Operations and Supply Chain Strategies Chapter 2

30 Slides809.00 KB

Operations and Supply Chain Strategies Chapter 2

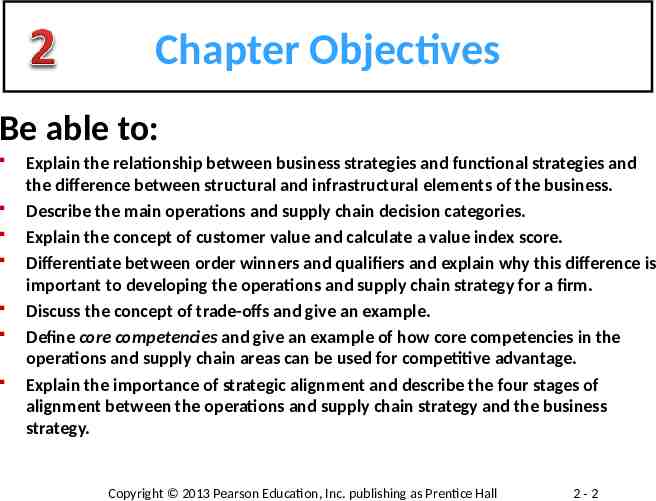

Chapter Objectives Be able to: Explain the relationship between business strategies and functional strategies and the difference between structural and infrastructural elements of the business. Describe the main operations and supply chain decision categories. Explain the concept of customer value and calculate a value index score. Differentiate between order winners and qualifiers and explain why this difference is important to developing the operations and supply chain strategy for a firm. Discuss the concept of trade-offs and give an example. Define core competencies and give an example of how core competencies in the operations and supply chain areas can be used for competitive advantage. Explain the importance of strategic alignment and describe the four stages of alignment between the operations and supply chain strategy and the business strategy. Copyright 2013 Pearson Education, Inc. publishing as Prentice Hall 2-2

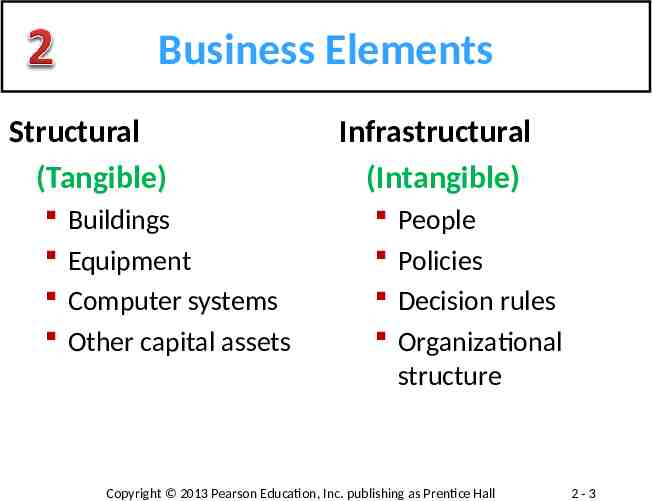

Business Elements Structural (Tangible) Buildings Equipment Computer systems Other capital assets Infrastructural (Intangible) People Policies Decision rules Organizational structure Copyright 2013 Pearson Education, Inc. publishing as Prentice Hall 2-3

Definitions Strategies - The mechanisms by which businesses coordinate their decisions regarding their structural and infrastructural elements. Mission Statement - Explains why an organization exists and what is important to the organization (its core values) and identifies the organization’s domain. Copyright 2013 Pearson Education, Inc. publishing as Prentice Hall 2-4

Definitions Business Strategy - The strategy that identifies a firm’s targeted customers and sets time frames and performance objectives for the business. Functional Strategy - A strategy that translates a business strategy into specific functional areas. Core Competency - An organizational strength or ability that customers find valuable and competitors find difficult or impossible to copy. Copyright 2013 Pearson Education, Inc. publishing as Prentice Hall 2-5

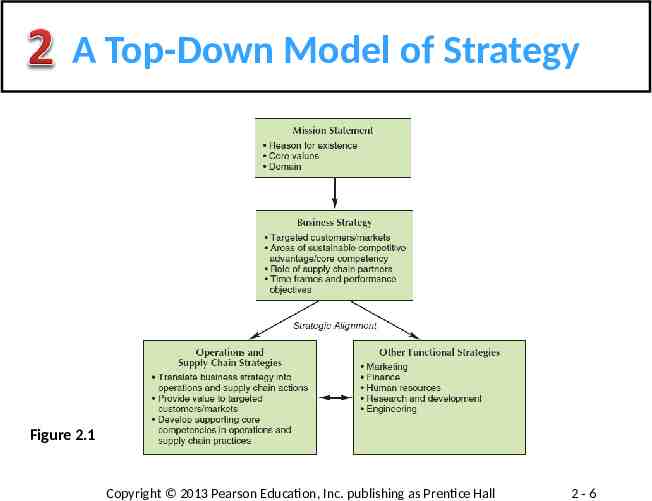

A Top-Down Model of Strategy Figure 2.1 Copyright 2013 Pearson Education, Inc. publishing as Prentice Hall 2-6

Operations and Supply Chain Strategies The operations and supply chain strategy is a functional strategy that indicates how the structural and infrastructural elements within the operations and supply chain areas will be acquired and developed to support the overall business strategy. What mix of structural and infrastructural elements ? Is the mix aligned with the business strategy? Does it support the development of core competencies? Copyright 2013 Pearson Education, Inc. publishing as Prentice Hall 2-7

Functional Strategy Translates the business strategy into functional terms. Assures coordination with other areas. Provides direction and guidance for operations and supply chain decisions. Copyright 2013 Pearson Education, Inc. publishing as Prentice Hall 2-8

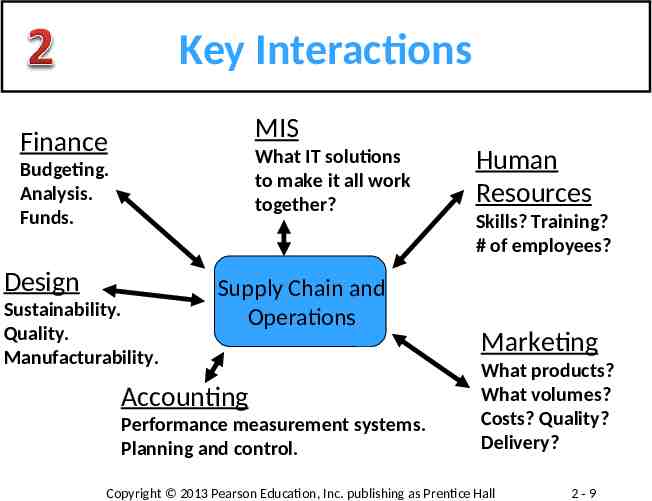

Key Interactions MIS Finance What IT solutions to make it all work together? Budgeting. Analysis. Funds. Design Sustainability. Quality. Manufacturability. Supply Chain and Operations Accounting Performance measurement systems. Planning and control. Human Resources Skills? Training? # of employees? Marketing What products? What volumes? Costs? Quality? Delivery? Copyright 2013 Pearson Education, Inc. publishing as Prentice Hall 2-9

Decisions Guided by the Structural Strategy Capacity Amount, Type, Timing Facilities Services/Manufacturing, Warehouses, Distribution hubs Size, location, degree of specialization Technology Services/Manufacturing, Material handling equipment, Transportation equipment, Information systems Copyright 2013 Pearson Education, Inc. publishing as Prentice Hall 2 - 10

Decisions Guided by the Infrastructural Strategy Organization Structure, Control/reward systems, Workforce decisions Sourcing/Purchasing Sourcing strategies, Supplier selection, Supplier performance measurement Planning and Control Forecasting, Tactical planning, Inventory management, Production planning and control Business Processes and Quality Management Six Sigma, Continuous improvement, Statistical process control Product and service development The developmental process, Organizational and supplier roles Copyright 2013 Pearson Education, Inc. publishing as Prentice Hall 2 - 11

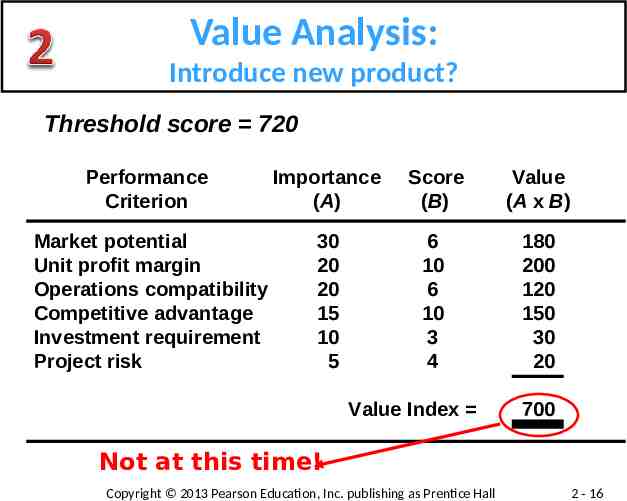

Customer Value Value Analysis - A process for assessing the value of a product or service. Value Index - A measure that uses the performance and importance scores for various dimensions of performance for an item or a service to calculate a score that indicates the overall value of an item or a service to a customer. Copyright 2013 Pearson Education, Inc. publishing as Prentice Hall 2 - 12

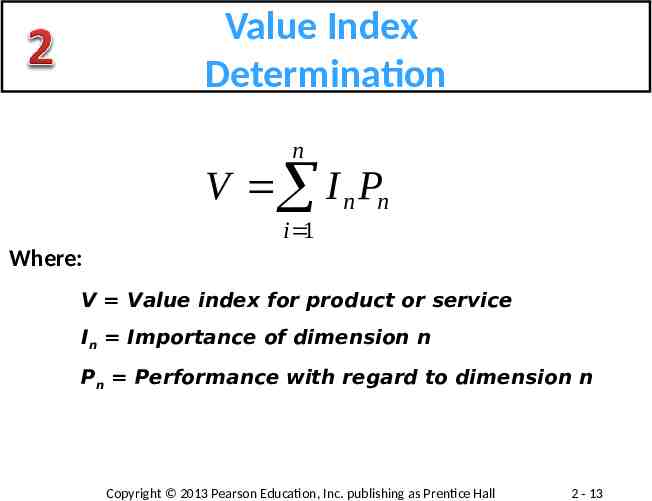

Value Index Determination n V I n Pn i 1 Where: V Value index for product or service In Importance of dimension n Pn Performance with regard to dimension n Copyright 2013 Pearson Education, Inc. publishing as Prentice Hall 2 - 13

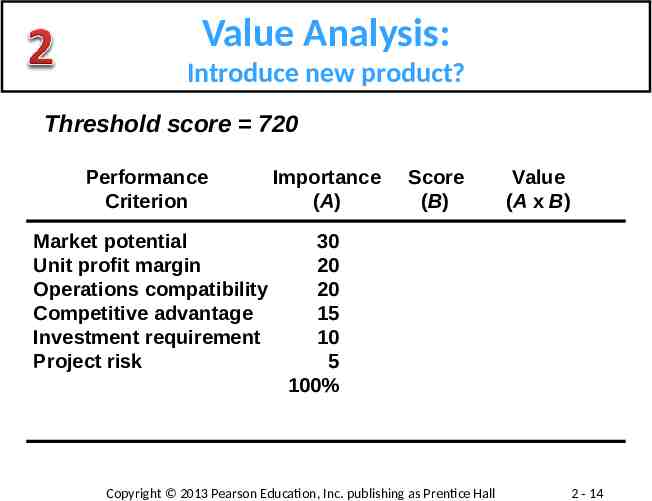

Value Analysis: Introduce new product? Threshold score 720 Performance Criterion Market potential Unit profit margin Operations compatibility Competitive advantage Investment requirement Project risk Importance (A) Score (B) Value (A x B) 30 20 20 15 10 5 100% Copyright 2013 Pearson Education, Inc. publishing as Prentice Hall 2 - 14

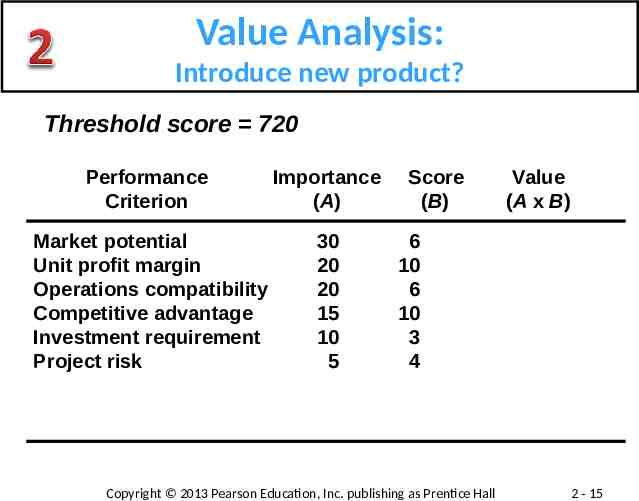

Value Analysis: Introduce new product? Threshold score 720 Performance Criterion Importance (A) Market potential Unit profit margin Operations compatibility Competitive advantage Investment requirement Project risk 30 20 20 15 10 5 Score (B) Value (A x B) 6 10 6 10 3 4 Copyright 2013 Pearson Education, Inc. publishing as Prentice Hall 2 - 15

Value Analysis: Introduce new product? Threshold score 720 Performance Criterion Importance (A) Score (B) Value (A x B) Market potential Unit profit margin Operations compatibility Competitive advantage Investment requirement Project risk 30 20 20 15 10 5 6 10 6 10 3 4 180 200 120 150 30 20 Value Index 700 Not at this time! Copyright 2013 Pearson Education, Inc. publishing as Prentice Hall 2 - 16

Four Performance Dimensions Quality Time Flexibility Cost Copyright 2013 Pearson Education, Inc. publishing as Prentice Hall 2 - 17

Four Performance Dimensions Quality Performance Quality – The basic operating characteristics of the product or service. Conformance Quality – Was the product made or the service performed to specifications? Reliability Quality – Will a product work for a long time without failing? Copyright 2013 Pearson Education, Inc. publishing as Prentice Hall 2 - 18

Four Performance Dimensions Time Delivery Speed - The ability for the operations or supply chain function to quickly fulfill a need once it has been identified. Delivery Reliability – The ability to deliver products or services when promised. Copyright 2013 Pearson Education, Inc. publishing as Prentice Hall 2 - 19

Four Performance Dimensions Flexibility Mix Flexibility – The ability to produce a wide range of products or services. Changeover Flexibility – The ability to produce a new product with minimal delay. Volume Flexibility – The ability to produce whatever volume the customer needs. Copyright 2013 Pearson Education, Inc. publishing as Prentice Hall 2 - 20

Four Performance Dimensions Cost Labor costs Material costs Engineering costs Quality-related costs Copyright 2013 Pearson Education, Inc. publishing as Prentice Hall 2 - 21

Trade-offs among Performance Dimensions Generally very difficult to excel at all four performance dimensions. Some common conflicts Low cost versus high quality Low cost versus flexibility Delivery reliability versus flexibility Conformance quality versus product flexibility Copyright 2013 Pearson Education, Inc. publishing as Prentice Hall 2 - 22

Order Winners and Order Qualifiers Order Winners A performance dimension that differentiates a company’s products and services from its competitors. Order Qualifiers A performance dimension on which customers expect a minimum level of performance to be considered. Copyright 2013 Pearson Education, Inc. publishing as Prentice Hall 2 - 23

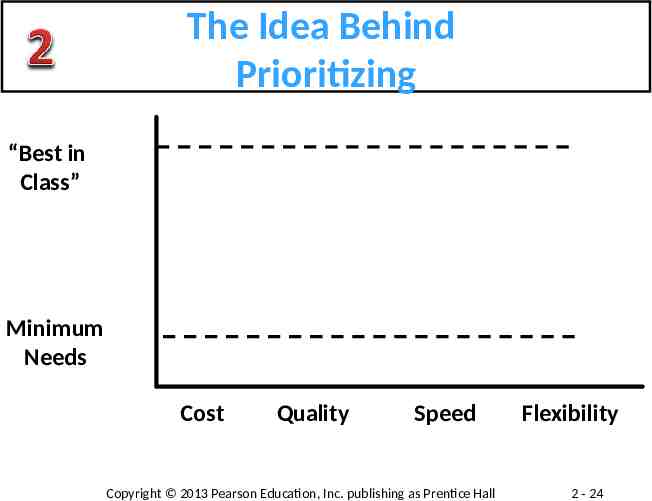

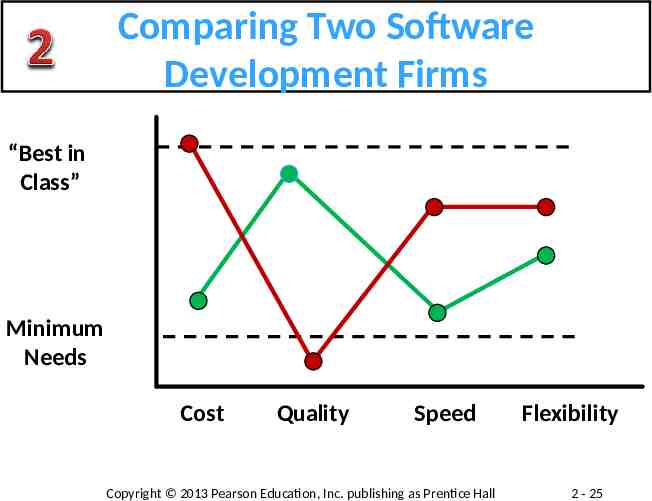

The Idea Behind Prioritizing “Best in Class” Minimum Needs Cost Quality Speed Copyright 2013 Pearson Education, Inc. publishing as Prentice Hall Flexibility 2 - 24

Comparing Two Software Development Firms “Best in Class” Minimum Needs Cost Quality Speed Copyright 2013 Pearson Education, Inc. publishing as Prentice Hall Flexibility 2 - 25

Measurements Performance against Customer needs Business objectives or standards Comparisons to competitors Comparisons to “best in class” Copyright 2013 Pearson Education, Inc. publishing as Prentice Hall 2 - 26

Stages of Alignment Between Supply Chain and Operations Strategies Stage 1 – Internally neutral Minimize negative potential in the operations and supply chain areas. Stage 2 – Externally neutral Follow industry practice. Stage 3 – Internally supportive Align structural and infrastructural elements with business strategy. Stage 4 – Externally supportive Seek to exploit core competencies. Copyright 2013 Pearson Education, Inc. publishing as Prentice Hall 2 - 27

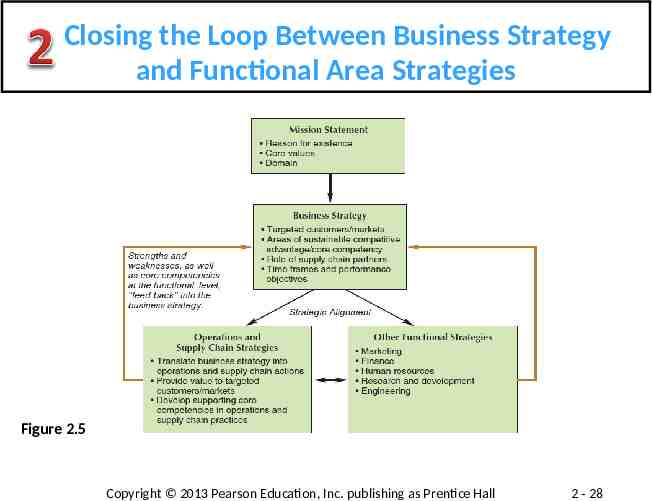

Closing the Loop Between Business Strategy and Functional Area Strategies Figure 2.5 Copyright 2013 Pearson Education, Inc. publishing as Prentice Hall 2 - 28

Operations and Supply Chain Strategies Case Study Catherine’s Confectionaries Copyright 2013 Pearson Education, Inc. publishing as Prentice Hall 2 - 29

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted, in any form or by any means, electronic, mechanical, photocopying, recording, or otherwise, without the prior written permission of the publisher. Printed in the United States of America. Copyright 2013 Pearson Education, Inc. publishing as Prentice Hall 2 - 30