An introduction to Infor EAM at CERN CMMS Service Sep 2016

33 Slides3.83 MB

An introduction to Infor EAM at CERN CMMS Service Sep 2016

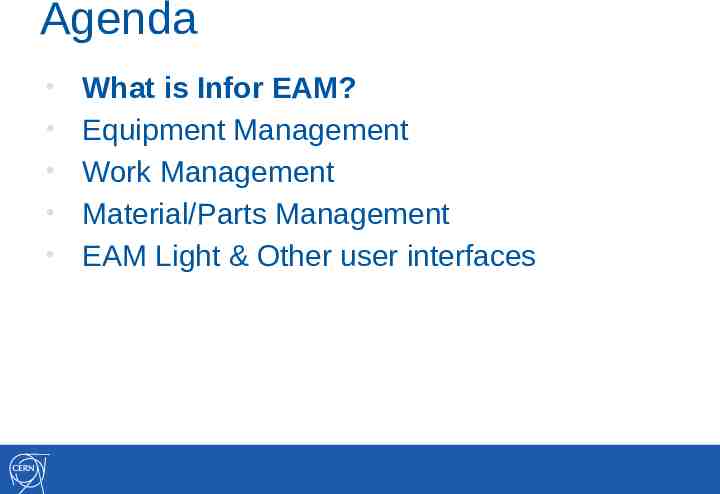

Agenda What is Infor EAM? Equipment Management Work Management Material/Parts Management EAM Light & Other user interfaces

What is Infor EAM? Managing the maintenance and performance of physical assets is a challenging task– especially for large and complex installations. Specialized tools exist to facilitate this work. CMMS (Computerized Maintenance Management Systems) EAM (Enterprise Asset Management) The official and centrally supported CMMS at CERN is called Infor EAM (previously known as Datastream 7i / D7i). June 2010 3

What is Infor EAM? Infor EAM is one of largest systems of its kind of the market and has been used in previous versions at CERN for over 25 years. CERN groups currently using Infor EAM: – – – – – – – EN: ACE, CV, EL, HE, ICE, MME & STI TE: CRG, VSC, MSC, MPE & ABT BE: CO, OP, ICS & BI SMB: SC, SE, SIS & SMS IT: CDA, CS & CF EP: ATL, CMX, DT & ESE HSE: RP, SEE, FB EAM at CERN manages currently information about 2 million equipment entries. It is based on an Oracle database and the web-based user interfaced can be accessed from both inside and outside CERN. June 2010 4

What is Infor EAM? Is EAM intuitive and can be used without training or initial instructions? Can it be used without knowing what equipment to maintain or how to maintain it? Will EAM solve all my maintenance problems? ! o N However, if I know my equipment and how to maintain it Can EAM help me organizing and documenting my maintenance work? Can EAM make the maintenance interventions more efficient by providing technical details and a complete technical history? Can EAM help me reducing MTTR and improve my scheduling of interventions? Yes!

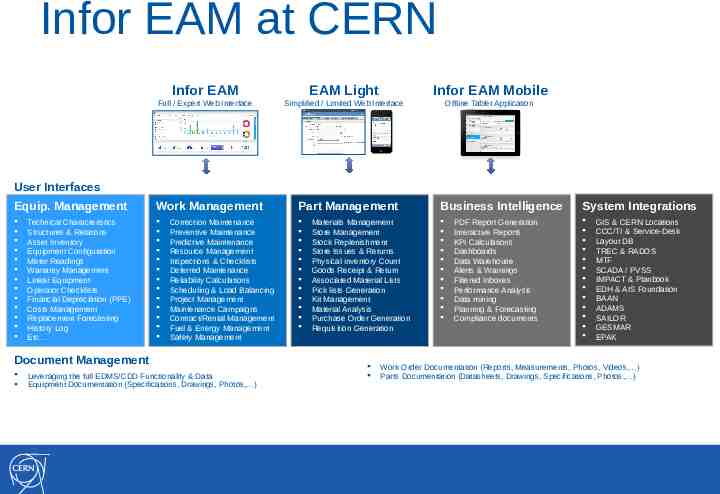

Infor EAM at CERN Infor EAM EAM Light Full / Expert Web Interface Simplified / Limited Web Interface Infor EAM Mobile Offline Tablet Application User Interfaces Equip. Management Technical Characteristics Structures & Relations Asset Inventory Equipment Configuration Meter Readings Warranty Management Linear Equipment Operator Checklists Financial Depreciation (PPE) Costs Management Replacement Forecasting History Log Etc Work Management Correction Maintenance Preventive Maintenance Predictive Maintenance Resource Management Inspections & Checklists Deferred Maintenance Reliability Calculations Scheduling & Load Balancing Project Management Maintenance Campaigns Contract/Rental Management Fuel & Energy Management Safety Management Document Management Leveraging the full EDMS/CDD Functionality & Data Equipment Documentation (Specifications, Drawings, Photos, ) Part Management Materials Management Store Management Stock Replenishment Store Issues & Returns Physical inventory Count Goods Receipt & Return Associated Material Lists Pick lists Generation Kit Management Material Analysis Purchase Order Generation Requisition Generation Business Intelligence PDF Report Generation Interactive Reports KPI Calculations Dashboards Data Warehouse Alerts & Warnings Filtered Inboxes Performance Analysis Data mining Planning & Forecasting Compliance documents System Integrations GIS & CERN Locations CCC/TI & Service-Desk Layout DB TREC & RADOS MTF SCADA / PVSS IMPACT & Planbook EDH & AIS Foundation BAAN ADAMS SAILOR GESMAR EPAK Work Order Documentation (Reports, Measurements, Photos, Videos, ) Parts Documentation (Datasheets, Drawings, Specifications, Photos, )

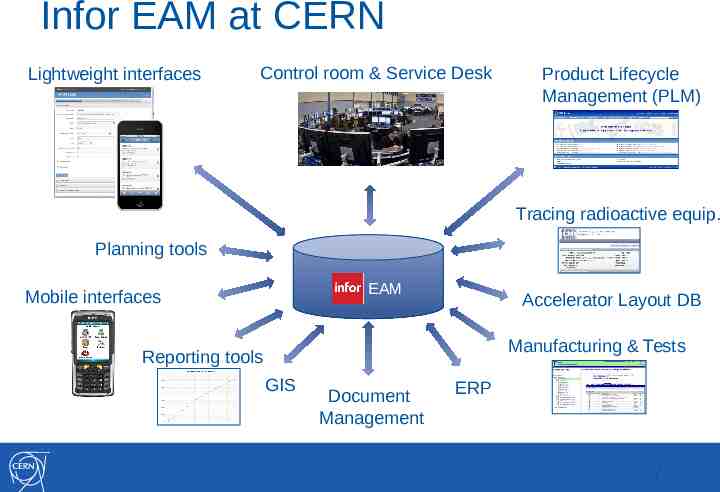

Infor EAM at CERN Lightweight interfaces Control room & Service Desk Product Lifecycle Management (PLM) Tracing radioactive equip. Planning tools EAM Mobile interfaces Accelerator Layout DB Manufacturing & Tests Reporting tools GIS Document Management ERP 7

Functionality – Main domains Lots of functionality, but the top 3 domains include: Equipment Management Equipment Inventory with technical details. Work Management Work/Interventions carried out on Equipment. Materials / Part Management Parts/Material required for performing Work.

Equipment Management

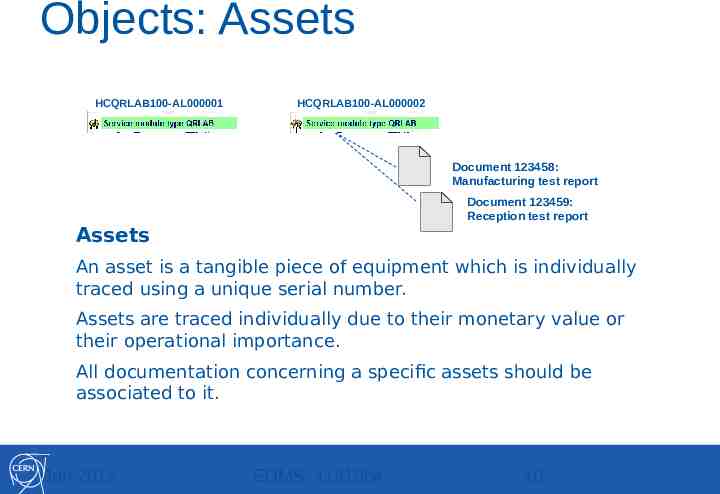

Objects: Assets HCQRLAB100-AL000001 HCQRLAB100-AL000002 Document 123458: Manufacturing test report Document 123459: Reception test report Assets An asset is a tangible piece of equipment which is individually traced using a unique serial number. Assets are traced individually due to their monetary value or their operational importance. All documentation concerning a specific assets should be associated to it. Jan 2012 EDMS: 1181854 10

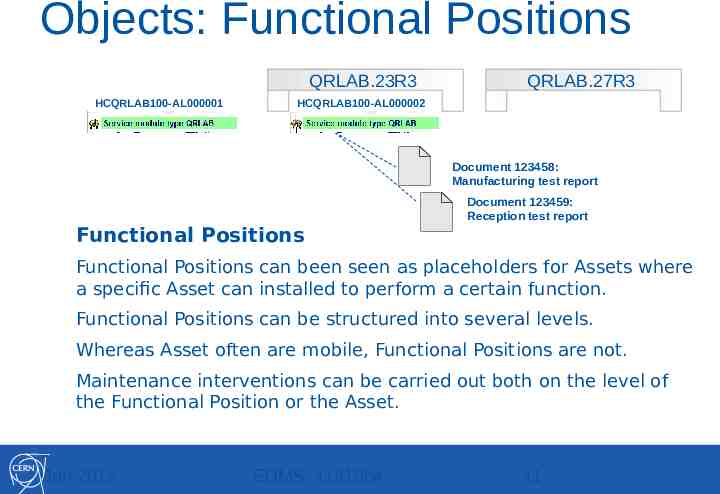

Objects: Functional Positions QRLAB.23R3 HCQRLAB100-AL000001 QRLAB.27R3 HCQRLAB100-AL000002 Document 123458: Manufacturing test report Document 123459: Reception test report Functional Positions Functional Positions can been seen as placeholders for Assets where a specific Asset can installed to perform a certain function. Functional Positions can be structured into several levels. Whereas Asset often are mobile, Functional Positions are not. Maintenance interventions can be carried out both on the level of the Functional Position or the Asset. Jan 2012 EDMS: 1181854 11

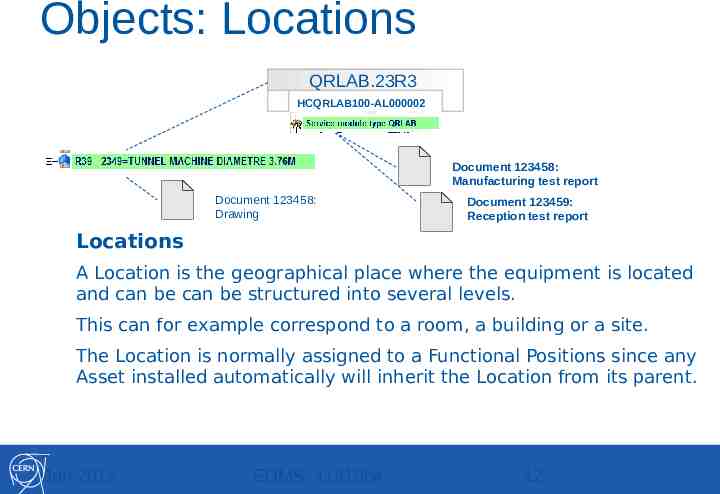

Objects: Locations QRLAB.23R3 HCQRLAB100-AL000002 Document 123458: Manufacturing test report Document 123458: Drawing Document 123459: Reception test report Locations A Location is the geographical place where the equipment is located and can be can be structured into several levels. This can for example correspond to a room, a building or a site. The Location is normally assigned to a Functional Positions since any Asset installed automatically will inherit the Location from its parent. Jan 2012 EDMS: 1181854 12

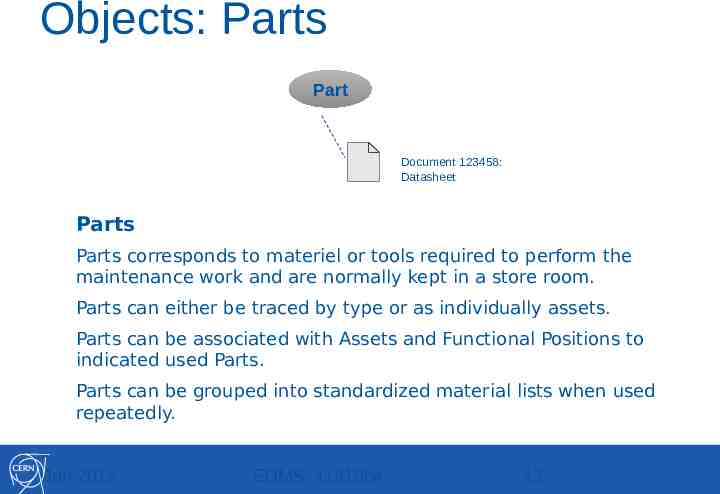

Objects: Parts Part Document 123458: Datasheet Parts Parts corresponds to materiel or tools required to perform the maintenance work and are normally kept in a store room. Parts can either be traced by type or as individually assets. Parts can be associated with Assets and Functional Positions to indicated used Parts. Parts can be grouped into standardized material lists when used repeatedly. Jan 2012 EDMS: 1181854 13

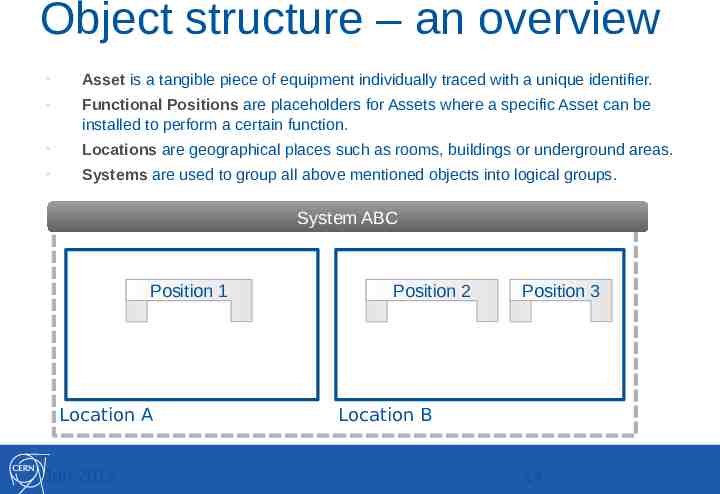

Object structure – an overview Asset is a tangible piece of equipment individually traced with a unique identifier. Functional Positions are placeholders for Assets where a specific Asset can be installed to perform a certain function. Locations are geographical places such as rooms, buildings or underground areas. Systems are used to group all above mentioned objects into logical groups. System ABC Position 1 Location A Jan 2012 Position 2 Position 3 Location B 14

Asset management Infor EAM allows you to: Identify, track, locate and analyze performance of physical assets. Associate technical characteristics and measured parameters and with assets. Create asset structures to track assembly configurations or to group assets by for example systems or locations.

Asset management Infor EAM allows you to: Log meter readings, inspection notes and free-form comments. Access its complete historical record, including location and status changes as well as all maintenance interventions. Associate technical documentation and photos.

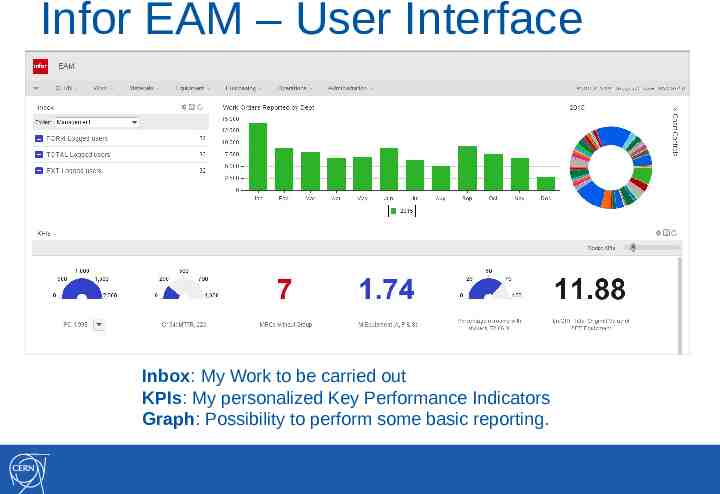

Infor EAM – User Interface Inbox: My Work to be carried out KPIs: My personalized Key Performance Indicators Graph: Possibility to perform some basic reporting.

Work Management

Work management Infor EAM allows you to: - Control work order processes for routine, reactive and periodic preventive maintenance. - Manage, plan and monitor work and resources needed to complete work. - Store material and tasks lists in a library for easy reference and retrieval. - Determine cause and effect relationships and generate statistics.

Work management Many more possibilities: - The Preventive Maintenance (PM) management module can generate work orders based on fixed dates, time intervals or meter readings. It is also possible to create routes to group interventions for multiple assets that require identical PM tasks under a single work order.

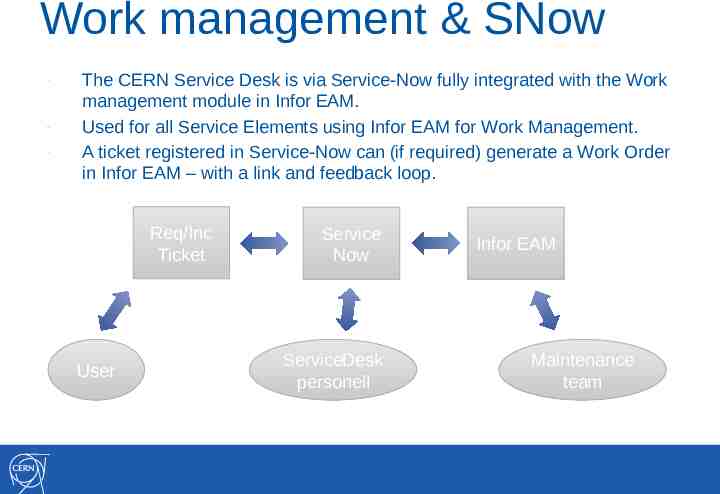

Work management & SNow - The CERN Service Desk is via Service-Now fully integrated with the Work management module in Infor EAM. Used for all Service Elements using Infor EAM for Work Management. A ticket registered in Service-Now can (if required) generate a Work Order in Infor EAM – with a link and feedback loop. Req/Inc Ticket User Service Now ServiceDesk personell Infor EAM Maintenance team

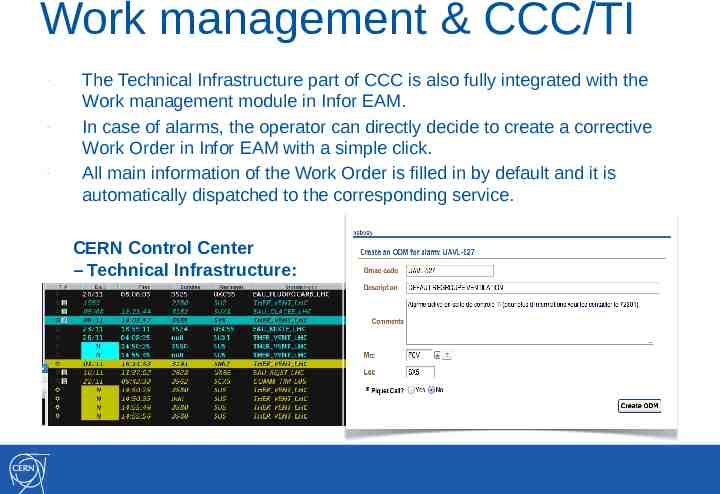

Work management & CCC/TI - The Technical Infrastructure part of CCC is also fully integrated with the Work management module in Infor EAM. In case of alarms, the operator can directly decide to create a corrective Work Order in Infor EAM with a simple click. All main information of the Work Order is filled in by default and it is automatically dispatched to the corresponding service. CERN Control Center – Technical Infrastructure:

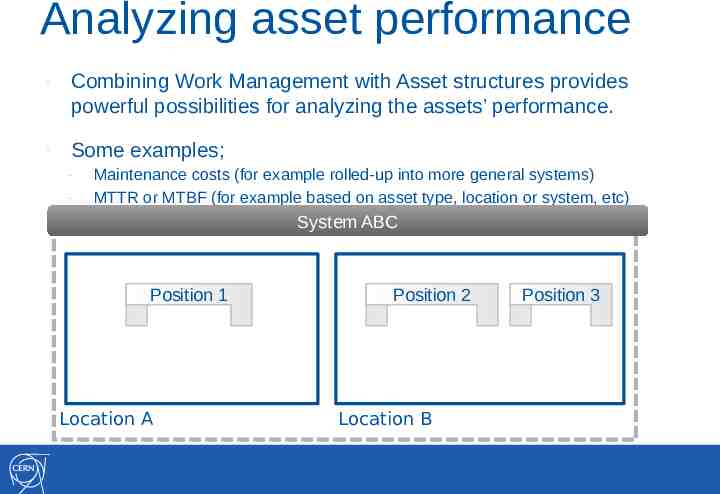

Analyzing asset performance - Combining Work Management with Asset structures provides powerful possibilities for analyzing the assets’ performance. - Some examples; - Maintenance costs (for example rolled-up into more general systems) MTTR or MTBF (for example based on asset type, location or system, etc) System ABC Position 1 Location A Position 2 Location B Position 3

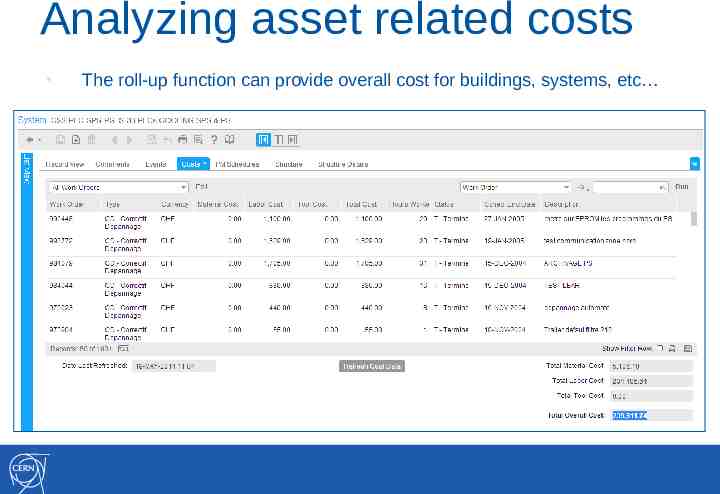

Analyzing asset related costs The roll-up function can provide overall cost for buildings, systems, etc

Material/Part Management

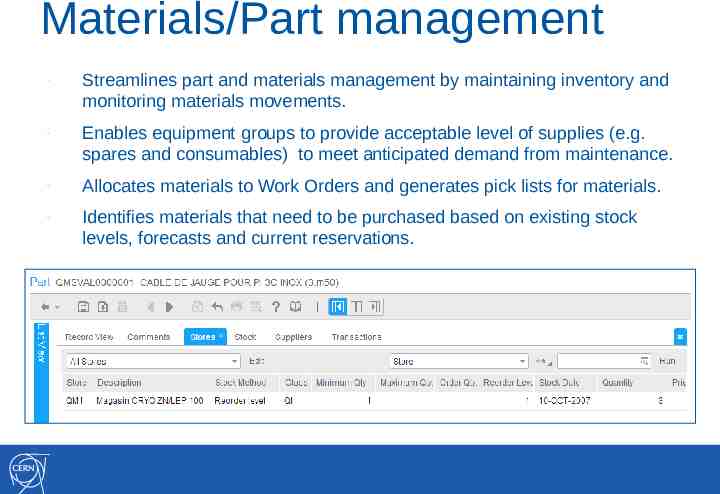

Materials/Part management - Streamlines part and materials management by maintaining inventory and monitoring materials movements. - Enables equipment groups to provide acceptable level of supplies (e.g. spares and consumables) to meet anticipated demand from maintenance. - Allocates materials to Work Orders and generates pick lists for materials. - Identifies materials that need to be purchased based on existing stock levels, forecasts and current reservations.

EAM Light & other interfaces

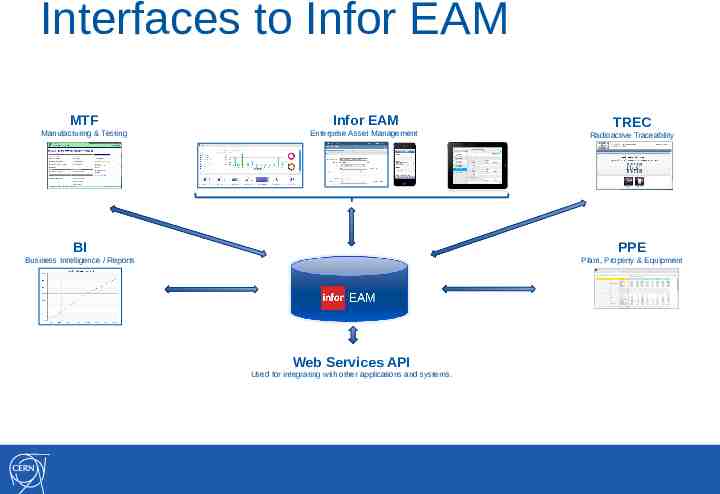

Interfaces to Infor EAM MTF Infor EAM Manufacturing & Testing Enterprise Asset Management TREC Radioactive Traceability BI PPE Business Intelligence / Reports Plant, Property & Equipment Web Services API Used for integrating with other applications and systems.

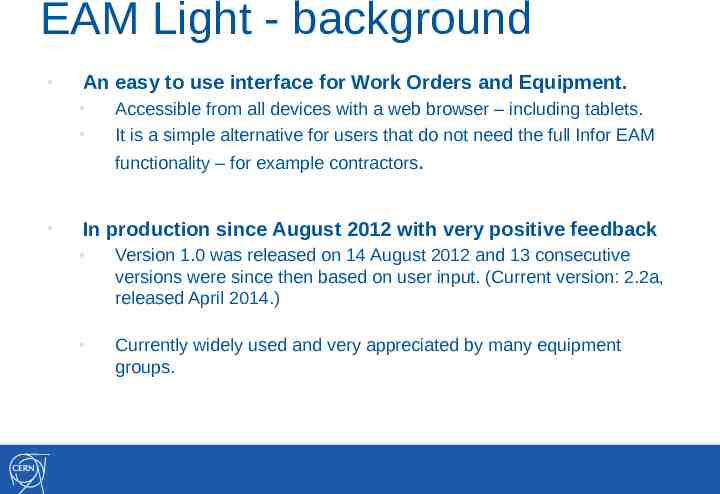

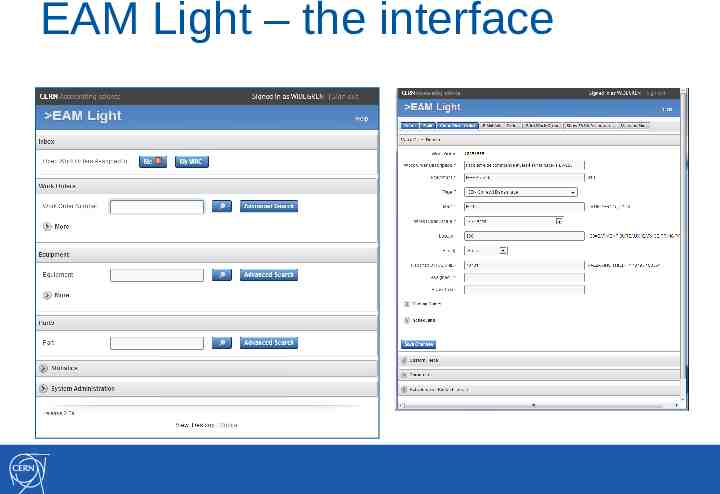

EAM Light - background An easy to use interface for Work Orders and Equipment. Accessible from all devices with a web browser – including tablets. It is a simple alternative for users that do not need the full Infor EAM functionality – for example contractors. In production since August 2012 with very positive feedback Version 1.0 was released on 14 August 2012 and 13 consecutive versions were since then based on user input. (Current version: 2.2a, released April 2014.) Currently widely used and very appreciated by many equipment groups.

EAM Light – the interface

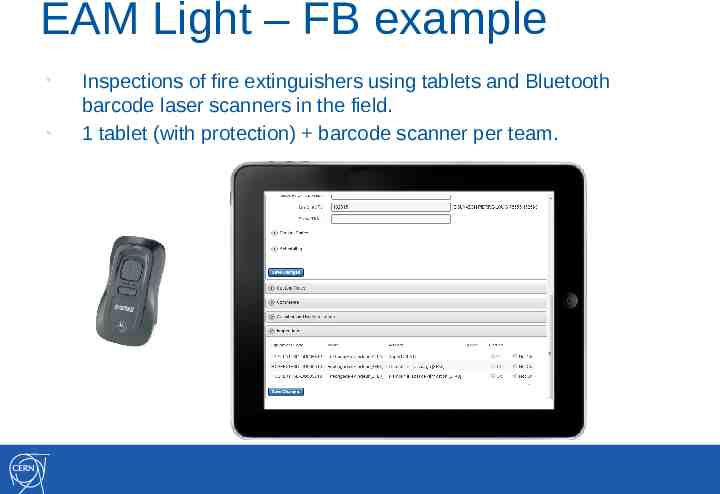

EAM Light – FB example Inspections of fire extinguishers using tablets and Bluetooth barcode laser scanners in the field. 1 tablet (with protection) barcode scanner per team.

EAM Light – smartphone version Smartphone friendly version of EAM Light with the same URL. Available for any smartphone (iOS, Android, Windows Phone, etc.) It is an online tool requiring internet connection (GSM or WiFi)

More information General information: www.cern.ch/cmms-service Documentation Manuals & Training material: https://edms.cern.ch/nav/CERN-0000088826 Questions or need help? [email protected]