Facility Planning & Design Prepared by: Brannon McGrotha

19 Slides498.00 KB

Facility Planning & Design Prepared by: Brannon McGrotha

Introduction Facilities planning 1. Strategy 2. Competition (bring in customer) Significance U.S. invested 1.038 trillion (320.8 billion, 92.7%, spent of structures) Since 1955, 8% of GNP ISE482 2

Introduction (con’t) Continuous improvement cycle School Improvement Cycle ISE482 3

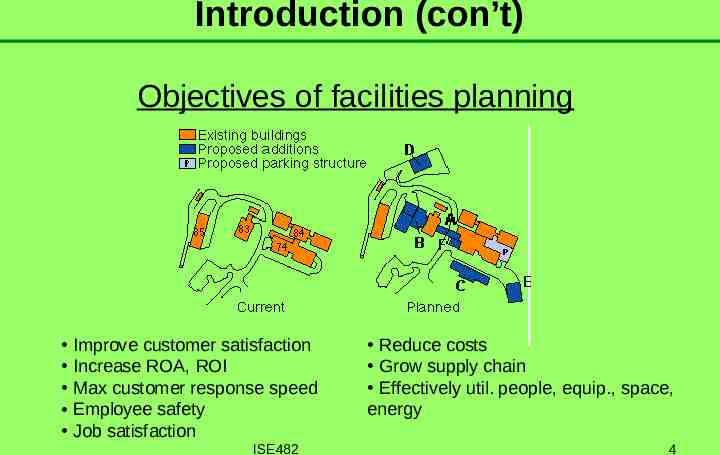

Introduction (con’t) Objectives of facilities planning Improve customer satisfaction Increase ROA, ROI Max customer response speed Employee safety Job satisfaction ISE482 Reduce costs Grow supply chain Effectively util. people, equip., space, energy 4

Introduction (con’t) Facilities planning process (6 steps) 1. 2. 3. 4. 5. 6. Define the problem Analyze the problem Determine space requirements Evaluate alternatives Select design Implement design ISE482 5

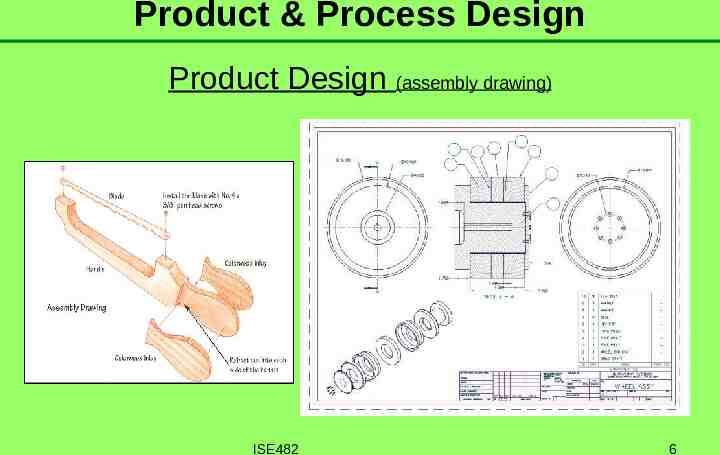

Product & Process Design Product Design (assembly drawing) ISE482 6

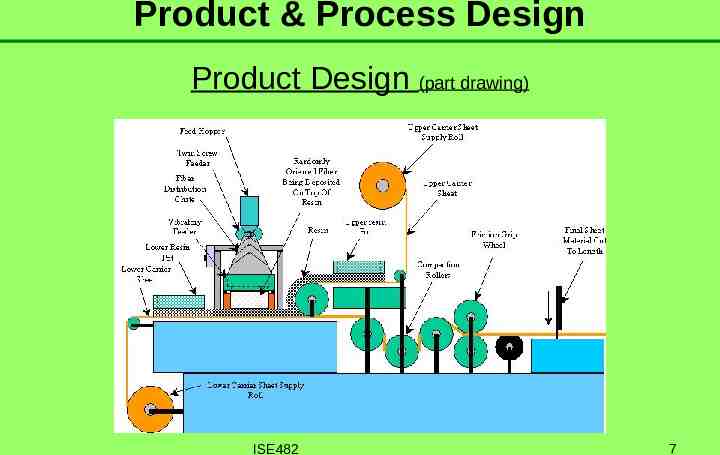

Product & Process Design Product Design (part drawing) ISE482 7

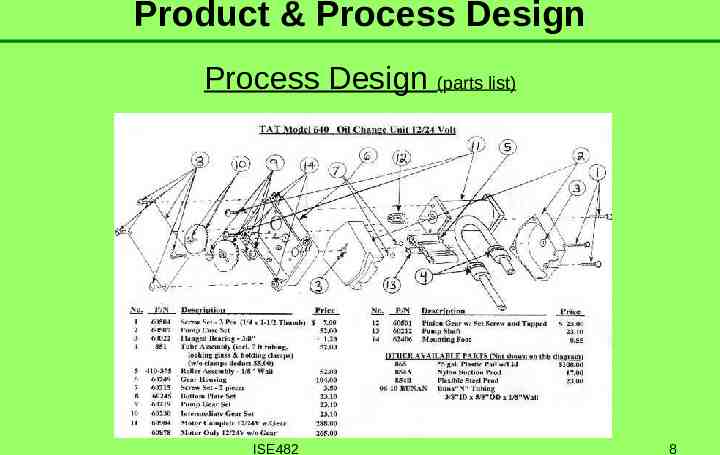

Product & Process Design Process Design (parts list) ISE482 8

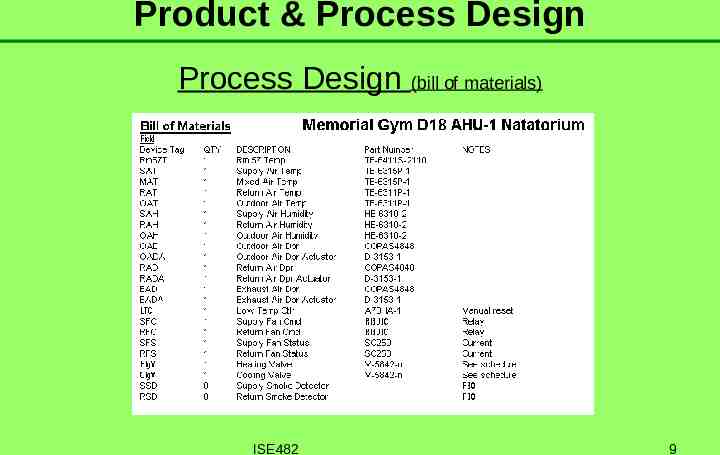

Product & Process Design Process Design (bill of materials) ISE482 9

Flow, Space, Activity Flow – depends on lot sizes, unit load sizes, space, activity relationships Space – function of the lots, storage system, production equipment and size, layout, building configuration Relationships – material flow, personnel flow, environmental considerations, org. structure, control issues, process requirements ISE482 10

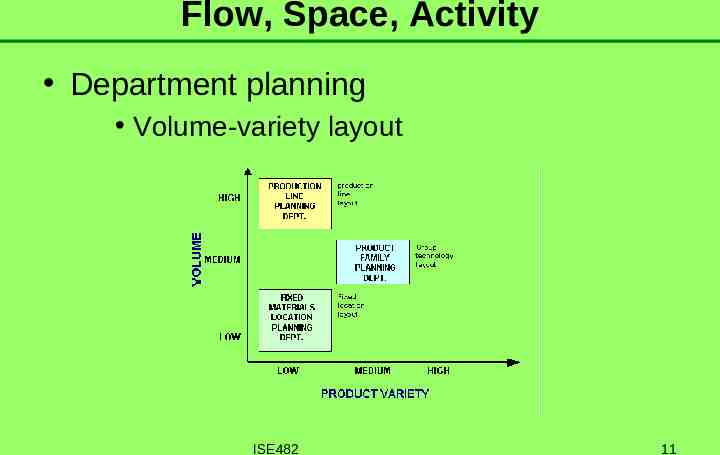

Flow, Space, Activity Department planning Volume-variety layout ISE482 11

Flow, Space, Activity Material flow 1. Product planning 2. Fixed materials location planning 3. Product family planning 4. Process planning ISE482 12

Flow, Space, Activity Cellular manufacturing Space requirements Flow patterns Product department Process department Line balancing ISE482 13

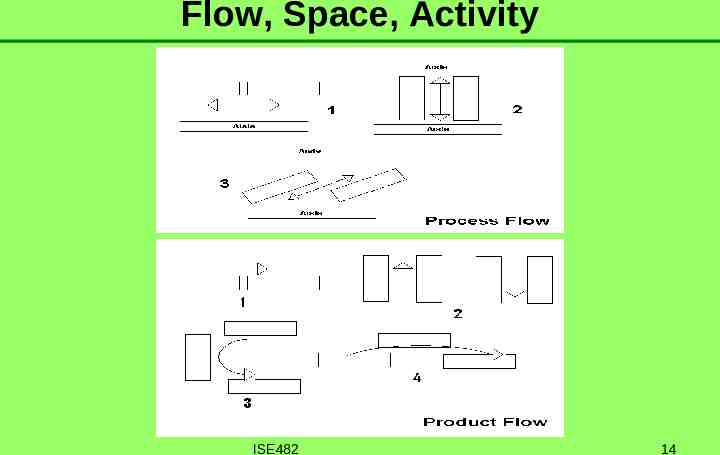

Flow, Space, Activity ISE482 14

Material Handling ISE482 15

Material Handling Definition - Art and science of moving, storing, protecting, controlling material - Moving the right amount of material, in the right condition, place, position, sequence, cost, methods Scope 25% of employees 55% of factory space 87% production time 15% - 70% total cost ISE482 16

Warehouse Operations Layout planning Receiving Shipping ISE482 17

Capacity Planning Measures Capacity Arrival time Service time Utilization (Arrival rate / Service rate) Queuing theory ( http://www.csee.umbc.edu/ plusquel/611/slides /chap6 3.html ) ISE482 18

Thank You Questions Comments