Rough-Cut Capacity Planning in SCM EGN 5623 Enterprise

56 Slides2.24 MB

Rough-Cut Capacity Planning in SCM EGN 5623 Enterprise Systems Optimization (Professional MSEM) Fall, 2011

Rough-Cut Capacity Planning in SCM Theories & Concepts EGN 5623 Enterprise Systems Optimization (Professional MSEM) Fall, 2011

Rough-cut Capacity Planning The main goal in rough-cut capacity planning is to identify where overloading or under-loading of production capacity occurs and revise the MPS as required. Overloading means that too much production of products has been planned in the facility and insufficient capacity exists to produce planned quantities of products required in MPS. Under-loading means that not enough production of products has been planned to fully load the facility.

The APICS-Standard Planning Framework (review)

Production Process (review) Requirements for Production Planning: to meet the demand to consider the resource capacities and the material availabilities to improve utilisation of the resources to lower the setup time to minimize the stock, and to minimize the work in process (WIP) to improve stability of the plan

Hierarchical Planning Framework (review) Long term Mid term Short term -Material programs - Supplier selection - Cooperation - Plant location - Production systems - Subcontractors - Physical distribution structure - Transportation strategy -- Personnel training -- Contracts -- Material Requirements Planning -- Master production Scheduling -- Capacity planning -- Distribution planning -- Personnel scheduling -- Material ordering -- lot-sizing - operations scheduling - shop floor control -- Mid-term sales planning - Warehouse replenishment - Transportation planning -- Mid-term sales planning EXECUTION Flow of goods - Product program - Strategic sales planning Information Feedback

Rough-Cut Capacity Planning in APO-SNP

Order Life Cycle for Make-to-Stock

Order Life Cycle for Make-to-Order

Forecast Consumption Mode and Horizon (Backword consumption of 4 days and a forward consumption of 3 days)

Transactional Data for Transferring Starting from a demand plan, SNP checks the resource capacities and delivers a medium/long-term plan for the estimated sales volumes. The plan includes the quantities to be transported between locations (e.g., DC-customer, or plant-DC) and the quantities to be produced (and procured), taking available capacity into consideration. SNP creates planned orders, purchase requisitions, and stock transfers that can be transferred directly to the connected OLTP systems.

Capacity Levelling Capacity leveling supports the following resource categories: Production resources Transportation resources Capacity levelling supports the following resource types: Bucket resources Single-mixed resources Multi-mixed resources Transportation resources

Capacity Levelling The planner can use the following methods to adjust the plan: Backward scheduling of the capacity load to fulfill demand using high priorities without due date violations. This rescheduling does not create any orders in the production horizon. Forward scheduling of the capacity load for lower priority demand and use of demand priorities to minimize due date violations A combination of backward and forward scheduling of the capacity load.

Capacity Levelling Profile The main settings in the capacity leveling profile are scheduling direction, prioritization, and method. Scheduling Direction controls whether Forward, Backward or Combined scheduling is used. Prioritization for the heuristic run defines how leveling determines the sequence of orders. The two possible choices for prioritization (to be sorted by ascending or descending order) are by order size or by product priority. The three Method choices are Heuristic, Optimizer or Badi (Business Aided-in).

Time-based Capacity Levelling

Capacity Levelling

Heuristics-based Capacity Levelling Heuristic-based capacity leveling compares, period by period, the capacity load on a resource with the requested load, either from the beginning or from the end of the planning horizon – depending on which scheduling direction is selected (forward or backward scheduling). If the resource is found overloaded, the system first selects all the activities or orders that cause the overload in this period. It then sorts these orders according to the priority that is defined and shifts orders or partial orders, one by one into subsequent or previous periods until the required maximum resource utilization is reached.

Heuristics-based Capacity Levelling For forward scheduling, the system moves the orders so far that the first activity using the resource to be leveled only begins after the overloaded period. For backward scheduling, the system moves the orders so far that the last activity using the resource to be leveled actually ends before the overloaded period. The system takes the lot sizes and rounding values defined in the master data into account when moving the orders.

SNP Heuristic as Location, Network, and Multi-Level Heuristic

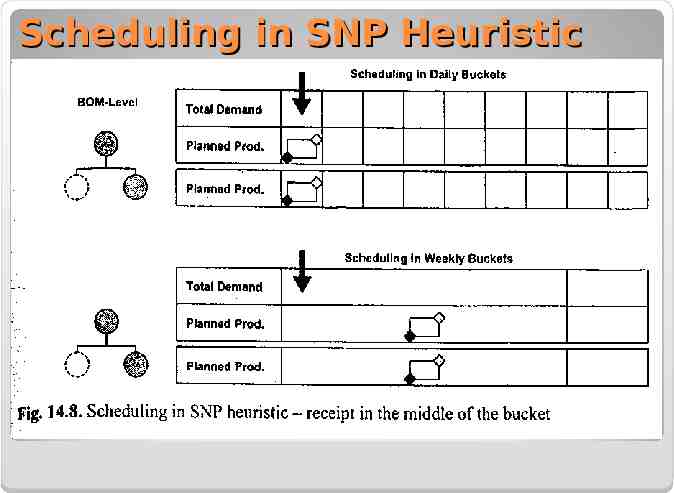

Scheduling in SNP Heuristic

Period Factor

Production Scheduling for Multiple BOM Levels

Scheduling in CTM

Heuristics-based Capacity Levelling Only orders that cause overloads are changed. This proves advantageous when a lot of orders exist but only some of them overload the resource. Prioritization is done by product or by product quantity. Select “Capacity Leveling” to balance the required work loads. from the menu

Benefits of SNP with SCM The benefits of Supply Network Planning with SAP SCM are as follows: 1.Cross-plant medium-term rough-cut planning 2.Cross-plant optimization of resource utilization Simultaneous planning of procurement, production and distribution Simultaneous material planning and finite capacity scheduling of production, storage, and transportation resources 3.Planning of critical components and bottleneck resources 4.Prioritization of demands and receipts 5.Collaborative supply planning over the Internet

Linear Programming (LP) EGN 5623 Enterprise Systems Optimization (Professional MSEM) Fall, 2011

Operation Research (OR) Operation research refers to the application of quantitative methods and techniques to business problems in order to best utilize a company’s resources. OR is used by many leading companies in recent years to optimize their limited resources in order to maximize their profits or minimize their costs. Linear programming (LP) is one of the most important tools of operation research.

Linear Programming (LP) Five common types of LP problems: Product mixed Ingredient mix Transportation Production plan Assignment

Five common types of LP problems

Five common types of LP problems

Steps in Formulating LP Problems 1. Define the objective 2. Define the decision variables 3. Write the mathematical function for the objective (objective function) 4. Write a one- or two-word description of each constraints 5. Write the right-hand side (RHS) of each constraint, including the unit of measure. 6. Write , , or for each equation 7. Write all the decision variables on the left-hand side of each constraints 8. Write the coefficient for each decision variable in each constraint.

Formulating LP

Formulating LP

Formulation LP

Formulation of Problem

Objective and Constraints

Steps in Graphical Solution Method

Graphical Solution

Graphical Solution

Graphical Solution

Graphical Solution

Transportation (Network) Problem

Requirement Assumption

Feasible Solutions Property

Cost Assumption

Parameter Table for Transportation Problem Supply S1 S2 . Sm

Transportation Problem Model Any problems (whether involving transportation or not) fits the model for a transportation problem if it can be described completely in term of a parameter table like Table 8.5 and it satisfies both the requirements assumption and cost assumption. The objective is to minimize the total cost of distributing the units. All the parameters of the model are included in this parameter table.

Objective Function & Constraints

Rough-Cut Planning in SCM SAP Implementation EGN 5623 Enterprise Systems Optimization (Professional MSEM) Fall, 2011

Planning Book and Views

Capacity Check view Now switch to the CAPACITY CHECK view. In the Selection profile section double click on ## RESOURCES. Double click on the work center (plant ##A1). Switch the TB Profile to 12MONTH. We appear to have enough capacity in the work center at the aggregated monthly level. Now change the TB Profile to 180 DAYS. We are overloaded in the first couple days as SCM has tried to produce all that is needed to satisfy safety stock in those days.

Capacity Levelling Scroll over to the next capacity usage. We are also overloaded in those periods. Multilevel Heuristic does not take capacity into consideration. Select

Key Figures and Categories in SNP Standard Planning Book

HW 4: Exercises: 1. Module 5 (Section 2) Work centers Create integration model for work centers in SAP ERP system Activate integration model for work centers in SAP ERP system Confirm data transfer for work centers in SCM system Purchasing Info Records (PIR) Create integration model for PIR in SAP ERP system Activate integration model for PIR in SAP ERP system Confirm data transfer in SCM system 2. Model 6 (Section 2) Production process model (PPM) Production data structure (PDS) Setting for PDS in SCM system Create integration model for PDS in SAP ERP system

HW 4: Exercises: Activate integration model for PDS in SAP ERP system Confirm data of PDS transfer in SCM system Create integration model for PDS SNP transfer Activate integration model for PDS SNP transfer Confirm data transfer (PDS SNP) in SCM system 3. Model 7 (Section 2) Transactional data in SAP ERP system Create integration model for Planned Independent Requirement (PIR) in SAP ERP system Activate integration model for PIR Confirm data transfer (PIR) in SCM system