12 : Managing Conformance Steel doesn’t always fit and there are

20 Slides159.00 KB

12 : Managing Conformance Steel doesn’t always fit and there are many reasons for it. A detailer can goof. The shop can goof. Even worse, Murphy can goof, and when I say Murphy, I mean an accumulation of tolerances, all added, like eighty-six basic steel tolerances, plus shop tolerances, plus the field tolerances. When they all add up to a misfit, then we have to address it. But we have troubleshooters on each job and they resolve them Gene Miller, Mosher Steel Graham M Winch Riding the Project Life-cycle 1

Managing Conformance the principles of conformance management systems – the quality model – QUENSH systems creating a culture of improvement – quality awards and self-assessment standardisation and pre-assembly conformance management in a project environment Graham M Winch Riding the Project Life-cycle 2

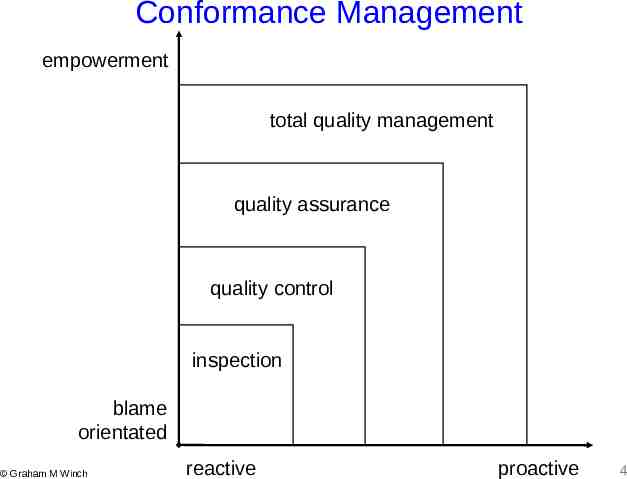

The Principles of Conformance Management inspection quality control quality assurance approaches to quality management – empowerment blame orientation – reactive proactive Graham M Winch Riding the Project Life-cycle 3

Conformance Management empowerment total quality management quality assurance quality control inspection blame orientated Graham M Winch reactive proactive 4

What is Conformance to Quality? the notion of tolerance acceptable quality level – sampling approach zero defects – “quality is free” - Crosby the quality loss function process capability reliability engineering Graham M Winch Riding the Project Life-cycle 5

Quality Loss Function and Zero Defects Approaches to Conformance target value lower specification limit lower specification limit upper specification limit upper specification limit measured quality characteristic measured quality characteristic quality loss function Graham M Winch Riding the Project Life-cycle zero defects 6

Process Capability Cp Graham M Winch Tu - Tl 6σ Riding the Project Life-cycle 7

Reliability Engineering failure mode and effects analysis – – – – probability of occurrence probability of detection severity of impact the Risk Priority Number the reliability profile – design life set in relation to life-cycle cost analysis Graham M Winch Riding the Project Life-cycle 8

design life commissioning The Reliability Profile total risk of failure failure due to wear out risk of failure failure due to nonconformance externally induced failures time Graham M Winch Riding the Project Life-cycle 9

Inspection “conformity evaluation by observation and judgement accompanied as appropriate by measurement, testing or gauging” the audit approach sampling requires dedicated resources Graham M Winch Riding the Project Life-cycle 10

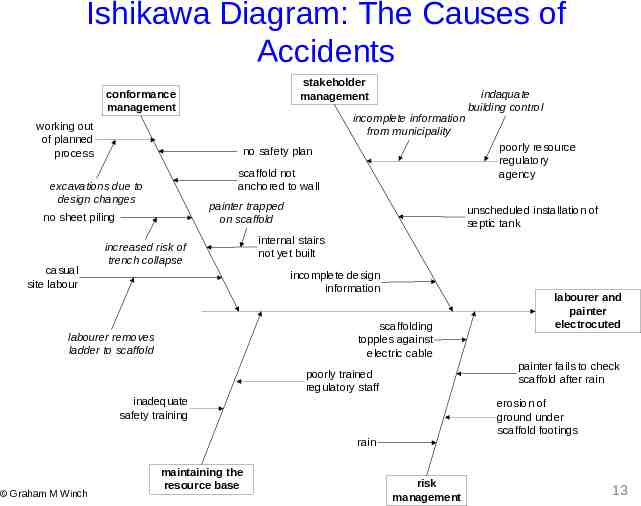

Quality Control “the part of quality management focused on fulfilling quality requirements” the 7 QC tools – Ishikawa process maps cause and effect diagrams data logging statistical process control Graham M Winch Riding the Project Life-cycle 11

Graham M Winch 30 Riding the Project Life-cycle 18 14 12 10 lack of skill of operative failure to protect completed work poor planning by operative 27 designer does not undertand materials poor site management 32 lack of knowledge of operatives 34 difficult to build 38 lack of coordination of design 39 low quality design design will not work lack of care by operatives unclear/missing design information Pareto Diagram : The Causes of Defects 129 84 12

Ishikawa Diagram: The Causes of Accidents stakeholder management conformance management incomplete information from municipality working out of planned process scaffold not anchored to wall painter trapped on scaffold no sheet piling casual site labour poorly resource regulatory agency no safety plan excavations due to design changes increased risk of trench collapse unscheduled installation of septic tank internal stairs not yet built incomplete design information scaffolding topples against electric cable labourer removes ladder to scaffold inadequate safety training erosion of ground under scaffold footings rain Graham M Winch labourer and painter electrocuted painter fails to check scaffold after rain poorly trained regulatory staff maintaining the resource base indaquate building control risk management 13

Quality Assurance “the part of quality management focused on providing confidence that quality requirements will be fulfilled” quality management systems – first party – second party – third party (ISO 9001 -2000) quality policy and the project quality plan QA certification arrangements the Glaxo project QA plan BS 8800 ISO 14001 Graham M Winch Riding the Project Life-cycle 14

The UK’s QA Certification Arrangements Department of Trade and Industry British Standards Institute policy and standards UK Accreditation Service accreditation Certification Body assessment and surveillance application for certification Firm Graham M Winch 15

Creating a Culture of Improvement the limitations of inspection, QA and QC – first order control loops – operationally orientated TQM as a project philosophy – the culture of the project - its values – safety culture creating a culture of improvement quality awards and self-assessment Graham M Winch Riding the Project Life-cycle 16

Generating a Culture of Improvement “the part of quality management focused on increasing the ability to fulfil quality requirements” empower those doing the work training is crucial for success organisational learning is the aim align incentives with desired performance senior management commitment is essential Graham M Winch Riding the Project Life-cycle 17

Quality Awards and Self-Assessment the EFQM model – Baldridge in US framework for developing a vision develop understanding of the business enter for the European Quality Awards diagnostic tool to enable – benchmarking – self-assessment Graham M Winch Riding the Project Life-cycle 18

Standardisation and Pre-assembly standardisation – standard components and modules – economies of scale pre-assembly – pre-fabrication and sub-assemblies – controlling the working environment mass customisation – combining the two – volumetric modules Graham M Winch Riding the Project Life-cycle 19

Quality Management in a Project Environment issues – incremental cycles of improvement – repeated sampling – equity in investment and return applications – sampling is at the component/ sub-assembly level – standardisation across projects – measuring process capability empowering the workforce Graham M Winch Riding the Project Life-cycle 20