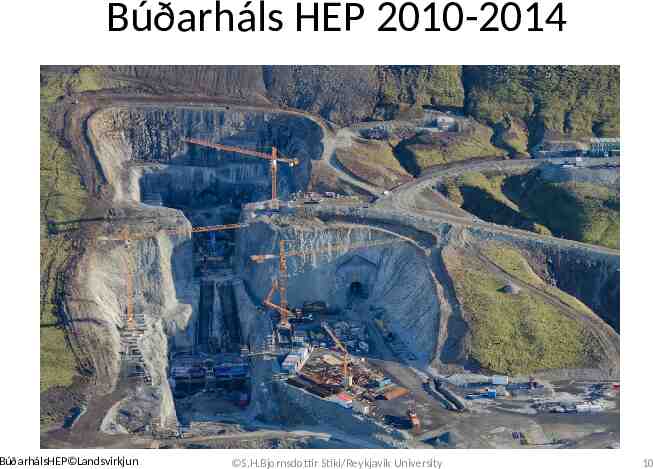

National Power Company Owned by the state Operates 15 power stations in Iceland Emphasis on operations in harmony with environment and society One of the largest producers of renewable energy in Europe Case Study: Latest Hydro Electro Project (HEP) Búðarháls, built in 2010-2014 S.H.Bjornsdottir Stiki/Reykjavik University 8

Búðarháls HEP 2010-2014 BúðarhálsHEP Landsvirkjun S.H.Bjornsdottir Stiki/Reykjavik University 9

Búðarháls HEP 2010-2014 BúðarhálsHEP Landsvirkjun S.H.Bjornsdottir Stiki/Reykjavik University 10

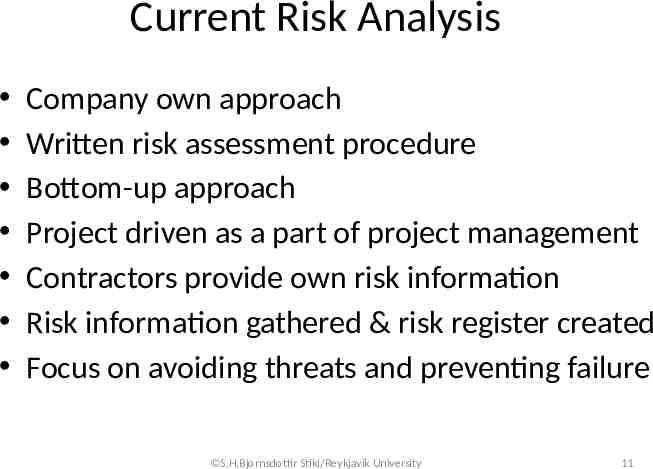

Current Risk Analysis Company own approach Written risk assessment procedure Bottom-up approach Project driven as a part of project management Contractors provide own risk information Risk information gathered & risk register created Focus on avoiding threats and preventing failure S.H.Bjornsdottir Stiki/Reykjavik University 11

RESEARCH METHOD S.H.Bjornsdottir Stiki/Reykjavik University 12

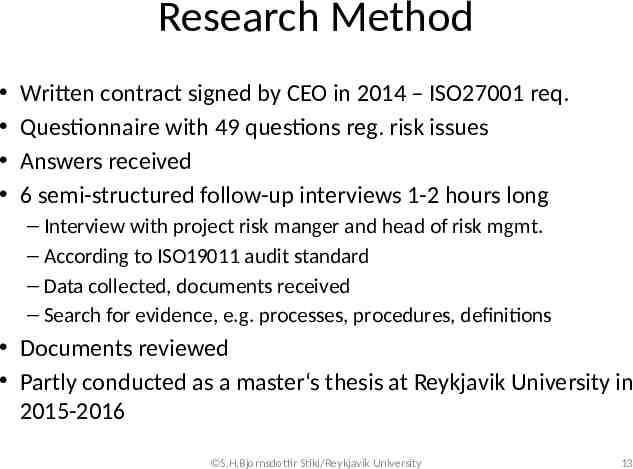

Research Method Written contract signed by CEO in 2014 – ISO27001 req. Questionnaire with 49 questions reg. risk issues Answers received 6 semi-structured follow-up interviews 1-2 hours long – Interview with project risk manger and head of risk mgmt. – According to ISO19011 audit standard – Data collected, documents received – Search for evidence, e.g. processes, procedures, definitions Documents reviewed Partly conducted as a master‘s thesis at Reykjavik University in 2015-2016 S.H.Bjornsdottir Stiki/Reykjavik University 13

APPLICATION OF STAMP/STPA S.H.Bjornsdottir Stiki/Reykjavik University 14

Why STAMP/STPA? Current risk methodology does not capture risk in a holistic way Company policy to seek continuous improvements in risk management Improve decision making process To get a different perspective on risk than currently exists Systems approach to risk identification and risk analysis is needed S.H.Bjornsdottir Stiki/Reykjavik University 15

Project Goals in the HEP Project goal is to complete and deliver a hydropower station: – In time for planned operation and energy sales – In compliance with law, regulations, contracts and standards – Without exceeding the approved budget plan – For safe operation and delivery of sufficient power S.H.Bjornsdottir Stiki/Reykjavik University 16

Accidents/Unacceptable Losses A1: A1: A3: A4: A5: A6: A7: Loss of human lives Financial loss (overrun of budget or project delay) Unsafe usage of equipment and other resources Power plant does not deliver sufficient power Breach of laws, regulations, contracts, standards Loss of public policy support Loss of safety/security/quality when outsourcing S.H.Bjornsdottir Stiki/Reykjavik University 17

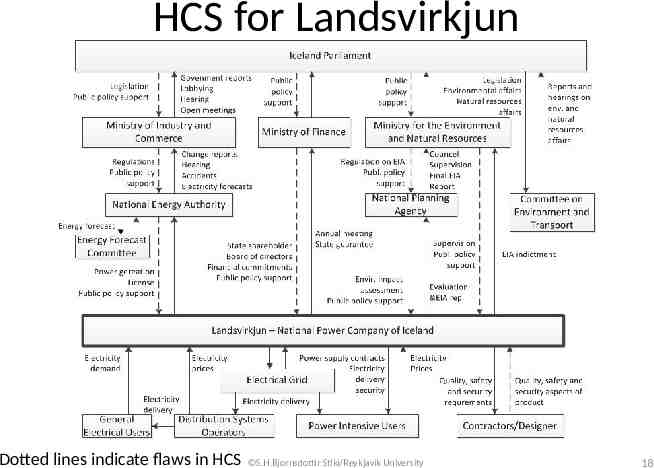

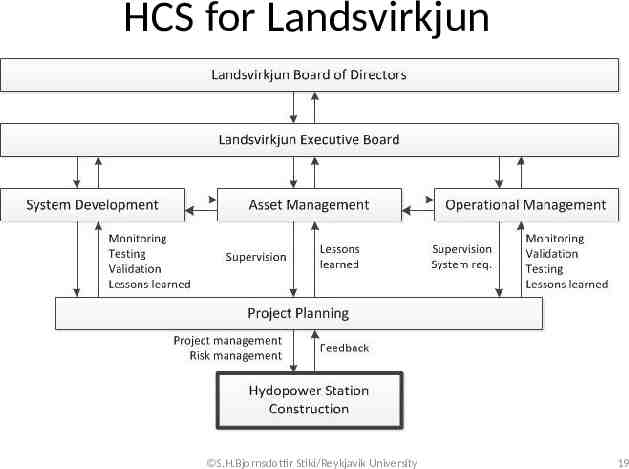

HCS for Landsvirkjun Dotted lines indicate flaws in HCS S.H.Bjornsdottir Stiki/Reykjavik University 18

HCS for Landsvirkjun S.H.Bjornsdottir Stiki/Reykjavik University 19

Main Hazards and Threats Three main hazards and threats: H1: Project not finished in time for operation to start H2: Injury or loss of human lives H3: Overrun of budget plan S.H.Bjornsdottir Stiki/Reykjavik University 20

System-Level Safety Constraints Management team must establish a control structure to manage project and project risk People working on construction site must not be injured Measure must be taken to reduce likelihood of accidents on construction site Means must be available and effective to treat risk on site Project risk manager must review and monitor risk in project plans Operational Management must be involved early enough to supervise and validate system requirements S.H.Bjornsdottir Stiki/Reykjavik University 21

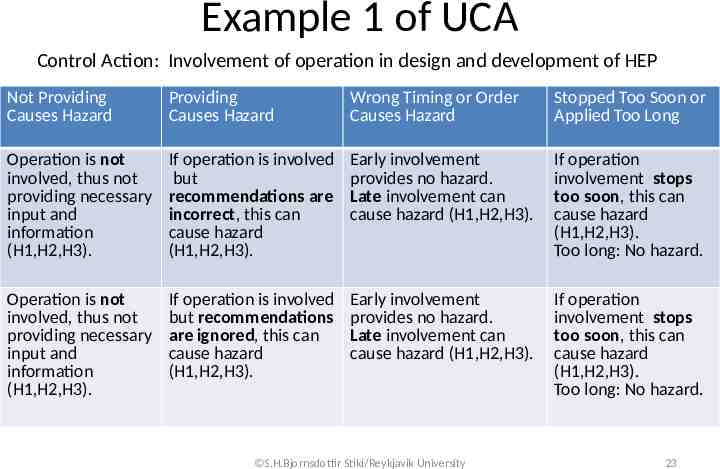

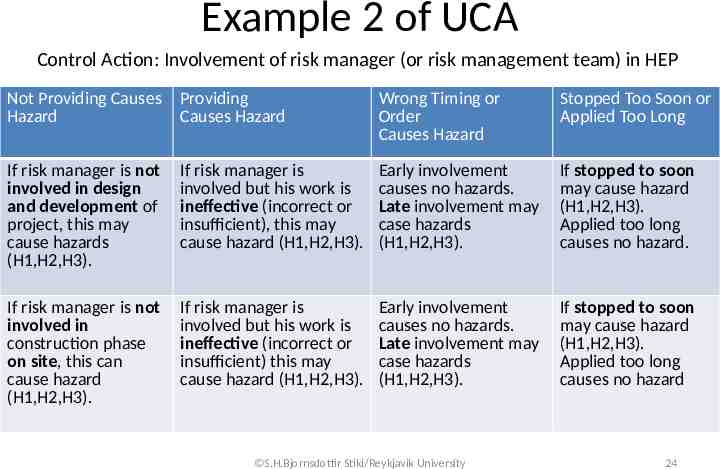

Control Actions Two cases of Control Actions investigated: – Involvement of operation in design and development of HEP – Involvement of risk manager (or risk management team) in HEP – investigated by a master’s student at Reykjavik University, see workshop poster S.H.Bjornsdottir Stiki/Reykjavik University 22

Example 1 of UCA Control Action: Involvement of operation in design and development of HEP Not Providing Causes Hazard Providing Causes Hazard Wrong Timing or Order Causes Hazard Stopped Too Soon or Applied Too Long Operation is not involved, thus not providing necessary input and information (H1,H2,H3). If operation is involved but recommendations are incorrect, this can cause hazard (H1,H2,H3). Early involvement provides no hazard. Late involvement can cause hazard (H1,H2,H3). If operation involvement stops too soon, this can cause hazard (H1,H2,H3). Too long: No hazard. Operation is not involved, thus not providing necessary input and information (H1,H2,H3). If operation is involved but recommendations are ignored, this can cause hazard (H1,H2,H3). Early involvement provides no hazard. Late involvement can cause hazard (H1,H2,H3). If operation involvement stops too soon, this can cause hazard (H1,H2,H3). Too long: No hazard. S.H.Bjornsdottir Stiki/Reykjavik University 23

Example 2 of UCA Control Action: Involvement of risk manager (or risk management team) in HEP Not Providing Causes Hazard Providing Causes Hazard Wrong Timing or Order Causes Hazard Stopped Too Soon or Applied Too Long If risk manager is not involved in design and development of project, this may cause hazards (H1,H2,H3). If risk manager is involved but his work is ineffective (incorrect or insufficient), this may cause hazard (H1,H2,H3). Early involvement causes no hazards. Late involvement may case hazards (H1,H2,H3). If stopped to soon may cause hazard (H1,H2,H3). Applied too long causes no hazard. If risk manager is not involved in construction phase on site, this can cause hazard (H1,H2,H3). If risk manager is involved but his work is ineffective (incorrect or insufficient) this may cause hazard (H1,H2,H3). Early involvement causes no hazards. Late involvement may case hazards (H1,H2,H3). If stopped to soon may cause hazard (H1,H2,H3). Applied too long causes no hazard S.H.Bjornsdottir Stiki/Reykjavik University 24

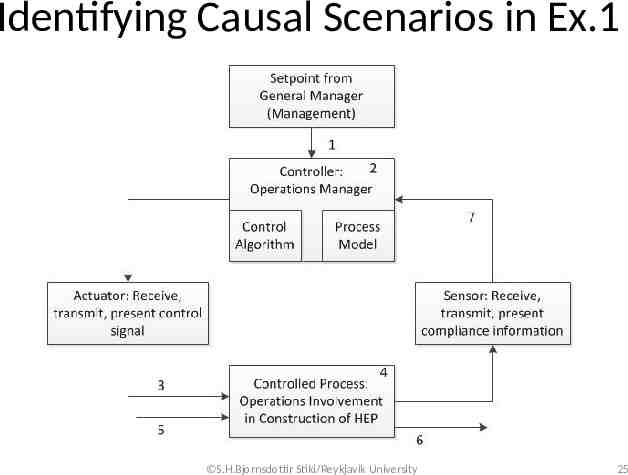

Identifying Causal Scenarios in Ex.1 S.H.Bjornsdottir Stiki/Reykjavik University 25

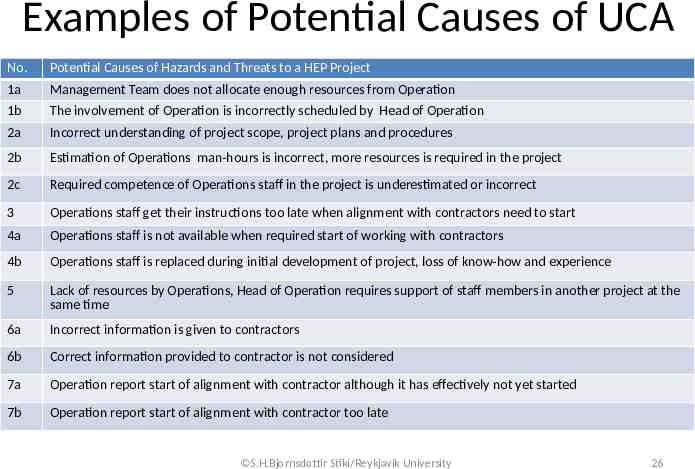

Examples of Potential Causes of UCA No. Potential Causes of Hazards and Threats to a HEP Project 1a Management Team does not allocate enough resources from Operation 1b The involvement of Operation is incorrectly scheduled by Head of Operation 2a Incorrect understanding of project scope, project plans and procedures 2b Estimation of Operations man-hours is incorrect, more resources is required in the project 2c Required competence of Operations staff in the project is underestimated or incorrect 3 Operations staff get their instructions too late when alignment with contractors need to start 4a Operations staff is not available when required start of working with contractors 4b Operations staff is replaced during initial development of project, loss of know-how and experience 5 Lack of resources by Operations, Head of Operation requires support of staff members in another project at the same time 6a Incorrect information is given to contractors 6b Correct information provided to contractor is not considered 7a Operation report start of alignment with contractor although it has effectively not yet started 7b Operation report start of alignment with contractor too late S.H.Bjornsdottir Stiki/Reykjavik University 26

FINDINGS AND EVALUATION S.H.Bjornsdottir Stiki/Reykjavik University 27

Findings and Evaluation Búðarháls HEP was a successful project – Time and budget plans were met – No major accident, however near-to losses – Risk management processes were followed Comparison of two risk registers: – Risk register from 2011 has 149 risks – Risk register from 2013-2014 has 154 risks Risk management strategy in Búðarháls HEP: – Define goals – Risk matrix approach with contribution from contractors S.H.Bjornsdottir Stiki/Reykjavik University 28

Findings and Evaluation STAMP/STPA takes a different approach: – Create HCS and define roles and responsibilities – Define unacceptable losses STAMP/STPA framework is a more structured approach Clear methodology and process for analyzing risk Traceability ensured Justification and rationale are available Identification of causes of unsafe or inadequate Control Actions CAs and causes of UCA or ICAs in the case study are credible S.H.Bjornsdottir Stiki/Reykjavik University 29

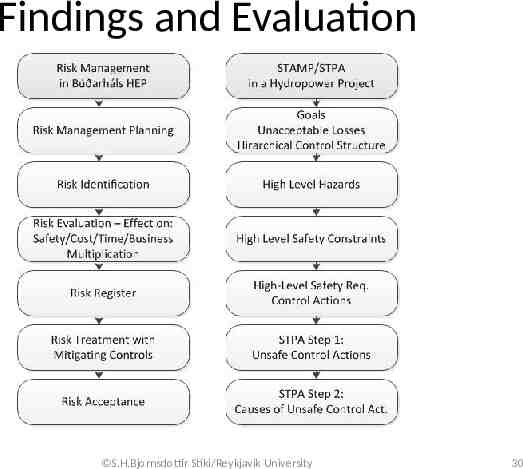

Findings and Evaluation S.H.Bjornsdottir Stiki/Reykjavik University 30

Findings and Evaluation With STPA more detailed and precise risk mitigation strategies can be developed The bottom-up risk approach in Búðarháls HEP proves to be practical in many ways – contractors are able to understand, share and participate Two types of project risk investigated – High level project risk – Risk in the risk management process itself STPA can be used independently by an analyst with knowledge of techniques and project context S.H.Bjornsdottir Stiki/Reykjavik University 31

Findings and Evaluation Not all risks in a hydropower project can be identified with project based bottom-up risk analysis methodology With STPA we get another perspective that helps us identify previously unidentified risks Flaws in the control structure were identified with STPA – but not by current method S.H.Bjornsdottir Stiki/Reykjavik University 32

Findings and Evaluation Request for combined use of STPA and bottomup risk analysis ISO standards require well defined risk analysis methodology – but don’t tell how In long term STAMP/STPA will influence: – Development of ISO risk management standards – Project management standards, e.g. requirements and checklists – Contracts, compliance requirements S.H.Bjornsdottir Stiki/Reykjavik University 33

CONCLUSIONS S.H.Bjornsdottir Stiki/Reykjavik University 34

Conclusions No generic risk analysis methodology has yet been defined as such, but STAMP/STPA has been applied in many different disciplines Risk terms not yet properly defined as science requires – depends on industry sector and research field Risk based thinking now required in ISO9001 quality management standard Risk analysis methodologies need to be defined for scientific use S.H.Bjornsdottir Stiki/Reykjavik University 35

Conclusions There are commonalities of risk analysis requirements in different industries, e.g. when using ISO31000 The requirements for a generic risk analysis methodology must be investigated further No limitation found to the applicability of STAMP/STPA other than it requires training, understanding – and preferably a software tool to support use S.H.Bjornsdottir Stiki/Reykjavik University 36

BúðarhálsHEP Landsvirkjun S.H.Bjornsdottir Stiki/Reykjavik University 37

Thanks to . Landsvirkjun Páll Jensson Robert Jan de Boer Katrín Dögg Sigurðardóttir Lorene Pelegrín S.H.Bjornsdottir Stiki/Reykjavik University 38

Questions and further information? Svana Helen Björnsdóttir [email protected] S.H.Bjornsdottir Stiki/Reykjavik University 39