Respiratory Protection

92 Slides5.60 MB

Respiratory Protection

Overview Commander’s written program Medical surveillance Mitigation Procedures Fit testing Storing and maintaining equipment Coordinating training Procurement of correct equipment

Commander’s Written Program Commanders Responsibilities Designate a Respiratory Protection Program Manager (RPPM) in writing for Marine Corps installations and units – Supporting OSH professionals will provide consultation to the RPPM

Commander’s Written Program RPPM Responsibilities Complete one of the following courses – OSHA Training Institute Course 2220, Respiratory Protection – OSHA Training Institute Education Centers Course 2225, Respiratory protection

Commander’s Written Program – NAVOSHENVTRACEN RPPM Course A-493-0072 – Respiratory protection course with at least 32 hours of training which covers all aspects of 29 CFR 1910.134

Commander’s Written Program Develop written SOPs governing the selection, issue, care, and use of respirators – Develop & post SOPs in general work areas – SOPs must include pertinent regulations, consensus standards, and emergency and rescue guidance as necessary

Commander’s Written Program Approve in writing all purchases of nonstandard respiratory protective equipment Ensure respiratory protection recommended by the IH is provided to appropriate personnel by their organizations

Commander’s Written Program Request the IH to conduct a health hazard evaluation of new or modified work operations to ensure appropriate respirators are specified Ensure tenants establish central maintenance facilities for storage, issue, cleaning, and maintenance

Commander’s Written Program Provide annual training to all respirator users and their supervisors Coordinate and ensure all users receive a medical evaluation prior to being fit tested

Commander’s Written Program Ensure all users of tight-fitting respirators are fit tested initially and annually Maintain all records pertaining to training and fit testing Conduct an annual program audit

Commander’s Written Program Supervisors Responsibilities Ensure only trained and medically qualified personnel are assigned to tasks requiring the use of respirators Ensure respirators are used IAW the listed references

Commander’s Written Program Users Responsibilities Use respirators IAW the listed references Report work site problems involving use of respirators to their supervisors Properly store, maintain, and clean respirators

Commander’s Written Program Supply Department Responsibilities Purchase only respiratory protective equipment that has been approved and authorized by the RPPM

Commander’s Written Program OSHA Standard Requirements The employer shall include in the written program the following provisions of the standard, as applicable: – Standard operating procedures governing the procedures for selecting respirators for use in the workplace

Commander’s Written Program – Medical evaluations of employees required to use respirators – Fit testing procedures for tight-fitting respirators – Procedures for proper use of respirators in routine and reasonably foreseeable emergency situations

Commander’s Written Program Procedures and schedules for cleaning, disinfecting, storing, inspecting, repairing, discarding, and otherwise maintaining respirators

Medical Surveillance Activities shall not fit test personnel or assign them to work in, or permit them to enter, areas requiring respiratory protection unless they have been medically evaluated.

Medical Surveillance Military personnel, who have been confirmed as “Fit for Full Duty” based on their current periodic physicals and PHA are considered qualified to wear any type of respiratory protection.

Medical Surveillance The PLHCP shall obtain the information requested by the questionnaire in Sections 1 and 2, Part A of App. C of 29 CFR 1910.134

Medical Surveillance Users of prescription eye wear who must wear a full-face respiratory shall be fitted with respiratory spectacles.

Mitigation Measures In controlling those occupational diseases caused by breathing contaminated air, the primary objective shall be to prevent atmospheric contamination.

Mitigation Measures SOPs Signs Respirators & Clothing Enclosures Ventilation Substitution

Mitigation Measures Appropriate respiratory protection shall be used: – when effective engineering controls are not feasible, – while controls are being instituted or evaluated

Mitigation Measures Respiratory Hazards Include - DUSTS - FOGS - FUMES - MISTS - GASES - SMOKE - SPRAYS -VAPORS

Mitigation Measures Hazardous Atmospheres – Oxygen deficient or rich – Toxic – Environmental pollution – Combination – Flammable – Immediately dangerous to life or health (IDLH)

Mitigation Measures Determining Hazards in an Atmosphere Oxygen Toxicants Explosives

Fit Testing Required before an employee may be required to use a negative or positive pressure tight-fitting face piece respirator Must be fit tested with the same make, model, style, and size of respirator that will be used.

Fit Testing Qualitative (QLFT) – A challenge agent, vapor, or aerosol released – Fit is inadequate if a presence of the agent is detected (irritation, taste, or odor)

Fit Testing Quantitative (QNFT) – Measures actual level of agent both inside and outside the respirator

Fit Testing Respirators rely on face-to-mask seal Fit testing determines which device and size will best fit and seal Stubble, beard, hairlines, glasses, and goggles will negatively affect fit

Fit Testing Corrective lenses may be mounted inside the face piece – Wearing contact lenses will be authorized by the medical dept. on a case by case basis

Fit Testing Fit testing should be conducted annually, if facial features change, or if a different respirator is used Users of tight fitting respirators must perform a user seal check each time the respirator is used

Fit Testing Proper Fit with Good Seal – Negative pressure check - inlets

Fit Testing Proper Fit with Good Seal – Positive pressure check - outlet -

Storage & Maintenance Inspection of equipment before and after each use Repair or replace damaged equipment Clean and sanitize equipment Proper storage and handling Training

Storage & Maintenance Visual Inspection for: – Holes in the filters – Loss of elasticity or tears in head straps and hoses – Broken or loose connectors and hoses

Storage & Maintenance – Cracked or scratched face pieces – Detergent residue – Dirt in valves – General cleanliness straps inhalation valves exhalation valve Facepiece valve cover

Storage & Maintenance Decontamination – Follow manufacturers directions – If worn by only one person, clean and disinfect periodically – If worn by more than one person, clean and disinfect after each use

Storage & Maintenance – Must be protected from dust, sunlight, heat, cold, moisture, and chemicals – Face piece should be stored in an individual plastic bag – Store masks with valves and breathing tubes in a natural, undistorted position

Don’t store them like

Training Procedures to ensure adequate air quality, quantity and flow of breathing air for atmosphere-supplying respirators Training of employees in the respiratory hazards to which they are potentially exposed during routine and emergency situations

Training Training of employees in the proper use of respirators, including putting on and removing them, any limitations on their use, and their maintenance Procedures for regularly evaluating the effectiveness of the program

Training Employees must be trained and demonstrate skill or knowledge of at least: Why use is necessary How improper use and care can compromise respirator effectiveness

Training Limitations and capabilities How to put on, remove, use, and inspect How to maintain and store General requirements of the OSHA standard 29 CFR 1910.134

Training Training must be provided: – Prior to use, annually, and whenever: Prior training becomes obsolete Employee’s skill or knowledge is deemed inadequate Any other situation arises in which retraining appears necessary

Training & Record Keeping Training and medical records must be maintained and made available Fit test records must be maintained until the next test is administered

Training & Record Keeping A written copy of the current program must be maintained All written materials must be available to affected employees, and state and federal agents

Equipment Procurement Types of Respirators - Air-Purifying Gas and vapor removing Particulate - Powered air purifying - Supplied air types

Equipment Procurement

Equipment Procurement

Equipment Procurement

Equipment Procurement Self contained breathing apparatus (SCBA) - Closed circuit - Open circuit - Demand pressure flow - Demand continuous flow - Escape only SCBAs

Equipment Procurement

Equipment Procurement Protection Against Gases & Vapors – An atmosphere-supplying respirator – An air-purifying respirator Equipped with an ESLI certified by NIOSH for the contaminant No ESLI, then the employer implements a cartridge change out schedule

Equipment Procurement Protection Against Particulates – An atmosphere-supplying respirator – An air-purifying respirator (APR) Equipped with a filter certified by NIOSH – HEPA filter or – An APR equipped with a filter certified for particulates

Equipment Procurement Air Purifying Limitations – Does not supply oxygen – Contaminant must be known and cannot exceed use limitations – Non-IDLH use only

Equipment Procurement Positive Pressure – A respirator in which the pressure inside the respiratory inlet covering exceeds the ambient air pressure outside the respirator

Equipment Procurement Powered Air Purifying – An APR that uses a blower/motor to force ambient air through air-purifying elements to the inlet covering

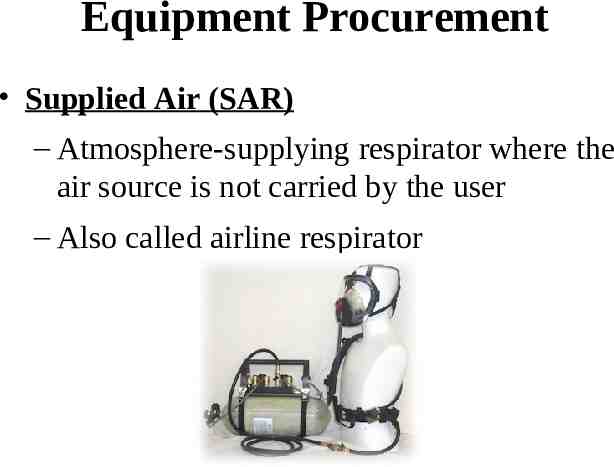

Equipment Procurement Supplied Air (SAR) – Atmosphere-supplying respirator where the air source is not carried by the user – Also called airline respirator

Equipment Procurement Airline Respirator – Has a pressure demand nozzle that allows user to control air flow – Use grade D breathing air – May be used with a hood or helmet – Hose limited to 300 feet – Some mobility restriction

Equipment Procurement Self Contained Breathing Apparatus (SCBA) – Breathing air is designed to be carried by the user Expensive to purchase and maintain Breathing air provided from pressurized tanks Provides highest level of protection and mobility

Equipment Procurement Commonly used in rescue or emergency situations Limited air (30 or 60 minutes/tank) Positive pressure provides maximum protection for both oxygen deficient and IDLH Standard requires fit testing of mask

Equipment Procurement Atmosphere Supplying – A respirator that supplies the user with breathing air from a source independent of the ambient atmosphere

Equipment Procurement – Includes SARs and SCBAs Continuous flow: Provides a continuous flow of breathing air to the respiratory inlet covering Pressure demand: Admits air to the face piece when the positive pressure inside the face piece is reduced by inhalation

Equipment Procurement Atmosphere Supplying – Type 1 - Airline respirator – Type 2 - SCBA

Equipment Procurement Escape Only – A respirator designed and intended to be used only for emergency exit

Equipment Procurement Respirators for IDLH Atmospheres – A full face piece pressure demand SCBA certified by NIOSH for a minimum service life of 30 minutes – A combination full face piece pressure demand supplied-air respirator (SAR) with auxiliary self-contained air supply

Equipment Procurement – Respirators for escape from IDLH atmospheres shall be NIOSH-certified for escape from the atmosphere in which they will be used – All oxygen-deficient atmospheres shall be considered IDLH

Equipment Procurement IDLH Atmosphere – Two employees located outside – Visual, voice, or signal communication must be maintained – Outside employees must be trained in rescue – Manager or supervisor must be notified before any rescue attempt

Equipment Procurement – Rescuers must be provided necessary assistance and equipment: A pressure demand or other positive pressure SCBA or SAR with auxiliary SCBA

Equipment Procurement Appropriate retrieval equipment Equipment means for rescue where retrieval equipment is not required – Emergency rope, auxiliary air supply – Retrieval equipment such as for confined space rescue

Equipment Procurement Breathing Air Quality – Compressed breathing air must meet at least the requirements for grade D breathing air – Systems supplying breathing air must be equipped with appropriate in-line air purifying sorbent beds and filters, and maintained per manufacturer’s instructions

Equipment Procurement – Oxygen content of 19.5% - 23.5% – No more than 5 milligrams of hydrocarbon (condensed) content per cubic meter (mg/m3) of air – Carbon monoxide content no more than 10 parts per million (ppm) – Carbon dioxide content no more than 1,000 ppm – Lack of noticeable odor

Equipment Procurement Non-IDLH Atmospheres – An atmosphere-supplying respirator – An air-purifying respirator, provided that: Has ESLI certified by NIOSH; or A dependable canister change schedule – Basis and reliance must be in writing

Equipment Procurement Filtering Face Piece Respirator – A negative pressure particulate respirator with a filter as an integral part of the face piece, or with the entire face piece composed of the filtering medium – “Dust mask” – N, R, or P

Equipment Procurement Reusable Half Mask Replaceable cartridges and filters to capture gases, vapors, and particulates Pre-filter to trap particles

Equipment Procurement Voluntary Respirator Use – 29 CFR 1910.134(c)(2) Appendix D – An employer may provide respirators at the request of employees or permit them to use their own as long as its use will not in itself create a hazard.

Equipment Procurement – If voluntary use is permitted Marine Corps commands will provide the respirators Users must be trained on the proper use, care, and limitations of the respirator Users do not have to placed in the medical surveillance program

Equipment Procurement Canister or Cartridge – Container with a filter, sorbent (catalyst), or combination – Removes specific contaminants

Equipment Procurement Filter Selection – Three levels of filter efficiency (95%, 99%, and 99.97%) – Three levels of filter resistance to efficiency degradation (N, R, and P) – Total of nine classes of filters

Equipment Procurement Filter Series N Non-specific service time Filter Series R One work shift (8 hours) service time Filter Series P Non-specific service time for use against both oil and non-oil particulate aerosols

Equipment Procurement Selection of N, R, or P depends on whether there are oil particles present – N for Not resistant to oil – R for Resistant to oil – P for oil Proof

Equipment Procurement No oil particles present – Use any series (N, R, or P) Oil particles present – Use only R or P series Oil particles present and filter is to be used more than one shift – Use only P series

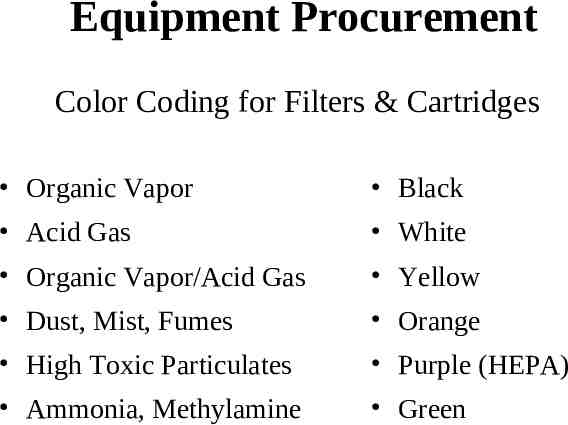

Equipment Procurement Color coded for intended use – Listing of color code: Manufacturer’s chart – NAVOSH Manual B-6 Filters labeled Cartridge combinations

Equipment Procurement Color Coding for Filters & Cartridges Organic Vapor Black Acid Gas White Organic Vapor/Acid Gas Yellow Dust, Mist, Fumes Orange High Toxic Particulates Purple (HEPA) Ammonia, Methylamine Green

Equipment Procurement Service life The time period a respirator, filter, sorbent, or other respiratory equipment provides adequate protection End of service life indicator (ESLI) warns of the approach of the end of adequate protection

Equipment Procurement Selection – Based on the respiratory hazards to which the worker is exposed, workplace factors, and user factors that affect respirator performance and reliability

Equipment Procurement – Respirators will be selected from a sufficient number of models and sizes to ensure correct fit and comfort – Job duration – Work site conditions

IDL H Supplied Air Respirator w/ 15 minute backup Air Required Respiratory Protection Mandatory (Filter Type Respirator or Supplied Air Respirator as Appropriate) PEL Respiratory Protection Optional

References NAVMC DIR 5100.8, Chapter 13 OPNAVINST 5100.23G, Chapter 15 29 CFR 1910.134 NAVMC DIR 5100.8 29 CFR 1910