Emergency Action Plans Bureau of Workers’ Compensation PA Training

26 Slides682.96 KB

Emergency Action Plans Bureau of Workers’ Compensation PA Training for Health & Safety (PATHS) OSHA 29CFR1910.38 PPT-009-01 1

What are EAPs? - Emergency Action Plans (EAP’s) describe the actions employees should take to ensure their safety in the event of a fire or other emergency. - Well developed EAP’s and proper employee training (to ensure employees understand their roles and responsibilities under the plan) will result in fewer and less severe employee injuries, in addition to less damage to the facility during emergencies. -An EAP must be in writing, kept in the workplace, and available to all employees for review. -An employer with 10 or fewer employees may communicate the plan orally. PPT-009-01 2

EAP Considerations Any emergency situation that can affect the operation of your facility such as: Tornado Hurricane Flood Security issue (hostages, robberies, etc.) Hazardous Materials incident Fire Building collapse Natural gas leak PPT-009-01 3

Mandatory Elements All EAP’s must have the following: Procedures for reporting a fire or other emergency. Procedures for emergency evacuation, including the type of evacuation and exit route assignments. Procedures to be followed by employees who must remain behind to operate critical plant/facility equipment/operations before they evacuate. PPT-009-01 4

Mandatory Elements Procedures to account for all employees after evacuation. Procedures to be followed by employees performing rescue or medical duties. Name and job title of every employee who may be contacted by employees needing more information about the plan or an explanation of their duties under the plan. PPT-009-01 5

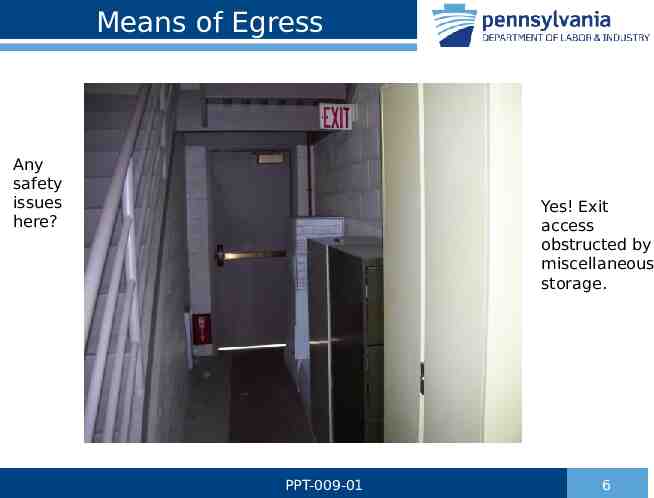

Means of Egress Any safety issues here? Yes! Exit access obstructed by miscellaneous storage. PPT-009-01 6

Means of Egress A continuous and unobstructed way of exit consisting of three parts: The pathway to the exit (access). The exit itself. The pathway from the exit (discharge). Includes both horizontal and vertical ways of travel. PPT-009-01 7

Exits Exits must be marked by a readily visible sign. Every exit sign must be distinctive and easily identifiable. Any doors, passageways, or stairways which are not exits must be marked as “NOT AN EXIT”. PPT-009-01 8

Exits Exits should not be blocked/obstructed at any time. Exits should not be chained shut, locked, or have any devices applied that make exiting difficult. Exit areas should be well-lit. Exit doors should be regularly maintained so they are easily operable. PPT-009-01 9

Developing an EAP Very simple plan will suffice for offices, small retail shops, and small manufacturing locations where there are few or no hazardous materials processes and employees evacuate when alarms sound or they’re notified by the public address system. PPT-009-01 10

Developing an EAP More complex plans are required at facilities that: Contain hazardous materials or Where employees fight fires, perform rescue and medical tasks, or Delay evacuation after alarms sound so they can shut down critical equipment. PPT-009-01 11

Developing an EAP EAP’s must be site specific with respect to: Emergency conditions evaluated, Evacuation policies and procedures, Emergency reporting procedures, mechanisms, and alarm systems. EAP keye w a H pa n y m o C PPT-009-01 12

Suggestions for EAPs Anticipate the worst and plan for it! PPT-009-01 13

EAPs-Planning Process These elements should be addressed: Preferred procedures for reporting emergencies such as dialing a particular phone number or using a manual fire alarm. A description of the alarm system to be used to notify employees. PPT-009-01 14

EAPs-Planning Process An evacuation policy, procedure, and escape route assignments so employees understand: Who is authorized to order an evacuation, Under what conditions an evacuation would be necessary, How to evacuate, and What routes to take. Procedures should describe what actions employees are to take before and while evacuating such as shutting windows, turning off equipment, etc. PPT-009-01 15

EAPs-Planning Process EAP’s should also include: Procedures for sheltering in place. Procedures for employees who may be required to use fire extinguishers or shut down electrical systems or other special equipment that could be damaged if left operating. Procedures to account for all employees after evacuation. This includes assigned safe meeting locations, who will take a roll call, etc. PPT-009-01 16

EAPs-Planning Process In addition EAP’s should include: A description of how employees will be informed of the contents of the plan and trained in their roles and responsibilities. A list of key personnel who should be notified during off-hours emergencies. PPT-009-01 17

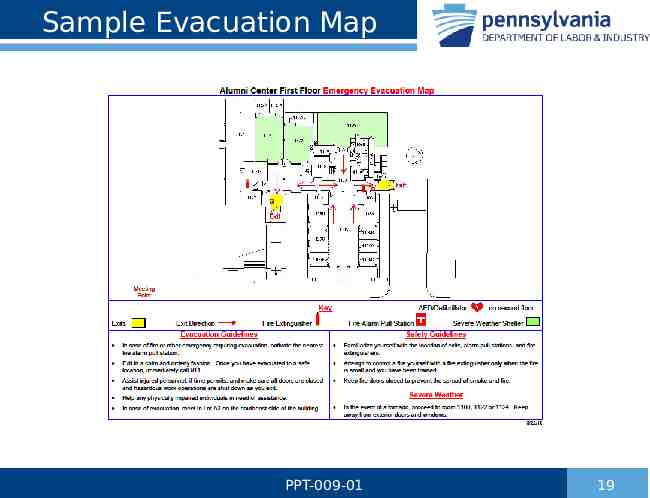

Evacuation Plans Suggest posting “evacuation maps” on the wall near the exits and in break areas. All exits should be identified on the “map”. Location of fire extinguishers should be identified. Check to ensure maps are current. If current map not available, draw simple map and place it on the wall. PPT-009-01 18

Sample Evacuation Map PPT-009-01 19

Other EAP Parts Fire prevention & protection! PPT-009-01 20

Fire - Classes CLASS A – Ordinary combustibles such as wood, rubber, or plastics. CLASS B – Flammable/combustible liquids and gases such as gasoline, kerosene, or propane. CLASS C – Energized electrical equipment (e.g. “live wires”). CLASS D – Combustible metals such as titanium and magnesium. CLASS K – “Animal fat” cooking oils. PPT-009-01 21

Fire Prevention Plan Suggested program elements: List of potential workplace fire hazards. Personnel responsible for controlling fire hazards. Proper handling and storage procedures to control hazards. Potential ignition sources. Appropriate maintenance and housekeeping. PPT-009-01 22

Good EAPs Are practical, functional, and understandable. Are kept updated and available to all employees (including contracted employees). Are put in practice by regular drills. Are shared with local emergency response agencies. PPT-009-01 23

EAPs - Review Must have one for each location. Must be communicated to employees. Must be reviewed at least annually and updated where appropriate. Employees must be trained on proper procedures and they need to understand the plan. Employees’ understanding of and willingness to follow the plan will ensure their safety! PPT-009-01 24

Contact Information Health & Safety Training Specialists 1171 South Cameron Street, Room 324 Harrisburg, PA 17104-2501 (717) 772-1635 [email protected] Like us on Facebook! https://www.facebook.com/BWCPATHS PPT-009-01 25

Questions PPT-009-01 26