Lockout/ Tagout Refresher Training

25 Slides385.50 KB

Lockout/ Tagout Refresher Training

Hazardous energy sources Evaluate machines, equipment, and processes Develop energy control plan 1a

Hazardous energy sources Look for all sources of energy Identify secondary and stored energy sources 1b

Why lockout/tagout is necessary Prevents injury due to unexpected startup of equipment or released energy 2a

Functions covered by lockout/tagout Servicing of machines and equipment Performing maintenance on equipment and machinery Normal operations 3a

Energy control program Authorized employees Affected employees Other employees 4a

Energy control program Energy control procedures Training Periodic audits 4b

Preparation for shutdown Locate all energy sources Inform all affected persons 5a

Shutdown procedure Each piece of equipment or machine must be shutdown according to written energy control procedures 6a

Shutdown procedure Orderly shutdown avoids additional or increased hazards Use shutdown procedures that are established for the machine 6b

Isolating machinery from its energy sources Type of devices to be used Placement of isolating devices 7a

Application of lockout/tagout devices Positioning of lockout/tagout devices Only authorized employees can attach the devices 8a

Releasing stored energy Check for and relieve: electrical energy capacitors residual pressure in lines and pipes 9a

Verification procedures Verify that all locks and tags are in place Try to operate the equipment 10a

Restoring energy to the equipment/machine Remove tools from the area, replace guards Ensure that employees are safely positioned or removed from the area 11a

Restoring energy to the equipment/machine The employee who applies the lock is the only one who can remove it Special requirements for testing and positioning equipment 11b

Lockout devices Types used Standardized for easy recognition 12a

Lockout devices Never use someone else’s lockout device The lock must identify the person who applied it 12b

Tags Types used Standardized for easy recognition 13a

Tags The attachment means for a tag must be: non-reusable attached by hand self-locking and non-reusable with locking strength of 50 pounds equivalent to a one-piece, allenvironment-tolerant nylon cable tie 13b

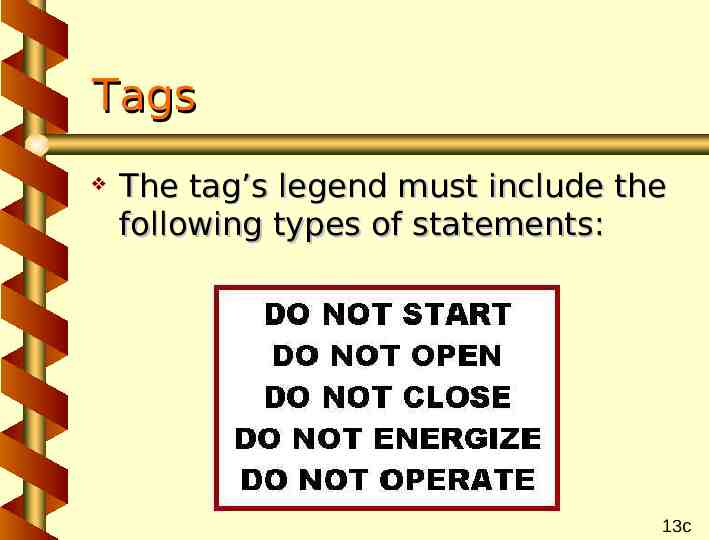

Tags The tag’s legend must include the following types of statements: 13c

Group lockouts Uses group lockout devices (hasps) to accommodate all locks Each authorized employee must affix a personal lockout or tagout device to the group lockout device when he/she begins work 14a

Group lockouts Each authorized employee must remove those devices when he/she stops working on the machine/equipment 14b

Shift changes The first employee’s lock remains in place until the next shift’s employee applies his/her lock 15a

Removing a lock If an employee is not available to remove a lock, the employer must: verify that the employee is not in the facility make reasonable efforts to contact the employee inform the employee of the removal before he/she resumes work 16a