Module Sixteen Organizational Change, Development, and Learning 1

56 Slides925.00 KB

Module Sixteen Organizational Change, Development, and Learning 1

A POINT OF DEPARTURE At the most basic level, an organization is viewed as a social entity created within a cultural context for the purpose of accomplishing tasks that individuals can not accomplish alone. As such an organization relies on coordinated activities, arrangements and grouping of tasks and people. Planned change involves a deliberate, purposeful and explicit managerial decision to engage in a program of change Planned change involves a complex process that must be designed and managed 2

THE MULTIDISCIPLINARY NATURE OF THE FIELD People in the field are drawn from a variety of disciplines (i.e., sociology, social psychology, anthropology, economics, biology, physics, engineering, ) Rich diversity of theories about change The richness of the disciplines can be seen in the wide array of definitions of the field 3

Burke’s Definition of OD OD is a planned process of change in an organization’s culture through the utilization of behavioral science technology, research, and theory. 4

French’s Definition of OD OD refers to a long-range effort to improve an organization’s problem-solving capabilities and its ability to cope with changes in its external environment with the help of external or internal behavioral-scientist consultants. 5

Beckhard’s Definition of OD OD is an effort (1) planned, (2) organization-wide, and (3) managed from the top, to (4) increase organization effectiveness and health through (5) planned interventions in the organization’s “processes,” using behavioral science knowledge. 6

Beer’s Definition of OD OD is a system-wide process of data collection, diagnosis, action planning, intervention, and evaluation aimed at: (1) enhancing congruence between organizational structure, process, strategy, people, and culture; (2) developing new and creative organizational solutions; and (3) developing the organization’s self-renewing capacity. It occurs through collaboration of organizational members working with a change agent using behavioral science theory, research, and technology. 7

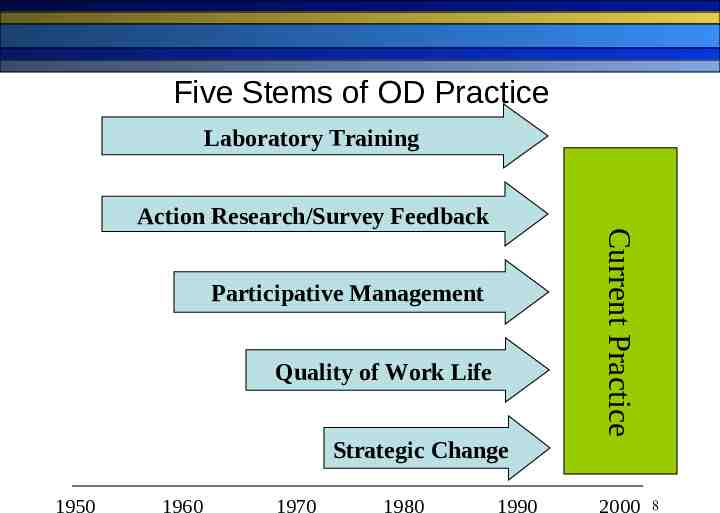

Five Stems of OD Practice Laboratory Training Participative Management Quality of Work Life Strategic Change 1950 1960 1970 1980 1990 Current Practice Action Research/Survey Feedback 2000 8

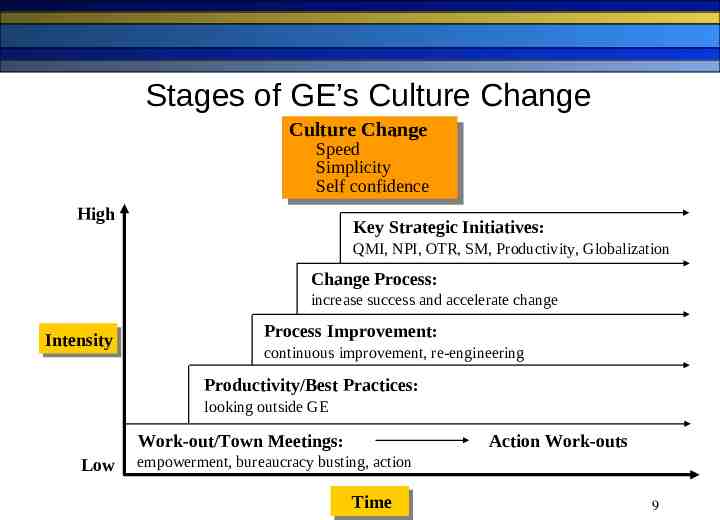

Stages of GE’s Culture Change Culture CultureChange Change Speed Speed Simplicity Simplicity Self Selfconfidence confidence High Key Strategic Initiatives: QMI, NPI, OTR, SM, Productivity, Globalization Change Process: increase success and accelerate change Intensity Process Improvement: continuous improvement, re-engineering Productivity/Best Practices: looking outside GE Work-out/Town Meetings: Low Action Work-outs empowerment, bureaucracy busting, action Time 9

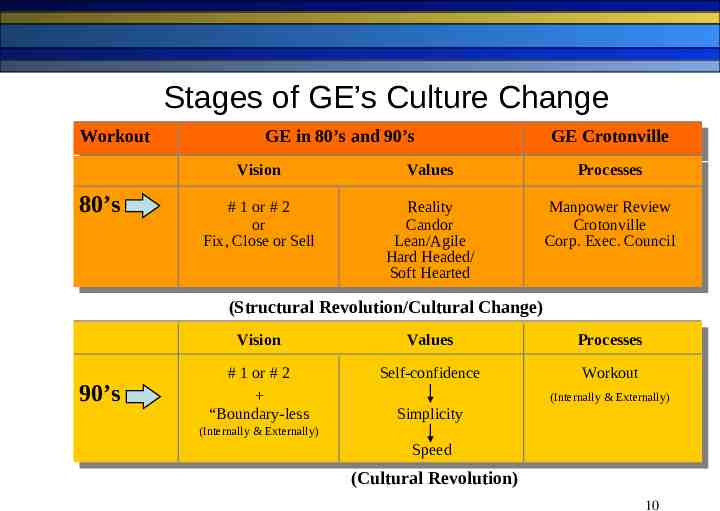

Stages of GE’s Culture Change Workout 80’s GE in 80’s and 90’s GE Crotonville Vision Values Processes # 1 or # 2 or Fix, Close or Sell Reality Candor Lean/Agile Hard Headed/ Soft Hearted Manpower Review Crotonville Corp. Exec. Council (Structural Revolution/Cultural Change) 90’s Vision Values Processes # 1 or # 2 “Boundary-less Self-confidence Workout (Internally & Externally) Simplicity (Internally & Externally) Speed (Cultural Revolution) 10

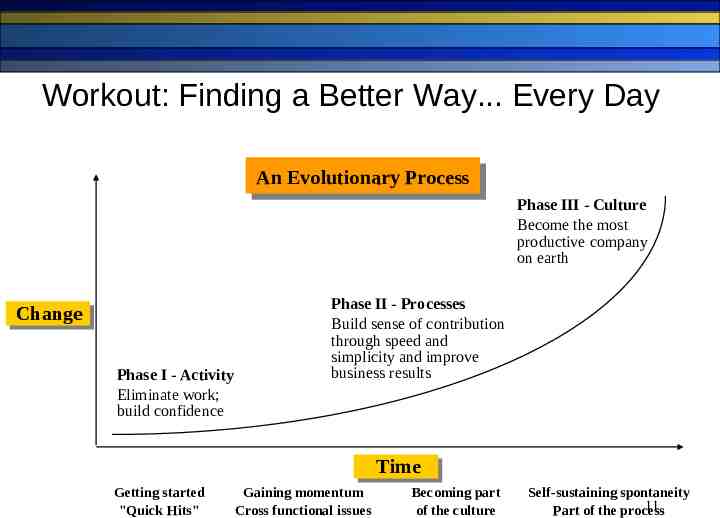

Workout: Finding a Better Way. Every Day An Evolutionary Process Phase III - Culture Become the most productive company on earth Change Phase I - Activity Eliminate work; build confidence Phase II - Processes Build sense of contribution through speed and simplicity and improve business results Time Getting started "Quick Hits" Gaining momentum Cross functional issues Becoming part of the culture Self-sustaining spontaneity 11 Part of the process

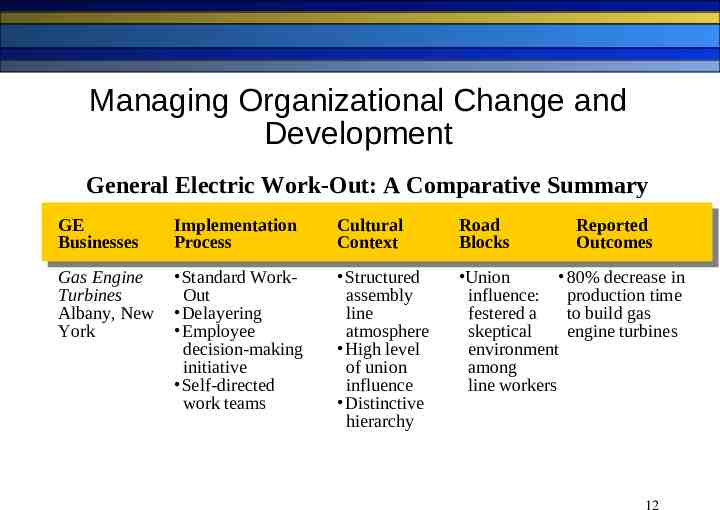

Managing Organizational Change and Development General Electric Work-Out: A Comparative Summary GE Businesses Implementation Process Cultural Context Road Blocks Gas Engine Turbines Albany, New York Standard WorkOut Delayering Employee decision-making initiative Self-directed work teams Structured assembly line atmosphere High level of union influence Distinctive hierarchy Union 80% decrease in influence: production time festered a to build gas skeptical engine turbines environment among line workers Reported Outcomes 12

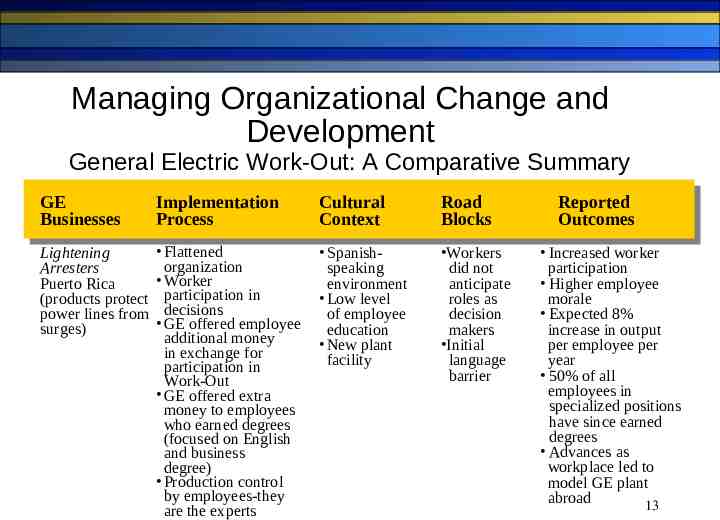

Managing Organizational Change and Development General Electric Work-Out: A Comparative Summary GE Businesses Implementation Process Cultural Context Road Blocks Lightening Arresters Puerto Rica (products protect power lines from surges) Flattened organization Worker participation in decisions GE offered employee additional money in exchange for participation in Work-Out GE offered extra money to employees who earned degrees (focused on English and business degree) Production control by employees-they are the experts Spanishspeaking environment Low level of employee education New plant facility Workers did not anticipate roles as decision makers Initial language barrier Reported Outcomes Increased worker participation Higher employee morale Expected 8% increase in output per employee per year 50% of all employees in specialized positions have since earned degrees Advances as workplace led to model GE plant abroad 13

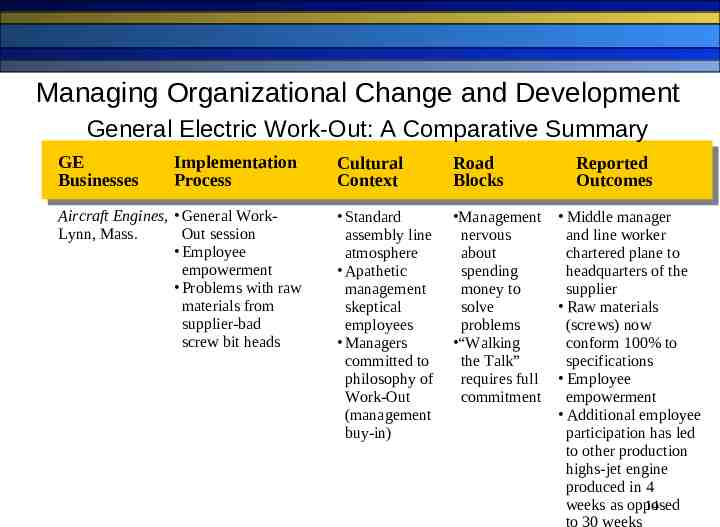

Managing Organizational Change and Development General Electric Work-Out: A Comparative Summary GE Businesses Implementation Process Aircraft Engines, General WorkLynn, Mass. Out session Employee empowerment Problems with raw materials from supplier-bad screw bit heads Cultural Context Road Blocks Standard assembly line atmosphere Apathetic management skeptical employees Managers committed to philosophy of Work-Out (management buy-in) Management nervous about spending money to solve problems “Walking the Talk” requires full commitment Reported Outcomes Middle manager and line worker chartered plane to headquarters of the supplier Raw materials (screws) now conform 100% to specifications Employee empowerment Additional employee participation has led to other production highs-jet engine produced in 4 weeks as opposed 14 to 30 weeks

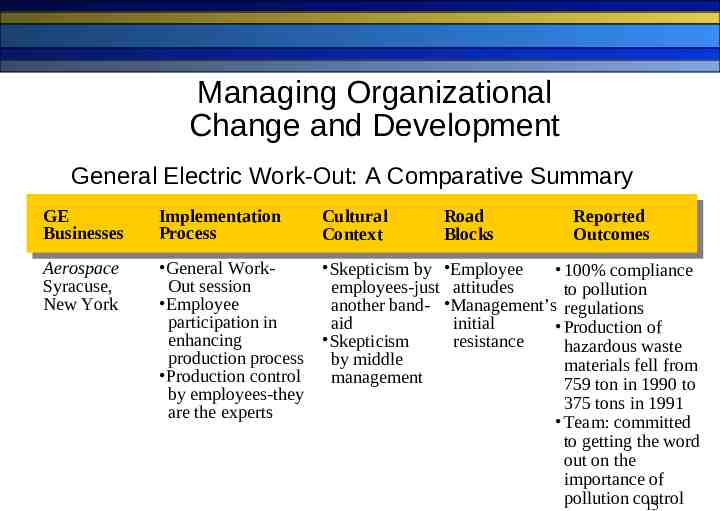

Managing Organizational Change and Development General Electric Work-Out: A Comparative Summary GE Businesses Implementation Process Aerospace Syracuse, New York General Work Skepticism by Employee 100% compliance Out session employees-just attitudes to pollution Employee another band- Management’s regulations participation in aid initial Production of Skepticism enhancing resistance hazardous waste production process by middle materials fell from Production control management 759 ton in 1990 to by employees-they 375 tons in 1991 are the experts Team: committed to getting the word out on the importance of pollution control 15 Cultural Context Road Blocks Reported Outcomes

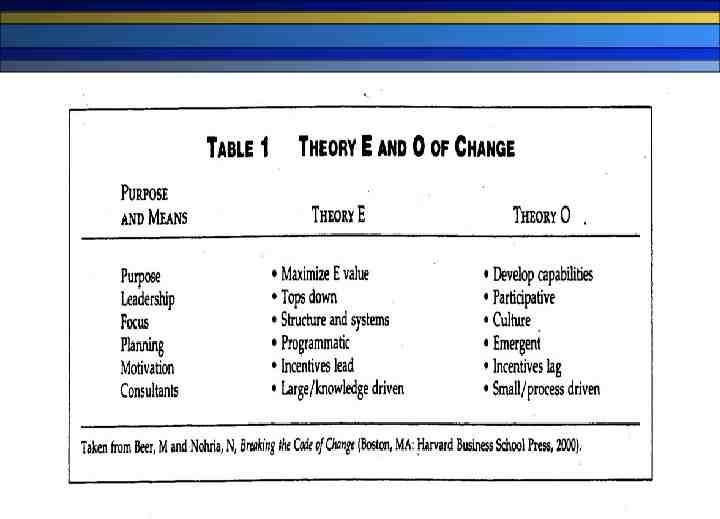

THEORY ORIENTATION IN OD&C THE LITERATURE MAKES DISTINCTION BETWEEN TWO TYPES OF CHANGE: 1ST ORDER AND 2ND ORDER FIRST-ORDER CHANGE CONSISTS OF MINOR IMPROVEMENTS AND ADJUSTMENTS THAT DO NOT CHANGE THE SYSTEM CORE SECOND-ORDER CHANGE (TRANSFORMATIONAL) IS DEFINED AS CHANGE IN CORE ORGANIZATION PROCESSES (I.E., ORG STRUCTURE, IMPLEMENTING NEW IT SYSTEM,.), IN MISSION & PURPOSE AND, IN CULTURE. 16

THREE PERSPECTIVES ON CHANGE (Ackerman, 2001) I. DEVELOPMENTAL CHANGE – IMPROVEMENT OF WHAT IS. II. TRANSITIONAL CHANGE – IMPLEMENTATION OF A KNOWN NEW STATE. MANAGEMENT OF THE INTERIM TRANSITION STATE, OVER A CONTROLLED PERIOD OF TIME. III. TRANSFORMATIONAL CHANGE – EMERGENCE OF A NEW STATE, UNKNOWN UNTIL IT TAKES SHAPE, OUT OF THE REMAINS OF THE CHAOTIC DEATH OF THE OLD STATE. TIME PERIOD NOT EASILY CONTROLLED. 17

CHANGE PROGRAMS CAN BE EXAMINED BY ADDRESSING THREE BASIC QUESTIONS: WHY – THE DRIVEN FORCES OF THIS TYPE OF CHANGE HOW – THE PHASES/STAGES AND PROCESS CHARACTERISTICS OF THE CHANGE WHAT – THE CONTENT OF THE CHANGE 18

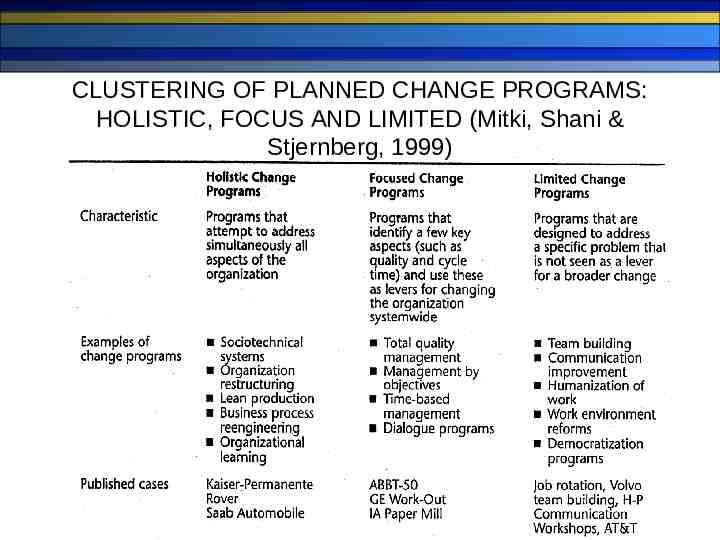

CLUSTERING OF PLANNED CHANGE PROGRAMS: HOLISTIC, FOCUS AND LIMITED (Mitki, Shani & Stjernberg, 1999) 19

20

Planned Change Models 21

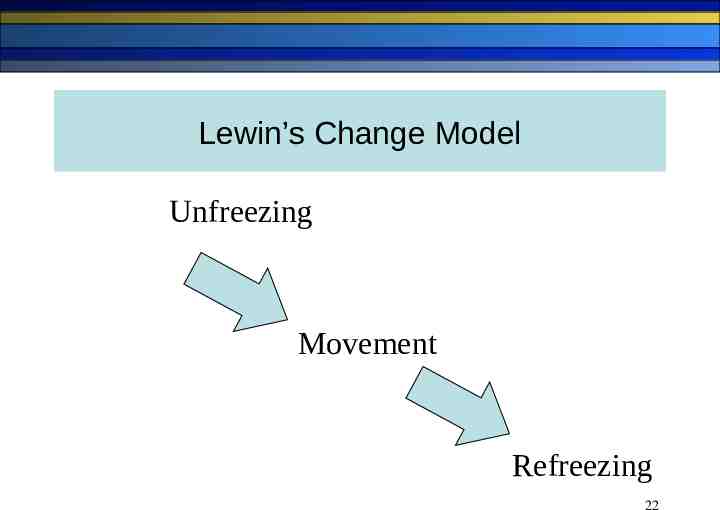

Lewin’s Change Model Unfreezing Movement Refreezing 22

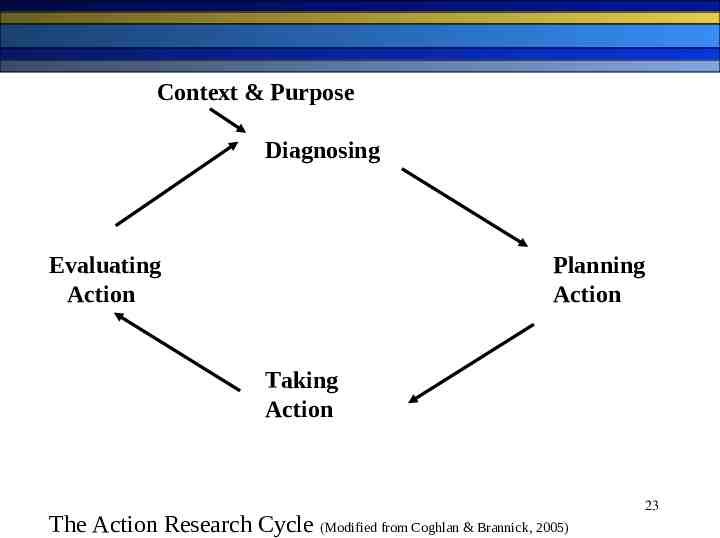

Context & Purpose Diagnosing Evaluating Action Planning Action Taking Action The Action Research Cycle (Modified from Coghlan & Brannick, 2005) 23

24

INTERVENTIONS 25

Definition of Interventions To intervene is to enter into an ongoing system of relationships, to come between or among persons, groups, or objects for the purpose of helping them. An OD intervention refers to the range of planned, programmatic activities intended to help the organization increase its effectiveness. Interventions purposely disrupt the status quo. 26

OD&C INTERVENTIONS AT THE CORE OF MOST OD&C INTERVENTIONS ONE CAN FIND TWO COMPONENTS: – ACTION RESEARCH – ORGANIZATIONAL LEARNING 27

Action Research Action Research - one of the many streams of Collaborative Research - is an emergent and systematic inquiry process, embedded in a true partnership between researchers and members of a living system, in which behavioral, social, organizational and management scientific knowledge is integrated with exiting organizational knowledge for the purpose of generating actionable knowledge. 28

Action Research At the most basic level, Action Research is viewed as: – A partnership among a variety of individuals forming a “community of inquiry” – An emergent inquiry process that differs from the notion of scientific research as a closed, linear, and planned activity 29

ACTION RESEARCH: SOME KEY FEATURES AND COMMON DENOMINATORS AR occurs in natural setting, focus on specific issues AR involves ‘research’ and ‘action’ partnership between researchers and practitioners AR involves the action researcher/s first hand AR involves mutual education AR involves the creation of a learning mechanism AR develops self-help competencies AR strives for systems development AR lays the foundation of a learning community AR generates valid and actionable knowledge 30

ORGANIZATIONAL LEARNING Organizational learning is a system of principles, activities, processes, and structures that enable an organization to realize the potential inherent in the knowledge and experience of its human capital. Organizational learning incorporates all the activities and processes taking place on the individual, team, and organizational levels. Schein argues that at least three distinctly different types of learning exist: knowledge acquisition and insights (cognitive learning), habit and skill learning, and emotional conditioning and learning anxiety. The concept of a learning organization, then, appears to focus more on the “what,” while the concept of organizational learning concentrates on the “how.” 31

LEARNING MECHANISMS During the 1990s the focus on Learning Organization, Organization Learning and Learning Capability seems to have taken a center stage in the MGT literature Recent lit review reveals over 1500 citations The literature is inconclusive in terms of definitions and findings 32

LEARNING MECHANISMS (2) Learning Mechanisms are defined as the conscious, planned proactive features that enable and encourage organizational learning. As such, LM are vied as the formalized strategies (policies, structures, procedures, rules, processes, methods, and tools) that are created within the firm for the purpose of enhancing learning. The literature of LM identifies three focuses: Cognitive, Structural and Procedural. 33

LEARNING MECHANISMS (3) Cognitive or cultural mechanisms (CMs) are the bearers of language, concepts, symbols, theories, frameworks, and values for thinking, reasoning, and understanding with the new capabilities. CMs are management’s main means for creating an understanding among all employees on the character, need, and priority. CMs include company values and mission statements, strategy documents, policies and plans, management-union or company-partner joint agreements. 34

LEARNING MECHANISMS (4) Structural mechanisms (SMs) are organizational, physical, technical and work system infrastructures that encourage practice-based learning. SMs house and enable the collaboration and discourse required for collective learning of new practice. SMs may include the following: – communication channels; – the establishments of lateral structures to enable learning of new practice across various core organizational units; – changes to the work organization; – formal and informal for joint exploration and debates; – learning specific structures such a parallel learning structures, bench-learning structures and process improvement teams. 35

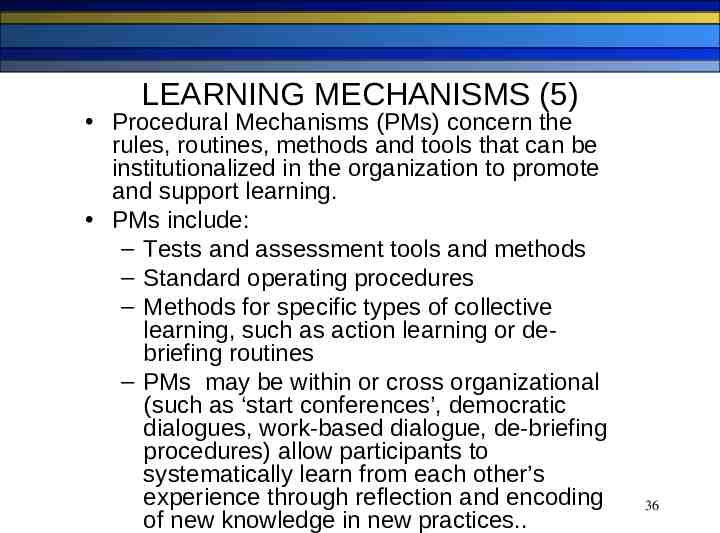

LEARNING MECHANISMS (5) Procedural Mechanisms (PMs) concern the rules, routines, methods and tools that can be institutionalized in the organization to promote and support learning. PMs include: – Tests and assessment tools and methods – Standard operating procedures – Methods for specific types of collective learning, such as action learning or debriefing routines – PMs may be within or cross organizational (such as ‘start conferences’, democratic dialogues, work-based dialogue, de-briefing procedures) allow participants to systematically learn from each other’s experience through reflection and encoding of new knowledge in new practices. 36

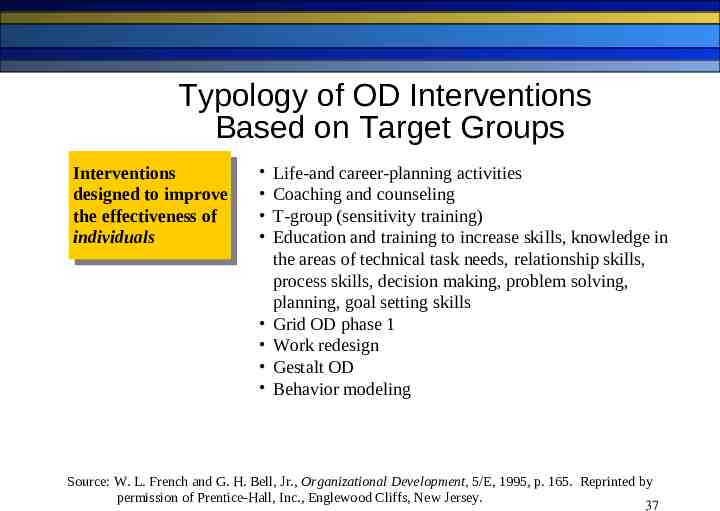

Typology of OD Interventions Based on Target Groups Interventions designed to improve the effectiveness of individuals Life-and career-planning activities Coaching and counseling T-group (sensitivity training) Education and training to increase skills, knowledge in the areas of technical task needs, relationship skills, process skills, decision making, problem solving, planning, goal setting skills Grid OD phase 1 Work redesign Gestalt OD Behavior modeling Source: W. L. French and G. H. Bell, Jr., Organizational Development, 5/E, 1995, p. 165. Reprinted by permission of Prentice-Hall, Inc., Englewood Cliffs, New Jersey. 37

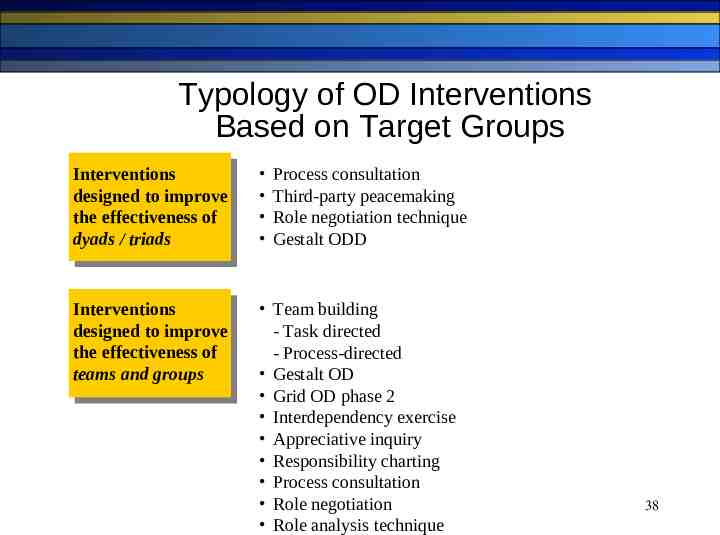

Typology of OD Interventions Based on Target Groups Interventions designed to improve the effectiveness of dyads / triads Interventions designed to improve the effectiveness of teams and groups Team building - Task directed - Process-directed Gestalt OD Grid OD phase 2 Interdependency exercise Appreciative inquiry Responsibility charting Process consultation Role negotiation Role analysis technique Process consultation Third-party peacemaking Role negotiation technique Gestalt ODD 38

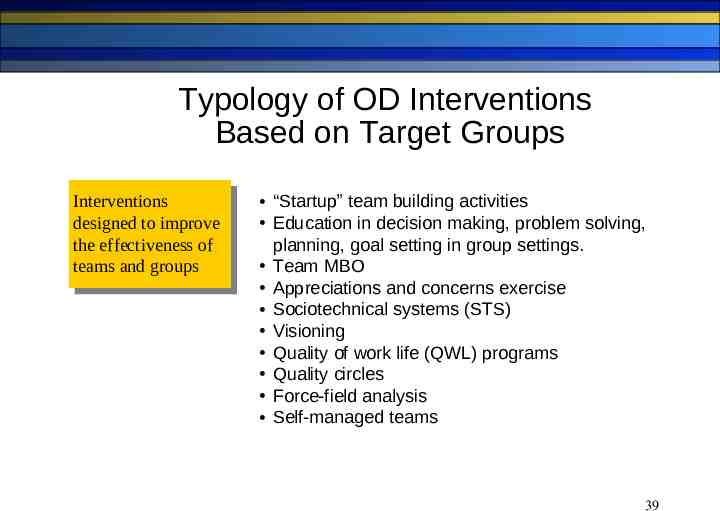

Typology of OD Interventions Based on Target Groups Interventions designed to improve the effectiveness of teams and groups “Startup” team building activities Education in decision making, problem solving, planning, goal setting in group settings. Team MBO Appreciations and concerns exercise Sociotechnical systems (STS) Visioning Quality of work life (QWL) programs Quality circles Force-field analysis Self-managed teams 39

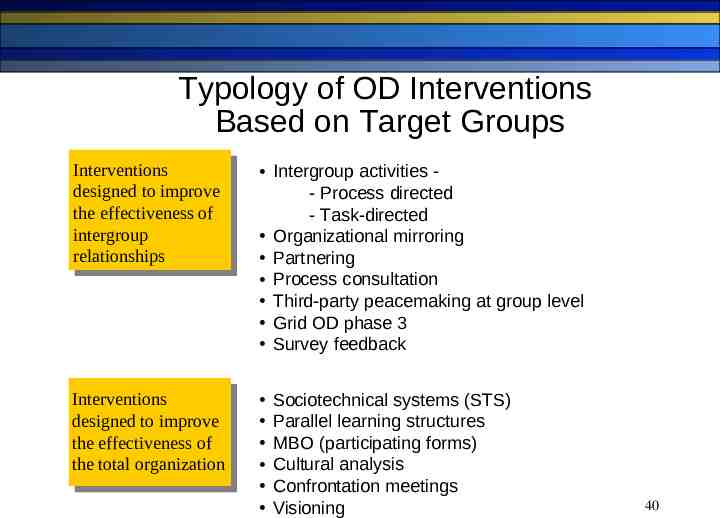

Typology of OD Interventions Based on Target Groups Interventions designed to improve the effectiveness of intergroup relationships Intergroup activities - Process directed - Task-directed Organizational mirroring Partnering Process consultation Third-party peacemaking at group level Grid OD phase 3 Survey feedback Interventions designed to improve the effectiveness of the total organization Sociotechnical systems (STS) Parallel learning structures MBO (participating forms) Cultural analysis Confrontation meetings Visioning 40

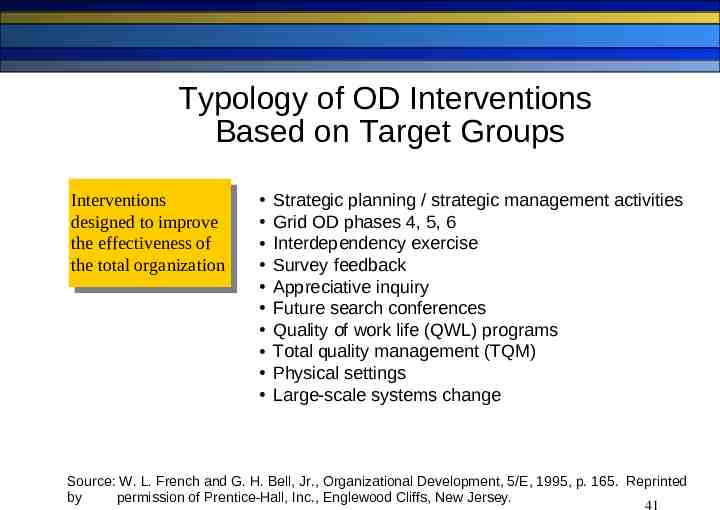

Typology of OD Interventions Based on Target Groups Interventions designed to improve the effectiveness of the total organization Strategic planning / strategic management activities Grid OD phases 4, 5, 6 Interdependency exercise Survey feedback Appreciative inquiry Future search conferences Quality of work life (QWL) programs Total quality management (TQM) Physical settings Large-scale systems change Source: W. L. French and G. H. Bell, Jr., Organizational Development, 5/E, 1995, p. 165. Reprinted by permission of Prentice-Hall, Inc., Englewood Cliffs, New Jersey. 41

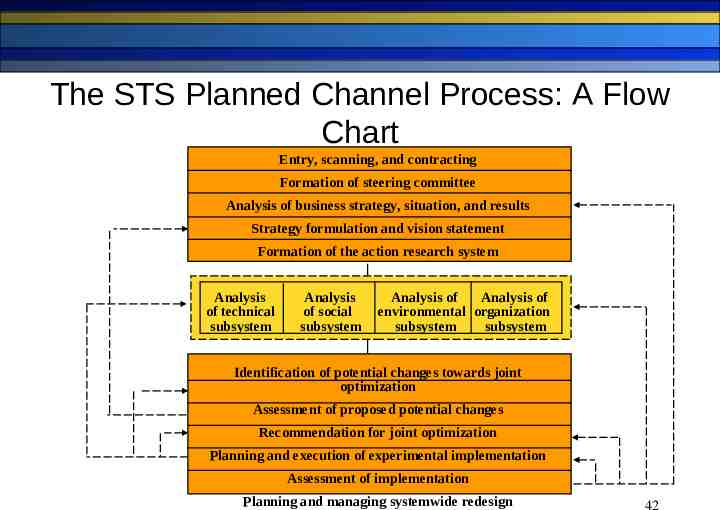

The STS Planned Channel Process: A Flow Chart Entry, scanning, and contracting Formation of steering committee Analysis of business strategy, situation, and results Strategy formulation and vision statement Formation of the action research system Analysis of technical subsystem Analysis of social subsystem Analysis of Analysis of environmental organization subsystem subsystem Identification of potential changes towards joint optimization Assessment of proposed potential changes Recommendation for joint optimization Planning and execution of experimental implementation Assessment of implementation Planning and managing systemwide redesign 42

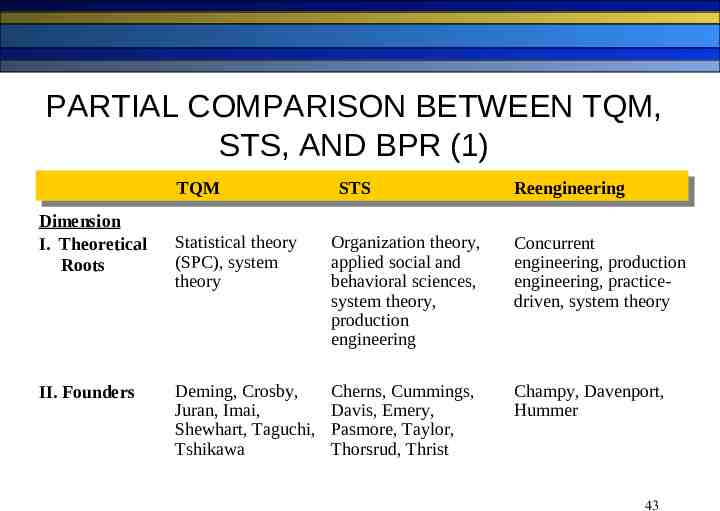

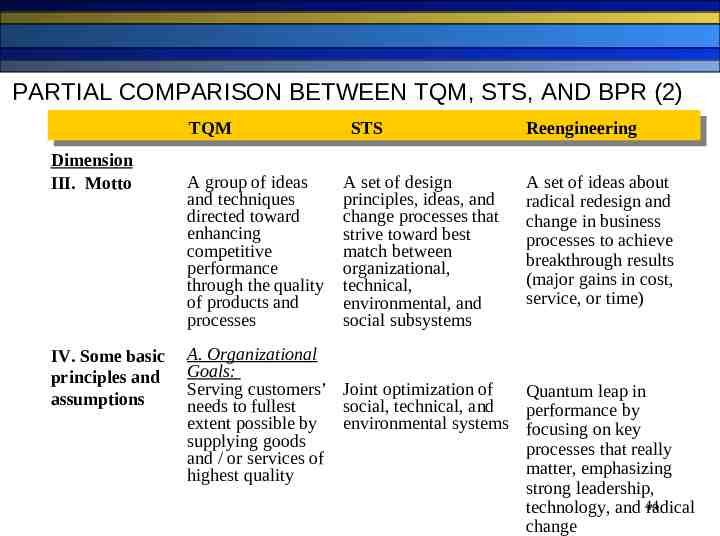

PARTIAL COMPARISON BETWEEN TQM, STS, AND BPR (1) TQM Dimension I. Theoretical Roots II. Founders STS Reengineering Statistical theory (SPC), system theory Organization theory, applied social and behavioral sciences, system theory, production engineering Concurrent engineering, production engineering, practicedriven, system theory Deming, Crosby, Juran, Imai, Shewhart, Taguchi, Tshikawa Cherns, Cummings, Davis, Emery, Pasmore, Taylor, Thorsrud, Thrist Champy, Davenport, Hummer 43

PARTIAL COMPARISON BETWEEN TQM, STS, AND BPR (2) TQM Dimension III. Motto IV. Some basic principles and assumptions A group of ideas and techniques directed toward enhancing competitive performance through the quality of products and processes STS A set of design principles, ideas, and change processes that strive toward best match between organizational, technical, environmental, and social subsystems A. Organizational Goals: Serving customers’ Joint optimization of needs to fullest social, technical, and extent possible by environmental systems supplying goods and / or services of highest quality Reengineering A set of ideas about radical redesign and change in business processes to achieve breakthrough results (major gains in cost, service, or time) Quantum leap in performance by focusing on key processes that really matter, emphasizing strong leadership, technology, and 44 radical change

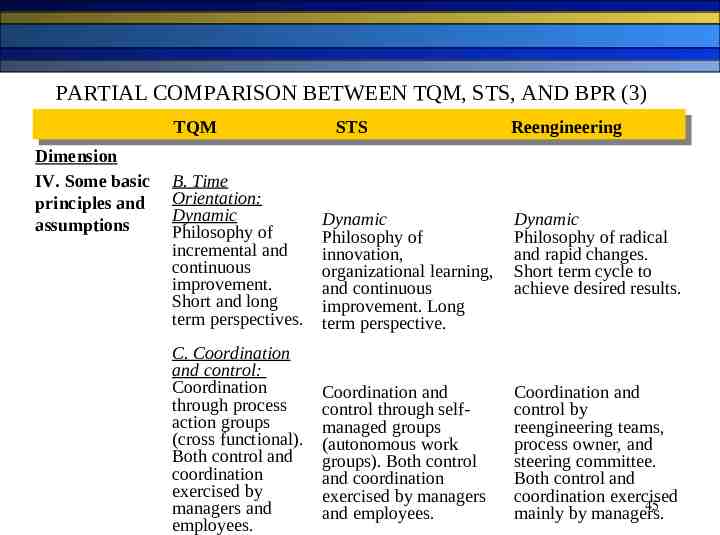

PARTIAL COMPARISON BETWEEN TQM, STS, AND BPR (3) TQM Dimension IV. Some basic principles and assumptions B. Time Orientation: Dynamic Philosophy of incremental and continuous improvement. Short and long term perspectives. C. Coordination and control: Coordination through process action groups (cross functional). Both control and coordination exercised by managers and employees. STS Reengineering Dynamic Philosophy of innovation, organizational learning, and continuous improvement. Long term perspective. Dynamic Philosophy of radical and rapid changes. Short term cycle to achieve desired results. Coordination and control through selfmanaged groups (autonomous work groups). Both control and coordination exercised by managers and employees. Coordination and control by reengineering teams, process owner, and steering committee. Both control and coordination exercised 45 mainly by managers.

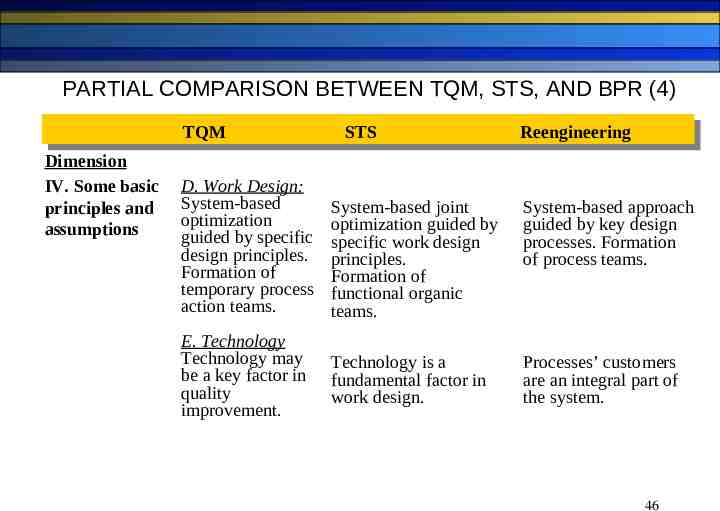

PARTIAL COMPARISON BETWEEN TQM, STS, AND BPR (4) TQM Dimension IV. Some basic principles and assumptions D. Work Design: System-based optimization guided by specific design principles. Formation of temporary process action teams. E. Technology Technology may be a key factor in quality improvement. STS Reengineering System-based joint optimization guided by specific work design principles. Formation of functional organic teams. System-based approach guided by key design processes. Formation of process teams. Technology is a fundamental factor in work design. Processes’ customers are an integral part of the system. 46

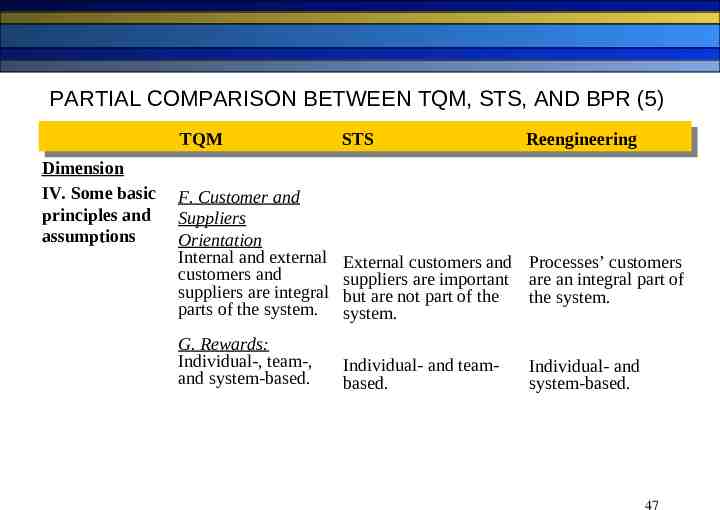

PARTIAL COMPARISON BETWEEN TQM, STS, AND BPR (5) Dimension IV. Some basic principles and assumptions TQM STS Reengineering F. Customer and Suppliers Orientation Internal and external customers and suppliers are integral parts of the system. External customers and Processes’ customers suppliers are important are an integral part of but are not part of the the system. system. G. Rewards: Individual-, team-, and system-based. Individual- and teambased. Individual- and system-based. 47

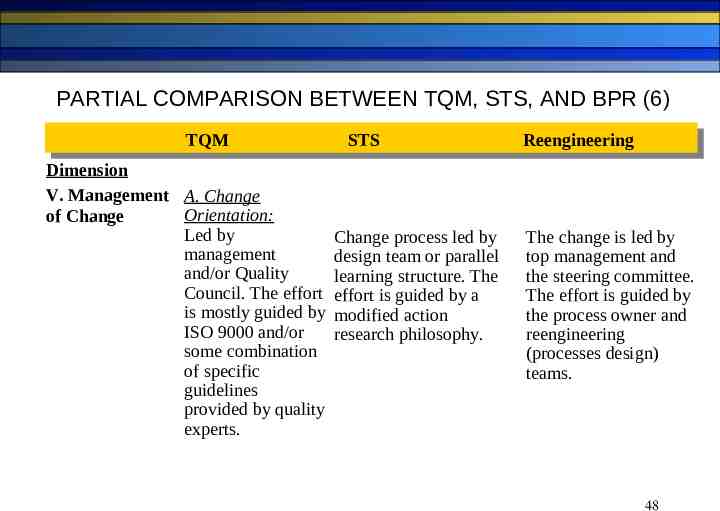

PARTIAL COMPARISON BETWEEN TQM, STS, AND BPR (6) TQM Dimension V. Management A. Change Orientation: of Change Led by management and/or Quality Council. The effort is mostly guided by ISO 9000 and/or some combination of specific guidelines provided by quality experts. STS Change process led by design team or parallel learning structure. The effort is guided by a modified action research philosophy. Reengineering The change is led by top management and the steering committee. The effort is guided by the process owner and reengineering (processes design) teams. 48

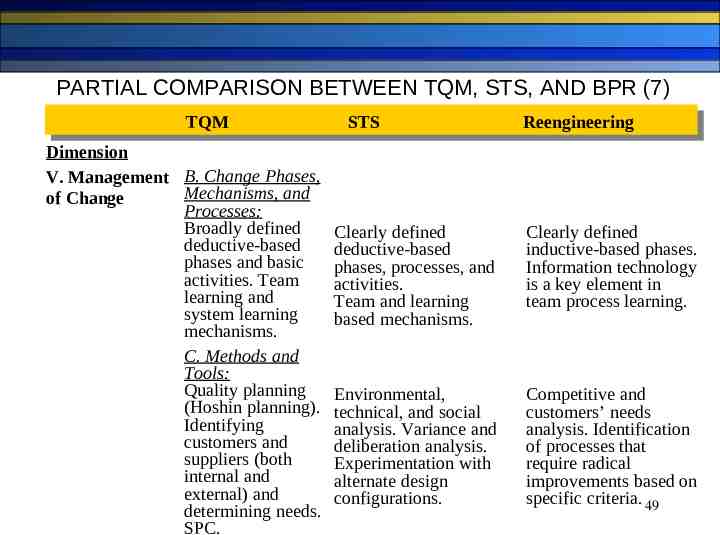

PARTIAL COMPARISON BETWEEN TQM, STS, AND BPR (7) TQM Dimension V. Management B. Change Phases, Mechanisms, and of Change Processes: Broadly defined deductive-based phases and basic activities. Team learning and system learning mechanisms. C. Methods and Tools: Quality planning (Hoshin planning). Identifying customers and suppliers (both internal and external) and determining needs. SPC. STS Reengineering Clearly defined deductive-based phases, processes, and activities. Team and learning based mechanisms. Clearly defined inductive-based phases. Information technology is a key element in team process learning. Environmental, technical, and social analysis. Variance and deliberation analysis. Experimentation with alternate design configurations. Competitive and customers’ needs analysis. Identification of processes that require radical improvements based on specific criteria. 49

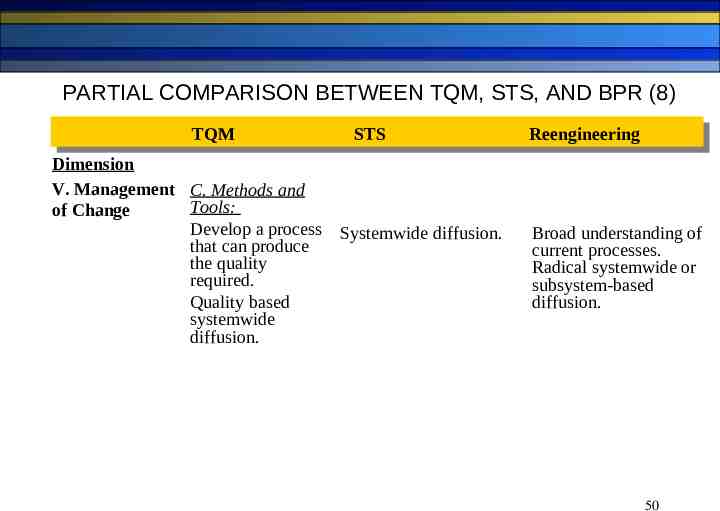

PARTIAL COMPARISON BETWEEN TQM, STS, AND BPR (8) TQM STS Dimension V. Management C. Methods and Tools: of Change Develop a process Systemwide diffusion. that can produce the quality required. Quality based systemwide diffusion. Reengineering Broad understanding of current processes. Radical systemwide or subsystem-based diffusion. 50

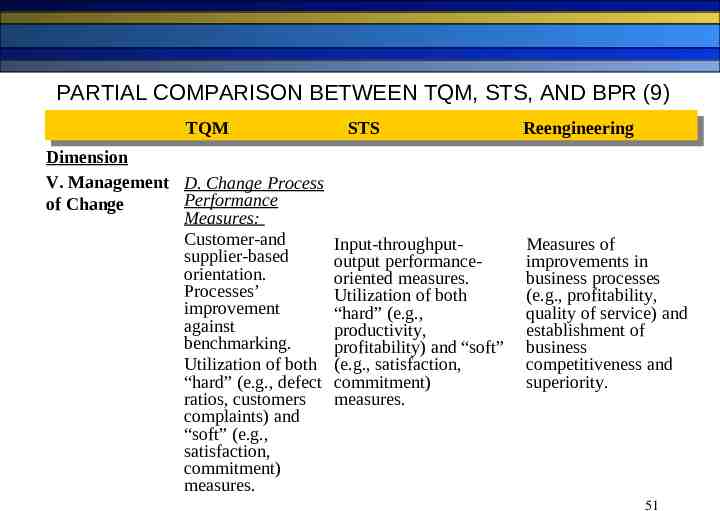

PARTIAL COMPARISON BETWEEN TQM, STS, AND BPR (9) TQM Dimension V. Management D. Change Process Performance of Change Measures: Customer-and supplier-based orientation. Processes’ improvement against benchmarking. Utilization of both “hard” (e.g., defect ratios, customers complaints) and “soft” (e.g., satisfaction, commitment) measures. STS Input-throughputoutput performanceoriented measures. Utilization of both “hard” (e.g., productivity, profitability) and “soft” (e.g., satisfaction, commitment) measures. Reengineering Measures of improvements in business processes (e.g., profitability, quality of service) and establishment of business competitiveness and superiority. 51

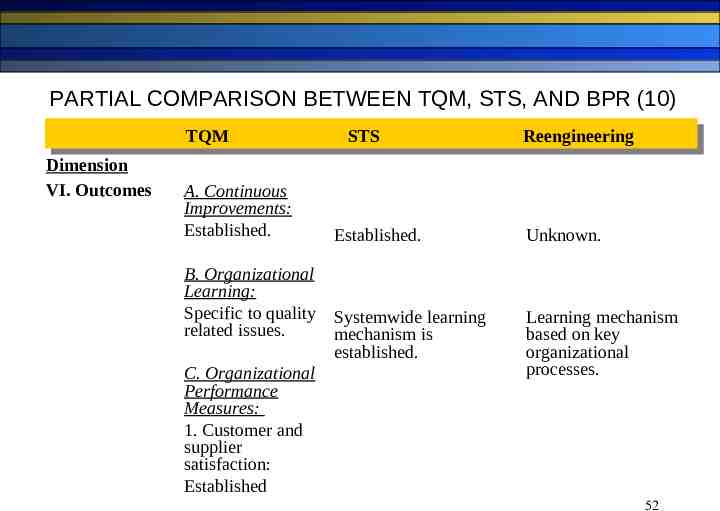

PARTIAL COMPARISON BETWEEN TQM, STS, AND BPR (10) TQM Dimension VI. Outcomes A. Continuous Improvements: Established. STS Established. B. Organizational Learning: Specific to quality Systemwide learning related issues. mechanism is established. C. Organizational Performance Measures: 1. Customer and supplier satisfaction: Established Reengineering Unknown. Learning mechanism based on key organizational processes. 52

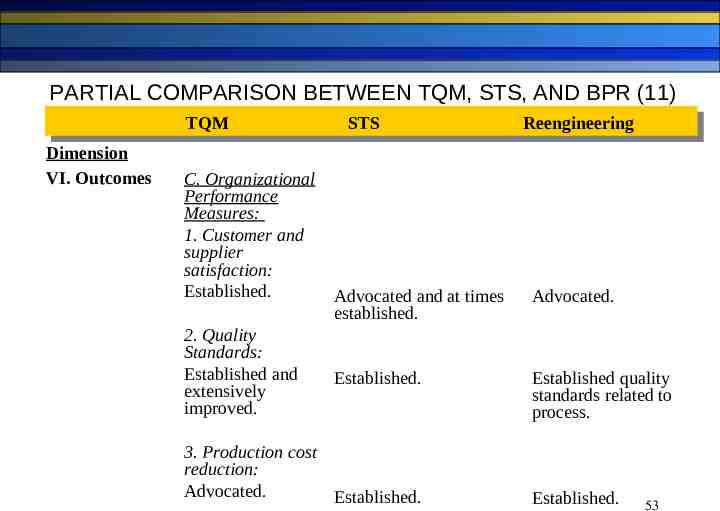

PARTIAL COMPARISON BETWEEN TQM, STS, AND BPR (11) TQM Dimension VI. Outcomes C. Organizational Performance Measures: 1. Customer and supplier satisfaction: Established. 2. Quality Standards: Established and extensively improved. STS Reengineering Advocated and at times established. Advocated. Established. Established quality standards related to process. 3. Production cost reduction: Advocated. Established. Established. 53

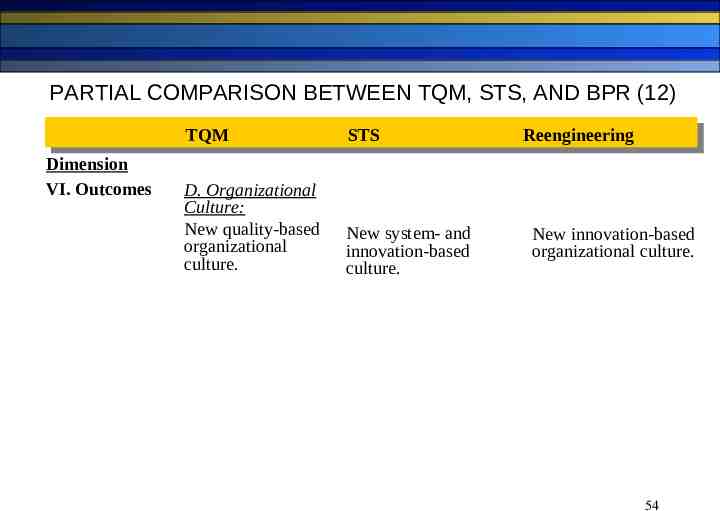

PARTIAL COMPARISON BETWEEN TQM, STS, AND BPR (12) Dimension VI. Outcomes TQM STS D. Organizational Culture: New quality-based organizational culture. New system- and innovation-based culture. Reengineering New innovation-based organizational culture. 54

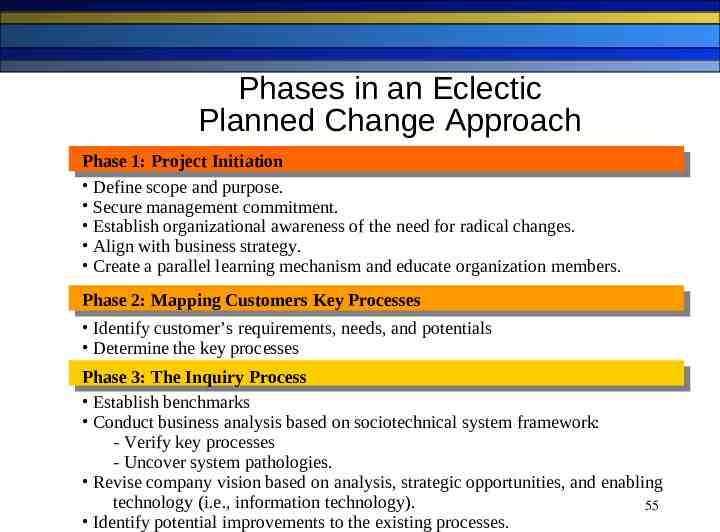

Phases in an Eclectic Planned Change Approach Phase 1: Project Initiation Define scope and purpose. Secure management commitment. Establish organizational awareness of the need for radical changes. Align with business strategy. Create a parallel learning mechanism and educate organization members. Phase 2: Mapping Customers Key Processes Identify customer’s requirements, needs, and potentials Determine the key processes Phase 3: The Inquiry Process Establish benchmarks Conduct business analysis based on sociotechnical system framework: - Verify key processes - Uncover system pathologies. Revise company vision based on analysis, strategic opportunities, and enabling technology (i.e., information technology). 55 Identify potential improvements to the existing processes.

Phases in an Eclectic Planned Change Approach Phase 4: Design/Redesign to Modify Existing Processes and Organizational Structure Formulate specific alternative sociotechnical-based design solutions (STS based design includes the optimal Integration of key organizational elements such as rewards, control, structure, information, people, and existing technology). Explore potential impact proposed solutions. Develop joint optimization of key processes. Establish learning processes for continuous improvement. Phase 5: Implementation and Reconstruction of the Key Processes and Organization Foster a climate that is conducive to change Create the implementation and support mechanisms. Develop training programs. Establish learning loops as an integral part of continuous improvement. 56