Continual Improvement Methods with Six Sigma, Lean, and Lean Six Sigma

66 Slides908.00 KB

Continual Improvement Methods with Six Sigma, Lean, and Lean Six Sigma Lakshmi Chava Swetha Munagala Stephen Rich

Major Topics Rationale for Continual Improvement Management’s Role in Continual Improvement Essential Improvement Activities Structure for Quality Improvement The Scientific Approach Identification of Improvement Needs Development of Improvement Plans Common Improvement Strategies Additional Improvement Strategies The Kaizen Approach Goldratt’s Theory of Constraints The CEDAC Approach Six Sigma Concept Lean Operations Lean Six Sigma

Continual Improvement One of the most fundamental elements of total quality. This concept applies to processes and the people who are operating them as well as to the products resulting from the processes.

Rationale for Continual Improvement Continual Improvement is fundamental to success in the global market place. Customer needs are not static; they change continually.

Management’s Role in Continual Improvement In his book Juran on Leadership for Quality, Joseph Juran writes: “ The picture of a company reaping big rewards through quality improvement is incomplete unless it includes some realities that have been unwelcome to most upper managers. Chief among these realities is the fact that the upper managers must participate personally and extensively in the effort. It is not enough to establish policies, create awareness, and then leave all else to subordinates. That has been tried, over and over again, with disappointing results”.

Cont’d Management should play necessary role in continual improvement by doing the following: Establishing an organization-wide quality council. Working with the quality council. Providing the necessary moral and physical support. Scheduling periodic progress reviews. Building continual quality improvement in to the regular reward system.

Essential Improvement Activities Maintain Communication. Correct obvious problems. Look upstream. Document problems and progress. Monitor changes.

Customers Needs Change Continually “ Quality improvement is needed for both kinds of quality: product features and freedom from deficiencies”.

Improvement Must Be Continual “Improve constantly and forever the system of production and service. Improvement is not a one-time effort. Management is obligated to continually look for ways to reduce waste and improve quality”.

Improvement Is Not Putting Out Fires “Putting out fires is not improvement. Finding a point out of control, finding the special cause and removing it is only putting the process back to where it was in the first place. It is not improvement of process”.

Structure for Quality Improvement Establishing a quality council. Develop a statement of responsibilities. Formulating policy as it relates to quality. Setting the benchmarks and dimensions. Establishing the team and project selection processes. Providing the necessary resources. Implementing the project. Establishing quality measures for monitoring progress and undertaking monitoring efforts. Implementing appropriate reward and recognition program.

Cont’d Establish the necessary infrastructure.

The Scientific Approach Collect Meaningful Data. Identify Root Causes of problems. Develop Appropriate Solutions. Plan and Make Changes.

Collecting Meaningful Data Before collecting meaningful data, decide exactly What data are needed How they can be best collected Where the data exists How they will be measured How you will know the data are accurate

Identify Root Causes of Problems Too many resources are wasted by organizations attempting to solve symptoms rather than problems. Total quality tools will help in separating problems from causes.

Develop Appropriate Solutions Collect the relevant data Make sure they are accurate Identify root causes Develop a solution that is appropriate

Plan and Make Changes Look a head Anticipate needs What resources will be used to satisfy them and Anticipate problems and consider how they should be handled

Importance of Statistical Thinking “Statistical thinking is critical to improvement of a system. Only by use of properly interpreted data can intelligent decisions be made”.

Improvement Can Be Measured Improvement can be measured and monitored by using performance indicators. Some of the examples are listed below: Number of errors or defects Number of or level of need for repetitions of work tasks Efficiency indicators Number of delays Duration of a given procedure or activity Response time or cycle Useability/cost ratio Amount of overtime required Changes in work load Vulnerability of the system Level of criticalness Level of standardization Number of unfinished documents

Identification of Improvement Needs Apply multi voting Identify customer needs Study the use of time Localize problems

Development of improvement plans Understand the process Eliminate errors Remove slack Reduce variation Plan for continual improvement

Common improvement strategies Establish boundaries for the process Flowchart the process Make a diagram of how the work flows Verify your work Correct immediately any obvious problems identified

Standardize the process Identify the currently known best practices and write them down Test the best practices to determine whether they are in fact the best, and improve them if there is room for improvement Make sure that everyone is using the newly standardized process Keep records of process performance, update them continually, and use to identify ways to improve the process even further on a continual basis

Eliminate errors in the process: Streamline the process Reduce sources of variation Bring the process under statistical control

Improve the design of the process Define the objectives of the experiment Decide which factors are going to be measured Design an experiment that will measure the critical factors and the answers the relevant questions Set up the experiment Conduct the experiment Analyze the results Act on the results

Total manufacturing management Reduced lead time Flow production Group technology Level production Synchronized production Overlapped/parallel production Flexible schedules Pull control

Visual control Stockless production Jidoka Reduced setup time In-process control Quality improvement Total cost cycles Cost curves

Mushroom concept Suppliers as comakers Total industrial engineering Total productive maintenance

Kaizen approach Kaizen value system Role of executive management Role of middle managers Role of supervisors Role of employees Kaizen and quality

Elements of kaizen Customer focus Teamwork Just-in-time Quality circles Automation Labor/ management cooperation Total productive maintenance

Kaizen Five-step plan Straighten up: involves separating necessary from unnecessary Put things in order: tools and materials in proper place and in order Clean up: keeping clean to proceed in efficient manner Personal cleanliness: employees being neat to appear better Discipline: careful adherence to standardized work procedures.

The five W’s and One H WHO WHAT WHERE HOW WHEN WHY

Five M checklist Measurement Methods Material Machine Man

Activity

Goldratt’s Theory of Constraints An approach to managing that helps organizations continually improve. It is an intuitive (instinctive) framework for managing organizations. Starts with: 1. clearly defined goals for the organization. 2. establishing measurements to determine the impact of any action on those goals.

What Is So Different? Does not apply the traditional system for measuring results (profits) Uses throughput, inventory, and operating expense.

What’s Different? It is based on the assumption that every organization faces constraints. Greatest negative impact on performance is policies as opposed to materials and resources.

Goldratt Defines Restraint “anything that limits an organization from achieving higher performance vis-à-vis (in comparison with) its goal.

How Is It Applied? Identify: any factor that tends to constrain. Exploit: how can the factor be turned into positive factors, eliminated, or circumvented.

CEDAC Approach CEDAC cause-and-effect with additional cards. 3 conditions must exist for continual improvement to occur. A reliable system (standardized and reliable) A favorable environment (favorable to improvement) Practicing as teams (Total Quality is performed by teams. Teams must practice)

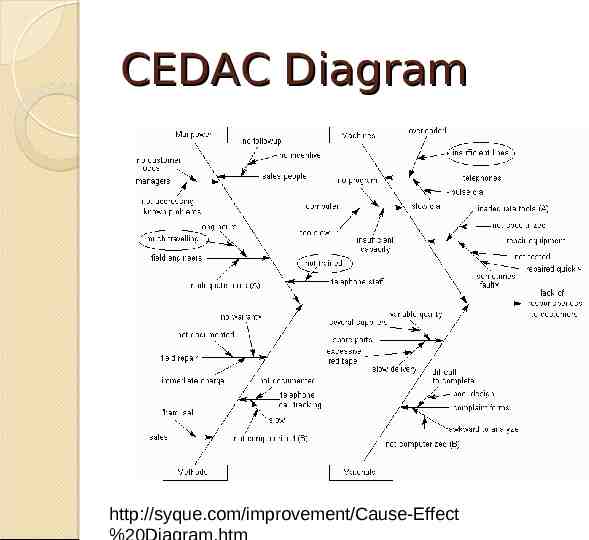

CEDAC Diagram http://syque.com/improvement/Cause-Effect

10-Step Process of Implimentation Draw Basic Diagram Select the focus of improvement efforts Name project leader Establish measurement method Establish improvement goal and date Format effect side of the diagram Collect fact cards for the cause side (each team member fills out cards with their ideas) Collect improvement cards Implement and test ideas Select cards for standardization

Six Sigma Concept http://www.youtube.com/watch?v LNtEW4DVRkE&feature related Introduced by Motorola in the mid-1980’s Purpose: to improve the performance process to where defects rate was 3.4 per million or less. Designed for high volume production settings.

Six Step Protocol 1. 2. 3. Identify the product characteristics wanted by customers. Classify the characteristics in terms of their criticality. Determine is the classified characteristics are controlled by part and/or process.

Protocol 4. Determine the maximum allowable tolerance for each classified characteristic. 5. Determine the process variation for each classified characteristic. 6. Change the design of the product, process, or both to achieve Six Sigma performance.

Six Sigma: The Name From the concept of standard deviation signified by lowercase Greek letter sigma: σ Processes and outputs typically measure in their standard deviations from the mean (ideal point).

What Does That Mean? Most good companies operate between 3 and 4 sigma. Or: 99.73% of process output will fall between 3 standard deviation at 3 sigma or 99.9937% at 4 sigma. 3 sigma operation will yield 2700 defective parts for every 1 million produced.

Six Sigma and Total Quality Six Sigma is an extension of Total Quality. Six Sigma is a total quality strategy, like all others, to achieve: superior performance, that is continually improved, forever. Six Sigma is achieved by improving process performance.

Lean Operations Lean Lean Manufacturing Lean Operations Lean: originally a manufacturing concept thus lean manufacturing. Lean Operations: because it is found to produce good results in both manufacturing AND service sectors.

Purpose of Adopting To produce better products or deliver better services using less resources. Doing more with less and doing it better.

Defining Lean Based on the Toyota Production System (TPS). Lean Operation: a better product is developed or a better service is delivered by using less of everything required.

Definition Lean is: being flexible enough to get the right things, to the right place, at the right time, in the right amounts. The Heart: reduction of waste and the improvement of workflow.

Lean Focuses on Waste Overproduction Waste Inventory Waste Motion Waste Transportation Waste Over-processing Waste Defects Waste Waiting Waste Underutilization Waste

Tools and Techniques of Lean Five-S workplace organization Visual workplace systems Layout Standardized work (SW) Point of usage storage (POUS) Batch size reduction Quick changeover(QCO) Poka-yoke

More Tools: Self-inspection Autonomation Pull systems/kanban Cellular and flow Just-in-time (JIT) Total productive maintenance (TPM) Value stream mapping (VSM) Change management Teamwork

Lean Six Sigma Combining Key Lean and Six Sigma Concepts: Green Belts Black Belts Master Black Belts Champions DMAIC Roadmap (or lean Six Sigma)

Where to Use? In Manufacturing: Especially effective for the following types of continual improvement projects: Accuracy in invoicing Capacity of line and product Lead time on delivery Production Replenish downtime on equipment and lines

Where to Use? In Service Sector: Accuracy in invoicing, delivery, and product Capacity of service area, call center, and product Lead time on delivery and call hold time Downtime on equipment, servers, and lines

DMAIC Roadmap The Nucleus of Six Sigma: Define, Measure, Analyze, Improve, and Control. Five Phases are constant Steps, tools and outputs of each phase may vary somewhat.

Define 1. initiate the project 2. Define the process 3. Determine Customer requirements 4. define key process output variables Possible tools: value stream maps, affinity diagrams, brainstorming, surveys

Measure 1. Understand the process 2. Evaluate risks on process inputs 3. Develop and evaluate measurements systems 4. measure current performance Results: Knowing your starting point, verification of measurement systems, current capabilities

Analyze 1. Analyze data to prioritize key input variables 2. Identify waste Results: root causes reduced. Prioritize potential key inputs, and list specific wastes. Tools: Five-S (sort, store, shine, standardize, & sustain)

Improve 1. verify critical outputs 2. Design Improvements 3. Pilot the new process Results: an action plan for improvement, future state process maps, control maps, new process design/documentation

Control 1. Finalize the control system 2. Verify long-term capability Results: a control system, improvement validated for long term, identified continual improvement opportunities, team recognition

Bibliography All information obtained from: Goetsch, D.L., Davis, S.B. Quality Management for organizational excellence: introduction to total quality. 2006. 5th edition

Why Do We Ned Six Sigma? Interview: http://www.youtube.com/watch?v 7rUQbTsc ms