COST CONTROL By Ms.M.Vandhana Asst. Prof. Dept. of Fashion

20 Slides1.00 MB

COST CONTROL By Ms.M.Vandhana Asst. Prof. Dept. of Fashion Technology and Costume designing Bon Secours college for women Thanjavur

# TYPES OF COST AND EXPENSES Cost is defined as expenditure incurred to manufacture a product or to carry out a process or to render a service. Modern business enterprise is vibrant in nature which has to function in an atmosphere of high competition and risk. There are thirteen types of cost which are presented out in the below: 1. Fixed cost, 2. Replacement cost, 3. Imputed cost, 4. Variable cost, 5. Semi-variable cost, 6. Research cost, 7. Step cost, 8. Conversion cost, 9. Development cost, 10. Shutdown cost, 11. Policy cost, 12. Sunk cost, 13. Differential cost. 1. Fixed cost: It is that type of cost which remains constant and does not vary within a period of time and ranges of activity in spite of fluctuation in textile and apparel production is termed as fixed cost. Fixed costs are rent, insurance charge, staff salary etc. it is also considered as period costs. 2. Replacement cost: The cost which can be replaced by the management as a replacement of the existing costs is known as replacement cost. Replacement costs are textile and apparel machinery replacement over a certain period of time. It may be 10 years. 3. Imputed cost: It is that type of cost which does not involve in any cash outlay is known as imputed cost. It is not included in cost accounts but are important for taking into consideration while management decision. Imputed costs are interest on internally generated fund, salary of the proprietor etc. 4. Variable cost: The cost which varies directly in proportion to every increase or decrease in the volume of output or textile and apparel production is known as variable cost. Variable costs are labor wages, labor cost, power etc. 5. Semi-variable cost: It does not vary proportionally but simultaneously cannot remain stationary at all the times is known as semi-variable cost. These are telephone charges, service and repairs etc.

6. Research cost: Research cost incurred for searching new or improved product such as new application of products or materials or improved methods. Examples of this costs are courier charge, sample charge etc. 7. Step cost: Step cost which remains fixed over a range of activity and then jump to a new level as activity changes. Steps cost are rental cost of delivery vehicles. 8. Conversion cost: The cost of transforming direct material into a finished product exclusive of direct material cost is known as conversion cost. It is normally takes as the aggregate of the cost of direct labor, direct expense and factory overhead. Converting yarn into fabric and garment is the perfect example for this type of cost. 9. Development cost: The cost of the methods or process which begins with the implementation of the decision to produce a new or improved product or to employ a new or improved methods and ends with the commencements of formal production of that product or by that method. Examples of development costs are sampling charge, product development cost etc. 10. Shutdown cost: A manufacturer rendering service may have to suspend its operation for a period of time on account of some temporary difficulties like raw material shortage, labor shortage, strikes etc. though no work is done during this period but certain fixed costs such as rent, salary, insurance etc. have to be incurred. 11. Policy cost: The cost of formulating the policy, directing the organization and controlling the operation of an undertaking which is not directly related to apparel or textile production, sales and distribution activity. Examples of this type of costs are special training for the employees, ISO 9000 implementation etc. 12. Sunk cost: Suck cost which has been created by a decision that was made in the past and cannot be changed by any decision that will be made in the future. It is also known as past cost. Examples of sunk costs are investment in building, plant, textile machineries etc. Apparel Costing Sheet Analysis Apparel Costing Format 13. Differential cost: The difference in total cost between two alternative choices is known as differential cost. EXPENSE An expense is the cost of an asset used by a company in its operations to produce revenues. In other words, an expense is the use of assets to create sales. Notice that I didn't say it's the amount of money spent to generate sales. Expenses are created when an asset is used up, not when cash is paid out.

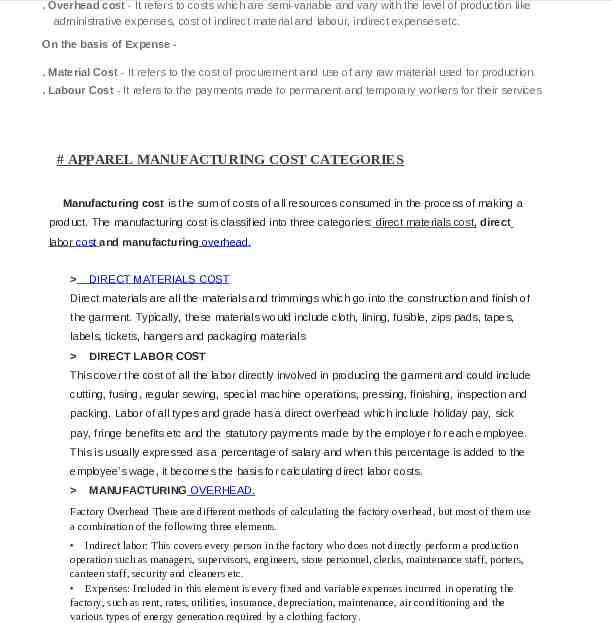

. Overhead cost - It refers to costs which are semi-variable and vary with the level of production like administrative expenses, cost of indirect material and labour, indirect expenses etc. On the basis of Expense . Material Cost - It refers to the cost of procurement and use of any raw material used for production. . Labour Cost - It refers to the payments made to permanent and temporary workers for their services # APPAREL MANUFACTURING COST CATEGORIES Manufacturing cost is the sum of costs of all resources consumed in the process of making a product. The manufacturing cost is classified into three categories: direct materials cost, direct labor cost and manufacturing overhead. DIRECT MATERIALS COST Direct materials are all the materials and trimmings which go into the construction and finish of the garment. Typically, these materials would include cloth, lining, fusible, zips pads, tapes, labels, tickets, hangers and packaging materials DIRECT LABOR COST This cover the cost of all the labor directly involved in producing the garment and could include cutting, fusing, regular sewing, special machine operations, pressing, finishing, inspection and packing. Labor of all types and grade has a direct overhead which include holiday pay, sick pay, fringe benefits etc and the statutory payments made by the employer for each employee. This is usually expressed as a percentage of salary and when this percentage is added to the employee’s wage, it becomes the basis for calculating direct labor costs. MANUFACTURING OVERHEAD. Factory Overhead There are different methods of calculating the factory overhead, but most of them use a combination of the following three elements. Indirect labor: This covers every person in the factory who does not directly perform a production operation such as managers, supervisors, engineers, store personnel, clerks, maintenance staff, porters, canteen staff, security and cleaners etc. Expenses: Included in this element is every fixed and variable expenses incurred in operating the factory, such as rent, rates, utilities, insurance, depreciation, maintenance, air conditioning and the various types of energy generation required by a clothing factory.

Indirect materials: Also known as consumables, this element contains all the materials not directly connected to the makeup of a garment. Some of the typical items involved are office materials, spare parts, marker paper, maintenance materials, chalk & pins. The total of these three elements is the factory overhead and because it cannot be conviently applied to specific cost units; it is generally expressed as a percentage of the direct labor costs. # SALE COST CONTROL The cost of sales is the accumulated total of all costs used to create a product or service, which has been sold. The cost of sales is a key part of the performance metrics of a company, since it measures the ability of an entity to design, source, and manufacture goods at a reasonable cost. The term is most commonly used by retailers. Cost of sales measures the cost of goods produced or services provided in a period by an entity. It includes the cost of the direct materials used in producing the goods, direct labor costs used to produce the good, along with any other direct costs associated with the production of goods. In case of services cost of sales includes the labor cost or salaries of the employees and other directly attributable costs. Cost of sales does not include indirect expenses such as distribution costs and marketing costs. It appears on the income statement and is deducted from the sales revenue for the calculation of gross profit (or gross margin). The exact costs included in the calculation of cost of sales will differ from one type of business to another. The cost of sales attributed to a company's products or services are expensed as the company sells these goods. As the cost of sales does not include overhead costs, it has a higher proportion of variable cost than the operating costs. Some fixed costs, such as labor costs, might be included in the cost of sales. But in most of the cases, the cost of sales consists almost entirely of variable costs. For example, a company has 10,000 of inventory on hand at the beginning of the month, expends 25,000 on various inventory items during the month, and has 8,000 of inventory on hand at the end of the month. What was its cost of sales during the month? The answer is: Beginning inventory 10,000 Purchases 25,000 - Ending inventory 8,000

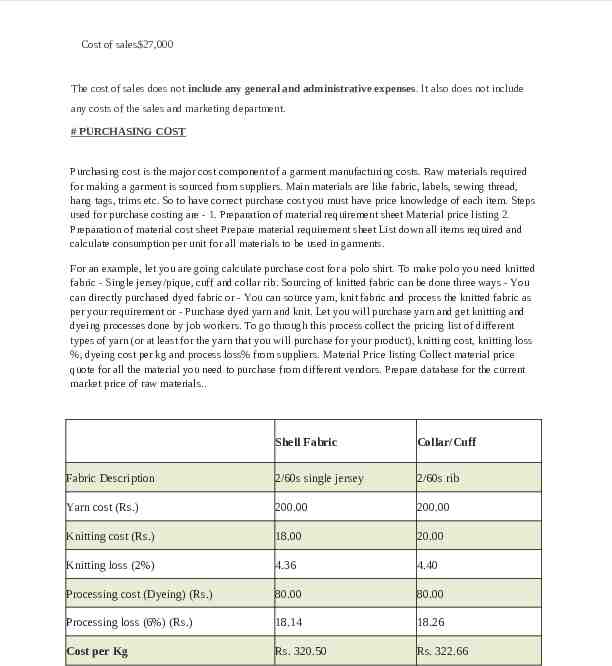

Cost of sales 27,000 The cost of sales does not include any general and administrative expenses. It also does not include any costs of the sales and marketing department. # PURCHASING COST Purchasing cost is the major cost component of a garment manufacturing costs. Raw materials required for making a garment is sourced from suppliers. Main materials are like fabric, labels, sewing thread, hang tags, trims etc. So to have correct purchase cost you must have price knowledge of each item. Steps used for purchase costing are - 1. Preparation of material requirement sheet Material price listing 2. Preparation of material cost sheet Prepare material requirement sheet List down all items required and calculate consumption per unit for all materials to be used in garments. For an example, let you are going calculate purchase cost for a polo shirt. To make polo you need knitted fabric - Single jersey/pique, cuff and collar rib. Sourcing of knitted fabric can be done three ways - You can directly purchased dyed fabric or - You can source yarn, knit fabric and process the knitted fabric as per your requirement or - Purchase dyed yarn and knit. Let you will purchase yarn and get knitting and dyeing processes done by job workers. To go through this process collect the pricing list of different types of yarn (or at least for the yarn that you will purchase for your product), knitting cost, knitting loss %, dyeing cost per kg and process loss% from suppliers. Material Price listing Collect material price quote for all the material you need to purchase from different vendors. Prepare database for the current market price of raw materials. Shell Fabric Collar/Cuff Fabric Description 2/60s single jersey 2/60s rib Yarn cost (Rs.) 200.00 200.00 Knitting cost (Rs.) 18.00 20.00 Knitting loss (2%) 4.36 4.40 Processing cost (Dyeing) (Rs.) 80.00 80.00 Processing loss (6%) (Rs.) 18.14 18.26 Cost per Kg Rs. 320.50 Rs. 322.66

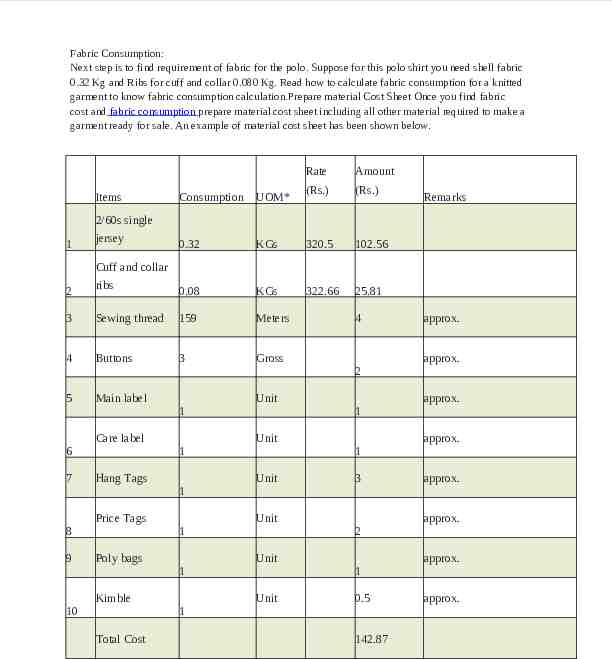

Fabric Consumption: Next step is to find requirement of fabric for the polo. Suppose for this polo shirt you need shell fabric 0.32 Kg and Ribs for cuff and collar 0.080 Kg. Read how to calculate fabric consumption for a knitted garment to know fabric consumption calculation.Prepare material Cost Sheet Once you find fabric cost and fabric consumption prepare material cost sheet including all other material required to make a garment ready for sale. An example of material cost sheet has been shown below. Items Consumption UOM* Rate Amount (Rs.) (Rs.) Remarks 2/60s single 1 jersey 0.32 KGs 320.5 102.56 2 Cuff and collar ribs 0.08 KGs 322.66 25.81 3 Sewing thread 159 Meters 4 Buttons 3 Gross 5 Main label 6 7 8 9 10 Care label Hang Tags Price Tags Poly bags Kimble Total Cost 1 1 1 1 1 1 Unit Unit Unit Unit Unit Unit 4 2 1 1 3 2 1 0.5 142.87 approx. approx. approx. approx. approx. approx. approx. approx.

So, Total fabric cost is Rs. 128.37 and including other material costs total cost of the material for making this Polo Rs. 142.87 Now for each item merchants generally purchased extra quantity of inventory (from 2% to 7%) as buffer. # PRODUCTION COSTS: production costs comprise all the expenditures that are involved in the production of a final product. These costs are called ‘cost of goods manufactured’ on the income statement. Production costs are split up into three parts such as raw material cost, direct labour cost and factory overhead. Raw materials like fabric, sewing thread and trim are called direct variable costs. Direct labour costs in most of the garment units comprise wages of supervisors and employees who work on an incentive, piece rate or hourly wage basis. Factory overhead includes both variable and non variable indirect manufacturing costs. Factory overhead costs are normally subdivided into (1) indirect labour, (2) factory occupancy costs and (3) other overhead. Indirect labour includes quality control, service personnel, material handlers, maintenance workers, industrial engineers and security. Non variable factory tenancy costs comprise rent, depreciation, insurance, property taxes and security. Machine parts and repairs and needles are examples of variable factory costs and other overhead costs include machinery and equipment costs, materials management and cost of compliance with regulations. Production cost control Improve fabric utilization: Fabric cost is the major part in total cost of making a garment. Control unnecessary wastage of fabrics in cutting. Fabric utilization is the percentage of total purchased fabric consumed in making you order. Correct estimation of fabric consumption saves excess inventory stock and cost of raw material. You can go for IT tools to improve fabric utilization in cutting room. Buy most economical fabric width: Fabric is available in various widths (and various diameters for knits). Select right fabric width based on the product specification (measurement). If your garment patterns don’t consume full width of a fabric, wastage will increase. So while purchasing fabrics for an order, check how much fabric width is required for your garments with mini marker/sample marker.

Go for a piece-rate production system: For a small set-up, it is better to start with piece-rate operators. It is called the piece-rate production system. In piece-rate, you will pay tailors based on the quantity produced by them. Secondly, your tailors will be motivated to produce more if they earn a piece-rate basis. This way you can control direct labour cost. Improve housekeeping: Keep floors and working areas neat and clean. You can prevent getting your goods dirty and stains by good housekeeping. This is the first step to improve your product quality. Produce Right first time quality: Develop a culture of right first time production. This way you can reduce cost of poor quality and at the same time can improve productivity and lead time. You can save in alteration and repair work. Reduce overhead cost as much as possible: Frequently analyze your factory overheads. Reduce overheads as much as possible. Don’t hire unnecessary manpower. Keep you fabric and trim store organized: By keeping things organized you can save time for your employees. This would help you to reduce unnecessary wastage of trims (threads, elastic, packing material etc). Also maintain inventory record - this will help you sourcing raw materials in advance and prevent unnecessary purchasing of items. Improve labour productivity: By improving labour productivity you can reduce per piece production cost and overhead cost. Labour productivity means number pieces (garments) produced per tailor per day. Monthly factory overhead cost remains almost same. So if you produce more piece than existing production, the overhead cost will be reduced proportionately. Refer to this article on production improvement tips. Personnel management: Develop a good relationship with/between your staff and workers as they are your main resources to take your business ahead. Build a productive team and improve their skills by conducting workshop and training if needed. # ADMINISTRATION COST What is the overhead cost? Costs those are not directly related to production volume. No matter how many garments factory produces or sales revenue factory generate, fixed cost to be met each month. These are fixed expenses or indirect cost required to operate a business. For example rent of the factory building, administration cost etc. Two types of overheads are there - fixed factory overhead and variable factory overheads.

What costs are included under overheads? List of overheads may vary factory to factory based on organization structure. When you calculate overheads for a production factory only then factory has less overhead. On the other hand, if you calculate overhead of a company having marketing, design, sales and warehouse departments then you will have a lot of other overhead parameters. Common overheads of a garment factory are like, Building rent Salary of the staffs and associate payroll costs Electricity Bills Utilities (Phone bill, internet bills) Transport expenses Expenses on consumables (Diesel, Chemicals for finishing department) Administration cost (salary and travel cost for the managers, CEOs and VPs), Employee welfare expenses Stationary & printing (indirect material cost) Professional and Legal expenses Pantry expenses House keeping Overtime expenses etc. STANDARD COST SHEET Apparel costing in the garment manufacturing process is one of the most important and critical procedures. Garment costing method is called the heart of ready-made garment business. Because profit depends on proper costing. There are many things that go into pricing a single piece of garment. A costing sheet makes the job of garment costing easier and faster. Because a well designed costing sheet will help to trace all details of costing. So become a less chance to miss any particular costing items. Normally merchandiser and the top management of a company are actively involved in deciding the cost of a garment. Costing can be defined as the process of approximation of the total cost to produce a garment, from a buyer’s perspective, including raw materials, labor, and other expenses. A garment costing sheet is used to trace the all costing components.

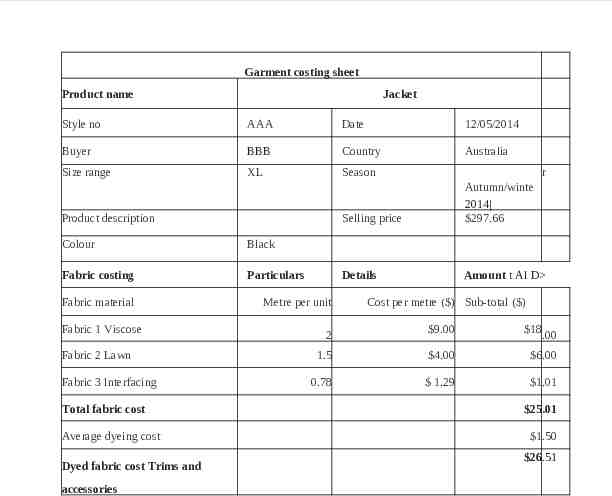

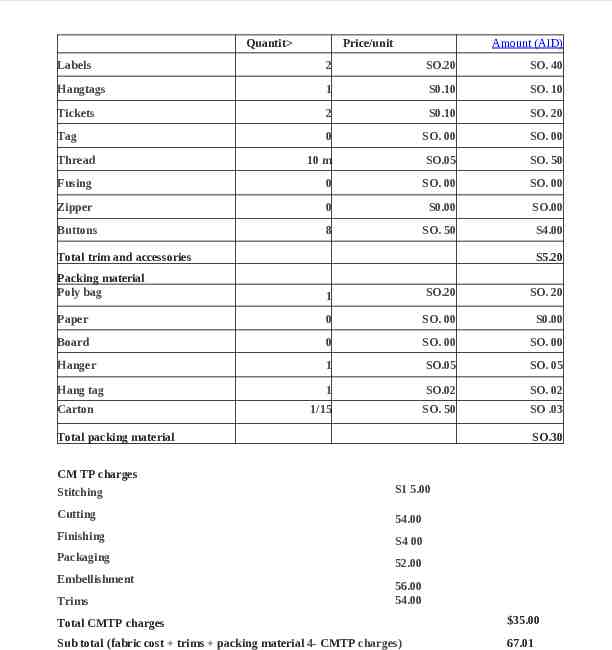

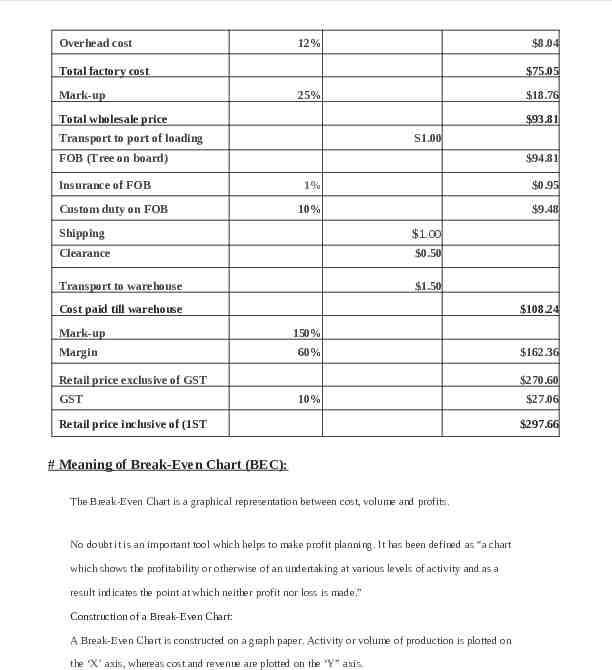

Costing includes all the activities related to purchase of raw materials, trimmings and accessories, fabrics, processing and finishing of fabrics, sewing and packing of garments, transport and conveyance, shipping, overheads, banking charges and commissions, etc. There are always fluctuations in the costs of raw materials and accessories; charges of weaving or knitting; processing, finishing, sewing and packing; charges of transportation; and conveyance. Hence, it is essential to have knowledge updates about the latest prices, procedures, quality systems, market prices and availability, transportation and freight charges. The volatile nature and rigorous competition in the global garment manufacturing industry drive all the companies to minimize their cost by controlling inventory, accurate forecasting and low mark-downs. It must be remembered that the quality depends on price; and price depends on quality. Each product will have different price according to its quality. While the manufacturers and retailers decide the retail price of a garment, factors such as the average customer’s buying level, quality and quantity and payment terms,should be taken into consideration. It is quite useful and handy to understand the percentage share of cost for each constituent of the apparel supply chain, including material used. The allocation of the cost depends upon multiple variables. Due to competitive manufacturing in Asian countries, a large proportion of the world’s garments are manufactured in China, India, Bangladesh, Pakistan, etc. The ‘cost to the factory’ where the garment is manufactured include types of fabrics used, dyeing cost, trims and accessories used (such as labels, hangers, threads, fusing, buttons, zippers, etc.), cutting cost, stitching cost, trimming cost, packaging cost, company overhead, labor cost, administration cost, etc. A reasonable mark-up is added on the finished garment to cover expenses incurred by the manufacturer and to earn profit. Once the garment is manufactured, road/rail transportation cost is added to deliver the garments to a port of loading. At the port of loading, the cost of freight forwarders and stevedoring is added. Normally, the garments are transported by sea unless the lead time requirement is very tight that demands air transport. The landed cost of the garment in the buyer’s country includes the FOB (free on board) price, shipping cost, clearance cost, custom duties and maritime insurance in the case of sea freight. The cleared garments from customs are road/rail transported to the buyer’s warehouse, where the cost of inventory holding is added onto the garment price. Margin is added to this final price (which is cost paid until the warehouse), which largely covers any mark-downs, expenses like salaries, sales promotion, rent, administration cost, insurance, taxes, etc., and finally the profit for the store. A detailed example of a costing sheet for a garment is given in Table

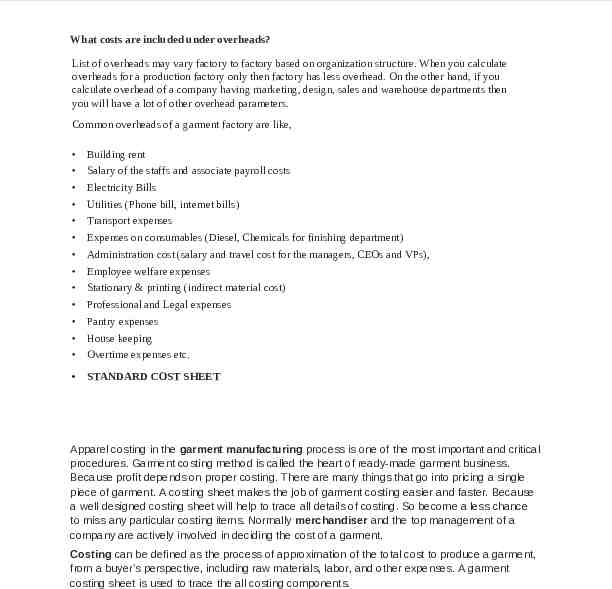

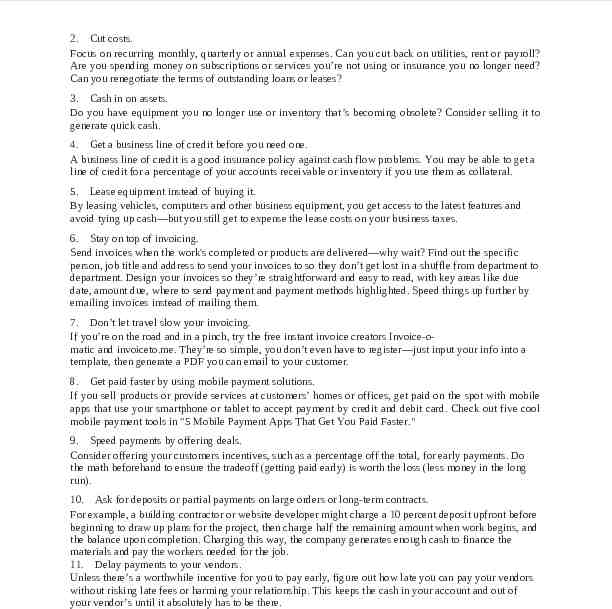

Garment costing sheet Product name Jacket Style no AAA Date 12/05/2014 Buyer BBB Country Australia Size range XL Season Product description Colour Black Fabric costing Particulars Fabric material Fabric 1 Viscose Fabric 2 Lawn Fabric 3 Interfacing Total fabric cost Average dyeing cost Dyed fabric cost Trims and accessories Metre per unit r Selling price Autumn/winte 2014 297.66 Details Amount t AI D Cost per metre ( ) Sub-total ( ) 2 9.00 18.00 1.5 4.00 6.00 0.78 1.29 1.01 25.01 1.50 26.51

Quantit Price/unit Amount (AID) Labels 2 SO.20 SO. 40 Hangtags 1 S0.10 SO. 10 Tickets 2 S0.10 SO. 20 Tag 0 SO. 00 SO. 00 Thread 10 m SO.05 SO. 50 Fusing 0 SO. 00 SO. 00 Zipper 0 S0.00 SO.00 Buttons 8 SO. 50 S4.00 Total trim and accessories S5.20 Packing material Poly bag 1 SO.20 SO. 20 Paper 0 SO. 00 S0.00 Board 0 SO. 00 SO. 00 Hanger 1 SO.05 SO. 05 Hang tag 1 SO.02 SO. 02 1/15 SO. 50 SO .03 Carton Total packing material SO.30 CM TP charges Stitching SI 5.00 Cutting 54.00 Finishing S4 00 Packaging 52.00 Embellishment Trims 56.00 54.00 Total CMTP charges 35.00 Sub total (fabric cost trims packing material 4- CMTP charges) 67.01

Overhead cost 12% 8.04 Total factory cost Mark-up 75.05 25% 18.76 Total wholesale price 93.81 Transport to port of loading S1.00 FOB (Tree on board) Insurance of FOB Custom duty on FOB 94.81 1% 0.95 10% 9.48 Shipping 1.00 Clearance 0.50 Transport to warehouse 1.50 Cost paid till warehouse Mark-up Margin 108.24 150% 60% Retail price exclusive of GST GST 162.36 270.60 10% Retail price inclusive of (1ST # Meaning of Break-Even Chart (BEC): The Break-Even Chart is a graphical representation between cost, volume and profits. No doubt it is an important tool which helps to make profit planning. It has been defined as “a chart which shows the profitability or otherwise of an undertaking at various levels of activity and as a result indicates the point at which neither profit nor loss is made.” Construction of a Break-Even Chart: A Break-Even Chart is constructed on a graph paper. Activity or volume of production is plotted on the ‘X’ axis, whereas cost and revenue are plotted on the ‘Y” axis. 27.06 297.66

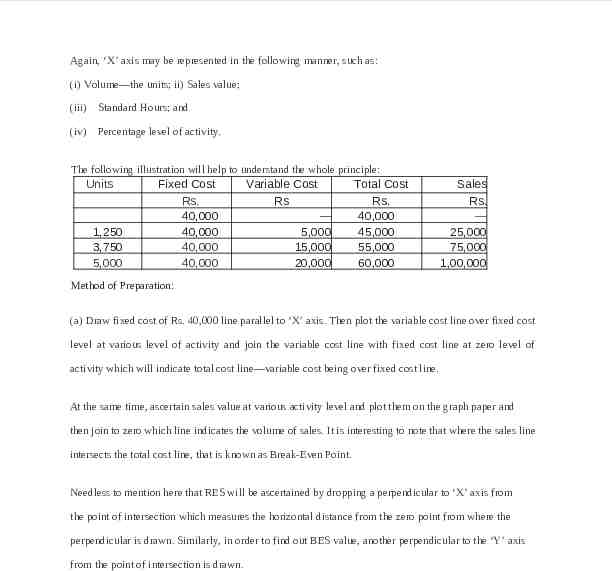

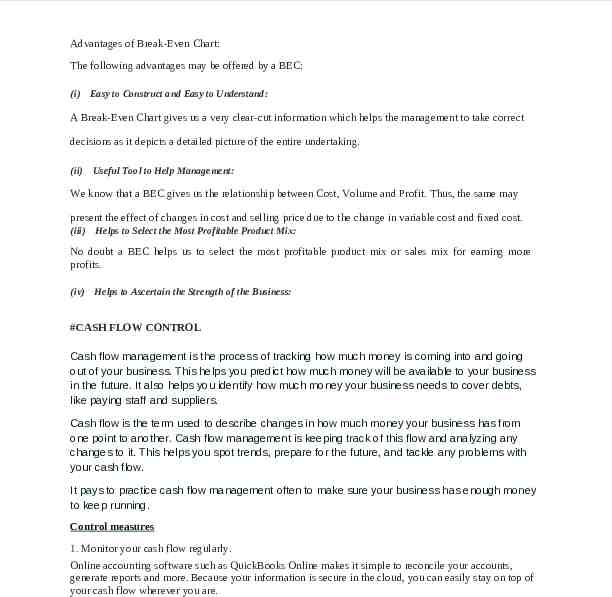

Again, ‘X’ axis may be represented in the following manner, such as: (i) Volume—the units; ii) Sales value; (iii) Standard Hours; and (iv) Percentage level of activity. The following illustration will help to understand the whole principle: Units 1,250 3,750 5,000 Fixed Cost Rs. 40,000 40,000 40,000 40,000 Variable Cost Rs — 5,000 15,000 20,000 Total Cost Rs. 40,000 45,000 55,000 60,000 Sales Rs. — 25,000 75,000 1,00,000 Method of Preparation: (a) Draw fixed cost of Rs. 40,000 line parallel to ‘X’ axis. Then plot the variable cost line over fixed cost level at various level of activity and join the variable cost line with fixed cost line at zero level of activity which will indicate total cost line—variable cost being over fixed cost line. At the same time, ascertain sales value at various activity level and plot them on the graph paper and then join to zero which line indicates the volume of sales. It is interesting to note that where the sales line intersects the total cost line, that is known as Break-Even Point. Needless to mention here that RES will be ascertained by dropping a perpendicular to ‘X’ axis from the point of intersection which measures the horizontal distance from the zero point from where the perpendicular is drawn. Similarly, in order to find out BES value, another perpendicular to the ‘Y’ axis from the point of intersection is drawn.

ii) Sales value; (iii) Standard Hours; and (iv) Percentage level of activity. TheUnits following illustration help to understand whole principle: Fixedwill Cost Variable the Cost Total Cost 1,250 3,750 5,000 Rs. 40,000 40,000 40,000 40,000 Rs. — 5,000 15,000 20,000 Rs. 40,000 45,000 55,000 60,000 Sales Rs. — 25,000 75,000 1,00,000 Method of Preparation: (a) Draw fixed cost of Rs. 40,000 line parallel to ‘X’ axis. Then plot the variable cost line over fixed cost level at various level of activity and join the variable cost line with fixed cost line at zero level of activity which will indicate total cost line—variable cost being over fixed cost line. At the same time, ascertain sales value at various activity level and plot them on the graph paper and then join to zero which line indicates the volume of sales. It is interesting to note that where the sales line intersects the total cost line, that is known as Break-Even Point. Needless to mention here that RES will be ascertained by dropping a perpendicular to ‘X’ axis from the point of intersection which measures the horizontal distance from the zero point from where the perpendicular is drawn. Similarly, in order to find out BES value, another perpendicular to the ‘Y’ axis from the point of intersection is drawn.

Advantages of Break-Even Chart: The following advantages may be offered by a BEC: (i) Easy to Construct and Easy to Understand: A Break-Even Chart gives us a very clear-cut information which helps the management to take correct decisions as it depicts a detailed picture of the entire undertaking. (ii) Useful Tool to Help Management: We know that a BEC gives us the relationship between Cost, Volume and Profit. Thus, the same may present the effect of changes in cost and selling price due to the change in variable cost and fixed cost. (iii) Helps to Select the Most Profitable Product Mix: No doubt a BEC helps us to select the most profitable product mix or sales mix for earning more profits. (iv) Helps to Ascertain the Strength of the Business: #CASH FLOW CONTROL Cash flow management is the process of tracking how much money is coming into and going out of your business. This helps you predict how much money will be available to your business in the future. It also helps you identify how much money your business needs to cover debts, like paying staff and suppliers. Cash flow is the term used to describe changes in how much money your business has from one point to another. Cash flow management is keeping track of this flow and analyzing any changes to it. This helps you spot trends, prepare for the future, and tackle any problems with your cash flow. It pays to practice cash flow management often to make sure your business has enough money to keep running. Control measures 1. Monitor your cash flow regularly. Online accounting software such as QuickBooks Online makes it simple to reconcile your accounts, generate reports and more. Because your information is secure in the cloud, you can easily stay on top of your cash flow wherever you are.

2. Cut costs. Focus on recurring monthly, quarterly or annual expenses. Can you cut back on utilities, rent or payroll? Are you spending money on subscriptions or services you’re not using or insurance you no longer need? Can you renegotiate the terms of outstanding loans or leases? 3. Cash in on assets. Do you have equipment you no longer use or inventory that’s becoming obsolete? Consider selling it to generate quick cash. 4. Get a business line of credit before you need one. A business line of credit is a good insurance policy against cash flow problems. You may be able to get a line of credit for a percentage of your accounts receivable or inventory if you use them as collateral. 5. Lease equipment instead of buying it. By leasing vehicles, computers and other business equipment, you get access to the latest features and avoid tying up cash—but you still get to expense the lease costs on your business taxes. 6. Stay on top of invoicing. Send invoices when the work's completed or products are delivered—why wait? Find out the specific person, job title and address to send your invoices to so they don’t get lost in a shuffle from department to department. Design your invoices so they’re straightforward and easy to read, with key areas like due date, amount due, where to send payment and payment methods highlighted. Speed things up further by emailing invoices instead of mailing them. 7. Don’t let travel slow your invoicing. If you’re on the road and in a pinch, try the free instant invoice creators Invoice-omatic and invoiceto.me. They’re so simple, you don’t even have to register—just input your info into a template, then generate a PDF you can email to your customer. 8. Get paid faster by using mobile payment solutions. If you sell products or provide services at customers’ homes or offices, get paid on the spot with mobile apps that use your smartphone or tablet to accept payment by credit and debit card. Check out five cool mobile payment tools in "5 Mobile Payment Apps That Get You Paid Faster." 9. Speed payments by offering deals. Consider offering your customers incentives, such as a percentage off the total, for early payments. Do the math beforehand to ensure the tradeoff (getting paid early) is worth the loss (less money in the long run). 10. Ask for deposits or partial payments on large orders or long-term contracts. For example, a building contractor or website developer might charge a 10 percent deposit upfront before beginning to draw up plans for the project, then charge half the remaining amount when work begins, and the balance upon completion. Charging this way, the company generates enough cash to finance the materials and pay the workers needed for the job. 11. Delay payments to your vendors. Unless there’s a worthwhile incentive for you to pay early, figure out how late you can pay your vendors without risking late fees or harming your relationship. This keeps the cash in your account and out of your vendor’s until it absolutely has to be there.

12. Get business credit cards to cushion your cash flow. Look for cards with rewards such as points you can use toward travel or business purchases. In addition to providing a cushion for lean times, business credit cards also categorize your purchases, so it’s easier to track expenses. Staying on top of your cash flow is key to your business success. Don't let a few cash flow missteps put you in a money crunch. All it takes are a few smart moves to keep your company in the black.

THANK YOU