Visibility Strategy September, 2006

24 Slides1.07 MB

Visibility Strategy September, 2006

Visibility Today CONFIRM provides piece level mail processing data that can be used for tracking for letters and flats 218 CONFIRM subscribers with an average of 353 million pieces per month Each piece receives an average of 2.4 scans Limited start-the-clock capabilities Some flats bypass processing equipment No container tracking data available 2

Recent Visibility Advancements Recent technology improvements enable more robust visibility offerings than previously available. Deployment of Surface Visibility PostalOne! capability to support Large/Medium/Small customers Deployment of FAST Deployment of passive tray scanning capabilities New unique barcodes for pieces and containers Implementation of common customer identifier across visibility systems (Business Entity ID) 3

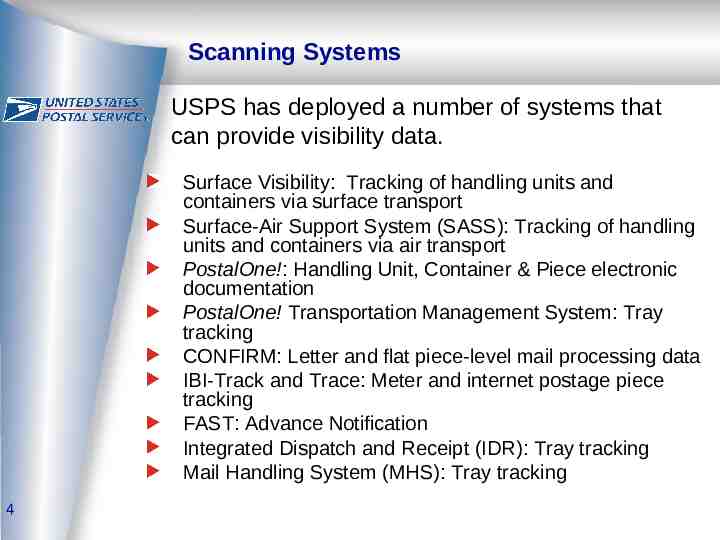

Scanning Systems USPS has deployed a number of systems that can provide visibility data. Surface Visibility: Tracking of handling units and containers via surface transport Surface-Air Support System (SASS): Tracking of handling units and containers via air transport PostalOne!: Handling Unit, Container & Piece electronic documentation PostalOne! Transportation Management System: Tray tracking CONFIRM: Letter and flat piece-level mail processing data IBI-Track and Trace: Meter and internet postage piece tracking FAST: Advance Notification Integrated Dispatch and Receipt (IDR): Tray tracking Mail Handling System (MHS): Tray tracking 4

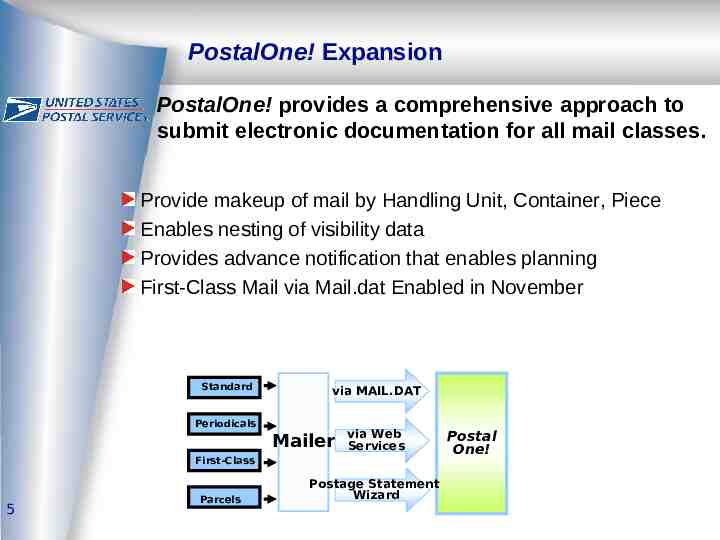

PostalOne! Expansion PostalOne! provides a comprehensive approach to submit electronic documentation for all mail classes. Provide makeup of mail by Handling Unit, Container, Piece Enables nesting of visibility data Provides advance notification that enables planning First-Class Mail via Mail.dat Enabled in November Standard via MAIL.DAT Periodicals Mailer via Web Services First-Class 5 Parcels Postage Statement Wizard Postal One!

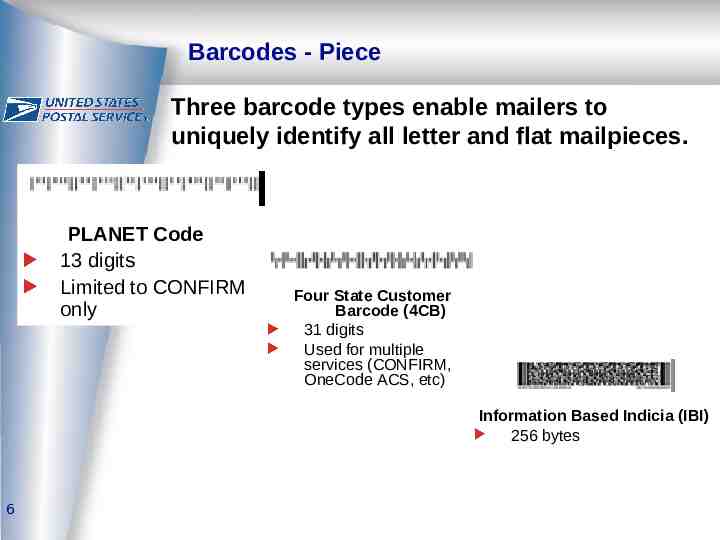

Barcodes - Piece Three barcode types enable mailers to uniquely identify all letter and flat mailpieces. PLANET Code 13 digits Limited to CONFIRM only Four State Customer Barcode (4CB) 31 digits Used for multiple services (CONFIRM, OneCode ACS, etc) Information Based Indicia (IBI) 256 bytes 6

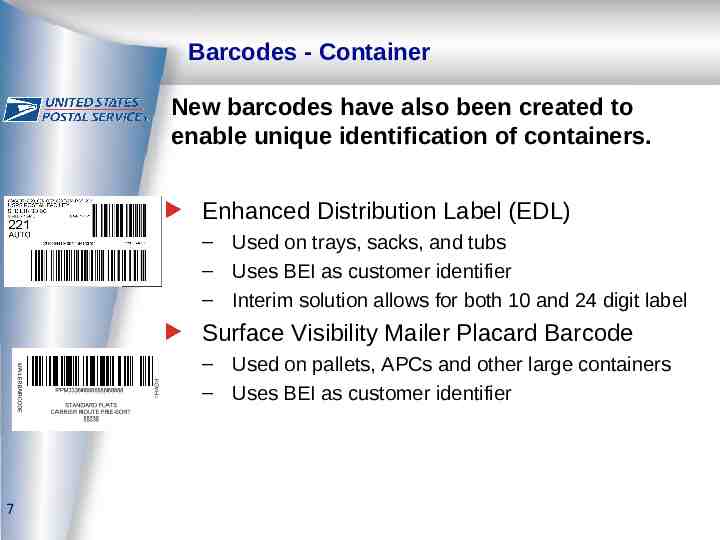

Barcodes - Container New barcodes have also been created to enable unique identification of containers. Enhanced Distribution Label (EDL) – Used on trays, sacks, and tubs – Uses BEI as customer identifier – Interim solution allows for both 10 and 24 digit label Surface Visibility Mailer Placard Barcode – Used on pallets, APCs and other large containers – Uses BEI as customer identifier 7

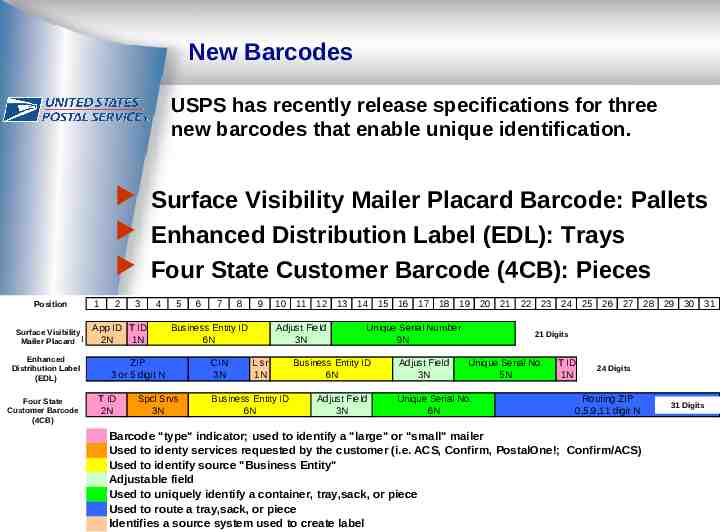

New Barcodes USPS has recently release specifications for three new barcodes that enable unique identification. Surface Visibility Mailer Placard Barcode: Pallets Enhanced Distribution Label (EDL): Trays Four State Customer Barcode (4CB): Pieces Position MTEL Surface Visibility Container Level Mailer Placard Enhanced 24Digit Distribution Label Piece Level (EDL) Four 4ST State Customer PieceBarcode Level (4CB) 8 1 2 3 4 App ID T ID 2N 1N 5 7 8 9 Business Entity ID 6N ZIP 3 or 5 digit N T ID 2N 6 Spcl Srvs 3N CIN 3N 10 11 12 Adjust Field 3N L sr 1N Business Entity ID 6N 13 14 15 16 17 18 19 Unique Serial Number 9N Business Entity ID 6N Adjust Field 3N Adjust Field 3N 20 21 22 23 24 25 26 27 28 29 30 21 Digits Unique Serial No. 5N Unique Serial No. 6N T ID 1N 24 Digits Routing ZIP 0,5,9,11 digit N Barcode "type" indicator; used to identify a "large" or "small" mailer Used to identy services requested by the customer (i.e. ACS, Confirm, PostalOne!; Confirm/ACS) Used to identify source "Business Entity" Adjustable field Used to uniquely identify a container, tray,sack, or piece Used to route a tray,sack, or piece Identifies a source system used to create label 31 Digits 31

Business Entity Identifier Initially, 20 BEIs will be granted per Customer Location Obtain BEI by calling PostalOne! help desk initially, will automate in future BEI can be 6 or 9 digits – 6-Digit BEIs provided to customers that require additional digits to maintain unique serial IDs over 90 days Will be used to identify a mailer in the Four State Barcode (4CB), Enhanced Distribution Label (EDL) and Mailer Placard barcodes Used to determine who to disseminate Confirm and OneCode ACS data Enhances existing USPS services and offerings and provides a foundation for additional services and offerings to customers of any size. 9

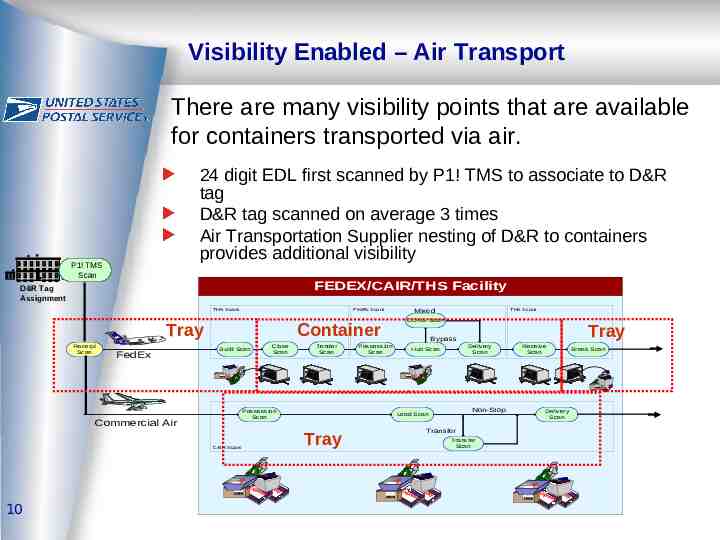

Visibility Enabled – Air Transport There are many visibility points that are available for containers transported via air. 24 digit EDL first scanned by P1! TMS to associate to D&R tag D&R tag scanned on average 3 times Air Transportation Supplier nesting of D&R to containers provides additional visibility P1! TMS Scan FEDEX/CAIR/THS Facility D&R Tag Assignment THS Scans FedEx Scans Tray Receipt Scan FedEx Container Build Scan Close Scan Tender Scan THS Scans Mixed CONS Scan Tray Bypass Possession Scan MA I LE R P LA CARD Delivery Scan Hub Scan Receive Scan Break Scan MA ILE R P LA CARD MA I LE R P LA CAR D Possession Scan Commercial Air CAIR Scans Non-Stop Load Scan Delivery Scan Transfer Tray Transfer Scan MA I LE R PLACA RD M AIL ER PLACA RD MA ILER P LA CARD 10

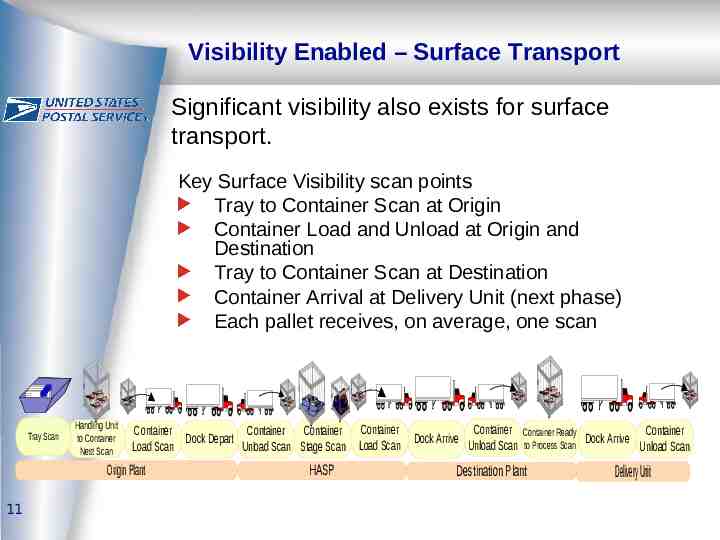

Visibility Enabled – Surface Transport Significant visibility also exists for surface transport. Key Surface Visibility scan points Tray to Container Scan at Origin Container Load and Unload at Origin and Destination Tray to Container Scan at Destination Container Arrival at Delivery Unit (next phase) Each pallet receives, on average, one scan Tray Scan Handling Unit to Container Nest Scan Container Container Container Dock Depart Load Scan Unload Scan Stage Scan Origin Plant 11 HASP Container Load Scan Container Container Ready Container Dock Arrive Unload Scan to Process Scan Dock Arrive Unload Scan Destination Plant Delivery Unit

Visibility Uses Robust visibility enables new capabilities that benefit both mailers and USPS. Respond to Customer Needs for Expanded Visibility Seamless Acceptance Network & Transportation Optimization Start-the-Clock Service Performance Measurement Enhanced Products and Services: CONFIRM 12

Seamless Acceptance Unique piece and container identifiers and accurate mailer documentation are critical to Seamless Acceptance. Presort: Piece scan patterns have been used to verify presort of ZIP groups Mailpiece Count: Number of inducted pieces has been determined from piece scans Short Tray Validation: Actual piece counts by ZIP group from scan data have been used to verify mail makeup Evaluating the use of the following: – – 13 Accurate Barcode Verification: Read rate for mailing can be compared to End-Of-Run (EOR) read rate for all mailings and eMIR reports for problem pieces Valid Barcode: POSTNET of piece documentation can be compared to the Delivery Point File (DPF Now) file to determine if valid POSTNET applied

Start-the-Clock Accurate electronic documentation and nesting information enables robust Start-the-Clock capabilities. Electronic documentation will link – Pieces to trays – Trays to pallets – Pallets to shipment Plant Loads Truck arrival and unload scans can be used to Start-the-Clock Pallet scans provide specific unload details (time and location of each pallet) Tray scans provide assurance that mail is being worked 14

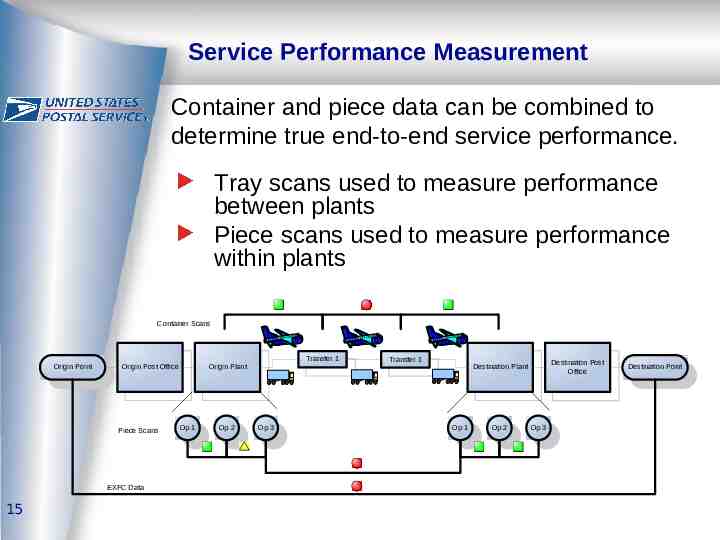

Service Performance Measurement Container and piece data can be combined to determine true end-to-end service performance. Tray scans used to measure performance between plants Piece scans used to measure performance within plants Container Scans Origin Point Origin Post Office Piece Scans EXFC Data 15 Transfer 1 Origin Plant Op 1 Op 2 Op 3 Transfer 1 Destination Post Office Destination Plant Op 1 Op 2 Op 3 Destination Point

Enhanced Products and Services: CONFIRM The CONFIRM infrastructure will be leveraged to provide additional scan data to customers. Single source/subscription for all visibility data Piece and container scans combined in a single source for mailers New subscriber levels will be defined Customers will get scans based on program participation and subscriber level (i.e. Seamless Acceptance participants will get applicable scans) 16

Requirements for Visibility Data Requirements for expanded visibility to include Pallet, Tray, Sack, Tub Scans – Advanced Notification – Electronic Documentation & Postage – Unique Barcodes on Handling Units and Containers 17

Requirements for Visibility Data Advanced Notification – Induction Location – Induction Date and Time – Plant Load Mailing Indicator and Last Process Location – Recurring (Frequency) or One-Time Mailing – Pre-sort of Handling Units (HU) – Average HU weight – Destination ZIP code of HUs – Number of Containers (Rolling Stock or Pallets) – Mail Shape 18

Requirements for Visibility Data Electronic Documentation & Payment – Manifest Mailers/List/MLOCR » Tray – – – – » Piece Level – – – » 19 Processing Category Batch/Itemized Manifest ID Unique 4 CB barcode/POSTNET (for Seamless Acceptance Only) Container – – » Unique Physical/Logical Tray Identification (unique) Pre-sort # of Mailpieces per Tray ZIP Code Range(s) Number of Containers (Rolling Stock or Pallets) Unique Surface Visibility Mailer Placard Barcode Unique Identifier for a Mailing

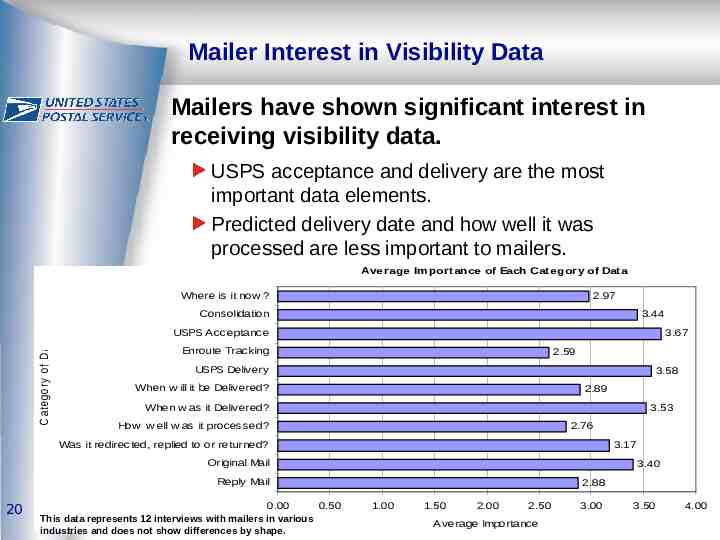

Mailer Interest in Visibility Data Mailers have shown significant interest in receiving visibility data. USPS acceptance and delivery are the most important data elements. Predicted delivery date and how well it was processed are less important to mailers. Average Im portance of Each Category of Data Where is it now ? 2.97 C ategory of D ata Consolidation 3.44 USPS Acceptance 3.67 Enroute Tracking 2.59 USPS Delivery 3.58 When w ill it be Delivered? 2.89 When w as it Delivered? 3.53 How w ell w as it processed? 2.76 Was it redirected, replied to or returned? 3.17 Original Mail 3.40 Reply Mail 20 0.00 0.50 This data represents 12 interviews with mailers in various industries and does not show differences by shape. 2.88 1.00 1.50 2.00 2.50 Average Importance 3.00 3.50 4.00

Information Needs Raw data preferred to individual inquiries Hold data elements for 90 days Timeliness of data – Real Time, Near Real Time, Daily – Parcel mailers in real time where and when – First-class, standard mailers near real time where & when – Periodical mailers daily Mailers have highly varied uses for the data 21 – Provide better customer service through increased information. – Actively manage the supply chain. – Optimize call center staffing to reduce labor costs. – Prevent or reduce fraudulent claims. – Improve marketing and fulfillment planning.

Questions for Group Visibility Scan Approach for Letters & Flats – – – – – – 22 Integration with Confirm Raw Data Unit Scans – Piece, Tray, Container Frequency of dissemination Data Elements to be included Mail Class Distinction – First, Standard, Periodicals

CONFIRM Scan Elements Scan ID: sequential scan identifier Scan Facility ID: 5 digit ID of the facility Operation Code: 3 digit code of the operation Scan Date/Time Scan POSTNET: the POSTNET of the piece Scan Tracking Code: the 4CB of PLANET code on the piece 23

Transportation Visibility Scan Elements ID Tag: the unique identifier on the container Scan Facility ID: the identifier of the location at which the scan occurred Scan Date/Time Scan Type: the type of scan that was conducted (i.e. possession, delivery, unload, load, etc.) Nested Info: the identifier if a parent or child record exists 24