Heuristics for Process Design Chapter 6 Terry A. Ring

13 Slides40.50 KB

Heuristics for Process Design Chapter 6 Terry A. Ring

Heuristics 1-Select raw materials and chemical reactions to avoid or reduce the handling and storage of hazardous and toxic chemicals. 2-Use an excess of one chemical reactant in a reaction to consume completely a valuable, toxic or hazardous chemical reactant. (see MSDS for chemical hazards)

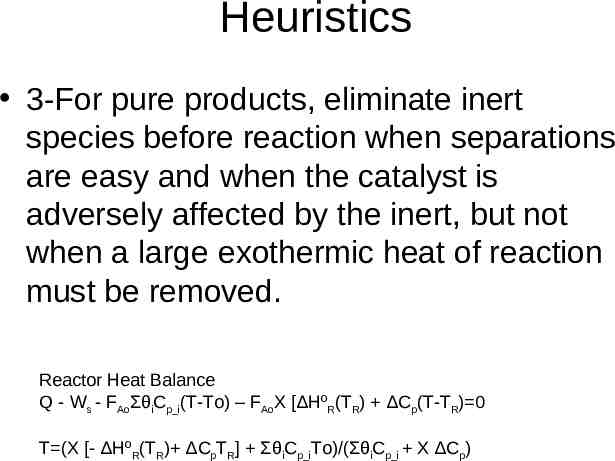

Heuristics 3-For pure products, eliminate inert species before reaction when separations are easy and when the catalyst is adversely affected by the inert, but not when a large exothermic heat of reaction must be removed. Reactor Heat Balance Q - Ws - FAoΣθiCp i(T-To) – FAoX [ΔHºR(TR) ΔCp(T-TR) 0 T (X [- ΔHºR(TR) ΔCpTR] ΣθiCp iTo)/(ΣθiCp i X ΔCp)

Heuristic 4- Introduce purge streams to provide exists for impurities when the impurities are in trace quantities or difficult to separate. Light species leave via vapor purge and heavier species leave via liquid purge streams.

Heuristic 5- Do not purge species that are valuable or toxic or hazardous even in small concentrations. Add separators to capture valuable species. Add reactors to eliminate toxic or hazardous species.

Heuristic 6- Byproducts that are produced in reversible reactions, in small quantities, are usually not recovered in separators or purged. Instead they are recycled to extinction A B C A D

Heuristic 7-For competing reactions, both in series and parallel adjust T and P and catalyst to obtain high yields of the desired products. Check that there are no kinetic limits to this assumption.

Heuristic 8-For reversible reactions, consider conducting them in a separation device capable of removing the products driving the reaction to more products. This gives a very different distribution of products. Reactive Distillation Reactor with selective membrane wall

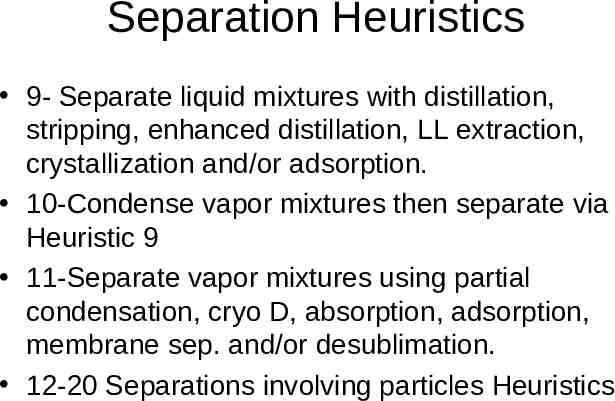

Separation Heuristics 9- Separate liquid mixtures with distillation, stripping, enhanced distillation, LL extraction, crystallization and/or adsorption. 10-Condense vapor mixtures then separate via Heuristic 9 11-Separate vapor mixtures using partial condensation, cryo D, absorption, adsorption, membrane sep. and/or desublimation. 12-20 Separations involving particles Heuristics

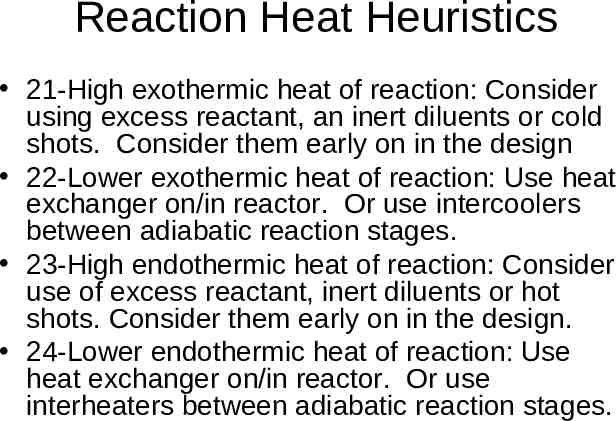

Reaction Heat Heuristics 21-High exothermic heat of reaction: Consider using excess reactant, an inert diluents or cold shots. Consider them early on in the design 22-Lower exothermic heat of reaction: Use heat exchanger on/in reactor. Or use intercoolers between adiabatic reaction stages. 23-High endothermic heat of reaction: Consider use of excess reactant, inert diluents or hot shots. Consider them early on in the design. 24-Lower endothermic heat of reaction: Use heat exchanger on/in reactor. Or use interheaters between adiabatic reaction stages.

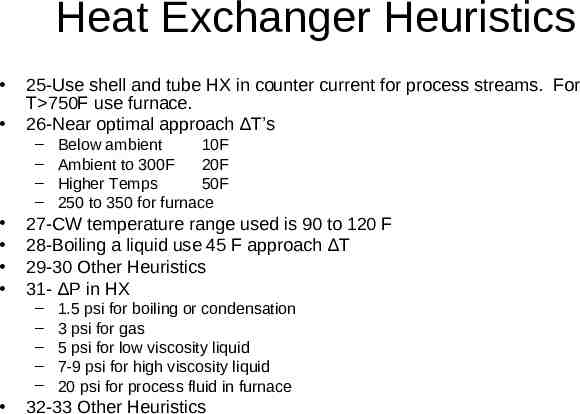

Heat Exchanger Heuristics 25-Use shell and tube HX in counter current for process streams. For T 750F use furnace. 26-Near optimal approach ΔT’s – – – – 27-CW temperature range used is 90 to 120 F 28-Boiling a liquid use 45 F approach ΔT 29-30 Other Heuristics 31- ΔP in HX – – – – – Below ambient 10F Ambient to 300F 20F Higher Temps 50F 250 to 350 for furnace 1.5 psi for boiling or condensation 3 psi for gas 5 psi for low viscosity liquid 7-9 psi for high viscosity liquid 20 psi for process fluid in furnace 32-33 Other Heuristics

Pressure Operation Heuristics 40-42- pressure decrease 43-pump a liquid rather than compress a gas, unless refrigeration is needed. 44- Air leak rate into vacuum 45-47 Vacuum pumps

Solid Particle Processing Heuristics 48-53 Covering – Conveying Pneumatic Conveyor belt – Reaction – Separations Cyclone Crystallization Agglomeration – Heat transfer