Pest management in storage Joe Rickman and Martin

17 Slides342.00 KB

Pest management in storage Joe Rickman and Martin Gummert, Agricultural Engineering, International Rice Research Institute, Philippines

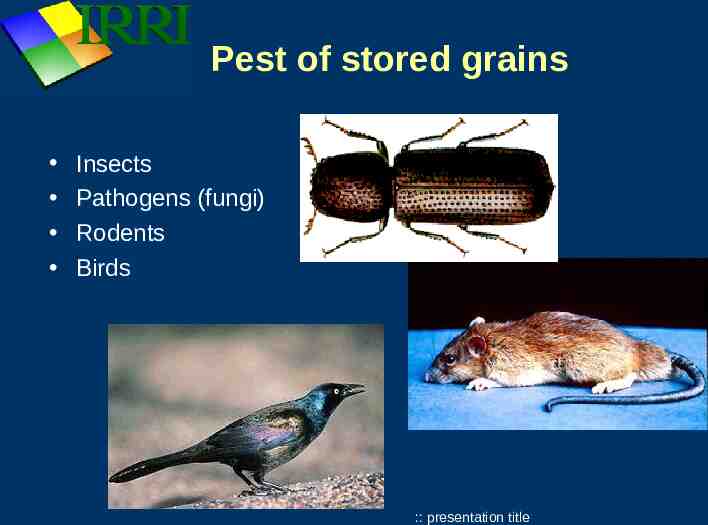

Pest of stored grains Insects Pathogens (fungi) Rodents Birds :: presentation title

Ideal Conditions for pest Environment Conditions Temperature 20 - 40oC Relative humidity 60-70% Mixing grain lots old and new Time Longer storage no insects :: presentation title

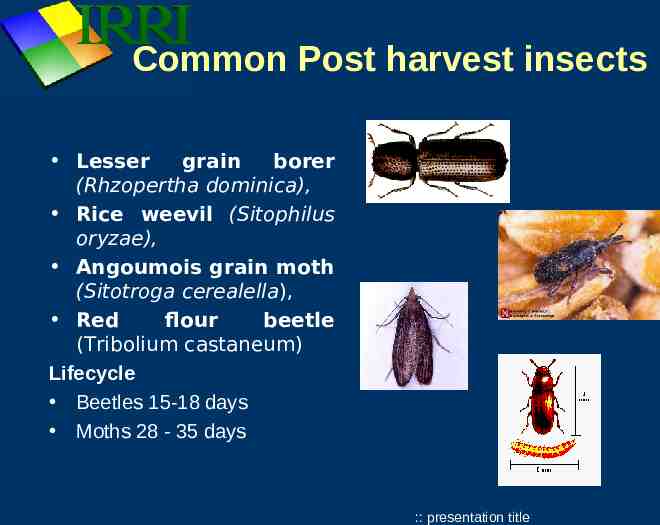

Common Post harvest insects Lesser grain borer (Rhzopertha dominica), Rice weevil (Sitophilus oryzae), Angoumois grain moth (Sitotroga cerealella), Red flour beetle (Tribolium castaneum) Lifecycle Beetles 15-18 days Moths 28 - 35 days :: presentation title

Management of insect pests :: presentation title

Harvesting and drying Grain moisture content (12-14%) Minimize cracked and broken grain during processing Don’t mix old and new grain :: presentation title

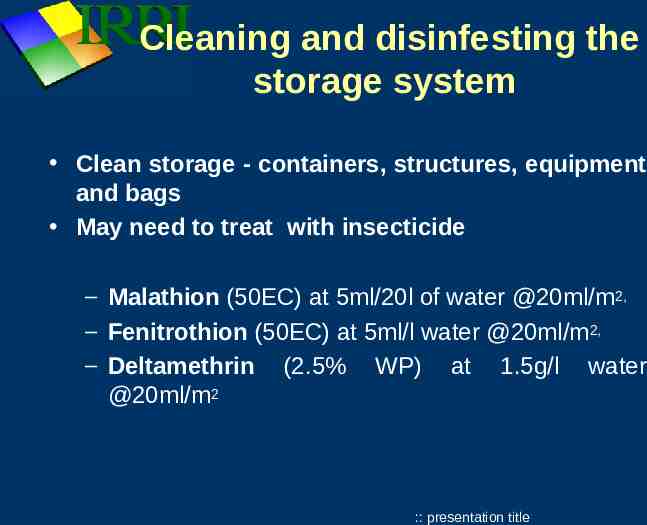

Cleaning and disinfesting the storage system Clean storage - containers, structures, equipment and bags May need to treat with insecticide – Malathion (50EC) at 5ml/20l of water @20ml/m2, – Fenitrothion (50EC) at 5ml/l water @20ml/m2, – Deltamethrin (2.5% WP) at 1.5g/l @20ml/m2 :: presentation title water

Treat infected grain Grain treatment Insecticide- malathion Fumigation – phosphine, – carbon dioxide Physical Heat 15, 55 (15mins) Impact – pneumatic conveyers Diatomaceous earth – dehydration :: presentation title

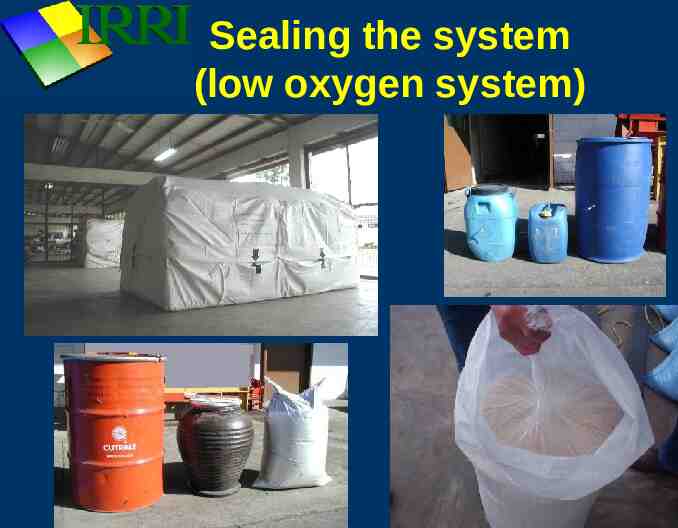

Sealing the system (low oxygen system) :: presentation title

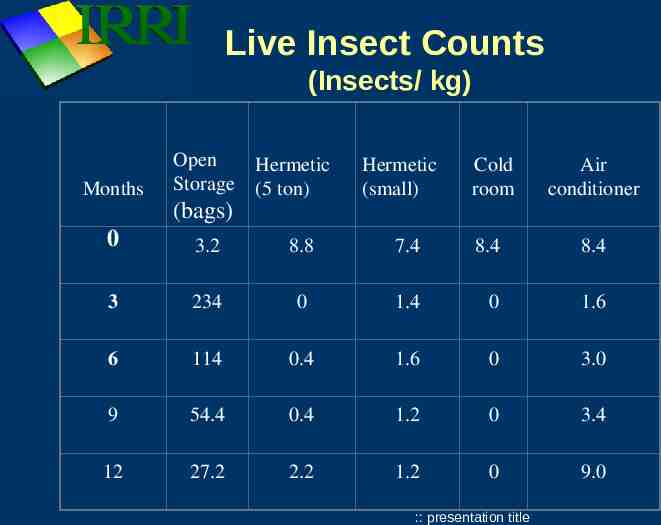

Live Insect Counts (Insects/ kg) Months Open Storage Hermetic (5 ton) Hermetic (small) Cold room Air conditioner (bags) 0 3.2 8.8 7.4 8.4 8.4 3 234 0 1.4 0 1.6 6 114 0.4 1.6 0 3.0 9 54.4 0.4 1.2 0 3.4 12 27.2 2.2 1.2 0 9.0 :: presentation title

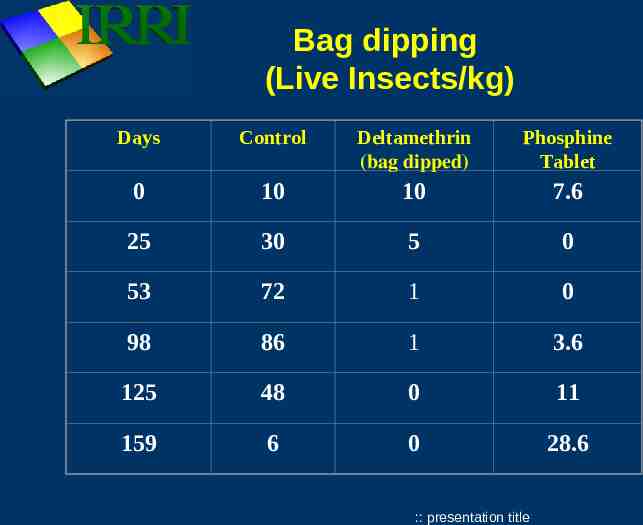

Bag dipping (Live Insects/kg) Days Control Deltamethrin (bag dipped) Phosphine Tablet 0 10 10 7.6 25 30 5 0 53 72 1 0 98 86 1 3.6 125 48 0 11 159 6 0 28.6 :: presentation title

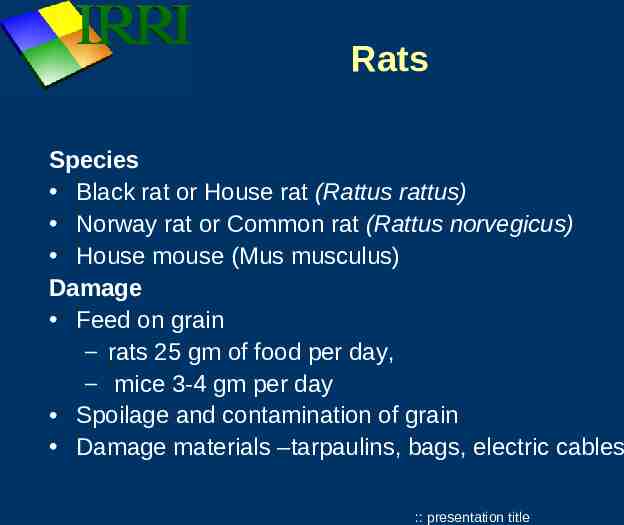

Rats Species Black rat or House rat (Rattus rattus) Norway rat or Common rat (Rattus norvegicus) House mouse (Mus musculus) Damage Feed on grain – rats 25 gm of food per day, – mice 3-4 gm per day Spoilage and contamination of grain Damage materials –tarpaulins, bags, electric cables :: presentation title

Rat management Keep the store clean-remove any spilt grain Store bags in tidy stacks set up on pallets, Store any empty or old bags and fumigation sheets on pallets, and if possible in separate stores! Keep the store free of rubbish Bum or bury it! Keep the area surrounding the store free of tall weeds Keep the area in the vicinity of the store free of any stagnant water :: presentation title

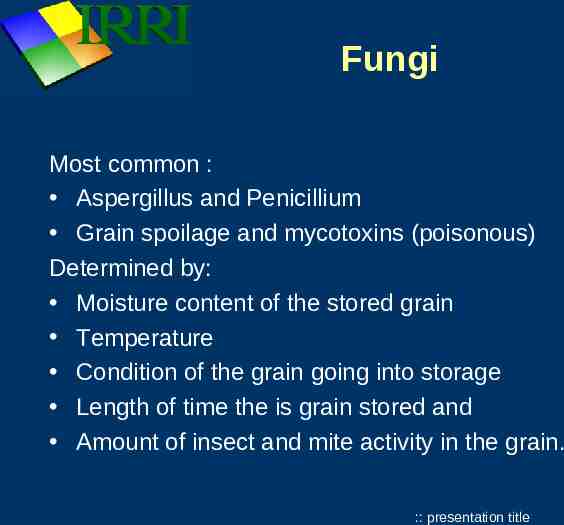

Fungi Most common : Aspergillus and Penicillium Grain spoilage and mycotoxins (poisonous) Determined by: Moisture content of the stored grain Temperature Condition of the grain going into storage Length of time the is grain stored and Amount of insect and mite activity in the grain. :: presentation title

Fungi Control Moisture content (12-14%) Heat – dry heat at 65oC for 6 days – hot water treatment at 52-55oC Fungicides – Dithane M-45 and Benlate at 3 grams kg-1. :: presentation title

Storage Hygiene Keep storage areas clean. Clean storage rooms after they are emptied Placing rat-traps and barriers in drying and storage areas. Cats deter and help control rats and mice Inspect storage room regularly to keep it vermin proof. Inspect the stored seeds once a week for signs of insect infestation. :: presentation title

Priorities Management Options 1. Good hygiene -cleanliness in store, clean bags 2. Hermetic storage 3. Bag dipping 4. Phosphine tablets 5. Fumigation-last resort :: presentation title