PXIE RFQ Design Review Introduction to the PXIE RFQ Engineering

13 Slides6.83 MB

PXIE RFQ Design Review Introduction to the PXIE RFQ Engineering Design Steve Virostek Engineering Division Lawrence Berkeley National Laboratory Berkeley, CA April 12, 2012

Topics LBNL RFQ experience PXIE RFQ design features Review of SNS RFQ design PXIE RFQ design methodology Thermal, RF and mechanical analyses Current progress S. Virostek: Introduction to RFQ Engineering Design PXIE RFQ Design Review, Berkeley, CA April 12, 2012

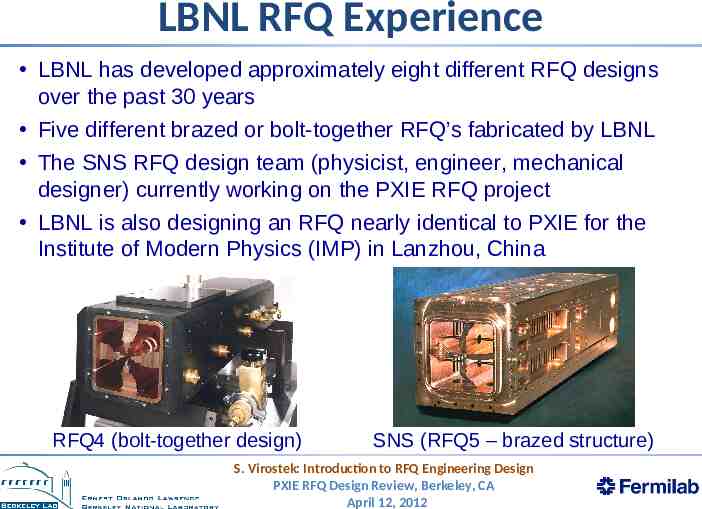

LBNL RFQ Experience LBNL has developed approximately eight different RFQ designs over the past 30 years Five different brazed or bolt-together RFQ’s fabricated by LBNL The SNS RFQ design team (physicist, engineer, mechanical designer) currently working on the PXIE RFQ project LBNL is also designing an RFQ nearly identical to PXIE for the Institute of Modern Physics (IMP) in Lanzhou, China RFQ4 (bolt-together design) SNS (RFQ5 – brazed structure) S. Virostek: Introduction to RFQ Engineering Design PXIE RFQ Design Review, Berkeley, CA April 12, 2012

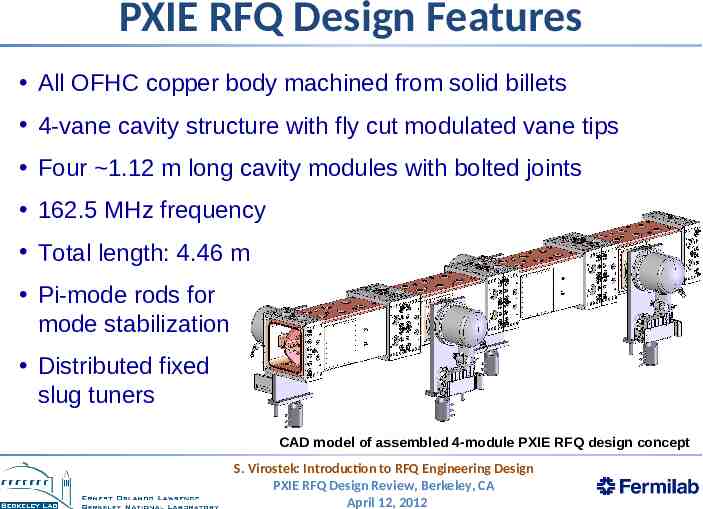

PXIE RFQ Design Features All OFHC copper body machined from solid billets 4-vane cavity structure with fly cut modulated vane tips Four 1.12 m long cavity modules with bolted joints 162.5 MHz frequency Total length: 4.46 m Pi-mode rods for mode stabilization Distributed fixed slug tuners CAD model of assembled 4-module PXIE RFQ design concept S. Virostek: Introduction to RFQ Engineering Design PXIE RFQ Design Review, Berkeley, CA April 12, 2012

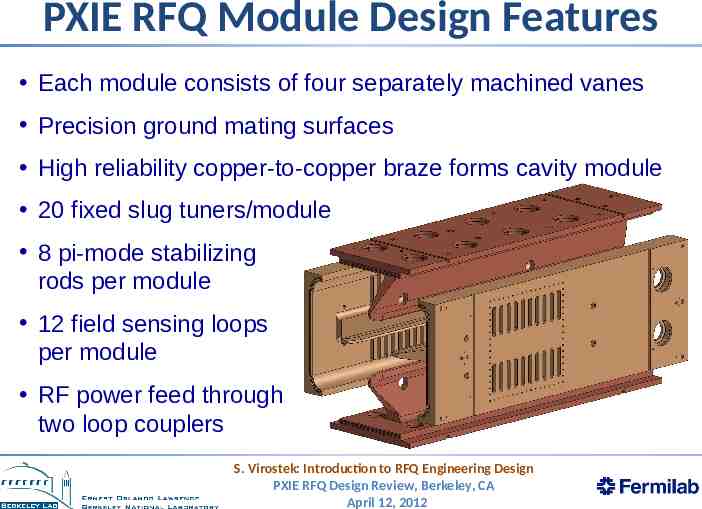

PXIE RFQ Module Design Features Each module consists of four separately machined vanes Precision ground mating surfaces High reliability copper-to-copper braze forms cavity module 20 fixed slug tuners/module 8 pi-mode stabilizing rods per module 12 field sensing loops per module RF power feed through two loop couplers S. Virostek: Introduction to RFQ Engineering Design PXIE RFQ Design Review, Berkeley, CA April 12, 2012

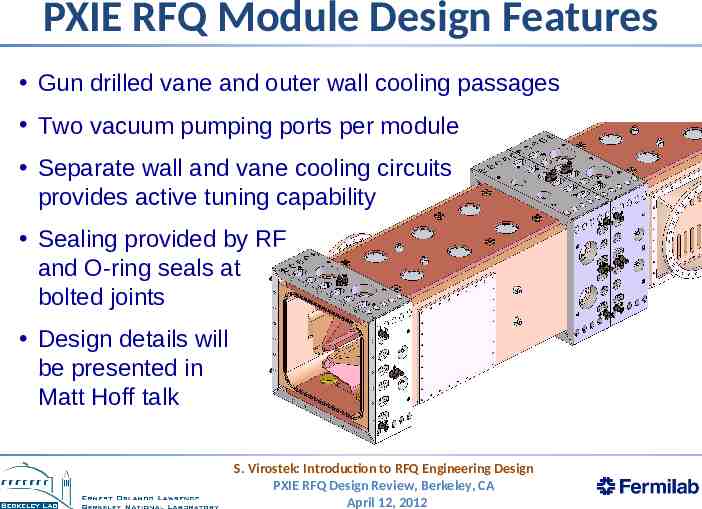

PXIE RFQ Module Design Features Gun drilled vane and outer wall cooling passages Two vacuum pumping ports per module Separate wall and vane cooling circuits provides active tuning capability Sealing provided by RF and O-ring seals at bolted joints Design details will be presented in Matt Hoff talk S. Virostek: Introduction to RFQ Engineering Design PXIE RFQ Design Review, Berkeley, CA April 12, 2012

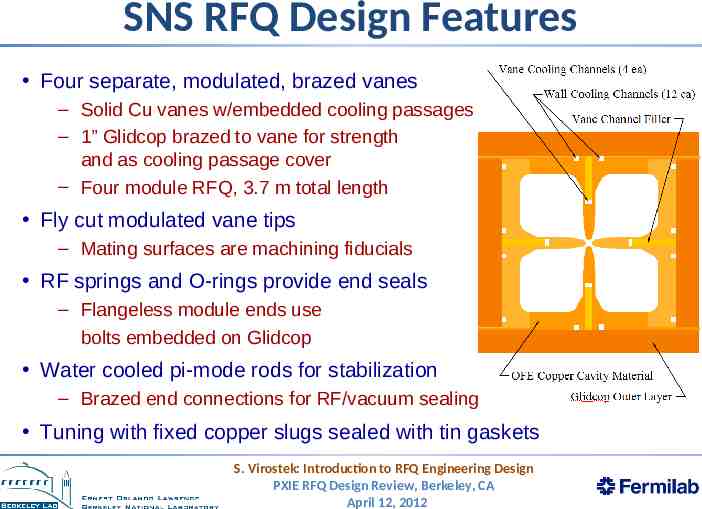

SNS RFQ Design Features Four separate, modulated, brazed vanes – Solid Cu vanes w/embedded cooling passages – 1” Glidcop brazed to vane for strength and as cooling passage cover – Four module RFQ, 3.7 m total length Fly cut modulated vane tips – Mating surfaces are machining fiducials RF springs and O-rings provide end seals – Flangeless module ends use bolts embedded on Glidcop Water cooled pi-mode rods for stabilization – Brazed end connections for RF/vacuum sealing Tuning with fixed copper slugs sealed with tin gaskets S. Virostek: Introduction to RFQ Engineering Design PXIE RFQ Design Review, Berkeley, CA April 12, 2012

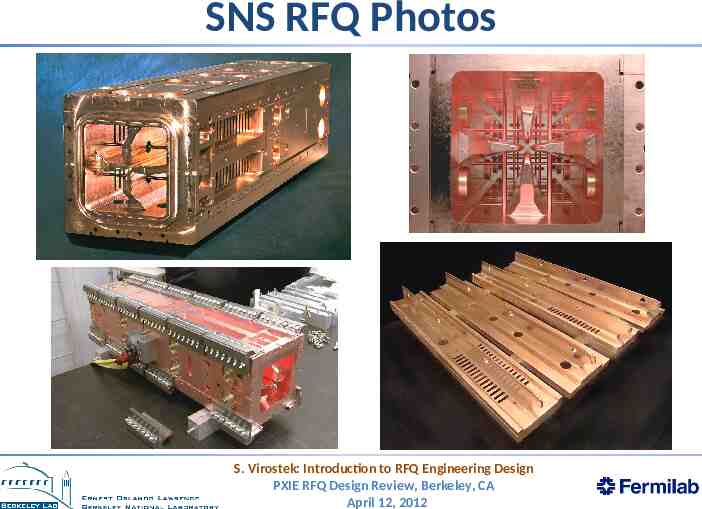

SNS RFQ Photos S. Virostek: Introduction to RFQ Engineering Design PXIE RFQ Design Review, Berkeley, CA April 12, 2012

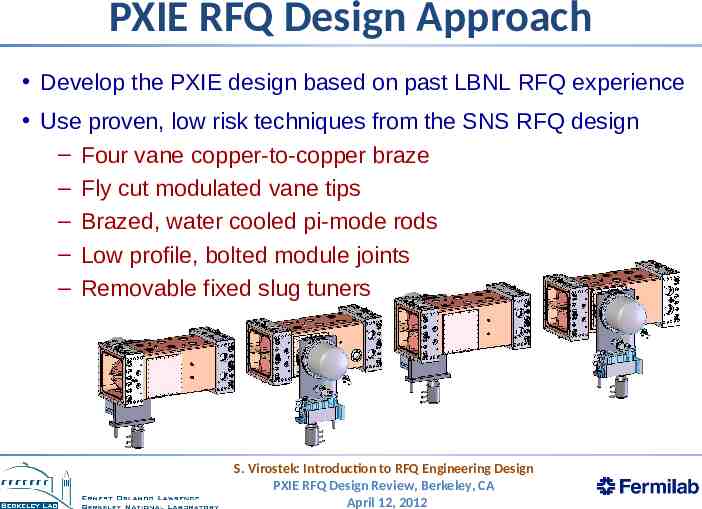

PXIE RFQ Design Approach Develop the PXIE design based on past LBNL RFQ experience Use proven, low risk techniques from the SNS RFQ design – Four vane copper-to-copper braze – Fly cut modulated vane tips – Brazed, water cooled pi-mode rods – Low profile, bolted module joints – Removable fixed slug tuners S. Virostek: Introduction to RFQ Engineering Design PXIE RFQ Design Review, Berkeley, CA April 12, 2012

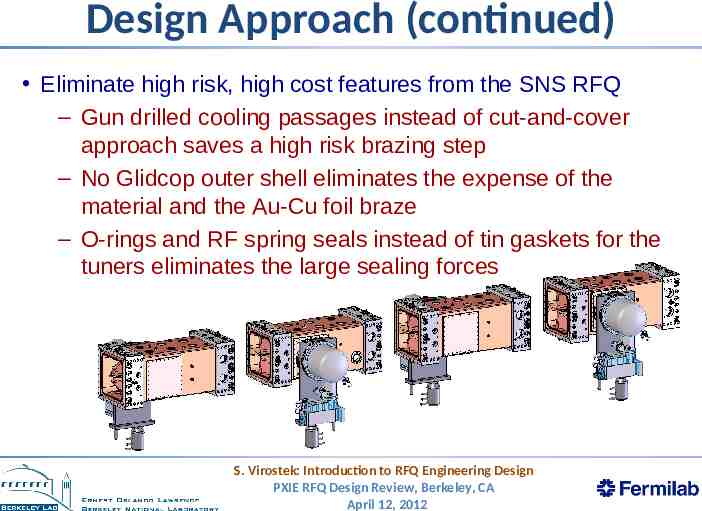

Design Approach (continued) Eliminate high risk, high cost features from the SNS RFQ – Gun drilled cooling passages instead of cut-and-cover approach saves a high risk brazing step – No Glidcop outer shell eliminates the expense of the material and the Au-Cu foil braze – O-rings and RF spring seals instead of tin gaskets for the tuners eliminates the large sealing forces S. Virostek: Introduction to RFQ Engineering Design PXIE RFQ Design Review, Berkeley, CA April 12, 2012

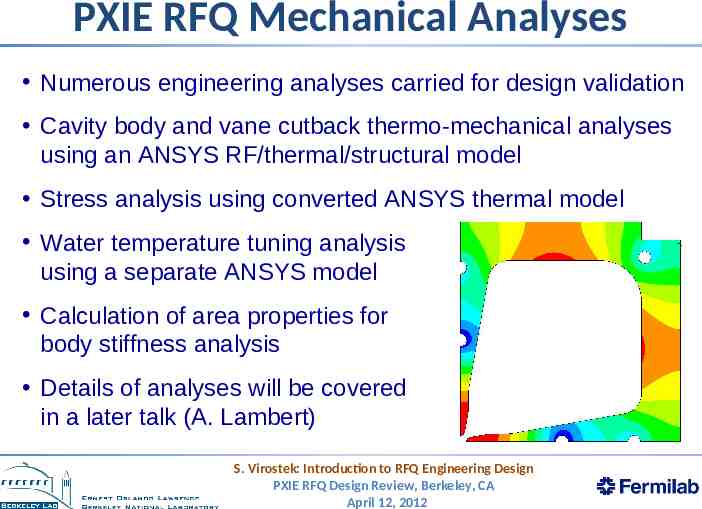

PXIE RFQ Mechanical Analyses Numerous engineering analyses carried for design validation Cavity body and vane cutback thermo-mechanical analyses using an ANSYS RF/thermal/structural model Stress analysis using converted ANSYS thermal model Water temperature tuning analysis using a separate ANSYS model Calculation of area properties for body stiffness analysis Details of analyses will be covered in a later talk (A. Lambert) S. Virostek: Introduction to RFQ Engineering Design PXIE RFQ Design Review, Berkeley, CA April 12, 2012

Current Progress RFQ engineering design nearly complete - finalize with input from this design review Accurate 3D CAD model of 4-module RFQ is complete Model includes: vanes w/gun drilled passages, pi-mode rods, tuner ports, vacuum ports, sensing loop ports, RF drive ports Model contains detail necessary to generate fab drawings Preliminary design of RFQ related subsystems is complete RFQ cooling scheme (body, cutbacks, pi-mode rods) RFQ vacuum system configuration (analysis TBD) Fabrication tests designed and under way (see M. Hoff talk) Thermal, RF and mechanical analyses are nearly complete S. Virostek: Introduction to RFQ Engineering Design PXIE RFQ Design Review, Berkeley, CA April 12, 2012

Additional Engineering Tasks Carry out fabrication tests (at LBNL and IMP-Lanzhou) Write engineering notes describing the test procedures Procure all necessary material Perform additional thermal and stress analyses Vacuum system analysis Tuner RF/heating analysis Final RFQ support points – stress and deflection analysis Complete final version of the RFQ 3D CAD model (close) Generate complete set of multi-step fabrication drawings Write a detailed engineering notes to document the final RFQ design and the results of the analyses S. Virostek: Introduction to RFQ Engineering Design PXIE RFQ Design Review, Berkeley, CA April 12, 2012