The Material Selection Process So many choices, so little time. How to

47 Slides1.59 MB

The Material Selection Process So many choices, so little time. How to select mechanical materials for prototypes and production devices Presented by Neil B. Kimerer, Jr. P. E. To the Williamsport Inventers Club January 28, 2015

Overview Discuss the selection Process Discuss the properties of materials Discuss material groups Discuss metal materials Discuss Plastic materials Discuss composite materials Give some examples Discuss Additive Manufacturing Materials

Basic Process Steps an elimination process 1. Define the environment 1. Select groups of materials that meet the requirements 2. Define the material’s mechanical property requirements 1. Select materials from the environmental groups that meet the requirements 3. Select a manufacturing process from the material candidates 4. Select from the candidates for cost 1. Select from the mechanical properties group the lowest cost material

Define the Environment There are two types of environments 1. Survival Environment An environment the product might be exposed to but it does not have to function while in it. 2. Operating Environment An environment where the product must be able to function properly.

Environment Characteristics that need to be considered 1. Temperature (Changes the properties of materials.) 2. Gas exposure (corrosion, oxidation, etc. Especially when two different metals are in direct contact with each other. gas, such as the atmosphere, liquids, such as water and sea water, Oils, etc.) 3. Liquid exposure (generally more active than gases. Especially when two different metals are in direct contact with each other.) 4. 5. 6. 7. Electromagnetic wave exposure (Visible light, Ultra violet light, Infrared light, X-rays, micro waves, Microwave ovens, etc.) Electric current (AC fields can induce currents in conductive materials.) Pressure (atmospheric, underwater, water lines, water heaters, engines, steam and internal combustion) Radio active particle fields ( Necular reactors, radiation treatment machines, X-Ray machines, devices lifted to high altitudes above the earth devices lowered into deep holes drilled into the Earth’s crust, etc.) 8. Magnetic fields (around electric motors, Transformers, generators, MRIs, etc.) 9. Consequences of the part failure 10.Time (materials deteriorate with time alone, plastics, concrete, wood, silk, etc.) 11.Shock (shock and vibration can cause grain boundary separations, plastic deformations, fracture, crakes, etc.)

Defining Material Mechanical properties (all solid materials) Stiffness (modulus of elasticity, Young’s modulus, PSI) Strength (yield, ultimate and endurance stress, PSI) Bulk Modulus (compression, PSI) Shear Modulus (resistance to shearing, PSI) Poison's ratio (inches/inch, dimensionless) Ductility (amount of yielding before failure, inches/inch, dimensionless) Thermal coefficient of expansion (inches/inch/ º F) Density (pounds/cubic inch) Transparency Hardness (resistance to denting and wear, empirical, HR, B) Conductivity (electrical, Ohms/in, and thermal, BTU/hour-feet/ º F) Magnetic permeability (sensitivity to magnetic fields) Shock resistance ( how brittle is the material ?) Notch sensitivity to fracture Specific Heat Capacity (BTU/pound) Creep Melting point ( º F) Freezing point ( º F)

Where to find a materials properties www.matweb.com Free to the buyer Several selection methods Sends you to sellers on request Ceramics - 8166 materials (matls) Fluids – 5494 matls Engineered – 5140 matls Metals - 14,540 matls Polymers – 78,836 matls Natural – 381 matls

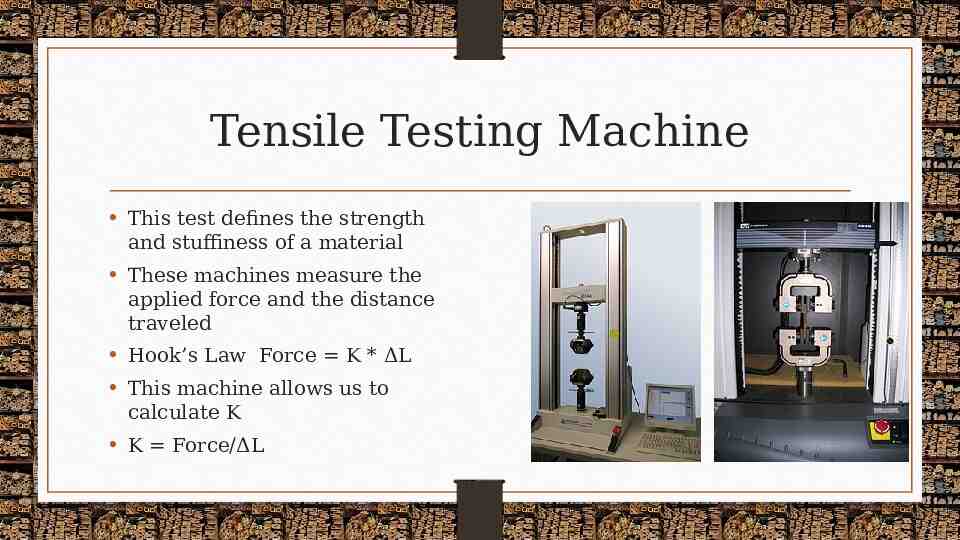

Tensile Testing Machine This test defines the strength and stuffiness of a material These machines measure the applied force and the distance traveled Hook’s Law Force K * ΔL This machine allows us to calculate K K Force/ΔL

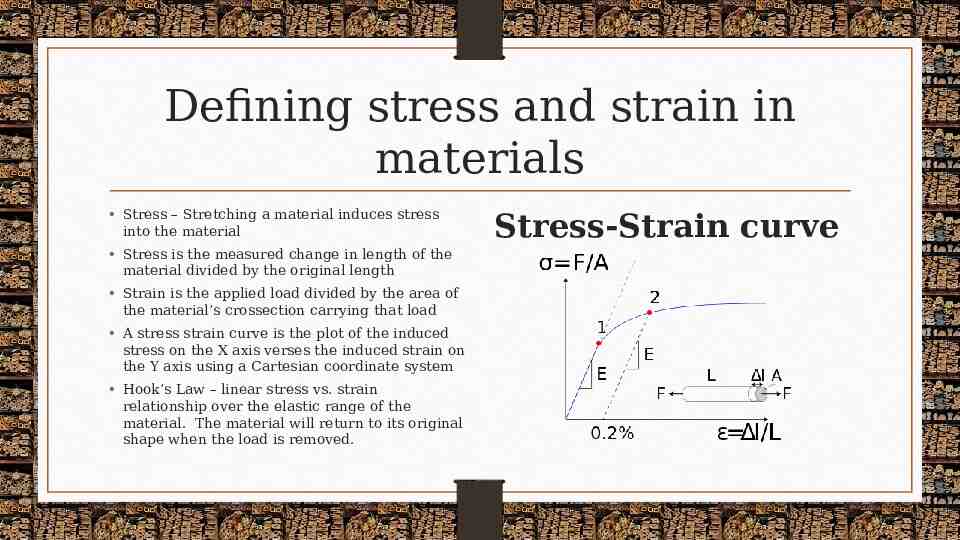

Defining stress and strain in materials Stress – Stretching a material induces stress into the material Stress is the measured change in length of the material divided by the original length Strain is the applied load divided by the area of the material’s crossection carrying that load A stress strain curve is the plot of the induced stress on the X axis verses the induced strain on the Y axis using a Cartesian coordinate system Hook’s Law – linear stress vs. strain relationship over the elastic range of the material. The material will return to its original shape when the load is removed. Stress-Strain curve

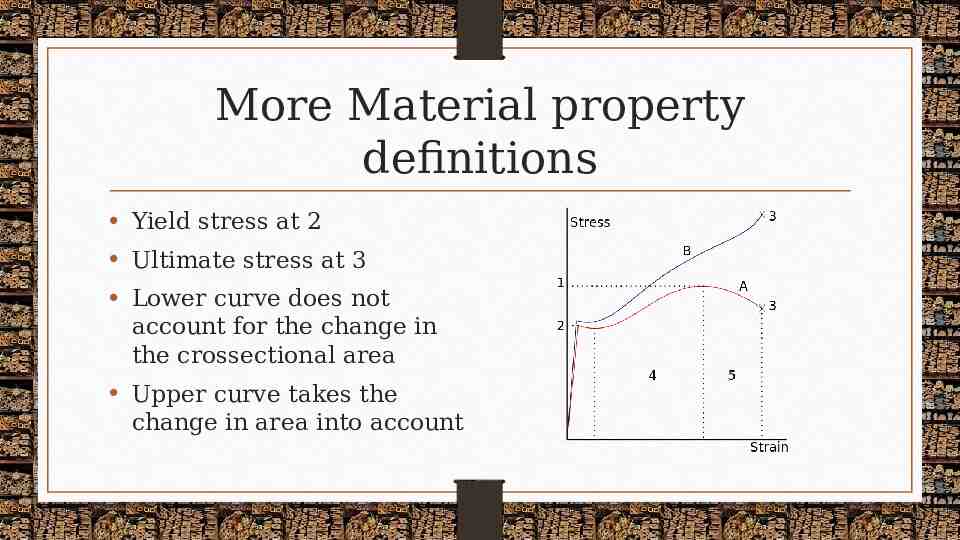

More Material property definitions Yield stress at 2 Ultimate stress at 3 Lower curve does not account for the change in the crossectional area Upper curve takes the change in area into account

Bulk Modulus Bulk Modulus is the equivalent to Young’s modulus except in compression Units in the English system are PSI

Shear Modulus A materials resistance to a shearing force. Shear modulus is directly related to the other moduli. If you know the Poisson’s Ratio, Bulk modulus and Young’s modulus the Shear modulus can be calculated.

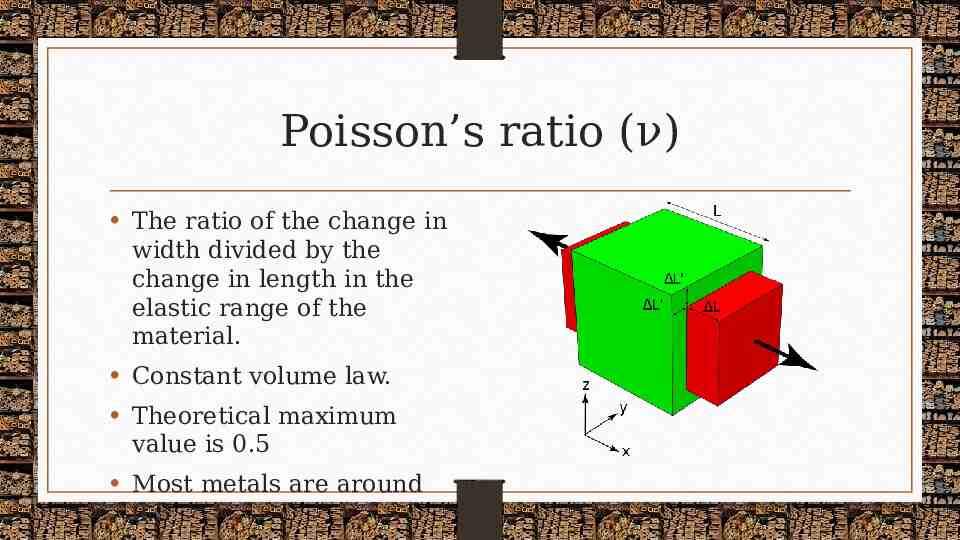

Poisson’s ratio (ν) The ratio of the change in width divided by the change in length in the elastic range of the material. Constant volume law. Theoretical maximum value is 0.5 Most metals are around 0.3

Ductility Ductility (in tension) Malleability (in compression) Depends on the metal treatment

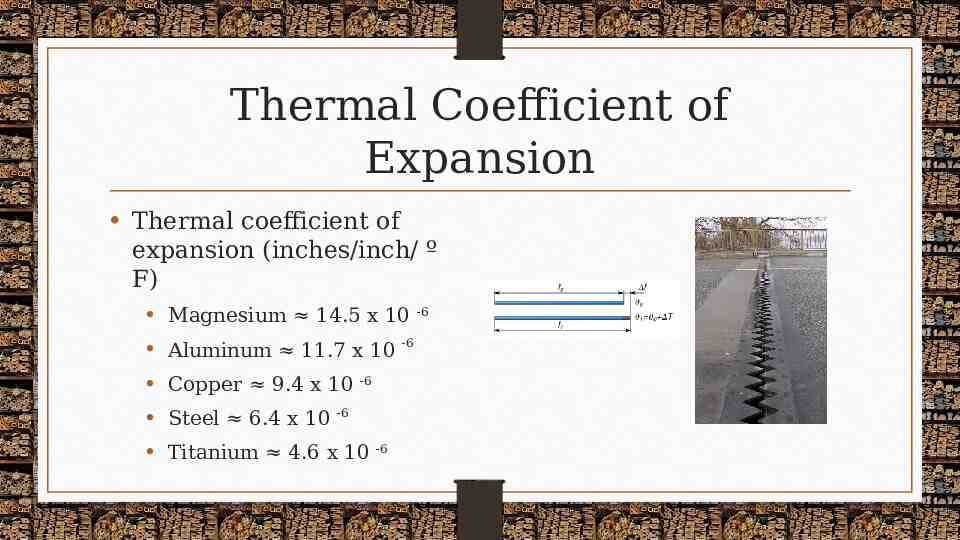

Thermal Coefficient of Expansion Thermal coefficient of expansion (inches/inch/ º F) Magnesium 14.5 x 10 -6 Aluminum 11.7 x 10 -6 Copper 9.4 x 10 -6 Steel 6.4 x 10 -6 Titanium 4.6 x 10 -6

Density Weight per unit volume Magnesium 0.063 lbs./ inch 3 Aluminum .100 lbs./inch 3 Titanium 0.160 lbs./inch 3 Steel 0.278 lbs./ inch 3 Copper 0.310 lbs./ inch 3 Lead 0.4097 lbs./ inch 3 Lead is 6.5 times as dense as Magnesium

Material Hardness Metal Hardness (resistance to denting) – Rockwell (HR) and Brinell (B) scales Empirical measurement Rockwell A, B and C Brinell Rubber like materials Hardness – Shore Durometer scale Empirical measurement

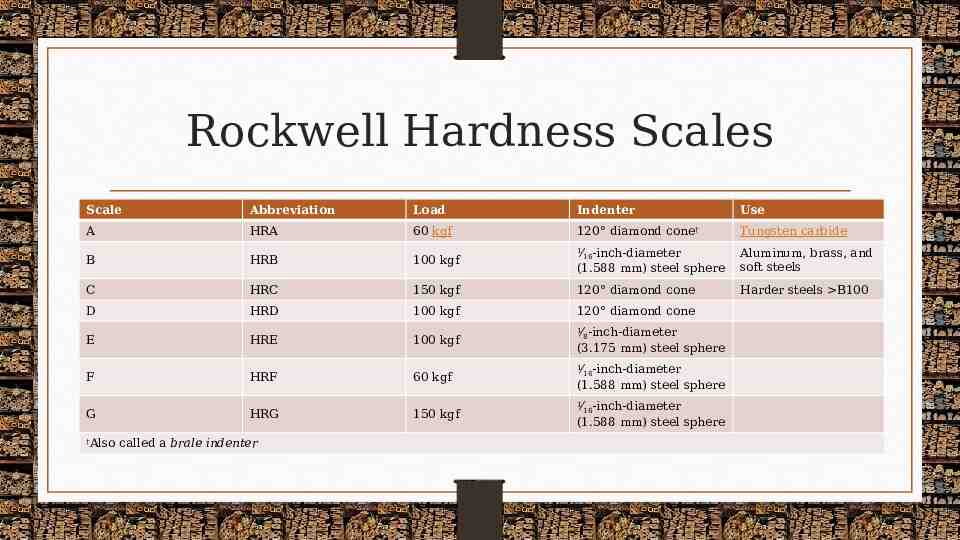

Rockwell Hardness Scales Scale Abbreviation Load Indenter Use A HRA 60 kgf 120 diamond cone† Tungsten carbide B HRB 100 kgf 1 16-inch-diameter (1.588 mm) steel sphere Aluminum, brass, and soft steels C HRC 150 kgf 120 diamond cone Harder steels B100 D HRD 100 kgf 120 diamond cone E HRE 100 kgf F HRF 60 kgf G HRG 150 kgf † Also called a brale indenter 8-inch-diameter (3.175 mm) steel sphere 1 16-inch-diameter (1.588 mm) steel sphere 1 16-inch-diameter (1.588 mm) steel sphere 1

Conductivity (electrical, Ohms/in, and thermal, BTU/hour-feet/ º F) Electrical Conducting current, transformers, motors, inductors, grounding Eliminating conduction, insulation for wires, electrical isolation mounts, Thermal Heat exchangers for cooling or heating Insulation for retaining heat or cold

Other properties Magnetic permeability (sensitivity to magnetic fields) Shock resistance ( how brittle is the material ) Notch sensitivity to fracture Specific Heat Capacity (BTU/pound) Creep Melting point ( º F) Freezing point ( º F)

Selecting the Material Category Discuss mechanical properties Homogeneous Materials (Isentropic) Have the same properties in all directions Composites (non-homogeneous, anisentropic) Materials Has directional dependent properties Strain - stiffness Stress - Strength (load carrying capacity)

Define the material’s mechanical property requirements Requires two conditions Loading shape How stiff? How strong? How hard? How tough?

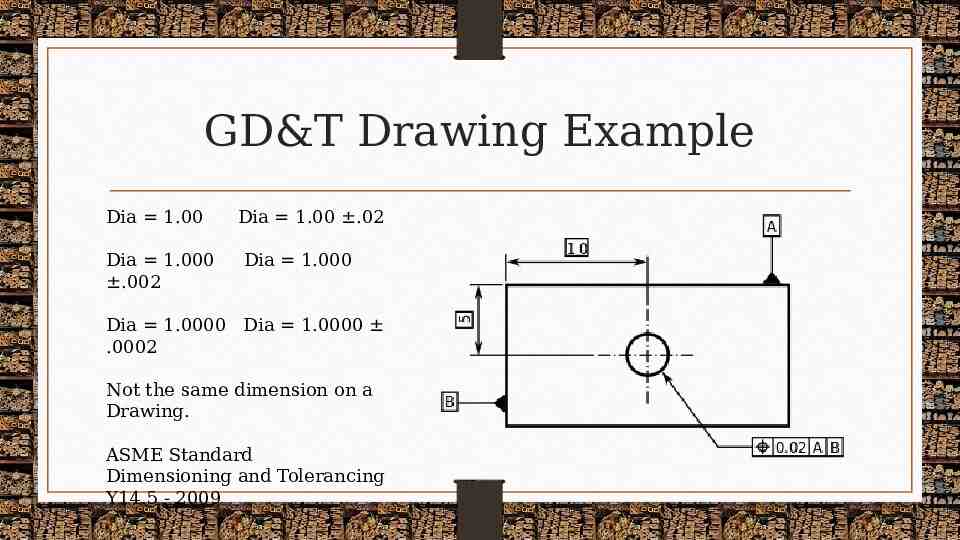

Cost Has two components Material cost Cost of material required Processing cost Cost required to turn the material into a part tooling Processing (including Specifications for Geometric Dimensioning and Tolerancing or GD&T) Total cost Material cost Processing cost

GD&T Drawing Example Dia 1.00 Dia 1.000 .002 Dia 1.00 .02 Dia 1.000 Dia 1.0000 Dia 1.0000 .0002 Not the same dimension on a Drawing. ASME Standard Dimensioning and Tolerancing Y14.5 - 2009

Material Groups Composite Materials (Nonhomogeneous) Homogeneous Materials (Isotropic - the same properties in all directions) Metals Ferrous – iron based Hard – steel, chromium, nickel, carbon in iron Soft – aluminum, magnesium, lead Polymers Plastics Rubber Epoxy Ceramics (Anisotropic – different properties in different directions) Wood Fiberglass composite Carbon fiber composite Boron fiber composite Concrete Reinforced concrete Natural stone

Processing shaping the material into a part Tooling processing costs Machining (subtractive manufacturing, turning, cutting, milling, grinding) Welding (fixtures some times required) 3D printing (Addative manufacturing, SLA, SLS, FDM, printing ) Plastic forming with and without heat( Bending, stamping, pressing) Casting (sand casting, investment casting, centrifugal casting) Extruding Molding (injection, pored) Forging Hydro-forming Explosive bonding and forming

Metals Matls – Metals in the mix only – does not define properties Properties come from the Materials and the processing (cold working, heating, cooling rate, heat treatments, etc.) Both must be specified to get the desired material

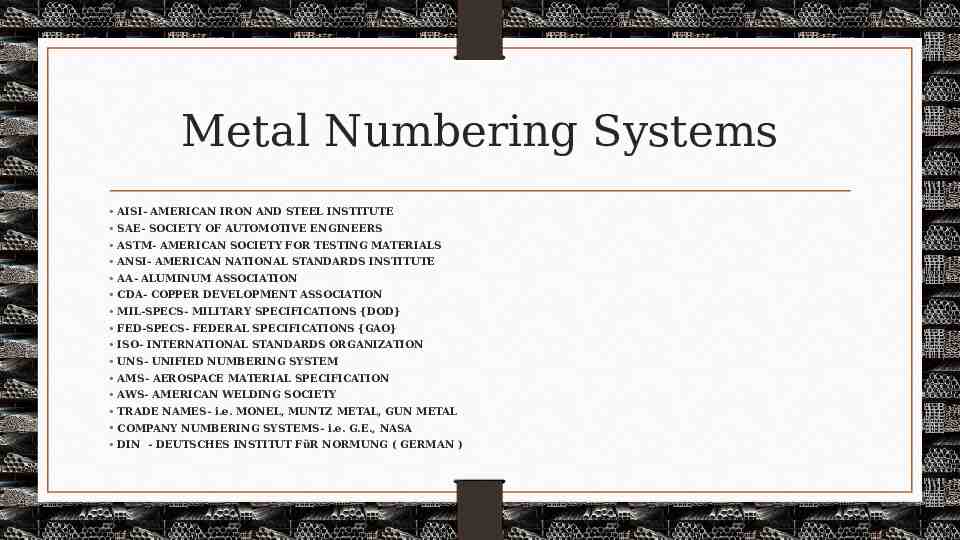

Metal Numbering Systems AISI- AMERICAN IRON AND STEEL INSTITUTE SAE- SOCIETY OF AUTOMOTIVE ENGINEERS ASTM- AMERICAN SOCIETY FOR TESTING MATERIALS ANSI- AMERICAN NATIONAL STANDARDS INSTITUTE AA- ALUMINUM ASSOCIATION CDA- COPPER DEVELOPMENT ASSOCIATION MIL-SPECS- MILITARY SPECIFICATIONS {DOD} FED-SPECS- FEDERAL SPECIFICATIONS {GAO} ISO- INTERNATIONAL STANDARDS ORGANIZATION UNS- UNIFIED NUMBERING SYSTEM AMS- AEROSPACE MATERIAL SPECIFICATION AWS- AMERICAN WELDING SOCIETY TRADE NAMES- i.e. MONEL, MUNTZ METAL, GUN METAL COMPANY NUMBERING SYSTEMS- i.e. G.E., NASA DIN - DEUTSCHES INSTITUT FüR NORMUNG ( GERMAN )

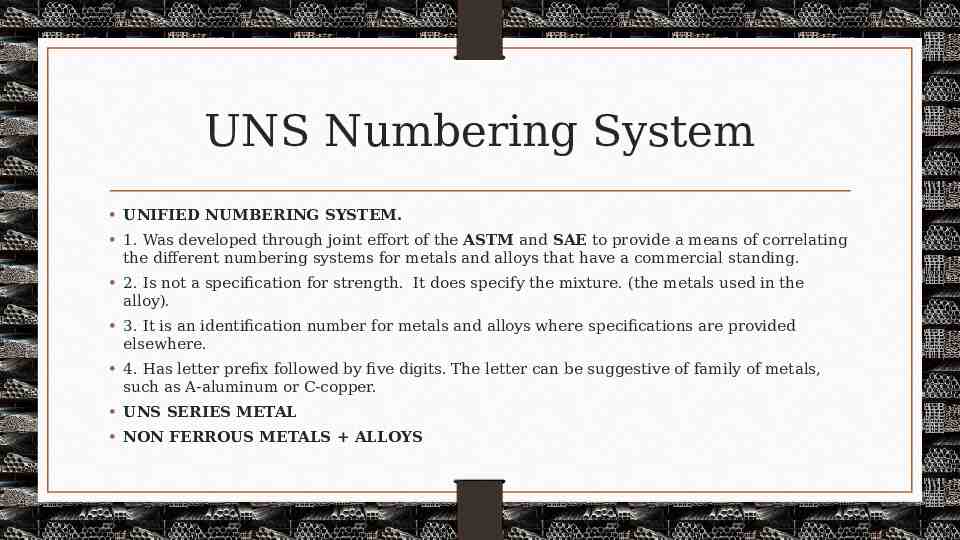

UNS Numbering System UNIFIED NUMBERING SYSTEM. 1. Was developed through joint effort of the ASTM and SAE to provide a means of correlating the different numbering systems for metals and alloys that have a commercial standing. 2. Is not a specification for strength. It does specify the mixture. (the metals used in the alloy). 3. It is an identification number for metals and alloys where specifications are provided elsewhere. 4. Has letter prefix followed by five digits. The letter can be suggestive of family of metals, such as A-aluminum or C-copper. UNS SERIES METAL NON FERROUS METALS ALLOYS

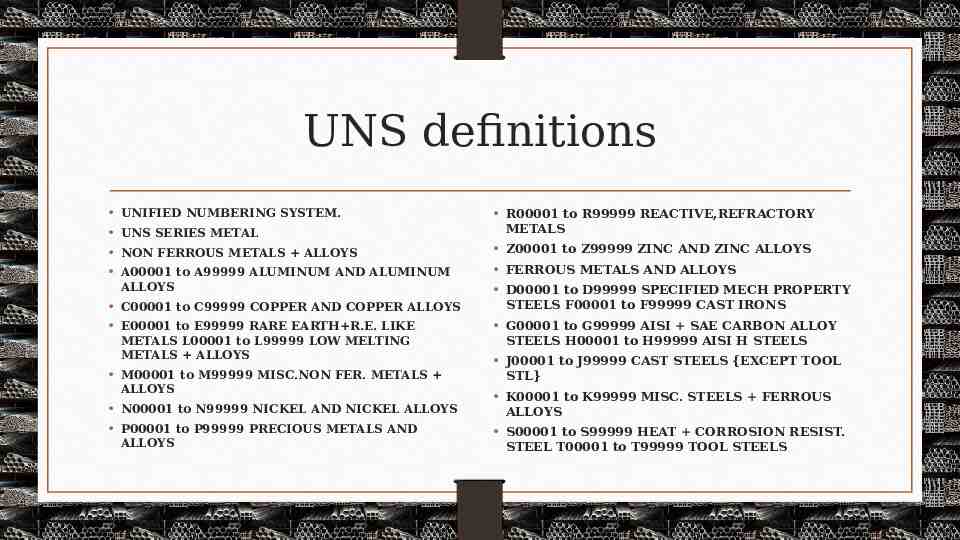

UNS definitions UNIFIED NUMBERING SYSTEM. UNS SERIES METAL NON FERROUS METALS ALLOYS A00001 to A99999 ALUMINUM AND ALUMINUM ALLOYS C00001 to C99999 COPPER AND COPPER ALLOYS E00001 to E99999 RARE EARTH R.E. LIKE METALS L00001 to L99999 LOW MELTING METALS ALLOYS M00001 to M99999 MISC.NON FER. METALS ALLOYS N00001 to N99999 NICKEL AND NICKEL ALLOYS P00001 to P99999 PRECIOUS METALS AND ALLOYS R00001 to R99999 REACTIVE,REFRACTORY METALS Z00001 to Z99999 ZINC AND ZINC ALLOYS FERROUS METALS AND ALLOYS D00001 to D99999 SPECIFIED MECH PROPERTY STEELS F00001 to F99999 CAST IRONS G00001 to G99999 AISI SAE CARBON ALLOY STEELS H00001 to H99999 AISI H STEELS J00001 to J99999 CAST STEELS {EXCEPT TOOL STL} K00001 to K99999 MISC. STEELS FERROUS ALLOYS S00001 to S99999 HEAT CORROSION RESIST. STEEL T00001 to T99999 TOOL STEELS

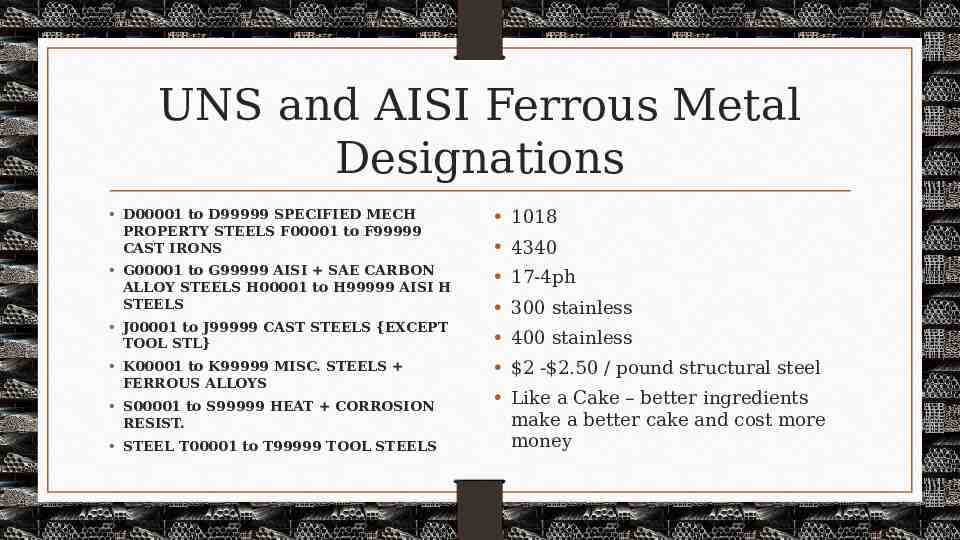

UNS and AISI Ferrous Metal Designations D00001 to D99999 SPECIFIED MECH PROPERTY STEELS F00001 to F99999 CAST IRONS G00001 to G99999 AISI SAE CARBON ALLOY STEELS H00001 to H99999 AISI H STEELS J00001 to J99999 CAST STEELS {EXCEPT TOOL STL} K00001 to K99999 MISC. STEELS FERROUS ALLOYS S00001 to S99999 HEAT CORROSION RESIST. STEEL T00001 to T99999 TOOL STEELS 1018 4340 17-4ph 300 stainless 400 stainless 2 - 2.50 / pound structural steel Like a Cake – better ingredients make a better cake and cost more money

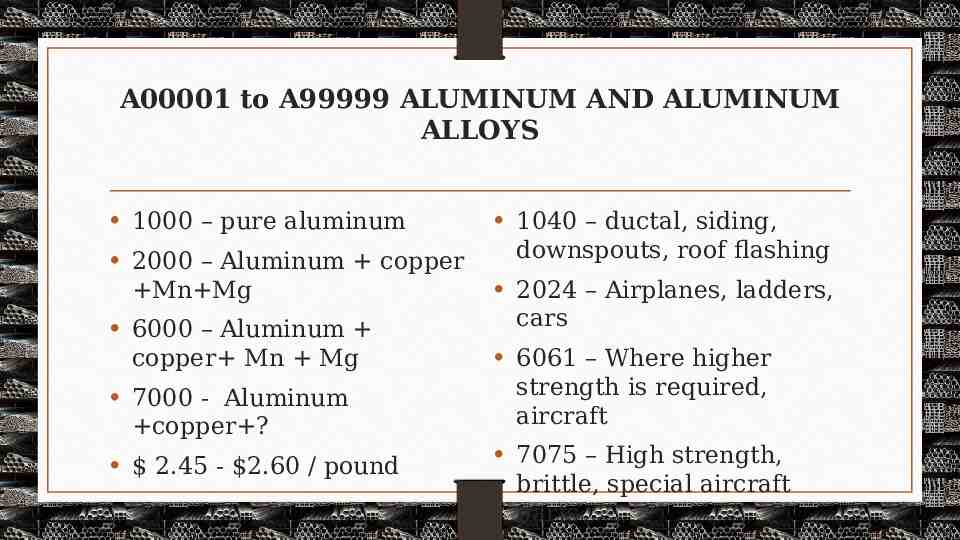

A00001 to A99999 ALUMINUM AND ALUMINUM ALLOYS 1000 – pure aluminum 2000 – Aluminum copper Mn Mg 6000 – Aluminum copper Mn Mg 7000 - Aluminum copper ? 2.45 - 2.60 / pound 1040 – ductal, siding, downspouts, roof flashing 2024 – Airplanes, ladders, cars 6061 – Where higher strength is required, aircraft 7075 – High strength, brittle, special aircraft parts

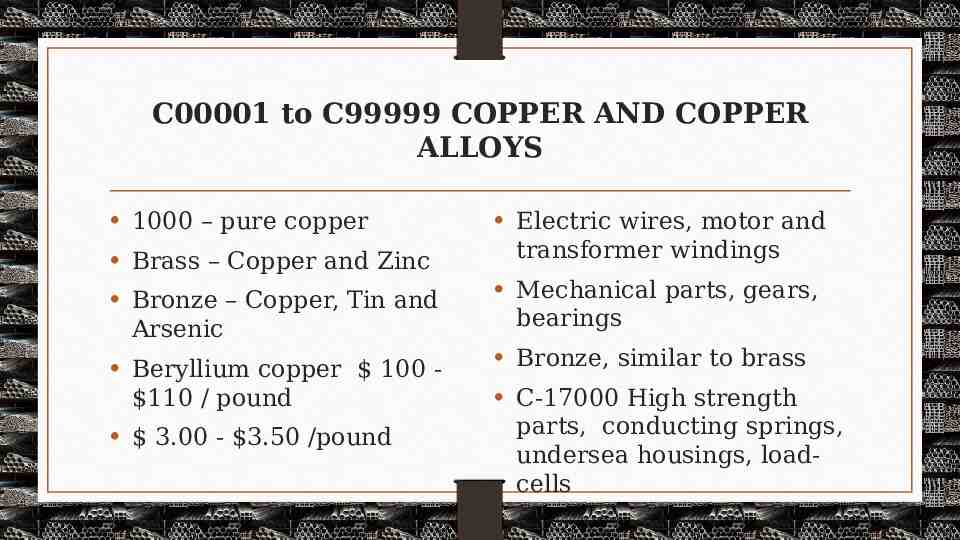

C00001 to C99999 COPPER AND COPPER ALLOYS 1000 – pure copper Brass – Copper and Zinc Bronze – Copper, Tin and Arsenic Beryllium copper 100 110 / pound 3.00 - 3.50 /pound Electric wires, motor and transformer windings Mechanical parts, gears, bearings Bronze, similar to brass C-17000 High strength parts, conducting springs, undersea housings, loadcells

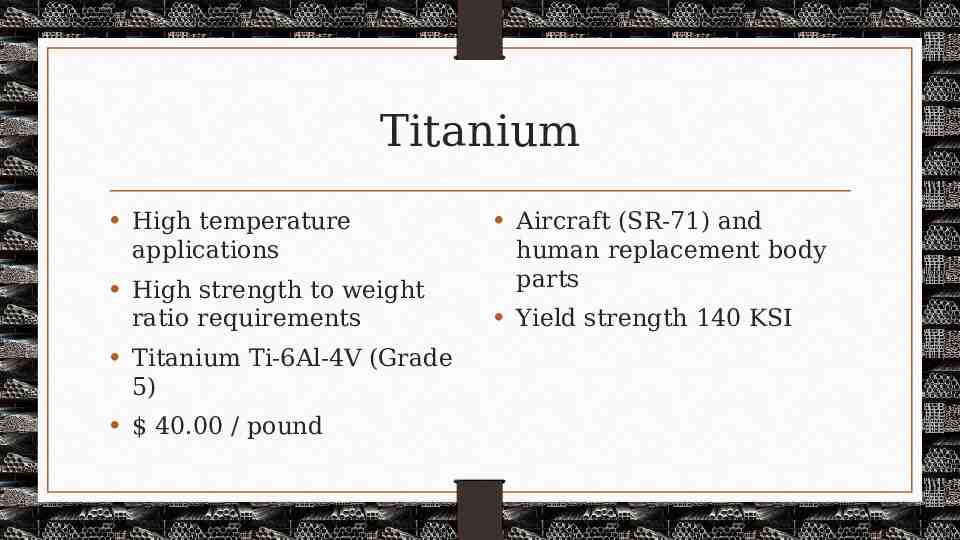

Titanium High temperature applications High strength to weight ratio requirements Titanium Ti-6Al-4V (Grade 5) 40.00 / pound Aircraft (SR-71) and human replacement body parts Yield strength 140 KSI

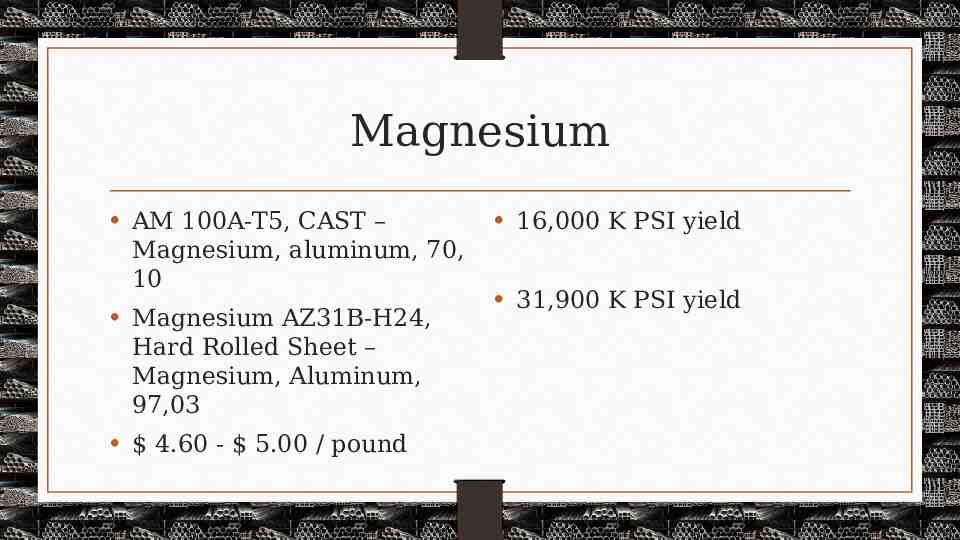

Magnesium AM 100A-T5, CAST – Magnesium, aluminum, 70, 10 Magnesium AZ31B-H24, Hard Rolled Sheet – Magnesium, Aluminum, 97,03 4.60 - 5.00 / pound 16,000 K PSI yield 31,900 K PSI yield

Stainless Steel 300 series – Iron, Chromium, Nickel 400 series – Iron, Chromium Precipitation Hardened series (17-4 Ph, 15-5 Ph, etc.) – Iron, Chromium, Copper, (special heat treatments to create the phase structures)

Thermal Plastics (Plastic) Polyethylene Terephthalate (PET, PETE, Type #1 plastic) Poly-ethylene (PE, HDPE Type #2 plastic) Poly-Vinyl-Chloride (PVC, Type #3 plastic) Poly-ethylene (LDPE, Type #4 plastic) Poly-propylene (PP, Type #5 plastic) Poly-styrene ( Type #6 plastic) Nylon Acrylonitrile butadiene styrene (ABS) Acetyl (Delrin?) Thermoplastic elastomer (TPE) Poly-carbonate Teflon Epoxies PC

Why Plastics? Derived from petroleum Cost of materials lower Processing cost MUCH lower Lower temperatures, lower pressures, easier to machine, tooling costs lower Some are transparent (PC for example) and can be used as lenses

Polyethylene Terephthalate PET, PETE, Type #1 plastic Common plastic – Disposable items, must be inexpensivewater bottles, soda bottles, etc. Yield strength 5000 – 10,000 PSI Young’s Modulus – 400 K PSI Melts around 480 º F

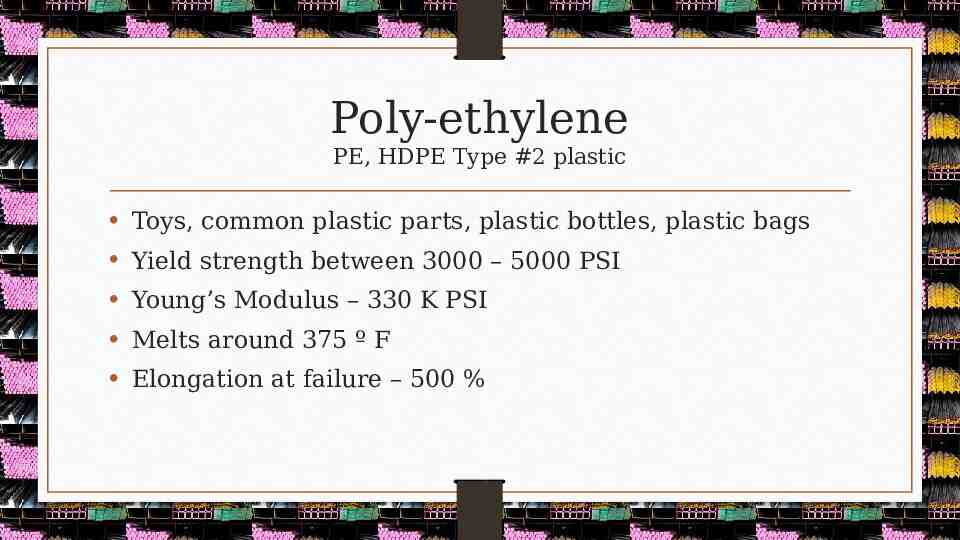

Poly-ethylene PE, HDPE Type #2 plastic Toys, common plastic parts, plastic bottles, plastic bags Yield strength between 3000 – 5000 PSI Young’s Modulus – 330 K PSI Melts around 375 º F Elongation at failure – 500 %

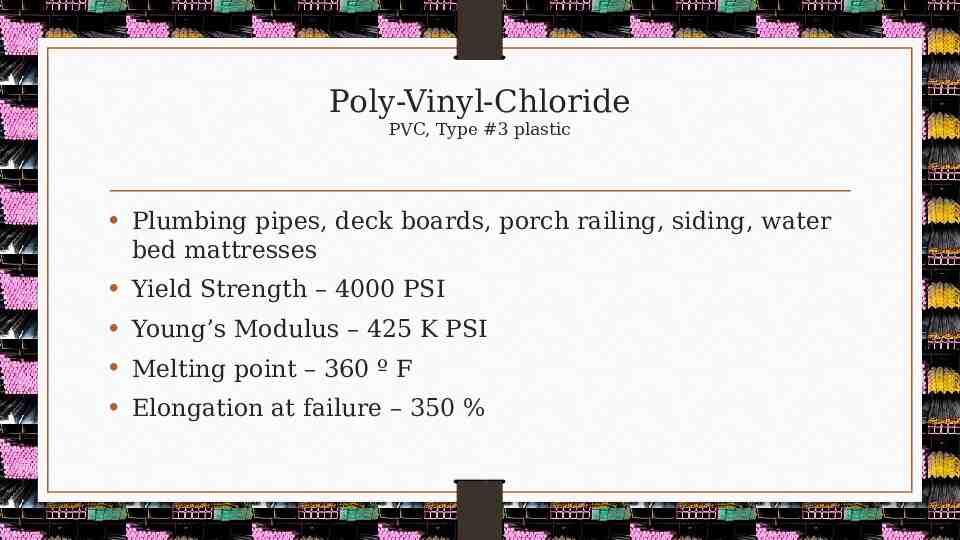

Poly-Vinyl-Chloride PVC, Type #3 plastic Plumbing pipes, deck boards, porch railing, siding, water bed mattresses Yield Strength – 4000 PSI Young’s Modulus – 425 K PSI Melting point – 360 º F Elongation at failure – 350 %

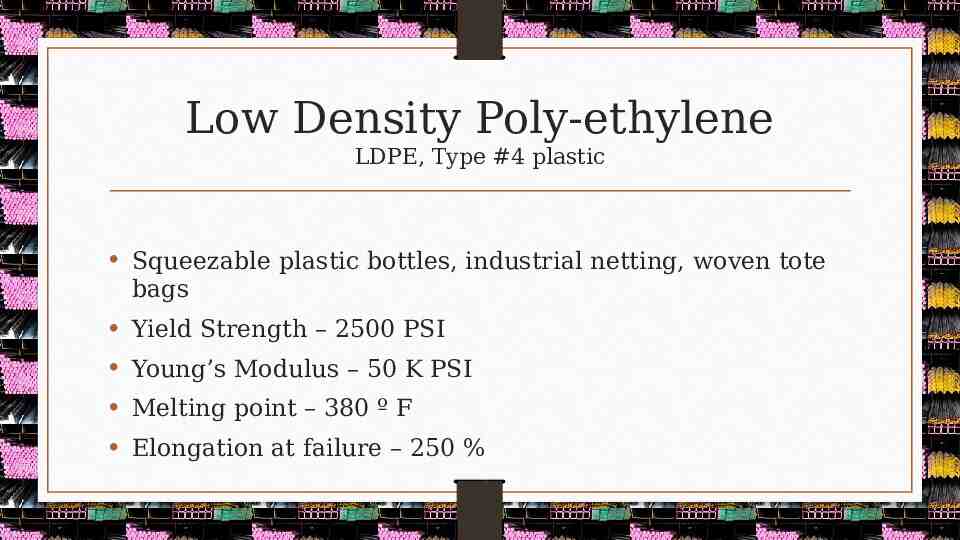

Low Density Poly-ethylene LDPE, Type #4 plastic Squeezable plastic bottles, industrial netting, woven tote bags Yield Strength – 2500 PSI Young’s Modulus – 50 K PSI Melting point – 380 º F Elongation at failure – 250 %

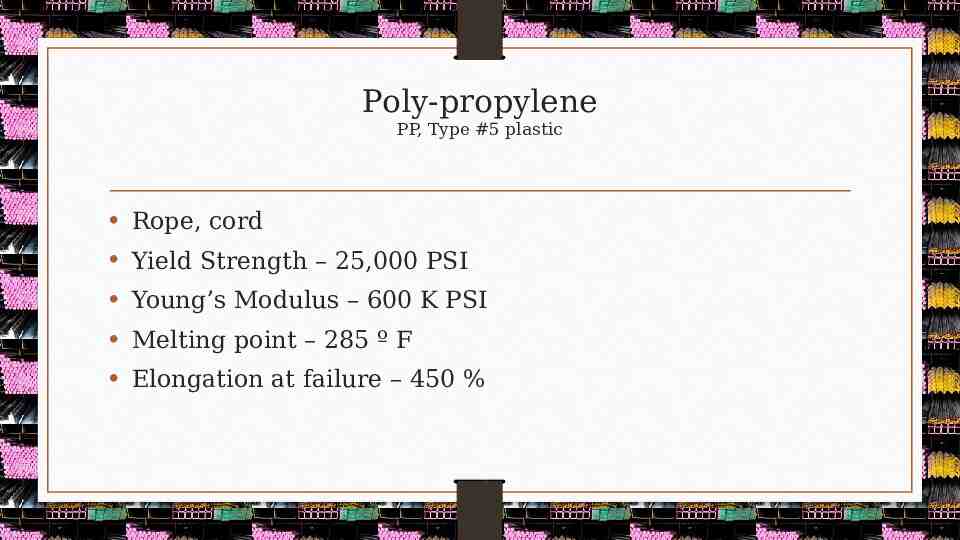

Poly-propylene PP, Type #5 plastic Rope, cord Yield Strength – 25,000 PSI Young’s Modulus – 600 K PSI Melting point – 285 º F Elongation at failure – 450 %

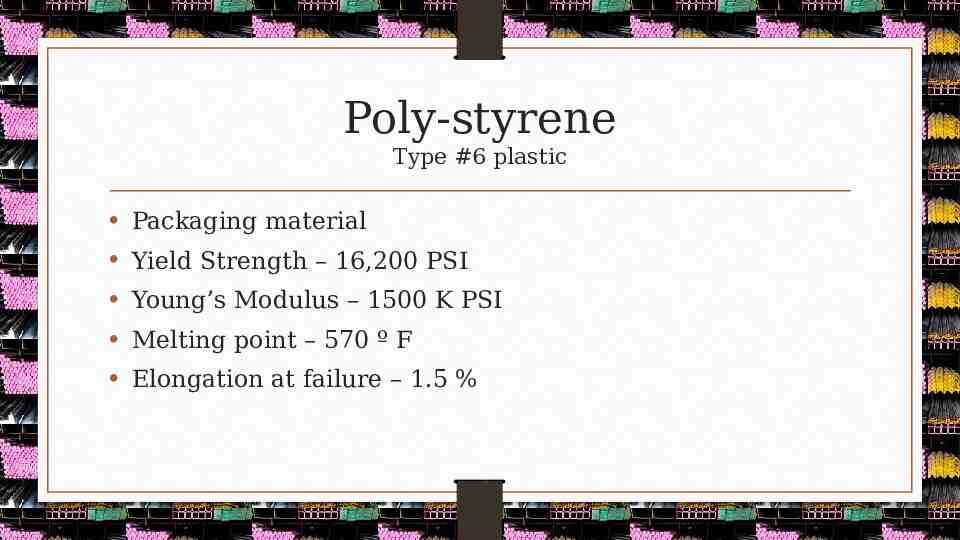

Poly-styrene Type #6 plastic Packaging material Yield Strength – 16,200 PSI Young’s Modulus – 1500 K PSI Melting point – 570 º F Elongation at failure – 1.5 %

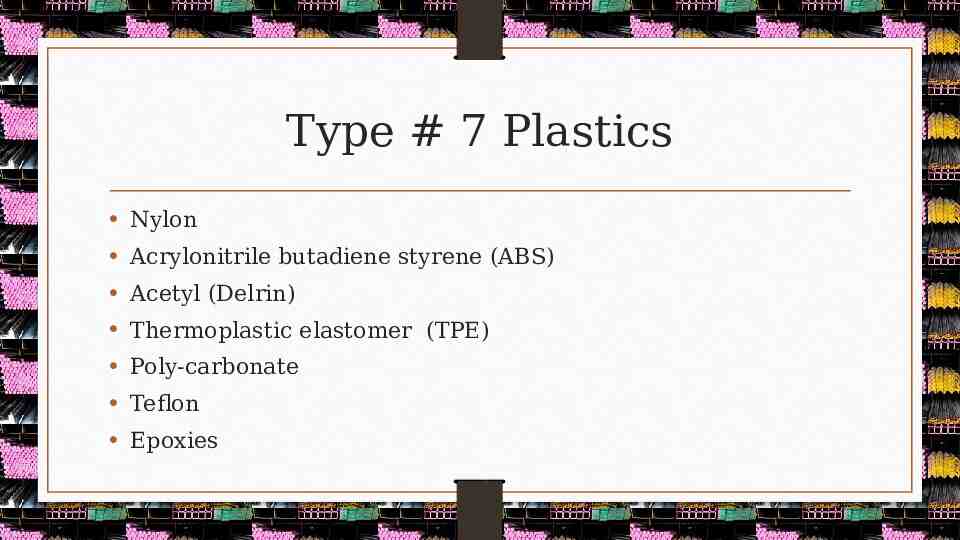

Type # 7 Plastics Nylon Acrylonitrile butadiene styrene (ABS) Acetyl (Delrin) Thermoplastic elastomer (TPE) Poly-carbonate Teflon Epoxies

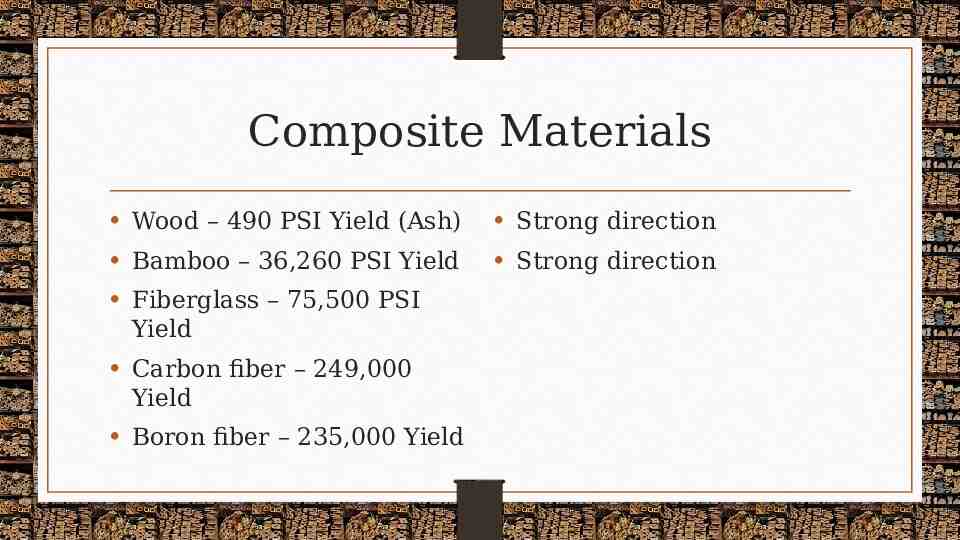

Composite Materials Wood – 490 PSI Yield (Ash) Bamboo – 36,260 PSI Yield Fiberglass – 75,500 PSI Yield Carbon fiber – 249,000 Yield Boron fiber – 235,000 Yield Strong direction Strong direction

3D Printing materials SLA SLS Nylon Metals FDM Printing