Cross-Connection Control and Backflow Prevention as a Post-Covid

26 Slides3.25 MB

Cross-Connection Control and Backflow Prevention as a Post-Covid Risk Management Tool By: National Water Specialties Company (NAWSC) Brian J. Preski, President NCRWA – ANNUAL CONFERENCE 2022

SECTION 15A NCAC 18C .0406 DISTRIBUTION SYSTEMS (b) Cross-Connections. No person shall construct, maintain, or operate a physical arrangement whereby a public water system has a cross-connection without the use of proper backflow protection. 2018 North Carolina Plumbing Code Section 608 Protection of Potable Water Supply 608.1 General - A potable water supply system shall be designed, installed and maintained in such a manner so as to prevent contamination from nonpotable liquids, solids or gases being introduced into the potable water supply through cross connections or any other piping connections to the system. Backflow preventer applications shall conform to Table 608.1, 2 except as specifically stated in Sections 608.2 through 608.16.10.

Cross-Connection Defined – General An arrangement allowing either a direct or indirect connection through which backflow, including backsiphonage and backpressure, can occur between the drinking water in a public water system and a system containing a source or potential source of contamination, or allowing treated water to be removed from any public water system, used for any purpose or routed through any device or pipes outside the public water system, and returned to the public water system. North Carolina Definition A cross-connection means: (A) any physical connection between a potable water supply system and any other piping system, sewer fixture, container, or device, whereby water or other liquids, mixtures, or substances may flow into or enter the potable water supply system; (B) any potable water supply outlet that is submerged or is designed or intended to be submerged in non-potable water or in any source of contamination; or (C) an air gap, that does not meet the requirements set forth in Subparagraph (2) of this Paragraph. Backflow means the undesirable reversal of flow of a liquid, gas, or other 3

SECTION 15A NCAC 18C .0406 DISTRIBUTION SYSTEMS (b) Cross-Connections. No person shall construct, maintain, or operate a physical arrangement whereby a public water system has a cross-connection without the use of proper backflow protection. (1) No person shall introduce any water into the distribution system of a public water supply through any means other than from a source of supply duly approved by the Department or its representatives or make any physical connection between an approved supply and unapproved supply unless authorized in an emergency by the Department or its representative. (2) Service Connection Relation to Plumbing Code. No supplier of water shall provide a service connection to any plumbing system that does not comply with the North Carolina State Building Code, Volume II, and all applicable local plumbing codes. Where required, the supplier of water 4 shall install or require to be installed an appropriate testable

5

Types of Backflow - Backpressure Backpressure Backpressure incidents can occur when the pressure on an individual system exceeds the pressure in the distribution system, resulting in undesirable gasses or liquids being introduced into the drinking water supply. Some examples include: A car wash that re-circulates soapy water A manufacturing plant that uses substantial water pressure for production 6

Types of Backflow - Backsiphonage Backsiphonage When a negative or reduced pressure is applied at a building’s tap, creating the potential for contaminants to be siphoned into the drinking water system. A pressure change could be caused by: Heavy water usage on the system (i.e. fighting a large fire) Water main breaks Unauthorized use of a fire hydrant 7

DEGREE OF HAZARD High-Health Hazard: A cross-connection or potential cross-connection involving any substance that could, if introduced into the potable water supply, cause illness or death, spread disease, or have a high probability of causing such effects. Low-Health Hazard: A cross-connection or potential cross-connection involving any substance that generally, would not be a health hazard but would constitute a nuisance or be aesthetically objectionable if introduced into the potable water supply Table 630.1 Determination of Degree of Hazard Cross-connections that meet or may meet the following conditions shall be rated at the corresponding degree of hazard. High Hazard Low Hazard The contaminant would be toxic, poisonous, noxious, unhealthy, or of unknown quality. The contaminant would only degrade the quality of the water aesthetically or impair the usefulness of the water. A health hazard would exist. The contaminant would disrupt the service of piped water for human consumption. A health hazard would not exist. The contaminant would not disrupt service of piped water for human consumption. Backflow would be by either backpressure or backsiphonage. Backflow would occur by backsiphonage. Examples: lawn irrigation systems, fire sprinkler systems with chemical additives or antifreeze, sewage, used water, nonpotable water, auxiliary water systems, and mixtures of water and other liquids, gases, or other chemicals. Examples: food residuals, coffee machines, non-carbonated beverage dispensers, and residential fire sprinkler systems constructed of materials designed for potable water flow. 8

Is COVID in the water system and did COVID change anything with respect to backflow? Abstract: The advent of severe acute respiratory syndrome and its potential environmental transmission indicates the need for more information on the survival of coronavirus in water and wastewater. The survival of representative coronaviruses, feline infectious peritonitis virus, and human coronavirus 229E was determined in filtered and unfiltered tap water (39.2 and 73.4 degrees F) and waste-water (73.4 degrees F). This was compared to poliovirus 1 under the same test conditions. Inactivation of coronaviruses in the test water was highly dependent on temperature, level of organic matter, and presence of antagonistic bacteria. The time required for the virus titer to decrease 99.9% (T99.9) shows that in tap water, coronaviruses are inactivated faster in water at 73.4 degrees F (10 days) than in water at 39.2 degrees F ( 100 days). Coronaviruses die off rapidly in wastewater, with T99.9 values of between 2 and 4 days. Poliovirus survived longer than coronaviruses in all test waters, except the 39.2 degrees F tap water. (University of Arizona, Published 2008) 9

Is COVID in the water system and did COVID change anything with respect to backflow? Abstract The emergence of a previously unknown coronavirus infection, Severe Acute Respiratory Syndrome (SARS), demonstrated that fecally contaminated liquid droplets are a potential vehicle for the spread of a respiratory virus to large numbers of people. To assess potential risks from this pathway, there is a need for surrogates for SARS coronavirus to provide representative data on viral survival in contaminated water. This study evaluated survival of two surrogate coronaviruses, transmissible gastroenteritis (TGEV) and mouse hepatitis (MHV). These viruses remained infectious in water and sewage for days to weeks. At 77 F, time required for 99% reduction in reagent-grade water was 22 days for TGEV and 17 days for MHV. In pasteurized settled sewage, times for 99% reduction were 9 days for TGEV and 7 days for MHV. At 39.2 F, there was 1 log10 infectivity decrease for both viruses after four weeks. Coronaviruses can remain infectious for long periods in water and pasteurized settled sewage, suggesting contaminated water is a potential vehicle for human exposure if aerosols are generated. 10

Its not Covid, the “party in the pipes” caused by the lockdowns that is the issue! Think Legionella. The CDC has acknowledged that Biofilm - In the human environment, biofilms can grow in showers very easily since they provide a moist and warm environment for the biofilm to thrive. Biofilms can form inside water and sewage pipes and cause clogging and corrosion. Biofilms on floors and counters can make sanitation difficult in food preparation areas. Biofilm in soil can cause bioclogging. Biofilms in cooling- or heating-water systems are known to reduce heat transfer. Biofilms in marine engineering systems, such as pipelines of the offshore oil and gas industry, can lead to substantial corrosion problems. Corrosion is mainly due to abiotic factors; however, at least 20% of corrosion is caused by microorganisms that are attached to the metal subsurface (i.e., microbially influenced corrosion). opportunistic premise plumbing pathogens (OPPPs) are the primary cause of waterborne disease in the United States. Legionella pneumophila, one type of OPPP, can develop in water supply systems and result in Legionnaires’ disease, a severe form of pneumonia. About 10,000 cases of this disease are reported each year in the U.S. Legionella are naturally occurring bacteria found in freshwater sources, such as rivers and lakes, where the bacteria generally are present in low amounts and do not lead to disease. However, Legionella can multiply to dangerous levels under certain conditions and potentially cause Legionnaires’ disease, or Legionellosis. People contract this disease by inhaling small droplets of the contaminated water through mist or vapor. 11

Containment Level Protection Containment protection is when the public water system is protected at the service connection only. Containment protection will ensure that backflow will not occur out into the public water distribution system. However, backflow could still occur inside the building, downstream of the backflow prevention device, putting occupants at risk. Containment protection usually means that a backflow preventer was installed just downstream of the meter. Many crossconnection control plans will only require containment protection. People need to understand that containment protection will not provide total protection.

ISOLATION LEVEL PROTECTION Isolation protection (point of use isolation) is protection at each cross-connection within the building. This means backflow protection of some kind must be installed on all cross-connections that are identified after (downstream) the meter. Air gaps and devices from the “vacuum breaker family”, as well as those devices that are used for containment, are commonly used for isolation protection. In most cases internal protection requirements are governed by plumbing codes like The International Plumbing Code (ITC) 2009.

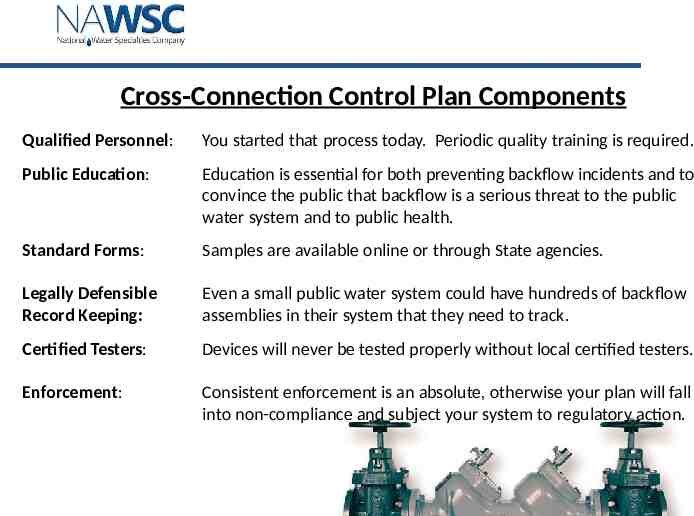

Cross-Connection Control Plan Components Qualified Personnel: You started that process today. Periodic quality training is required. Public Education: Education is essential for both preventing backflow incidents and to convince the public that backflow is a serious threat to the public water system and to public health. Standard Forms: Samples are available online or through State agencies. Legally Defensible Record Keeping: Even a small public water system could have hundreds of backflow assemblies in their system that they need to track. Certified Testers: Devices will never be tested properly without local certified testers. Enforcement: Consistent enforcement is an absolute, otherwise your plan will fall into non-compliance and subject your system to regulatory action.

10 Steps to a Cross-Connection Control Program Step 1: Understand Cross-Connection Control Concepts Step 2: Establish a Legal Foundation Step 3: Establish a Priority System Step 4: Understand Customer Implementation Costs Step 5: Develop Implementation Timetable Step 6: Review your Proposed Plan with Government Regulators Step 7: Educate the Public Step 8: Notify Affected Customer Step 9: Monitor Program Installation & Testing Requirements Step 10: Maintain Records

Degree of Hazard Determining the degree of hazard of a given crossconnection is very important in ensuring that the correct backflow device is selected to control the crossconnection. Degree of Hazard is a way of assigning the level of risk that a given cross-connection creates. There are generally only two degrees of hazard: Low Hazard High Hazard

Establish a priority system To begin this process, use your billings and your properly trained distribution system maintenance personnel to develop three master lists with the following titles: A: Hazardous Facilities – High Hazards B: Aesthetically Objectionable Facilities – Low Hazards C: Non-Hazardous Facilities – Low Hazards Then use distribution system records to identify areas that have been prone to main breaks, leaks, and low pressure. The information gathered can be transferred to a distribution system map to locate customers in categories A and B. This may highlight more vulnerable areas of the distribution system.

Establish a priority system (cont.) Now you can establish a priority list, which could be broken down into the following five levels: First Priority: Hazardous facilities located within the most vulnerable portion of the distribution system – High Hazards Second Priority: Hazardous facilities not within the most vulnerable area – High Hazards Third Priority: Aesthetically objectionable facilities located within the most vulnerable area (pollutants only) – Low Hazards Fourth Priority:Aesthetically objectionable facilities not within the most vulnerable areas of the distribution system – Low Hazards Fifth Priority: Non-traditional residential connections – High or Low Hazards A thoughtfully drafted priority system will make implementation much easier and will make efficient use of your time.

Typical Forms for Implementing a CCC Program A. Program Implementation Notice B. Cross-Connection Control Survey Report Form C. Inspection Results Notice, and need to install a backflow prevention assembly D. Need to Conduct Periodic Test Notice with return report form E. Follow-up Letter (Second Notice) for item D. F. Discontinuance of Service Notice/Imposition of Fine G. Repair or Replace the Backflow Prevention Assembly Notice H. New Service Investigation and Report Forms I. Assembly / Installation Approval Form J. Approved Backflow Prevention Assembly Testers List K. Temporary Shutdown of Water Service Notice L. Test Report Form

Educate the Public This step could begin at any time during the implementation process. A good general public education flyer, brochure, or pamphlet would be the best way to start. Adding information onto the water system’s website is another way to facilitate educating the public.

Monitor Program Progress Follow-up monitoring of program progress should be done at least bi-annually during the implementation period and at least annually thereafter. Items you should be monitoring during the implementation Follow-up on individual customer compliance agreements. Are you on schedule to meet your timetable deadlines? Are you maintaining your cross-connection control data- base? Is enforcement being used consistently when necessary to achieve compliance?

CCC-SMART – Cross-Connection Control System Management in Real-Time – Individual Street or Valve

Initiate Testing – Installation is not Enough For in-line testable devices, which mean devices with test cocks that can be tested with a differential pressure gauge, testing should be conducted annually. Annual testing of backflow prevention assemblies is industry standard. Most CCC programs across the United States require annual testing because major certification organizations such as the American Society of Sanitary Engineers (ASSE) and the International Plumbing Code (IPC), require backflow prevention assemblies to be tested routinely at least on an annual basis.

Record Keeping

Record Keeping Master List of all Establishments with assemblies used for premise isolation, including location, assembly used, make, model, size, serial number etc.; Correspondence between water system and its customers Copy of Approved Plan and or Approved Policy/ordinance Test reports for each assembly Copies of Certificates of Competency/Licensure for each tester Copies of test kit certifications and yearly calibrations Yearly Testing/Inspection Reports Backflow incident reports Records on initial surveys, recommendations, follow-up, corrective action, routine reinspections, etc. A file system designed to call to the attention of the cross-connection control personnel when testing and reinspections of premises are needed. Public education pamphlets and information.

Contact Information NATIONAL WATER SPECIALTIES COMPANY (NAWSC) 1-888-843-7155 (570) 655-8633 Brian Preski - President [email protected] (215) 740-7095